Technical Contents

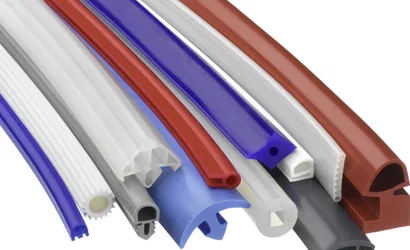

Engineering Guide: 1 Thick Rubber Strips

Engineering Insight: Material Selection Imperatives for 1-Inch Thick Rubber Strips

The dimensional specification of 1-inch thickness in industrial rubber strips is frequently misunderstood as the primary design driver. In reality, this substantial cross-section intensifies material performance demands, making off-the-shelf solutions prone to catastrophic field failure. Generic rubber strips, often formulated for cost-driven, low-stress applications, lack the engineered molecular structure required to manage the unique thermal, mechanical, and chemical stresses inherent in thick-section components. When subjected to compression, dynamic flexing, or environmental exposure, these strips experience non-uniform stress distribution and significant internal heat buildup. The resulting thermal degradation accelerates exponentially, leading to premature cracking, permanent set, seal leakage, or complete structural disintegration. This is not a dimensional failure; it is a fundamental mismatch between material science and application physics.

Material selection must address the core challenge: a 1-inch cross-section drastically reduces heat dissipation compared to thinner profiles. Standard SBR or low-grade EPDM compounds, common in catalog items, exhibit excessive hysteresis under cyclic loading. This generates internal temperatures exceeding the rubber’s thermal stability limit, even in ambient external conditions. Simultaneously, thick sections magnify the impact of chemical exposure; permeation rates cause deeper, irreversible substrate attack, while inadequate compression set resistance leads to irreversible loss of sealing force. Off-the-shelf strips typically utilize broad-specification polymers without tailored cure systems or reinforcement packages. They fail to account for critical variables like service temperature extremes, fluid compatibility beyond basic resistance, or the precise durometer stability required over 50,000+ compression cycles. The consequence is unplanned downtime, safety hazards, and costs far exceeding the initial savings from a generic purchase.

Precision engineering for 1-inch strips demands polymer systems validated for deep-section performance. The table below outlines critical material considerations versus common failure modes in unoptimized solutions.

| Polymer Type | Critical Application Limits for 1″ Sections | Common Off-the-Shelf Failure Modes | ASTM D2000 Reference Line Example |

|---|---|---|---|

| High-AcN NBR | >80°C continuous oil exposure; High pressure sealing | Swelling, loss of tensile strength, extrusion | BK3 737 A14 B14 F17 Z1 Z2 |

| Peroxide-Cured EPDM | -50°C to 150°C; Ozone/weathering critical | Cracking (ozone/thermal), hardening, seal leak | EG4 744 A10 B14 F17 F21 |

| Specialty Silicone | -60°C to 230°C; High purity/food/pharma | Compression set failure, tearing under stress | SC3 605 A10 B14 F17 F21 |

| Hydrogenated NBR | >120°C; Biofuels & advanced lubricants | Rapid degradation, loss of elasticity | BK4 744 A20 B14 F17 F21 |

Suzhou Baoshida Trading Co., Ltd. rejects the commoditization of critical rubber components. Our engineering process begins with rigorous application profiling—quantifying dynamic loads, thermal transients, fluid chemistry, and lifecycle requirements. We formulate compounds with controlled polymer architecture, optimized filler networks for thermal conductivity, and precision cure kinetics tailored to the 1-inch mass. This ensures uniform crosslink density throughout the section, mitigating internal stress concentrations and thermal runaway. Standard catalog items cannot replicate this depth of material science integration. When failure consequences include production halts or safety incidents, the only viable solution is rubber engineered at the molecular level for your specific operational reality. Contact our technical team to initiate a failure mode analysis for your current strip application.

Material Specifications

Material Specifications for 1 Inch Thick Rubber Strips

Suzhou Baoshida Trading Co., Ltd. provides high-performance 1 inch thick rubber strips engineered for demanding industrial applications. These strips are manufactured using premium elastomeric compounds, ensuring dimensional stability, mechanical resilience, and long-term service life under extreme environmental conditions. The primary materials offered—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—are selected based on chemical resistance, temperature tolerance, and mechanical performance requirements.

Viton rubber strips deliver exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With a continuous service temperature range up to 230°C (446°F), Viton is ideal for aerospace, automotive, and chemical processing environments where thermal degradation and fluid exposure are critical concerns. Its low compression set and excellent aging characteristics ensure reliable sealing and structural integrity over extended operational cycles.

Nitrile rubber strips are widely used in hydraulic, pneumatic, and industrial machinery applications due to their superior resistance to petroleum-based oils, greases, and aliphatic hydrocarbons. Operating effectively within a temperature range of -30°C to +100°C (-22°F to 212°F), NBR offers excellent abrasion resistance and tensile strength, making it a cost-effective solution for dynamic and static sealing applications in manufacturing and transportation sectors.

Silicone rubber strips are selected for applications requiring extreme temperature flexibility, from -60°C to +200°C (-76°F to 392°F), along with outstanding UV and ozone resistance. While less resistant to petroleum-based fluids compared to Viton or Nitrile, silicone excels in electrical insulation, food-grade compliance, and outdoor exposure applications such as construction, medical devices, and electronic enclosures. Its inherent flexibility and low toxicity further support use in sensitive environments.

All 1 inch thick rubber strips from Suzhou Baoshida are precision-extruded and vulcanized to ensure consistent cross-sectional dimensions and material homogeneity. Custom durometer ratings (Shore A) are available within each material class to match specific load-bearing and sealing requirements.

The following table summarizes key physical and chemical properties of the three primary materials used in our 1 inch thick rubber strip production.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 212 | -76 to 392 |

| Durometer Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Excellent (oil, grease, water) | Poor (oils), Good (water, ozone) |

| Compression Set Resistance | Excellent | Good | Moderate |

| Electrical Insulation | Good | Fair | Excellent |

| Common Applications | Aerospace seals, chemical gaskets | Hydraulic seals, O-rings, rollers | Electrical insulation, food processing, outdoor seals |

Each material is subject to rigorous quality control per ASTM and ISO standards, ensuring repeatability and compliance with OEM specifications. Suzhou Baoshida supports custom formulations, splicing, and packaging to meet project-specific needs.

Manufacturing Capabilities

Advanced Engineering Capabilities for Precision 1-Inch Rubber Strips

Suzhou Baoshida Trading Co., Ltd. delivers engineered reliability for demanding industrial applications requiring 1-inch thick rubber strips. Our core strength resides in the integrated expertise of dedicated technical personnel: five specialized Mold Engineers and two advanced Formula Engineers. This concentrated team ensures every strip meets exacting performance criteria from molecular architecture to final extrusion, eliminating the guesswork common in standard rubber supply.

Our Formula Engineers possess deep expertise in polymer science and compounding specifically for high-section products. They meticulously develop and validate custom elastomer formulations addressing critical challenges inherent in thick-section rubber, such as optimizing cure kinetics to prevent scorch during processing while ensuring complete vulcanization through the cross-section. This expertise directly translates to superior resistance against compression set, enhanced thermal stability across extended temperature ranges, and tailored chemical resistance for exposure to oils, fuels, or industrial fluids. Each formulation undergoes rigorous laboratory testing and pilot-scale validation before full production, guaranteeing consistent material performance that meets or exceeds ASTM D2000 or customer-specific standards.

Complementing this material science foundation, our five Mold Engineers focus on precision tooling design and process optimization for extrusion and vulcanization. They analyze strip geometry, material flow characteristics, and thermal dynamics to design dies and curing systems that minimize internal stresses, eliminate voids, and maintain dimensional stability within tight tolerances. Tooling tolerances are held to ±0.05mm, critical for applications requiring precise sealing force or fit. This engineering rigor ensures uniform physical properties throughout the entire 1-inch cross-section, a non-negotiable requirement for long-term functional integrity in demanding environments like heavy machinery seals, marine fenders, or industrial vibration dampeners.

As a certified OEM partner, Suzhou Baoshida provides end-to-end engineering collaboration. We translate your functional requirements into optimized rubber solutions, managing the entire process from initial concept and material selection through prototyping, validation testing, and high-volume production. Our engineers work directly with your design and quality teams to resolve application-specific challenges, ensuring the final 1-inch strip performs reliably within your assembly under real-world operational stresses.

The following table outlines key performance specifications achievable for our standard and custom 1-inch thick rubber strips, reflecting our engineering control:

| Property | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 40 – 90 | ASTM D2240 |

| Tensile Strength (MPa) | 10.0 – 25.0 | ASTM D412 |

| Elongation at Break (%) | 150 – 600 | ASTM D412 |

| Compression Set (B) | ≤ 25% (70°C x 22h) | ASTM D395 |

| Temperature Range | -50°C to +150°C | ASTM D573 |

| Specific Gravity | 1.10 – 1.50 | ASTM D297 |

This engineering-centric approach, underpinned by dedicated formula and mold specialists, positions Suzhou Baoshida as the strategic partner for mission-critical 1-inch rubber strip applications. We deliver not just a product, but a precisely engineered solution backed by robust quality management systems (ISO 9001 certified) and a commitment to technical excellence throughout the OEM lifecycle.

Customization Process

Customization Process for 1 mm Thick Rubber Strips at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., precision and performance are the cornerstones of our industrial rubber solutions. When manufacturing 1 mm thick rubber strips to meet specific application requirements, we follow a structured four-stage customization process: Drawing Analysis, Formulation Development, Prototyping, and Mass Production. This ensures consistency, reliability, and compliance with OEM and industrial standards.

The process begins with Drawing Analysis, where our engineering team evaluates technical schematics provided by the client. Key parameters such as cross-sectional dimensions, length tolerances, surface finish, and intended operating environment are assessed. We verify compliance with international dimensional standards (e.g., ISO 3302, ISO 2768) and identify any design constraints that may affect extrusion or curing. This phase also includes material compatibility checks against fluids, temperatures, and mechanical stresses the strip will encounter in service.

Following drawing validation, we proceed to Formulation Development. Our rubber chemists design a compound tailored to the performance criteria. For 1 mm strips, dimensional stability and extrusion fidelity are critical, requiring precise control over polymer selection, filler content, vulcanization system, and processing aids. Common base polymers include EPDM for weather resistance, NBR for oil resistance, and silicone for high-temperature applications. Hardness, tensile strength, elongation at break, and compression set are optimized through iterative lab-scale mixing and testing.

Once the formulation is finalized, we initiate Prototyping. Using precision extrusion lines and continuous vulcanization (hot air or microwave), short production runs generate sample strips. These prototypes undergo rigorous quality checks, including dimensional inspection, hardness testing (Shore A), and application-specific performance validation. Clients receive physical samples along with material test reports (MTRs) for approval. Adjustments are made if necessary, ensuring full alignment with functional requirements.

Upon client confirmation, we transition to Mass Production. Our automated extrusion and curing systems ensure high throughput while maintaining tight tolerances. Each production batch is subject to in-process and final quality inspections, including continuous thickness monitoring via laser gauges and batch-wise physical property testing. All materials are traceable, and production documentation is archived for compliance.

The table below outlines typical specifications for 1 mm thick rubber strips under this process.

| Parameter | Standard Range | Testing Standard |

|---|---|---|

| Thickness | 1.0 ± 0.1 mm | ISO 3302 |

| Width | 5–50 mm (custom) | ISO 3302 |

| Hardness (Shore A) | 40–80 | ISO 48-4 |

| Tensile Strength | ≥7 MPa | ISO 37 |

| Elongation at Break | ≥250% | ISO 37 |

| Operating Temperature | -40°C to +150°C (varies by compound) | DIN 53508 |

| Color | Black, gray, red, or custom | Visual standard |

Through this systematic approach, Suzhou Baoshida delivers high-performance, application-specific rubber strips with repeatability and industrial-grade consistency.

Contact Engineering Team

Engineering Precision in Every Strip: Finalize Your Specification Pathway

Suzhou Baoshida Trading Co., Ltd. operates at the critical intersection of polymer science and industrial application demands. Our specialization in precision-manufactured 1 inch thick rubber strips is not merely a product offering; it represents a commitment to solving complex sealing, cushioning, and vibration isolation challenges inherent in heavy machinery, transportation systems, and infrastructure projects. Achieving optimal performance in these demanding environments requires absolute adherence to dimensional tolerances, material compound integrity, and environmental resistance. Generic off-the-shelf solutions often fail under sustained operational stress, leading to premature failure, costly downtime, and safety compromises. Our engineered strips undergo rigorous OEM validation protocols, ensuring each batch meets or exceeds the stringent requirements dictated by your specific application physics and lifecycle expectations. The critical parameters governing performance are non-negotiable and must be precisely defined during the specification phase.

The following table details the core technical specifications achievable for our standard 1 inch thick rubber strip formulations. These values represent baseline capabilities for common industrial compounds; bespoke formulations for extreme chemical exposure, ultra-low temperature, or flame retardancy are developed through our dedicated R&D pipeline.

| Parameter | Standard EPDM Compound | Standard Nitrile (NBR) Compound | Standard Natural Rubber (NR) Compound | Test Standard |

|---|---|---|---|---|

| Thickness | 25.4 mm ± 0.3 mm | 25.4 mm ± 0.3 mm | 25.4 mm ± 0.3 mm | ASTM D3776 |

| Hardness (Shore A) | 50 – 90 | 50 – 90 | 30 – 70 | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 10.0 | ≥ 12.0 | ≥ 18.0 | ASTM D412 |

| Elongation at Break (%) | ≥ 250 | ≥ 200 | ≥ 400 | ASTM D412 |

| Temperature Range (°C) | -50 to +150 | -30 to +120 | -50 to +80 | Material Specific |

| Compression Set (70°C, 22h) | ≤ 25% | ≤ 30% | ≤ 35% | ASTM D395 Method B |

| Specific Gravity | 1.15 – 1.25 | 1.05 – 1.20 | 0.92 – 0.95 | ASTM D297 |

Translating these technical capabilities into your operational success requires direct collaboration with our engineering team. Material selection, compound modification, and dimensional control must align precisely with your dynamic load profiles, media exposure, and assembly constraints. Suzhou Baoshida does not merely supply rubber; we co-engineer resilient system components. Our OEM management process integrates seamlessly with your procurement and quality assurance workflows, providing full traceability from raw material certification through final dimensional inspection reports. We understand that a 0.5mm deviation in thickness or a 5-point variance in Shore hardness can cascade into system failure – our manufacturing tolerances are calibrated to prevent such outcomes.

Initiate the qualification process for your specific 1 inch thick rubber strip requirement by contacting Mr. Boyce, our dedicated OEM Account Manager and Rubber Formulation Specialist. Mr. Boyce possesses direct oversight of technical specifications, production scheduling, and quality assurance protocols for all strip extrusion projects. He will facilitate the technical dialogue necessary to translate your application data sheet into a validated manufacturing specification. Submit your dimensional schematics, operational parameters, and performance validation criteria directly to him. This targeted engagement ensures your project receives the precise engineering attention it demands from inception through volume production.

Contact Mr. Boyce immediately at [email protected] to commence material qualification. Include your project reference number, required annual volume, and critical performance thresholds in your initial communication. Suzhou Baoshida Trading Co., Ltd. stands ready to deliver not just rubber strips, but engineered solutions guaranteeing longevity and reliability within your most demanding industrial systems. Your pathway to optimized component performance begins with this technical consultation.

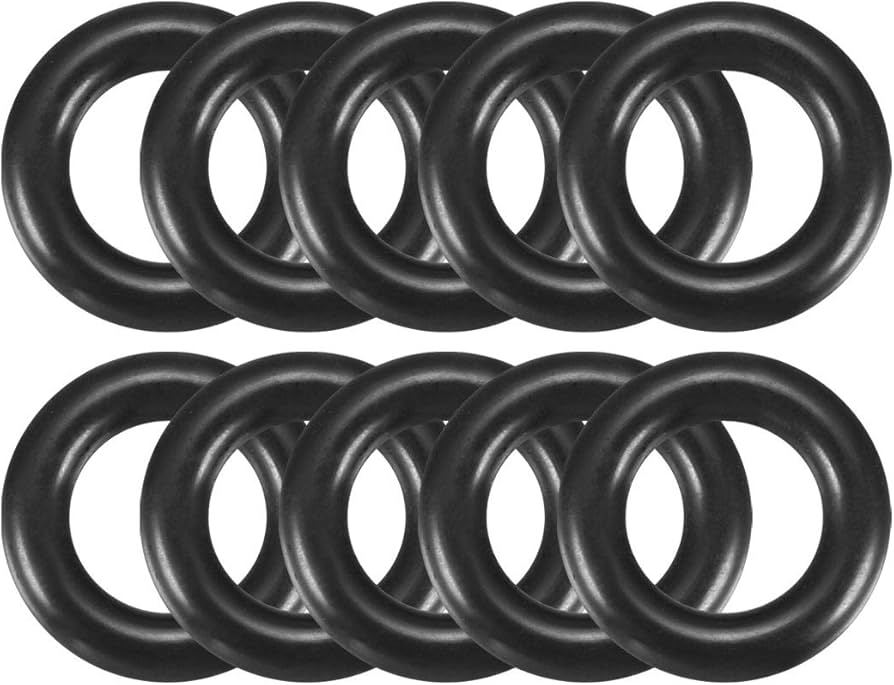

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).