Technical Contents

Engineering Guide: 1/4 Thick Rubber Sheet

Engineering Insight: Material Selection Imperatives for 1/4 Inch Rubber Sheets

The specification of a 1/4 inch thick rubber sheet is frequently reduced to a dimensional requirement, neglecting the foundational engineering principle that material composition dictates performance. Off-the-shelf solutions fail catastrophically in demanding industrial applications because generic compounds cannot address the specific chemical, thermal, mechanical, and environmental stresses encountered. Thickness alone is a neutral parameter; without precise material science alignment, even nominally identical sheets exhibit divergent failure modes under operational loads.

Critical failure mechanisms stem from unaddressed service conditions. A standard NBR sheet may suffice for mild oil resistance at room temperature but rapidly degrades in high-heat hydraulic systems due to inadequate thermal stability. Similarly, an EPDM sheet marketed for “general use” often lacks the tailored ozone resistance required for outdoor conveyor belts, leading to surface cracking and loss of tensile integrity. Compression set failure is equally prevalent: low-cost blends with insufficient polymer crosslinking rebound poorly under sustained load, compromising sealing efficacy in flange gaskets. These failures incur significant downtime and replacement costs, directly attributable to inadequate compound formulation rather than dimensional inaccuracies.

Material selection must begin with rigorous operational profiling. Key variables include maximum/minimum service temperatures, exposure to oils, acids, solvents, or UV radiation, dynamic versus static loading requirements, and regulatory constraints (e.g., FDA, NSF, UL). Suzhou Baoshida’s engineering process mandates this analysis prior to compound development. We do not treat 1/4 inch as a standalone specification but as a physical constraint within a broader performance matrix. Our OEM partnerships involve co-defining failure thresholds—such as maximum allowable compression set at 70°C after 72 hours—to formulate proprietary blends that exceed baseline industry standards.

The table below illustrates why generic material categorizations are insufficient for critical applications. Performance boundaries vary significantly even within rubber families, necessitating engineered solutions.

| Material Type | Temperature Range (°C) | Key Chemical Resistances | Critical Limitations in 1/4″ Applications |

|---|---|---|---|

| Standard EPDM | -50 to +135 | Steam, alkalis, oxygen | Swells in petroleum oils; poor adhesion without primers |

| Custom EPDM | -60 to +150 | Customized for ketones, phosphate esters | Enhanced compression set resistance via peroxide curing |

| Standard NBR | -40 to +107 | Aliphatic hydrocarbons | Fails in polar solvents; ozone degradation above 70°C |

| High-ACN NBR | -30 to +120 | Hydraulic fluids, silicones | Reduced flexibility; requires plasticizer stabilization |

| Neoprene | -45 to +120 | Flame resistance, mild acids | Swells in aromatic solvents; moderate weathering limits |

| Silicone | -100 to +230 | Extreme temperatures, steam | Poor abrasion resistance; high cost for non-critical uses |

Suzhou Baoshida rejects the commoditization of rubber sheeting. Our 1/4 inch solutions integrate OEM-specific engineering data into every compound batch, ensuring dimensional stability and functional reliability under defined stressors. Generic sheets fail because they prioritize inventory efficiency over application physics. Precision material science is not optional—it is the sole determinant of lifecycle performance in engineered rubber components. Partner with our technical team to transform your specification from a dimension into a validated performance solution.

Material Specifications

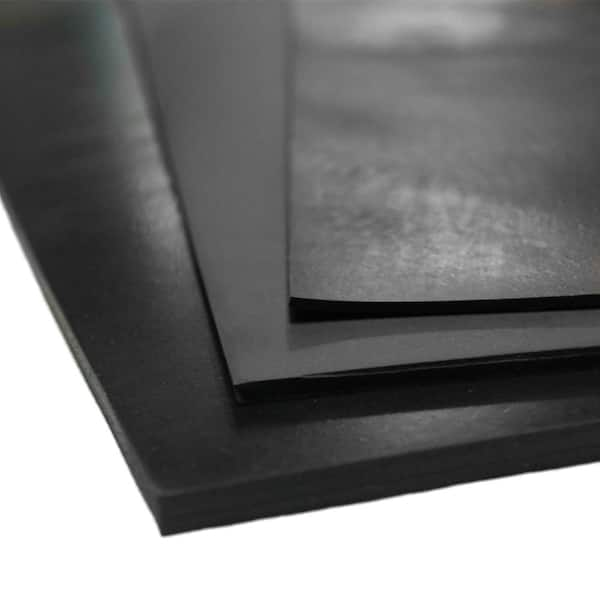

Material Specifications for 1/4 Inch Thick Rubber Sheet

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber sheets in a standard 1/4 inch (6.35 mm) thickness, engineered for demanding applications across automotive, aerospace, chemical processing, and manufacturing sectors. Our precision-cut rubber sheets are available in three core elastomers: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct chemical, thermal, and mechanical properties tailored to specific operational environments.

Viton rubber sheets deliver exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With continuous service capability up to 200°C (392°F) and intermittent exposure tolerance to 250°C (482°F), Viton is ideal for sealing and gasketing in extreme conditions. Its low gas permeability and excellent aging characteristics make it a preferred choice in aerospace and refinery applications where reliability is critical.

Nitrile rubber, also known as Buna-N, is a cost-effective solution for applications involving petroleum-based oils, hydraulic fluids, and greases. It exhibits high abrasion resistance and tensile strength, maintaining integrity under mechanical stress. Nitrile sheets perform reliably in temperatures ranging from -30°C to 120°C (-22°F to 248°F), making them suitable for seals, diaphragms, and vibration dampening components in industrial machinery and automotive systems.

Silicone rubber sheets offer superior flexibility and thermal stability across a broad temperature range, from -60°C to 230°C (-76°F to 446°F). While not as resistant to petroleum derivatives as Viton or Nitrile, silicone excels in applications requiring electrical insulation, food-grade compliance, and resistance to ozone and UV radiation. Its non-toxic formulation and FDA compliance support use in medical devices, food processing equipment, and outdoor electrical enclosures.

All 1/4 inch rubber sheets from Suzhou Baoshida are manufactured to stringent quality standards, ensuring uniform thickness, consistent durometer (hardness), and minimal surface defects. Custom sheet sizes, tolerances, and durometer options are available upon request to meet OEM specifications.

The following table compares key technical parameters of the three materials:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness (Shore A) | 70–90 | 60–90 | 40–80 |

| Temperature Range (°C) | -20 to 200 (up to 250 intermittent) | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Excellent (petroleum oils, greases) | Poor to fair (excellent for water, ozone) |

| Electrical Insulation | Good | Fair | Excellent |

| FDA Compliant Grades Available | Yes | Limited | Yes |

Suzhou Baoshida ensures traceability and repeatability in every batch, supporting long-term reliability in industrial supply chains.

Manufacturing Capabilities

Engineering Excellence in 1/4 Inch Rubber Sheet Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep material science expertise to deliver precision-engineered 1/4 inch rubber sheets tailored for demanding industrial applications. Our core strength lies in the integration of dedicated formula development and advanced mold engineering, ensuring every sheet meets exacting performance criteria. With five specialized mold engineers and two certified rubber formula engineers on staff, we control the entire production continuum—from molecular polymer design to final dimensional validation. This vertical integration eliminates third-party dependencies, accelerating time-to-market while guaranteeing repeatability.

Material science drives our approach to 1/4 inch sheet production. At this critical thickness, factors like compression set resistance, thermal stability, and extrusion consistency become paramount. Our formula engineers optimize polymer chains, filler dispersion, and curing kinetics to counteract common pitfalls such as edge curling or inconsistent durometer across the sheet’s cross-section. By fine-tuning sulfur systems and antioxidant packages, we achieve extended service life in aggressive environments—whether exposed to ozone, hydraulic fluids, or extreme temperatures. This scientific rigor ensures the sheet maintains its structural integrity under sustained load, a non-negotiable requirement for gasketing, vibration damping, and sealing applications.

Our OEM capabilities transform client specifications into engineered reality. We collaborate from the concept phase, analyzing application stress points to recommend optimal compound formulations—be it Nitrile (NBR) for oil resistance, EPDM for weathering, or Silicone for extreme temperatures. The mold engineering team then designs extrusion tooling with precision-calibrated land lengths and die geometries to eliminate knit lines and ensure ±0.005 inch thickness tolerance across wide widths. This co-engineering process mitigates production risks, such as material waste from improper flow dynamics, directly reducing our clients’ total cost of ownership.

The table below outlines standard technical specifications for our 1/4 inch rubber sheets, all achievable through our in-house engineering pipeline. Custom formulations consistently exceed these baselines based on OEM requirements.

| Property | Standard Value | Test Method | OEM Customization Notes |

|---|---|---|---|

| Thickness Tolerance | ±0.005 inch (±0.13mm) | ASTM D3772 | Adjustable for critical sealing interfaces |

| Hardness Range | 40–90 Shore A | ASTM D2240 | Optimized for compression recovery needs |

| Tensile Strength | ≥1,500 psi | ASTM D412 | Enhanced to 2,800+ psi for high-stress uses |

| Temperature Range | -40°F to +250°F | ASTM D573 | Extensible to -65°F/+400°F with specialty compounds |

| Elongation at Break | ≥250% | ASTM D412 | Tuned for flexibility vs. tear resistance |

| Compression Set (22h) | ≤25% | ASTM D395 | Reduced to ≤15% for dynamic sealing apps |

Suzhou Baoshida’s engineering framework ensures that every 1/4 inch rubber sheet is not merely manufactured but scientifically validated. We provide comprehensive material traceability, including batch-specific cure curves and FTIR validation reports, empowering clients with data-driven quality assurance. For OEM partners, this translates to reduced field failures, seamless integration into automated assembly lines, and compliance with ISO 9001-certified processes. Partner with us to convert material challenges into competitive advantages through precision rubber science.

Customization Process

Customization Process for 1/4 Inch Thick Rubber Sheets at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering precision-engineered rubber solutions tailored to the exact needs of industrial clients. Our systematic customization process ensures optimal performance, durability, and cost-efficiency for every 1/4 inch thick rubber sheet we produce. The process begins with Drawing Analysis and progresses through Formulation, Prototyping, and Mass Production—each stage governed by strict quality control and technical validation.

The first step, Drawing Analysis, involves a detailed technical review of customer-provided engineering drawings or specifications. Our team evaluates critical parameters such as dimensional tolerances, surface finish requirements, hardness (Shore A), intended operating environment (temperature, chemical exposure, compression load), and application-specific performance criteria. This phase ensures that all geometric and functional requirements are fully understood and feasible within material and manufacturing constraints.

Following drawing validation, we proceed to Formulation. Based on the application environment, our rubber formula engineers select the appropriate base polymer—such as Nitrile (NBR), EPDM, Natural Rubber (NR), Silicone (VMQ), or Neoprene (CR)—and develop a custom compound. The formulation is optimized for key properties including tensile strength, elongation at break, compression set resistance, abrasion resistance, and fluid compatibility. Additives such as reinforcing fillers, antioxidants, plasticizers, and vulcanizing agents are precisely balanced to meet performance targets while maintaining processability during curing.

Once the formulation is finalized, we initiate the Prototyping phase. A small-batch sample of the 1/4 inch rubber sheet is produced using calibrated open mills and hydraulic press vulcanization under controlled time, temperature, and pressure conditions. The prototype undergoes rigorous physical and chemical testing, including hardness measurement, tensile testing, compression deflection analysis, and environmental exposure trials. The results are documented and shared with the client for approval. Adjustments are made if necessary, ensuring complete alignment with performance expectations.

Upon client approval, the project transitions to Mass Production. We leverage automated calendaring and continuous vulcanization lines to ensure uniform thickness, consistent cure, and high dimensional accuracy across large volumes. Every production batch is subject to in-process and final quality inspections, with full traceability maintained for raw materials and processing parameters.

The table below outlines key technical specifications typically associated with our 1/4 inch (6.35 mm) thick rubber sheets:

| Property | Typical Value Range | Test Standard |

|---|---|---|

| Thickness | 6.35 mm ± 0.3 mm | ASTM D3767 |

| Hardness (Shore A) | 40–90 (customizable) | ASTM D2240 |

| Tensile Strength | 10–30 MPa | ASTM D412 |

| Elongation at Break | 200–600% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Operating Temperature | -40°C to +150°C (varies by type) | Material-dependent |

This structured approach ensures that each 1/4 inch rubber sheet meets the highest standards of industrial performance and reliability.

Contact Engineering Team

Technical Engagement: Precision Rubber Solutions for Industrial Applications

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered rubber compound development and OEM manufacturing, specializing in high-tolerance industrial rubber sheets. Our 1/4 inch thick rubber sheet product line exemplifies rigorous material science application, designed to meet exacting performance demands across automotive, aerospace, marine, and heavy machinery sectors. Each sheet undergoes stringent QC protocols including ASTM D2000 compliance validation, laser micrometer thickness verification, and batch-specific durometer certification. We prioritize dimensional stability and chemical resistance in formulations, ensuring consistent performance under dynamic operational stresses.

The table below details critical technical specifications for our standard 1/4 inch (6.35 mm) rubber sheet offerings. These values represent baseline metrics; Suzhou Baoshida excels in custom compound engineering to address unique client requirements including extreme temperature resilience, conductive properties, or specialized fluid resistance.

| Property | Nitrile (NBR) | EPDM | Neoprene | Silicone |

|---|---|---|---|---|

| Hardness (Shore A) | 50±5 | 60±5 | 55±5 | 40±5 |

| Tensile Strength (MPa) | ≥15.0 | ≥12.0 | ≥14.0 | ≥8.0 |

| Elongation at Break (%) | ≥300 | ≥250 | ≥280 | ≥400 |

| Temperature Range (°C) | -30 to +100 | -50 to +130 | -40 to +120 | -60 to +200 |

| Compression Set (B) (%) | ≤25 (70°C/22h) | ≤30 (100°C/22h) | ≤20 (70°C/22h) | ≤20 (200°C/22h) |

| Thickness Tolerance (mm) | ±0.15 | ±0.15 | ±0.15 | ±0.20 |

Material selection directly impacts system longevity and safety margins. Suzhou Baoshida’s engineering team collaborates with clients during the specification phase to optimize compound formulations for specific load conditions, environmental exposures, and lifecycle expectations. Our OEM production facilities feature automated calendaring lines with real-time thickness monitoring, ensuring uniform cross-section integrity critical for sealing and vibration damping applications. We maintain ISO 9001-certified processes with traceable material lot records and accelerated aging test data available upon request.

Initiate your project with direct access to our technical leadership. Contact Mr. Boyce, Rubber Formula Engineer and OEM Manager, for authoritative guidance on material selection, prototype validation, and production scaling. Mr. Boyce possesses 14 years of compound development experience across 37 industrial sectors and will provide a detailed technical consultation addressing your exact operational parameters. His team specializes in resolving complex challenges such as low-temperature flexibility retention, ozone cracking mitigation, and FDA-compliant food-grade formulations.

Do not proceed with generic rubber suppliers lacking compound-level engineering oversight. Suzhou Baoshida delivers documented performance assurance through material test reports, finite element analysis support, and post-installation performance tracking. Email Mr. Boyce at [email protected] with your application details, required certifications, and volume projections. Include any existing material failure data for immediate compound optimization recommendations. Our technical response window is under 4 business hours for qualified industrial inquiries. Partner with an OEM that treats rubber as a precision engineering component, not a commodity. Your next-generation application demands material science expertise—contact Suzhou Baoshida to secure performance-critical rubber solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).