Technical Contents

Engineering Guide: 30 X 40 Foam Board

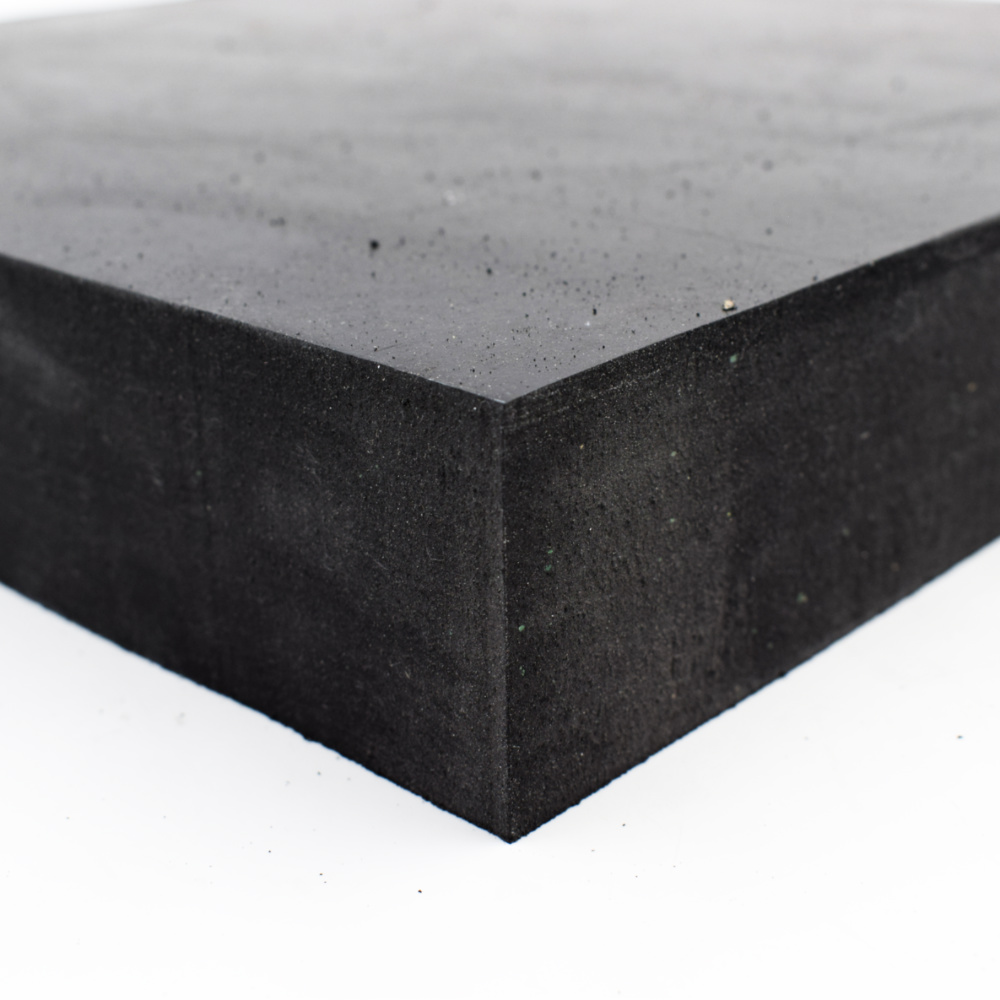

Engineering Insight: 30 x 40 Foam Board – The Critical Role of Material Selection

In industrial sealing and gasketing applications, the 30 x 40 foam board has become a standard dimension for prototyping, custom die-cutting, and short-run production. While this size offers logistical convenience and compatibility with common cutting systems, its performance is fundamentally determined not by dimensions, but by the engineered composition of the rubber or elastomeric material used. Off-the-shelf foam boards often fail in demanding environments due to generic formulations that prioritize cost and availability over functional durability.

Material selection directly influences compression set resistance, thermal stability, chemical compatibility, and tensile recovery—parameters that define long-term sealing integrity. Standard polyethylene (PE) or ethylene-vinyl acetate (EVA) foam boards, commonly found in general-purpose supply channels, degrade rapidly under sustained load or elevated temperatures. These materials exhibit high permanent deformation after compression, leading to seal leakage in dynamic or thermally cycled assemblies. Additionally, their limited resistance to oils, solvents, and UV exposure restricts use in automotive, industrial machinery, or outdoor applications.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific formulation. Our engineered rubber foam boards are compounded with controlled cross-linking densities, reinforcing fillers, and stabilizing additives to meet OEM performance thresholds. For instance, in HVAC systems requiring consistent low-compression-force deflection (CFD), a closed-cell silicone rubber foam maintains resilience across -50°C to +200°C, whereas a generic foam would harden or creep. Similarly, nitrile rubber (NBR) based foams offer superior resistance to hydrocarbon exposure, making them ideal for engine compartment gasketing.

The failure of generic foam boards often manifests not during initial installation, but after weeks or months of service. This delayed breakdown increases warranty claims, maintenance costs, and reputational risk—far exceeding the nominal savings from choosing a lower-cost material. True cost efficiency comes from total lifecycle performance, not unit price.

We recommend a qualification protocol that includes compression set testing (ASTM D395), fluid immersion analysis (ASTM D471), and thermal aging per customer-specific duty cycles. Only through such rigorous evaluation can material suitability be confirmed.

Below are representative specifications for high-performance foam board formulations available through our industrial rubber solutions portfolio.

| Material | Density (kg/m³) | Hardness (Shore A) | Temp Range (°C) | Compression Set (%) | Key Applications |

|---|---|---|---|---|---|

| Silicone Foam | 300–450 | 30–50 | -50 to +200 | ≤25 (22h @ 150°C) | High-temp seals, electronics |

| Nitrile (NBR) Foam | 350–500 | 40–60 | -30 to +120 | ≤30 (22h @ 100°C) | Oil-resistant gaskets |

| EPDM Foam | 320–480 | 35–55 | -40 to +135 | ≤28 (22h @ 125°C) | Outdoor enclosures, weatherstripping |

| Neoprene Foam | 380–520 | 45–65 | -35 to +110 | ≤32 (22h @ 100°C) | Industrial housings, vibration dampening |

Material selection is not a commodity decision—it is an engineering imperative. Partnering with a technical supplier ensures that the 30 x 40 foam board you specify performs as designed, not just as delivered.

Material Specifications

Material Specifications for 30 x 40 Rubber Foam Board

Suzhou Baoshida Trading Co., Ltd. supplies precision-engineered closed-cell rubber foam board in the standard industrial dimension of 30 mm thickness x 400 mm width (30 x 40). This format ensures compatibility with automated gasket cutting systems and structural sealing applications across automotive, aerospace, and industrial machinery sectors. Critical performance hinges on elastomer selection, where Viton (FKM), Nitrile (NBR), and Silicone (VMQ) formulations deliver distinct property profiles. All foam boards undergo stringent density control (45–65 kg/m³) and exhibit closed-cell integrity (<10% open cells per ASTM D2471), ensuring consistent compression set resistance and barrier properties. Hardness is maintained within ±5 Shore A units across the sheet, validated via ISO 7619-1 testing protocols.

Material selection directly impacts operational longevity under thermal, chemical, and mechanical stress. Viton foam excels in extreme chemical environments, particularly against aromatic hydrocarbons and high-temperature fuels. Nitrile foam offers optimal cost-performance balance for oil and grease resistance in hydraulic systems. Silicone foam provides unparalleled thermal stability and biocompatibility, critical for medical and semiconductor applications. Each compound is engineered with precise blowing agent ratios to achieve uniform cell structure, minimizing outgassing and dimensional drift during service.

The following table details comparative specifications for standard formulations. Values represent typical ranges after compression molding and vulcanization under controlled OEM parameters.

| Material Property | Viton (FKM) Foam | Nitrile (NBR) Foam | Silicone (VMQ) Foam |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +230 |

| Hardness (Shore A) | 50–70 | 40–60 | 30–50 |

| Tensile Strength (MPa) | 1.8–2.5 | 1.2–1.8 | 0.8–1.5 |

| Elongation at Break (%) | 150–250 | 180–300 | 200–400 |

| Compression Set (22h/70°C) | ≤25% | ≤35% | ≤20% |

| Key Chemical Resistances | Fuels, Acids, Oils | Aliphatic Oils, Water | Steam, Ozone, Acids |

| Density (kg/m³) | 50–60 | 45–55 | 55–65 |

Suzhou Baoshida’s OEM process integrates material science with dimensional precision. Foam boards are produced using peroxide-cured systems to minimize extractables, with lot-specific certificates of conformance (CoC) verifying ASTM D2000/ISO 3733 compliance. For critical applications, we recommend Viton for sustained exposure above 150°C or aggressive chemical contact, Nitrile for dynamic sealing in oil-lubricated assemblies below 120°C, and Silicone for cryogenic flexibility or high-purity environments. All materials undergo 100% visual inspection for surface defects and dimensional verification via laser micrometry. Consult our engineering team for formulation adjustments to meet ISO 1629 or SAE AS5127/1 requirements, ensuring seamless integration into your manufacturing workflow. Empirical validation of material suitability against your specific media and stress conditions remains essential prior to full-scale implementation.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Industrial Foam Board Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of specialized 30 x 40 foam board products. With a dedicated team of five certified mould engineers and two advanced formula engineers, we integrate material science with precision manufacturing to deliver consistent, high-performance foam board solutions tailored to OEM requirements.

Our formula engineers specialize in elastomer chemistry, focusing on optimizing rubber compounds for density, compression set, thermal stability, and environmental resistance. Each formulation is developed with application-specific performance in mind, whether for sealing, insulation, vibration damping, or gasketing in automotive, electronics, or industrial equipment sectors. We utilize EPDM, silicone, neoprene, and NBR-based compounds, fine-tuning cell structure and cross-link density to achieve the desired balance of softness, resilience, and durability in the final foam board.

Complementing our material expertise, our five in-house mould engineers ensure dimensional accuracy and repeatability in production tooling. They employ advanced CAD/CAM systems and finite element analysis (FEA) to simulate compression molding behavior, minimizing defects and optimizing cycle times. This synergy between formulation and mould design enables us to produce 30 x 40 foam boards with tight tolerances, uniform cell distribution, and consistent physical properties across large production runs.

Our OEM capabilities are built on a foundation of collaborative engineering. We work directly with clients from concept to commercialization, supporting custom thicknesses, hardness levels, adhesive backing integration, and flame-retardant treatments. Prototyping is conducted in-house with rapid tooling options, allowing for quick validation and iteration. All materials are tested per ASTM and ISO standards for compression deflection, tensile strength, elongation, and aging performance before mass production.

Suzhou Baoshida maintains full traceability and documentation for every formulation and tooling design, ensuring compliance with industry-specific regulatory demands. Our engineering team also provides technical dossiers, material certifications, and production process validation reports upon request, supporting our clients’ quality assurance and audit processes.

Through this integrated engineering approach, we ensure that every 30 x 40 foam board not only meets but exceeds functional and reliability expectations in demanding industrial environments.

| Property | Standard Range | Test Method |

|---|---|---|

| Density | 0.3 – 0.8 g/cm³ | ASTM D3574 |

| Hardness (Shore 00) | 20 – 80 | ASTM D2240 |

| Compression Deflection (25%) | 0.8 – 5.0 psi | ASTM D575 |

| Tensile Strength | 2.0 – 8.0 MPa | ASTM D412 |

| Elongation at Break | 100% – 300% | ASTM D412 |

| Operating Temperature | -40°C to +150°C (varies by compound) | — |

| Available Thickness | 1 mm – 50 mm | Customizable |

| Standard Sheet Size | 30 x 40 inches (762 x 1016 mm) | Cut-to-size options available |

Customization Process

Customization Process for 30 x 40 Foam Board Industrial Applications

Suzhou Baoshida Trading Co., Ltd. executes a rigorous four-phase customization protocol for 30 x 40 foam board solutions, ensuring alignment with OEM technical and operational demands. This structured methodology mitigates production risks while guaranteeing material performance under specified industrial conditions.

Drawing Analysis

Initial engagement requires comprehensive scrutiny of client-provided engineering drawings and application environment data. Our engineering team verifies dimensional tolerances (critical for 30 x 40 mm edge sealing interfaces), compression load requirements, fluid exposure profiles, and thermal cycling parameters. Deviations from standard foam board geometries or service conditions trigger cross-functional assessment to identify formulation and processing constraints. All measurements are validated against ISO 2768-mK general tolerance standards, with non-conformities documented for client consultation prior to progression.

Formulation Development

Based on drawing analysis outcomes, our rubber chemists design proprietary closed-cell foam formulations. Key variables include elastomer base selection (EPDM, NBR, or silicone), blowing agent chemistry, crosslink density optimization, and additive packages for flame resistance or chemical inertness. The table below illustrates how standard properties are modified for custom applications.

| Property | Standard Foam Board | Customized Foam Board | Test Method |

|---|---|---|---|

| Density (kg/m³) | 80 ± 10 | 65–120 (client-specified) | ASTM D3574 |

| Compression Set (%), 22h/70°C | ≤ 25 | ≤ 15 (dynamic sealing) | ASTM D395 |

| Temperature Range (°C) | -40 to +100 | -55 to +150 (silicone) | ISO 188 |

| Hardness (Shore A) | 45 ± 5 | 30–60 (gradient options) | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 0.8 | ≥ 1.2 (high-stress apps) | ASTM D412 |

Formulation iterations undergo accelerated aging simulations and finite element analysis (FEA) to predict long-term compression force deflection (CFD) behavior before physical prototyping.

Prototyping & Validation

Precision-cured prototypes are manufactured using client-approved tooling inserts and processing parameters. Each 30 x 40 mm sample undergoes dimensional metrology (CMM verification to ±0.1 mm), followed by application-specific performance testing. This includes cyclic compression testing per SAE J1460, fluid immersion resistance checks, and adhesion validation for bonded assemblies. Clients receive detailed test reports with statistical process control (SPC) data. Three iterative prototype rounds are included in standard service, with deviations requiring engineering change order (ECO) approval.

Mass Production Transition

Upon prototype sign-off, production transitions to ISO 9001-certified manufacturing lines with dedicated process control. Key measures include real-time rheometer monitoring of compound scorch time, automated vision inspection for cell structure uniformity, and batch traceability via laser-etched lot codes. All 30 x 40 foam boards undergo 100% dimensional verification and random batch testing per ASTM D3574. Production yields are maintained above 98.5% through statistical process control charts tracking critical-to-quality (CTQ) parameters. Suzhou Baoshida ensures seamless scale-up from prototype to full-volume output with zero requalification requirements.

This disciplined approach guarantees that customized foam boards meet exacting industrial specifications while maintaining manufacturing repeatability and supply chain resilience for global OEM operations.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber and foam solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in precision material supply. Our expertise in industrial rubber applications extends to specialized products such as the 30 x 40 foam board, engineered to meet the rigorous demands of sealing, insulation, vibration damping, and gasketing across automotive, electronics, construction, and machinery sectors. Every foam board we supply is manufactured under strict quality control protocols to ensure dimensional accuracy, consistent density, and long-term performance in dynamic environments.

The 30 x 40 foam board is available in multiple formulations, including EPDM, Neoprene, and Polyethylene, each tailored for specific environmental resistance properties. Whether your application requires UV stability, moisture resistance, or thermal insulation, our technical team can guide you toward the optimal material composition. These foam boards are ideal for CNC cutting, die-cutting, and custom fabrication, enabling seamless integration into automated production lines and high-volume manufacturing processes.

To ensure compatibility with your operational requirements, we provide comprehensive technical data sheets and material certifications upon request. Our production capabilities support both small-batch prototyping and large-scale OEM supply, backed by reliable logistics and just-in-time delivery options to minimize downtime and inventory costs.

For immediate technical consultation or material sampling, contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over a decade of experience in rubber compounding and industrial material solutions, Mr. Boyce leads client engagements with a focus on application-specific performance and cost-effective scalability. He is available to review your project specifications, recommend material alternatives, and support custom formulation development when standard options do not meet performance benchmarks.

| Specification | Detail |

|---|---|

| Dimensions | 30 inches x 40 inches (762 mm x 1016 mm) |

| Thickness Range | 1 mm to 50 mm (customizable) |

| Material Types | EPDM, Neoprene, Polyethylene, EVA, Nitrile |

| Density Range | 30–200 kg/m³ |

| Temperature Resistance | -40°C to +120°C (varies by compound) |

| Compression Set | <30% (at 70°C, 22 hrs, 25% deflection) |

| Hardness (Shore A) | 15–60 (adjustable) |

| Customization | Die-cutting, laminating, adhesive backing, printing |

Partnering with Suzhou Baoshida means access to technical depth, manufacturing agility, and responsive support. We prioritize engineering collaboration to deliver materials that enhance product reliability and reduce total cost of ownership.

Contact Mr. Boyce directly at [email protected] to discuss your foam board requirements, request samples, or initiate a technical evaluation. Let us help you optimize your material selection with data-driven solutions from a proven industrial supplier.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).