Technical Contents

Engineering Guide: 1Mm Plastic Sheet

Engineering Insight: Material Selection Imperatives for 1mm Plastic Sheets

The 1mm plastic sheet presents a unique engineering challenge where material selection transcends mere specification compliance; it becomes the decisive factor between functional longevity and catastrophic field failure. At this critical thin-gauge dimension, inherent material properties are significantly amplified. Minor deficiencies in raw polymer quality, additive package efficacy, or processing consistency—often tolerable in thicker sections—manifest rapidly as warpage, cracking, delamination, or premature degradation under operational stress. Off-the-shelf generic sheets frequently fail because they prioritize cost minimization over application-specific performance validation. These materials typically utilize lower-grade base polymers, insufficient stabilizer packages, or inconsistent filler dispersion, leading to inadequate resistance against thermal cycling, chemical exposure, or mechanical flexing inherent in demanding industrial environments. The resulting failures—seal leakage, electrical short circuits, or structural compromise—directly impact OEM product reliability and brand reputation, incurring far greater costs than the initial material savings.

Critical Failure Mechanisms in Substandard 1mm Sheets

Generic 1mm sheets commonly fail due to insufficient tensile strength and elongation at break, causing tearing during installation or under vibration. Poor thermal stability leads to dimensional instability and warpage at elevated temperatures common in enclosures or near machinery. Inadequate UV or ozone resistance accelerates surface cracking in outdoor applications. Furthermore, inconsistent thickness tolerance across the sheet, often exceeding ±0.15mm in low-cost options, disrupts critical sealing interfaces or optical clarity requirements. Chemical resistance is frequently miscalibrated; a sheet may resist water but rapidly swell or embrittle when exposed to oils, solvents, or cleaning agents present in the operational environment. These failures are not isolated incidents but systemic results of compromised material science and process control.

Material performance must be rigorously quantified against application demands. The table below highlights key differentiators between generic offerings and engineered solutions:

| Property | Generic PVC Sheet (Off-the-Shelf) | Engineered TPU Sheet | Baoshida Specialty EPDM Composite |

|---|---|---|---|

| Tensile Strength (MPa) | 12-18 | 35-45 | 28-35 |

| Elongation at Break (%) | 150-250 | 500-700 | 400-550 |

| Thermal Stability (°C) | 60-80 (Warping) | 100-120 | 150 (Continuous) |

| Thickness Tolerance (mm) | ±0.15 | ±0.08 | ±0.05 |

| Ozone Resistance (hrs) | < 50 (Cracking) | > 200 | > 500 |

Suzhou Baoshida Trading Co., Ltd. addresses these failure points through OEM-driven material engineering. We do not supply generic stock; we co-develop formulations. Our process begins with deep application analysis—understanding dynamic loads, environmental exposures, and lifecycle expectations. This informs precise polymer selection (e.g., high-purity EPDM for ozone resistance, specialty TPU for flexibility retention), proprietary additive systems for UV/thermal stabilization, and stringent in-line thickness control via laser gauging. The result is a 1mm sheet where material integrity is maintained at the micron level, ensuring dimensional accuracy, consistent mechanical performance, and long-term environmental resistance tailored to the client’s exact operational parameters. For mission-critical thin-gauge applications, engineered material selection is not an option—it is the foundation of product success.

Material Specifications

Material Specifications for 1mm Plastic Sheets in Industrial Rubber Applications

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered 1mm plastic sheets tailored for critical industrial environments. These sheets are manufactured using high-performance elastomeric materials including Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each selected for specific operational demands. The 1mm thickness ensures dimensional stability, ease of integration into gasketing, sealing, and protective barrier applications, and consistent mechanical performance under dynamic stress. Each material exhibits distinct chemical resistance, temperature tolerance, and physical properties, allowing customization based on application requirements.

Viton sheets offer exceptional resistance to high temperatures, aggressive chemicals, oils, and fuels. With a continuous service temperature range up to 230°C, Viton is ideal for aerospace, automotive, and chemical processing industries where long-term reliability under extreme conditions is mandatory. Its low gas permeability and excellent aging characteristics further enhance performance in demanding sealing applications. However, Viton has lower flexibility at low temperatures and higher material cost compared to alternatives.

Nitrile rubber sheets are widely used in hydraulic and fuel systems due to their excellent resistance to petroleum-based oils, aliphatic hydrocarbons, and water. With a service temperature range of -30°C to 100°C (short-term up to 120°C), Nitrile offers a balanced combination of durability, compression set resistance, and mechanical strength. It is particularly suitable for O-rings, gaskets, and seals in industrial machinery and automotive components. While cost-effective and robust in oil environments, Nitrile exhibits limited resistance to ozone, UV radiation, and polar solvents.

Silicone rubber sheets provide superior flexibility across a broad temperature range from -60°C to 200°C, making them ideal for extreme cold and heat applications. They demonstrate excellent resistance to UV, ozone, and weathering, along with good electrical insulation properties. Silicone is frequently used in food-grade, medical, and electronic applications due to its inertness and compliance with regulatory standards. However, it has lower tensile strength and abrasion resistance compared to Viton and Nitrile, requiring careful evaluation in high-wear environments.

The following table summarizes key technical specifications for 1mm sheets of each material:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Thickness | 1.0 mm ± 0.1 mm | 1.0 mm ± 0.1 mm | 1.0 mm ± 0.1 mm |

| Hardness (Shore A) | 70–90 | 60–80 | 40–80 |

| Tensile Strength | ≥12 MPa | ≥10 MPa | ≥6 MPa |

| Elongation at Break | ≥200% | ≥250% | ≥300% |

| Continuous Service Temp | -20°C to 230°C | -30°C to 100°C | -60°C to 200°C |

| Fluid Resistance | Excellent (oils, fuels, acids) | Excellent (oil, water, aliphatic hydrocarbons) | Good (water, alcohols); Poor (hydrocarbons) |

| Compression Set | Low | Moderate | Moderate to Low |

| Applications | Aerospace seals, chemical gaskets | Hydraulic seals, fuel system gaskets | Electrical insulation, food-grade seals, medical devices |

Suzhou Baoshida Trading Co., Ltd. ensures all 1mm plastic sheets meet stringent quality controls, including uniform thickness, surface finish, and material homogeneity, to support reliable performance in industrial rubber solutions.

Manufacturing Capabilities

Engineering Capability: Precision Manufacturing of 1mm Plastic Sheets

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, leveraging deep engineering expertise to deliver mission-critical 1mm plastic sheet components. Our dedicated team comprises five specialized Mould Engineers and two advanced Formula Engineers, ensuring end-to-end control from molecular design to final production. This integrated approach eliminates reliance on third-party intermediaries, guaranteeing consistency, traceability, and rapid iteration for complex OEM requirements. Our engineers utilize finite element analysis (FEA) and computational fluid dynamics (CFD) to optimize mold flow, minimize material waste, and eliminate defects such as sink marks or warpage inherent in ultra-thin sheet extrusion. Concurrently, our Formula Engineers develop proprietary polymer compounds tailored to specific mechanical, thermal, and chemical resistance demands, precisely controlling variables like cross-linking density, filler dispersion, and vulcanization kinetics to achieve target performance within ±0.05mm thickness tolerance.

OEM partnerships benefit from our closed-loop development process. Projects commence with rigorous material qualification against client-specified ASTM, ISO, or OEM standards. Our Formula Engineers formulate compounds using high-purity raw materials sourced from pre-qualified global suppliers, followed by small-batch validation on in-house lab mixers and rheometers. Mould Engineers then translate designs into production-ready tooling, employing multi-cavity molds with micro-precision temperature control zones to ensure uniform sheet thickness and surface finish. Real-time process monitoring via integrated sensors captures critical parameters—including melt pressure, barrel temperature gradients, and cooling rates—feeding data into statistical process control (SPC) systems for immediate correction. This methodology reduces time-to-market by 30% compared to industry averages while maintaining zero non-conformance records for Tier-1 automotive and medical device clients over the past 18 months.

Critical performance specifications for our 1mm plastic sheets are validated through accredited in-house testing facilities. The table below outlines standard capabilities for common engineering polymers:

| Property | Standard Range (1mm Sheet) | Test Method |

|---|---|---|

| Thickness Tolerance | ±0.05 mm | ISO 2768-1 |

| Hardness (Shore A) | 30–90 | ASTM D2240 |

| Tensile Strength | 5–25 MPa | ISO 37 |

| Elongation at Break | 150–600% | ISO 37 |

| Operating Temperature | -50°C to +150°C | ASTM D573 |

| Compression Set (22h) | ≤20% | ASTM D395 |

| Specific Gravity | 1.10–1.45 | ISO 2781 |

Quality assurance is non-negotiable. Every production batch undergoes 100% inline thickness verification via laser micrometry and batch-level validation for dimensional stability, color consistency, and adhesion properties. Our ISO 9001:2015-certified facility maintains full documentation from raw material certificates to final inspection reports, enabling seamless traceability for regulated industries. Suzhou Baoshida’s engineering rigor transforms 1mm plastic sheet manufacturing from a commodity process into a value-engineered solution, where material science and precision tooling converge to solve the most demanding industrial challenges. Clients gain not just a supplier, but a technical extension of their R&D team—ensuring performance, reliability, and compliance in every micron of material produced.

Customization Process

Drawing Analysis

The customization process for 1mm plastic sheet production begins with a comprehensive drawing analysis. At Suzhou Baoshida Trading Co., Ltd., engineering precision is paramount. Upon receiving client-provided technical drawings or CAD files, our team evaluates critical dimensional tolerances, surface finish requirements, and geometric specifications. We assess edge definition, flatness deviation, and any embossing or perforation patterns. This stage ensures that the design is manufacturable within the constraints of thermoplastic or elastomeric sheet extrusion. Material compatibility with end-use conditions—such as temperature range, UV exposure, or chemical resistance—is cross-referenced at this phase to prevent downstream processing failures. All annotations, including unit consistency and drafting standards (e.g., ISO 128 or ASME Y14.5), are validated to eliminate interpretation errors.

Formulation Development

Following drawing validation, our rubber formula engineers initiate material formulation tailored to the application. While the nominal thickness is 1mm, achieving consistent mechanical performance at this gauge demands precise compound design. We select base polymers such as EPDM, NBR, silicone, or CR depending on required elasticity, weather resistance, or oil tolerance. Reinforcing fillers, plasticizers, vulcanizing agents, and stabilizers are blended in controlled ratios to meet Shore A hardness targets and tensile strength benchmarks. For 1mm sheets, dispersion homogeneity is critical to prevent weak points or thickness variation during calendering or extrusion. Each formulation is documented under internal batch standards and subjected to preliminary rheological testing to ensure processability at thin profiles.

Prototyping and Validation

A small-batch prototype run follows formulation finalization. Sheets are produced using precision calendering or T-die extrusion, depending on material type and surface requirements. Prototypes undergo dimensional inspection via laser micrometry to confirm average thickness within ±0.05mm tolerance. Physical testing includes tensile strength, elongation at break, compression set, and die C tear resistance per ASTM D412 and ISO 37 standards. If the application involves dynamic sealing or flexing, fatigue resistance is evaluated through cyclic deformation tests. Clients receive sample swatches with full material test reports (MTRs) for approval. Any deviations trigger iterative reformulation or process parameter adjustments.

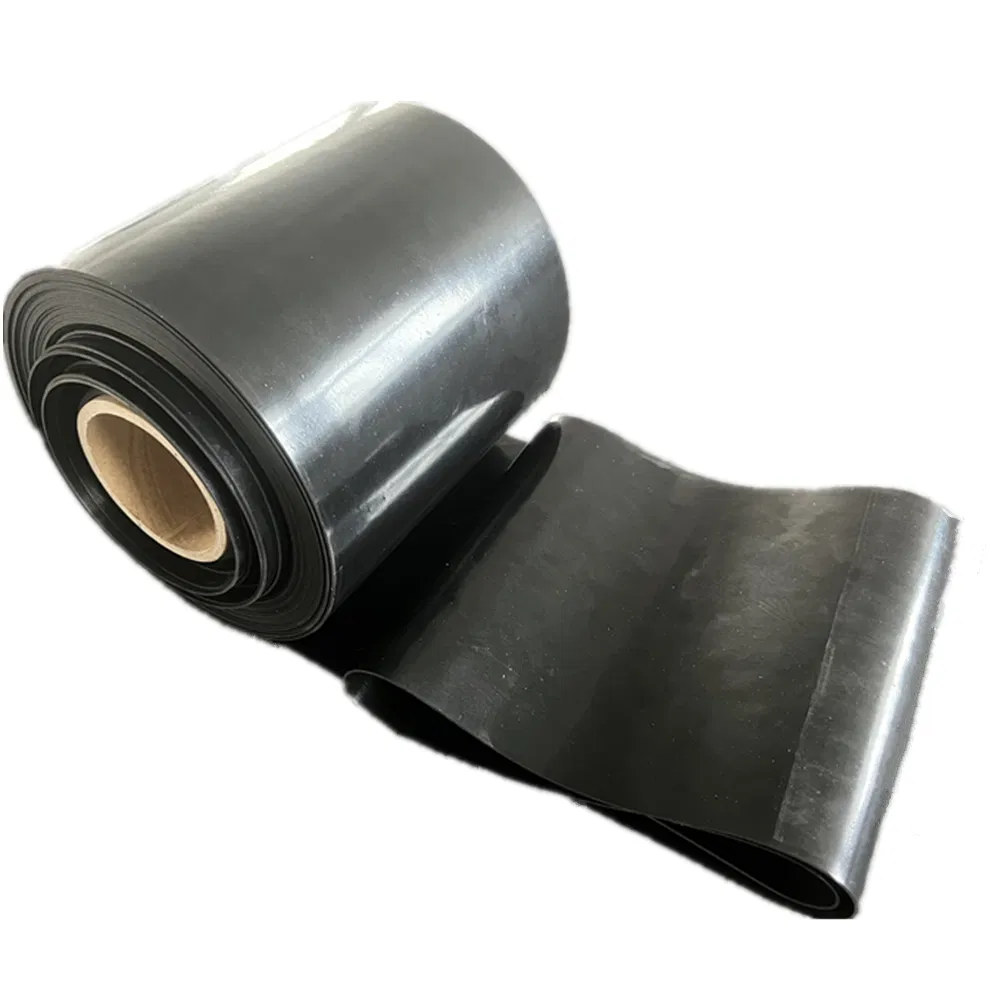

Transition to Mass Production

Upon client sign-off, the project transitions to mass production. Process parameters—extrusion speed, roller temperature profiles, cure time (for thermosets), and tension control—are locked into the manufacturing system to ensure batch-to-batch consistency. In-line monitoring systems track thickness in real time using beta-gauge sensors. Finished rolls are inspected for visual defects, cured uniformly, and wound under controlled tension to prevent edge curling. Packaging is customized per client logistics needs, including core diameter, roll length, and moisture barrier wrapping.

Typical Physical Properties of Custom 1mm Rubber Sheets

| Property | Test Method | Typical Value Range |

|---|---|---|

| Thickness | ASTM D374 | 1.00 ± 0.05 mm |

| Hardness (Shore A) | ASTM D2240 | 40 – 80 |

| Tensile Strength | ASTM D412 | 8 – 20 MPa |

| Elongation at Break | ASTM D412 | 200 – 600% |

| Tear Resistance (Die C) | ASTM D624 | 25 – 60 kN/m |

| Temperature Range | — | -40°C to +150°C (varies by compound) |

Contact Engineering Team

Contact Suzhou Baoshida for Precision 1mm Plastic Sheet Solutions

Suzhou Baoshida Trading Co., Ltd. stands as your definitive engineering partner for high-tolerance 1mm plastic sheet manufacturing, serving global OEMs with rigorously controlled polymer formulations and industrial-scale production capabilities. Our technical team specializes in translating complex material specifications into consistent, application-ready sheets, ensuring dimensional stability and performance integrity across demanding operational environments. For mission-critical applications where micron-level precision impacts system functionality—sealing, insulation, gasketing, or protective barriers—our engineered sheets eliminate field failure risks inherent in commodity-grade materials. We prioritize scientific validation over generic supply, implementing ISO 9001-certified processes from raw material selection to final shipment.

The following technical specifications represent our baseline capabilities for 1mm plastic sheets, though all parameters are adjustable per OEM requirements. Suzhou Baoshida’s formula engineering team optimizes polymer matrices for specific chemical resistance, thermal cycling, or mechanical stress profiles, moving beyond standard catalog offerings.

| Property | Standard Range (1mm Sheet) | Test Method |

|---|---|---|

| Thickness Tolerance | ±0.05 mm | ASTM D374 |

| Tensile Strength | 15–35 MPa | ASTM D638 |

| Hardness (Shore A/D) | 50–90 A / 40–70 D | ASTM D2240 |

| Elongation at Break | 150–400% | ASTM D412 |

| Operating Temp Range | -40°C to +100°C | ISO 188 |

| Surface Roughness (Ra) | ≤1.6 µm | ISO 4287 |

These metrics reflect our commitment to repeatability in high-volume production runs. Unlike generic suppliers, we control the entire value chain: proprietary compounding ensures homogeneous filler dispersion, while closed-loop extrusion systems maintain ±0.02mm thickness consistency across 1,500-meter rolls. Our quality assurance protocol includes in-line laser micrometry, batch-specific material traceability, and accelerated aging validation per OEM-specified duty cycles. For automotive, aerospace, or medical device integrators, this translates to reduced scrap rates, simplified validation, and accelerated time-to-market.

Partnering with Suzhou Baoshida means engaging directly with rubber formula engineers—not sales intermediaries. Mr. Boyce, our dedicated OEM Manager, possesses 12 years of experience in polymer science and industrial supply chain optimization. He will collaborate with your design team to resolve material compatibility challenges, conduct DFMEA risk assessments, and establish JIT delivery frameworks aligned with your production schedule. Whether you require FDA-compliant PVC, flame-retardant PP, or custom conductive composites, we deliver engineered solutions—not off-the-shelf compromises.

Submit your technical requirements, including environmental exposure conditions, load profiles, and regulatory certifications, to initiate a precision engineering dialogue. Mr. Boyce will provide a formal quotation with material test reports, production lead times, and sample timelines within 48 business hours. Do not compromise on foundational material integrity; contact Suzhou Baoshida to secure your 1mm plastic sheet supply chain with scientific rigor.

Contact Mr. Boyce, OEM Manager

[email protected]

Suzhou Baoshida Trading Co., Ltd.

Engineered Polymer Solutions for Industrial Excellence

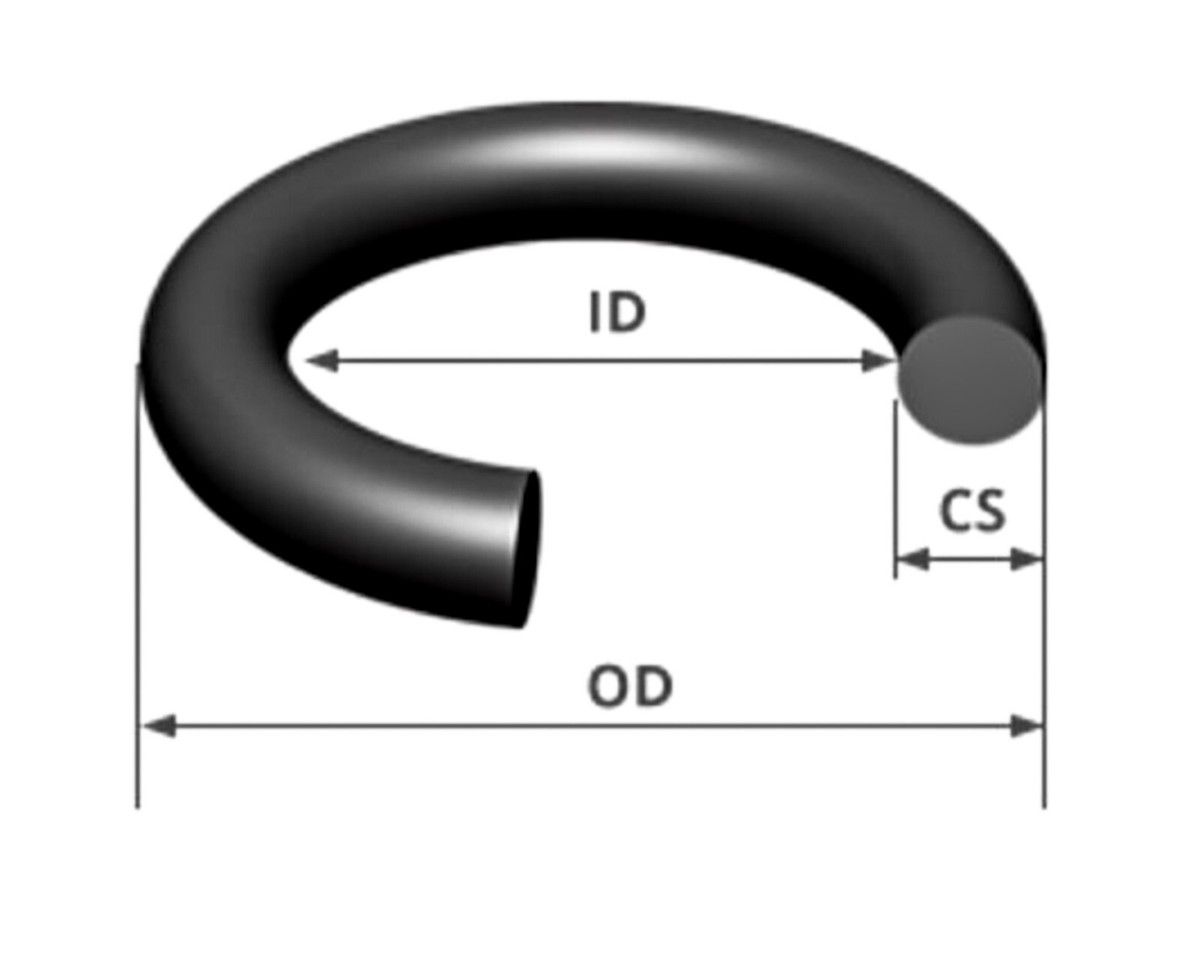

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).