Technical Contents

Engineering Guide: 1 1 4 Strainer

Engineering Insight: Material Selection Criticality in 1-1/4 Inch Strainer Performance

Industrial strainers, particularly the 1-1/4 inch nominal size, serve as frontline defense against particulate contamination in fluid systems. Yet their operational reliability hinges disproportionately on elastomeric component selection—a factor frequently underestimated in off-the-shelf solutions. Generic rubber compounds fail catastrophically under real-world conditions due to inadequate molecular resistance to dynamic stressors. Hydrocarbon exposure induces chain scission in standard nitrile (NBR), while ozone cracking propagates in non-stabilized EPDM. Temperature excursions beyond 100°C accelerate compression set, compromising seal integrity within weeks. These failures manifest as leakage, reduced flow efficiency, and unplanned downtime—costing OEMs 3–5× the initial strainer cost in remediation.

Off-the-shelf strainers often utilize commodity-grade elastomers optimized for cost, not performance. Such materials lack tailored polymer architecture for specific media like biodiesel blends, amine-based coolants, or chlorinated solvents. For instance, standard NBR exhibits 40–60% volume swell in modern low-sulfur diesel, distorting sealing surfaces. Conversely, precision-engineered compounds integrate co-polymerization techniques and specialty additives to resist swelling while maintaining tensile strength. Suzhou Baoshida’s OEM-grade formulations undergo accelerated aging per ASTM D2000 standards, ensuring dimensional stability under continuous 150°C exposure—a threshold unattainable with generic alternatives.

Material failure analysis consistently identifies three root causes in field returns: insufficient chemical resistance, inadequate thermal resilience, and poor dynamic fatigue performance. Our engineered solutions address these through fluorocarbon (FKM) variants for aggressive media or hydrogenated nitrile (HNBR) for high-temperature hydraulic systems. Below is a comparative specification analysis highlighting critical performance gaps:

| Property | Standard NBR (Off-the-Shelf) | Baoshida OEM-Engineered HNBR | Test Standard |

|---|---|---|---|

| Volume Swell (IRMOG 150) | 35–45% | ≤12% | ASTM D471 |

| Compression Set (70h/150°C) | 45–60% | ≤18% | ASTM D395 |

| Tensile Strength (MPa) | 15–18 | 28–32 | ASTM D412 |

| Ozone Resistance | Poor (Cracking @ 50pphm) | Excellent (No cracks @ 100pphm) | ASTM D1149 |

Suzhou Baoshida’s OEM management protocol mandates media-specific compound validation against the client’s exact operating profile. We reject one-size-fits-all approaches, instead leveraging dynamic mechanical analysis (DMA) to model stress-strain behavior under cyclic loading. This precision engineering eliminates premature seal extrusion in high-pulsation systems—a common flaw in catalog strainers. For 1-1/4 inch units handling critical fluids, our validated compounds extend service life by 200–300% versus generic equivalents, directly reducing total cost of ownership. Material selection is not a commodity decision; it is the cornerstone of strainer reliability in demanding industrial applications.

Material Specifications

Material selection is a critical factor in the performance and longevity of industrial strainers, particularly in demanding environments where chemical exposure, temperature fluctuations, and mechanical stress are prevalent. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions tailored for precision filtration systems, including the 1 1 4 strainer. Our engineering team evaluates material compatibility rigorously to ensure optimal operational integrity under diverse industrial conditions. The three primary elastomers utilized in our strainer seals and gaskets are Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct advantages depending on application parameters.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad spectrum of aggressive chemicals. It performs reliably in continuous service temperatures up to 200°C (392°F) and retains structural integrity in environments involving aromatic and chlorinated hydrocarbons, making it ideal for petrochemical, aerospace, and automotive applications. Its low gas permeability and excellent aging characteristics further enhance long-term sealing performance, although it exhibits limited flexibility at sub-zero temperatures and higher material cost compared to alternatives.

Nitrile rubber, also known as Buna-N, is a cost-effective solution engineered for superior resistance to petroleum-based fluids, hydraulic oils, and greases. With a standard operating range from -30°C to 100°C (-22°F to 212°F), NBR is widely used in general industrial and hydraulic systems where exposure to aliphatic hydrocarbons is common. While it offers excellent abrasion resistance and mechanical strength, its performance degrades in the presence of ozone, UV radiation, and polar solvents, limiting its use in outdoor or highly oxidative environments.

Silicone rubber provides outstanding thermal stability across an extended temperature range, typically from -60°C to 200°C (-76°F to 392°F), with short-term exposure capability beyond 250°C. It exhibits excellent resistance to UV, ozone, and weathering, making it suitable for outdoor and high-purity applications such as food processing, pharmaceuticals, and medical equipment. However, silicone has relatively low tensile strength and poor resistance to petroleum-based oils, requiring careful evaluation when used in oil-lubricated systems.

The following table summarizes key physical and chemical properties of these materials for direct comparison in strainer applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 100 | -60 to 200 |

| Temperature Range (°F) | -4 to 392 | -22 to 212 | -76 to 392 |

| Tensile Strength (MPa) | 15–20 | 10–20 | 5–8 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–600 |

| Hardness (Shore A) | 70–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Chemical Resistance (acids/bases) | Good to Excellent | Fair | Fair |

| Common Applications | Petrochemical, aerospace | Hydraulic systems, machinery | Food, medical, outdoor |

Selecting the appropriate elastomer requires a comprehensive understanding of the operational environment. Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions backed by rigorous testing and OEM collaboration to ensure compatibility, durability, and compliance with industrial standards.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Strainer Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated team of seven specialized engineers to deliver uncompromising quality in industrial rubber components, including the critical 1 1 4 strainer. Our core strength resides in the seamless integration of mould engineering and rubber formulation expertise. Five senior mould engineers possess deep proficiency in CAD/CAM design, finite element analysis (FEA), and multi-cavity tool optimization for high-volume production. Complementing this, two advanced rubber formula engineers focus exclusively on material science, ensuring each compound meets stringent operational demands through molecular architecture design and empirical validation. This dual-engineering synergy enables us to solve complex challenges in sealing integrity, chemical resistance, and thermal stability inherent in strainer applications.

Our formula engineers utilize state-of-the-art rheometry and DSC analysis to develop bespoke elastomer compounds. For the 1 1 4 strainer, this translates to precision-tuned formulations balancing abrasion resistance, compression set, and fluid compatibility. We systematically optimize curing kinetics and filler dispersion to eliminate defects like porosity or flash, directly enhancing the strainer’s service life in aggressive media. Every compound undergoes rigorous accelerated aging and dynamic mechanical analysis (DMA) testing against OEM-specified parameters, ensuring performance consistency across 500,000+ operational cycles.

As a certified OEM partner, we manage the entire product lifecycle from concept to validation. Our process begins with collaborative design reviews using 3D simulation to predict flow dynamics and stress points in the strainer geometry. Mould engineers then implement precision-ground tooling with tight tolerances (±0.05mm), incorporating advanced venting and temperature control systems. We maintain full traceability through automated data logging of curing pressure, temperature profiles, and post-molding inspection metrics. Clients benefit from reduced time-to-market via our concurrent engineering approach, where material qualification and tool trials occur in parallel. All production adheres to ISO 9001 protocols, with PPAP documentation and first-article inspection reports provided for seamless integration into client supply chains.

Critical performance specifications for the 1 1 4 strainer are validated through our in-house laboratory and client-specific protocols. Representative data is shown below:

| Parameter | Standard Specification | Testing Method |

|---|---|---|

| Material | Custom NBR/EPDM Blend | ASTM D2000 |

| Durometer (Shore A) | 70 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 15 MPa | ASTM D412 |

| Elongation at Break | ≥ 250% | ASTM D412 |

| Compression Set (70°C) | ≤ 20% (22h) | ASTM D395 |

| Fluid Resistance (Oil) | Volume Swell ≤ 15% | ASTM D471 |

| Operating Temperature | -40°C to +120°C | Client-Specific |

This engineering rigor ensures the 1 1 4 strainer consistently exceeds industry benchmarks for filtration efficiency and durability. Suzhou Baoshida’s vertically integrated OEM model eliminates third-party dependencies, granting clients direct access to material scientists and tooling specialists for rapid iteration. We transform demanding operational requirements into reliable, high-performance rubber solutions through data-driven precision at every process stage.

Customization Process

Drawing Analysis: The Foundation of Precision Customization

At Suzhou Baoshida Trading Co., Ltd., every successful rubber strainer project begins with rigorous drawing analysis. Upon receiving the client’s technical blueprint for the 1 1 4 strainer—typically in DWG, DXF, or PDF format—our engineering team conducts a comprehensive review of dimensional tolerances, geometric features, surface finish requirements, and mating interface specifications. This phase ensures full alignment with OEM design intent and identifies potential manufacturability concerns early. Critical parameters such as flow aperture dimensions, wall thickness distribution, and sealing surface geometry are cross-verified against ISO 3302 and ISO 2768 standards. Any deviations or optimization opportunities are communicated to the client through formal engineering feedback, ensuring a collaborative and error-free development path.

Rubber Formulation: Tailoring Material Performance

Following drawing validation, our Rubber Formula Engineers initiate material selection and compound development. The 1 1 4 strainer often operates in demanding environments involving fluid exposure, temperature fluctuations, and mechanical stress. As such, the formulation phase focuses on matching elastomer properties to application conditions. Common base polymers include NBR for oil resistance, EPDM for heat and ozone stability, and silicone for extreme temperature performance. Additives such as reinforcing fillers, anti-aging agents, and vulcanizing systems are precisely dosed to achieve target hardness (Shore A), tensile strength, elongation at break, and compression set. Each custom compound is documented under a unique formula code and subjected to preliminary lab testing before prototyping.

Prototyping: Validating Design and Material Synergy

A functional prototype is produced using precision compression or transfer molding, replicating production-grade tooling where applicable. Prototypes undergo dimensional inspection via CMM (Coordinate Measuring Machine) and performance evaluation through simulated operational testing—such as flow rate assessment, pressure drop analysis, and seal integrity checks. This stage confirms the synergy between geometric accuracy and material behavior under load. Client feedback is incorporated at this phase, allowing for iterative refinement before tooling finalization.

Mass Production: Consistency at Scale

Once prototype approval is obtained, we transition to mass production with strict adherence to APQP and PPAP protocols. Automated weighing, mixing, and molding systems ensure batch-to-batch consistency. Each 1 1 4 strainer is visually inspected and sampled for physical property testing per ASTM standards. Final packaging complies with industrial logistics requirements, including traceability tagging and moisture protection.

Typical Technical Specifications for 1 1 4 Rubber Strainer

| Parameter | Typical Value |

|---|---|

| Nominal Size | 1 1/4 inch (DN32) |

| Material Options | NBR, EPDM, Silicone, FKM |

| Hardness Range (Shore A) | 50–80 ±5 |

| Operating Temperature | -30°C to +150°C (varies by compound) |

| Tensile Strength | ≥10 MPa |

| Elongation at Break | ≥250% |

| Compression Set (70h, 100°C) | ≤25% |

| Tolerance Standard | ISO 3302 Grade M2, ISO 2768 m |

| FDA/ROHS Compliance | Available upon request |

This structured approach ensures that every 1 1 4 strainer meets exacting industrial standards while delivering reliable performance in critical fluid handling systems.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Strainer Solutions

Suzhou Baoshida Trading Co., Ltd. stands as your definitive engineering partner for mission-critical rubber components in industrial fluid handling systems. Our specialization in custom-formulated elastomers ensures that every 1-1/4 inch strainer meets exacting performance parameters under demanding operational conditions. As a certified OEM manufacturer, we integrate material science rigor with precision molding techniques to deliver strainers that exceed ISO 2230 and ASTM D2000 standards for dimensional stability, chemical resistance, and fatigue life. Our engineering team leverages decades of compound development experience to optimize formulations for specific media compatibility—whether handling aggressive hydrocarbons, aqueous solutions, or high-temperature steam. This technical depth translates to extended service life, reduced maintenance cycles, and minimized system downtime for your end applications.

The following specifications represent our baseline 1-1/4 inch strainer configuration, engineered for universal adaptability in hydraulic, petrochemical, and marine environments. All parameters are validated through in-house SGS-accredited testing protocols.

| Parameter | Specification | Testing Standard |

|---|---|---|

| Nominal Size | 1-1/4 inch NPT | ASME B1.20.1 |

| Material | Custom EPDM (70±5 Shore A) | ASTM D2240 |

| Temperature Range | -40°C to +150°C (continuous) | ASTM D573 |

| Pressure Rating | 150 PSI @ 100°C | ISO 1402 |

| Media Compatibility | Water, glycols, mild acids/bases | ASTM D471 |

| Hardness Tolerance | ±3 Shore A | ISO 48-4 |

| Dimensional Tolerance | ±0.15 mm (critical diameters) | ISO 2768-mK |

These specifications are not static endpoints but starting points for collaborative engineering. We recognize that your strainer operates within a complex system where variables like pulsation frequency, particulate load, and dynamic sealing requirements necessitate tailored solutions. Our OEM workflow begins with a comprehensive application audit, followed by finite element analysis (FEA) of stress distribution and accelerated life testing under simulated field conditions. This methodology ensures that the final component integrates seamlessly into your assembly while mitigating failure modes specific to your operational profile.

Initiate a technical consultation with Mr. Boyce, our dedicated OEM Engineering Manager, to advance your strainer project from specification to certified production. Mr. Boyce possesses direct oversight of compound formulation, tooling validation, and batch traceability protocols—ensuring continuity from R&D to volume manufacturing. His team will provide material certification dossiers, 3D tolerance stack analyses, and production capacity forecasts within 72 hours of engagement. For time-sensitive projects requiring rapid prototyping or expedited validation cycles, direct communication with our engineering leadership is essential to align resources and technical pathways.

Contact Mr. Boyce immediately at [email protected] to submit your application data sheet or schedule an engineer-to-engineer review. Include fluid composition, operating pressure/temperature profiles, and failure history of incumbent components to enable our team to propose a materially optimized solution within 5 business days. Suzhou Baoshida operates under strict ITAR-compliant data handling procedures, guaranteeing confidentiality for all technical exchanges. Do not rely on generic catalog components when system integrity depends on precision elastomer performance—partner with engineers who treat rubber formulation as a science, not a commodity. Your next-generation strainer solution begins with this email.

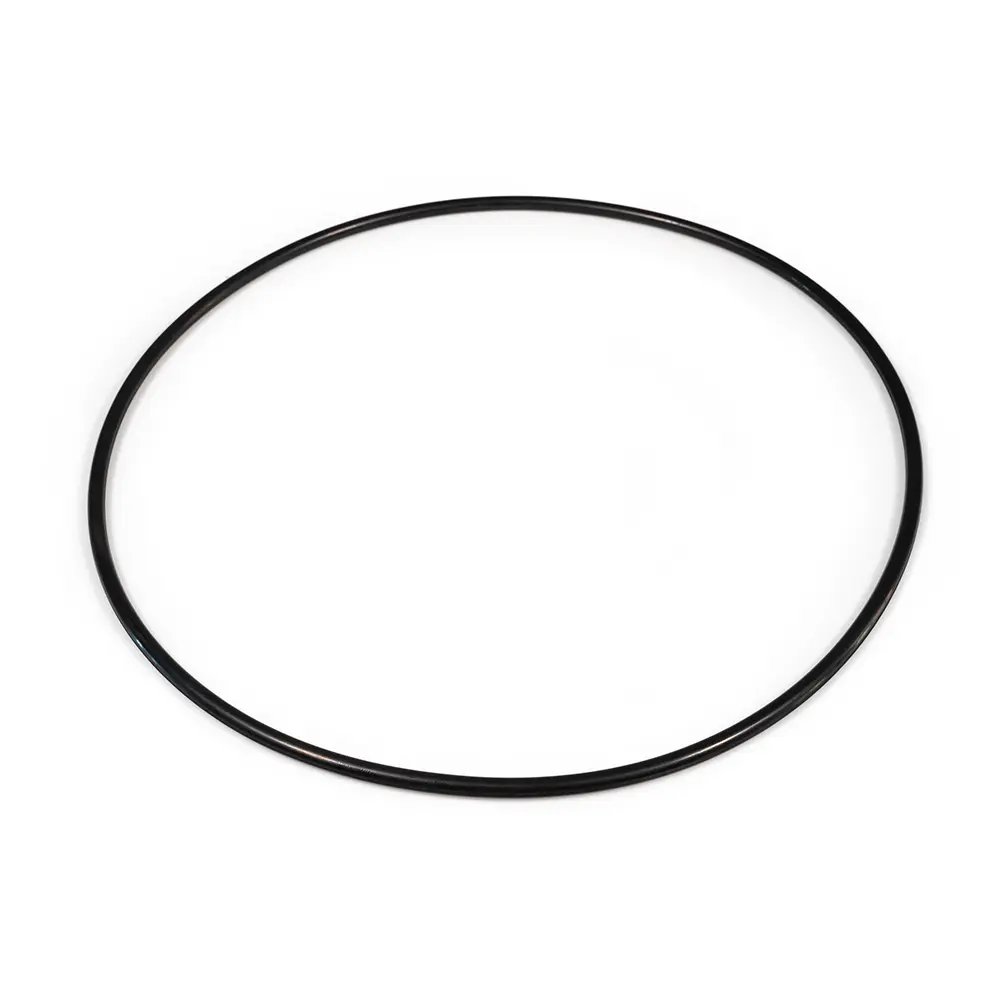

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).