Technical Contents

Engineering Guide: 4 Inch Thick Foam Strips

Engineering Insight: Material Selection Imperatives for 4 Inch Thick Foam Strips

Thickness specification alone is a dangerous oversimplification in industrial sealing and cushioning applications. At 4 inches, foam strips operate under unique mechanical and environmental stresses where generic material formulations catastrophically fail. Off-the-shelf solutions prioritize cost and availability over performance physics, ignoring critical interactions between polymer chemistry, cell structure, and operational parameters. Standard foams exhibit unacceptable compression set deviation beyond 25% deflection at this thickness, leading to permanent deformation and seal integrity loss within weeks. The core failure mechanism lies in inadequate crosslink density and unstable cell morphology—variables invisible in catalog specifications but decisive in field performance.

Material selection must address three non-negotiable factors: dynamic load distribution across the 101.6 mm cross-section, thermal expansion coefficients matching adjacent substrates, and chemical resistance to specific fluid exposures. Polyethylene (PE) foams, commonly used in consumer applications, suffer catastrophic creep under sustained 0.5 psi loads at elevated temperatures due to low crystallinity. Conversely, precision-engineered nitrile rubber (NBR) or ethylene propylene diene monomer (EPDM) compounds with controlled sulfonate crosslinking maintain dimensional stability under 1.2 psi continuous compression. Crucially, closed-cell structures below 85% integrity permit fluid ingression at high cyclic stress points—rendering even chemically resistant base polymers ineffective.

Suzhou Baoshida’s OEM process begins with substrate adhesion profiling and fluid compatibility mapping. We isolate failure points through accelerated aging tests simulating 5,000-hour exposure to hydraulic fluids, ozone, or UV radiation at operational temperatures. This data drives polymer blending: adding halogenated butyl rubber for fuel resistance or ceramic microspheres for thermal stability without compromising elongation. The result is a tailored compound where compression set remains below 15% after 72 hours at 70°C—exceeding ASTM D395 Method B standards by 40%.

Performance Comparison: Standard vs. Engineered 4″ Foam Strips

| Parameter | Generic PE Foam | Baoshida Engineered NBR/EPDM Blend |

|---|---|---|

| Density Range (kg/m³) | 28-32 | 45-52 |

| Compression Set (70°C/22h) | 38-45% | 11-14% |

| Temp Range (°C) | -20 to 80 | -45 to 150 |

| Tensile Strength (MPa) | 0.8-1.1 | 2.3-2.8 |

| Fluid Resistance (ISO 1817) | Fails in 72h (SK2 oil) | <15% volume swell after 168h |

Field failures consistently trace to unverified material assumptions. A major automotive client experienced gasket blowouts due to silicone foam’s poor adhesion to anodized aluminum—a failure predictable via surface energy analysis omitted in their off-the-shelf procurement. True reliability demands formulation calibrated to your exact load profile, substrate, and environmental envelope. Thickness is merely the starting dimension; the polymer matrix defines functional lifespan. Consult our engineering team with your operational parameters to prevent costly field remediation. Submit load-deflection curves and chemical exposure data for immediate material simulation analysis.

Material Specifications

Material Specifications for 4 Inch Thick Foam Strips

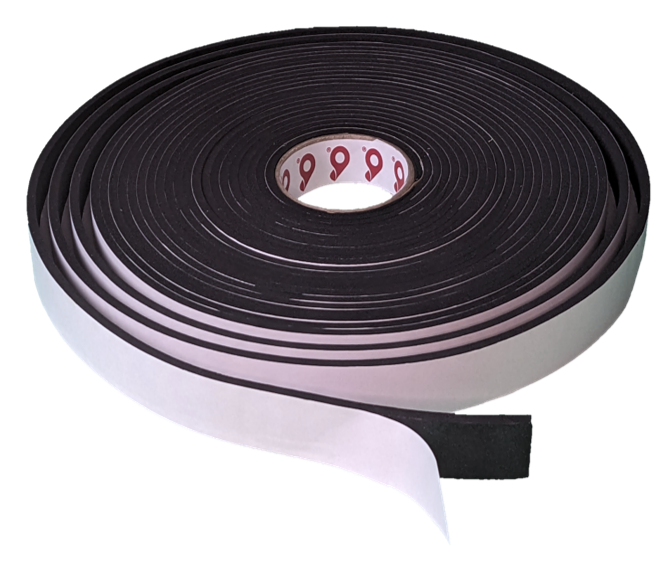

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored to demanding sealing, gasketing, and insulation applications. Our 4 inch thick foam strips are engineered for superior compressibility, resilience, and environmental resistance. These foam strips are available in three primary elastomeric materials: Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each offering distinct performance characteristics suitable for specific operational environments.

Viton foam strips deliver exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service temperatures up to 200°C and excellent ozone and UV stability, Viton is ideal for aerospace, automotive, and chemical processing industries where long-term reliability under extreme conditions is critical. The material maintains structural integrity and sealing performance even after prolonged exposure to harsh media, making it the premium choice for mission-critical applications.

Nitrile foam strips offer a balanced combination of oil resistance, mechanical strength, and cost efficiency. Designed primarily for use in hydraulic systems, machinery seals, and industrial equipment, NBR foam performs reliably in environments exposed to petroleum-based fluids, greases, and water. Its service temperature range extends from -30°C to 100°C, making it suitable for standard industrial operating conditions. Nitrile foam also exhibits good compression set resistance and abrasion performance, ensuring durable sealing over extended cycles.

Silicone foam strips are optimized for extreme temperature flexibility, with a functional range from -60°C to 230°C. This material excels in applications requiring thermal insulation, weather resistance, and biocompatibility. Silicone foam is commonly used in electronics, medical devices, food processing, and architectural sealing due to its low toxicity, excellent aging properties, and resistance to moisture and UV radiation. While it has lower tensile strength compared to Viton and Nitrile, its thermal stability and clean performance make it indispensable in sensitive environments.

The following table summarizes key physical and chemical properties of the three foam materials used in our 4 inch thick foam strips:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Density (g/cm³) | 0.75–0.85 | 0.65–0.75 | 0.45–0.60 |

| Hardness (Shore A) | 40–60 | 50–70 | 30–50 |

| Tensile Strength (MPa) | 6–10 | 8–12 | 4–7 |

| Elongation at Break (%) | 150–250 | 200–300 | 150–200 |

| Compression Set (22 hrs, 150°C) | ≤30% | ≤25% | ≤20% |

| Continuous Service Temperature | -20°C to 200°C | -30°C to 100°C | -60°C to 230°C |

| Resistance to Oils/Fuels | Excellent | Very Good | Poor |

| Resistance to UV/Ozone | Excellent | Good | Excellent |

| Water Resistance | Excellent | Good | Excellent |

Each material is available in custom densities, hardness grades, and cell structures to meet specific application requirements. All foam strips are manufactured under strict quality control protocols to ensure dimensional accuracy and consistent performance.

Manufacturing Capabilities

Engineering Capability: Precision Manufacturing of 4 Inch Thick Foam Strips

Suzhou Baoshida Trading Co., Ltd. delivers exceptional engineering rigor specifically for demanding industrial foam strip applications, particularly 4 inch thick profiles requiring stringent dimensional stability and performance. Our core strength resides in the integrated expertise of a dedicated technical team: five specialized Mould Engineers and two advanced Rubber Formula Engineers. This dual-discipline structure ensures comprehensive control from molecular composition to final extruded or molded product, directly addressing the unique challenges of thick-section foam manufacturing where consistency is paramount.

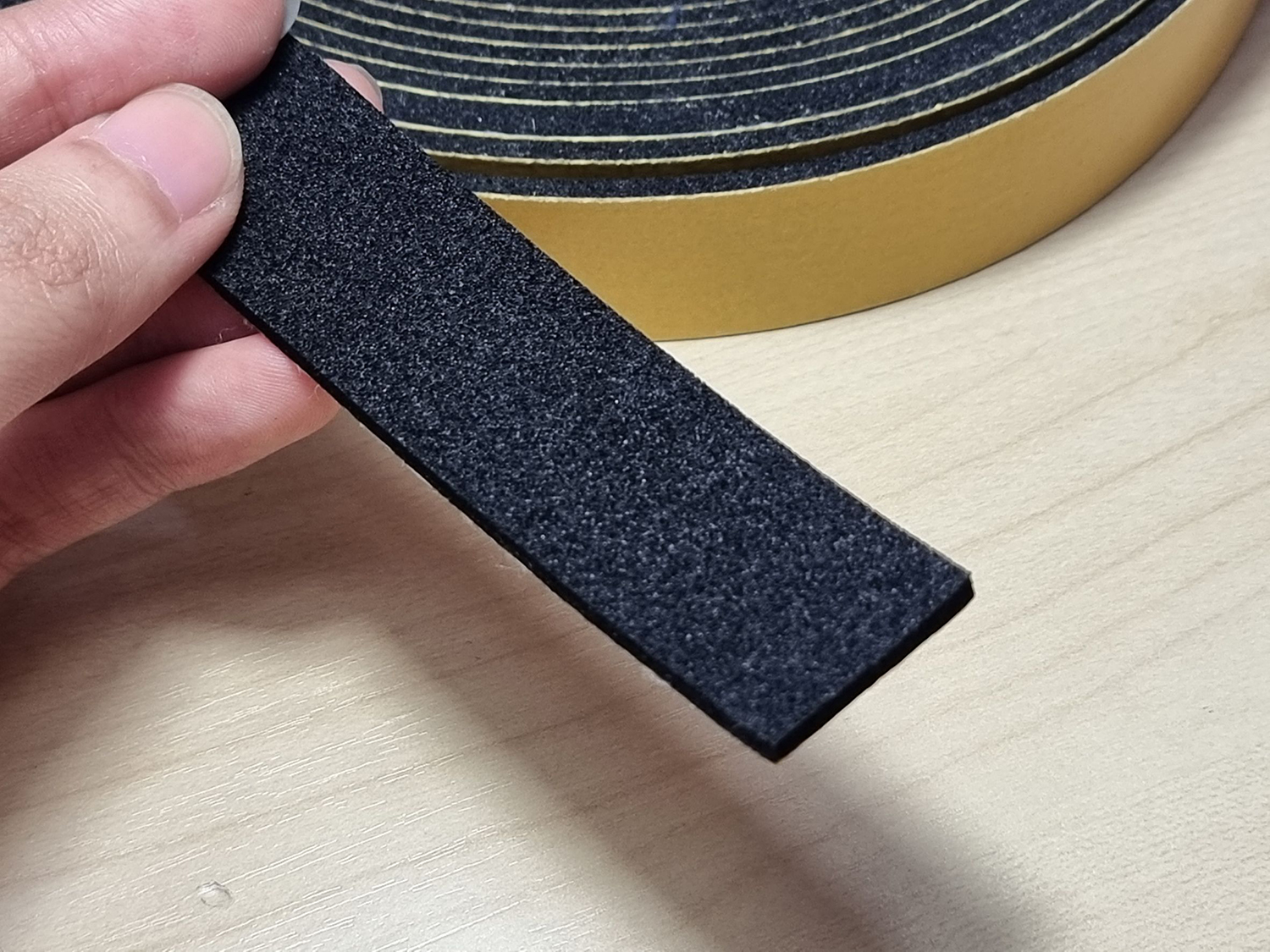

Our Rubber Formula Engineers possess deep expertise in polymer science and compounding. They meticulously develop and optimize proprietary closed-cell foam formulations, primarily based on nitrile (NBR), EPDM, or silicone elastomers, tailored to exact client specifications for compression set, density, temperature resistance, and chemical exposure. For 4 inch thick sections, achieving uniform cell structure and eliminating core defects like shrinkage or voids demands precise control over blowing agents, crosslink density, and cure kinetics – a challenge our formula team masters through iterative laboratory testing and advanced rheological analysis. Material performance is validated against international standards including ASTM D1056 and ISO 1856 before scale-up.

Complementing this, our five Mould Engineers translate these complex formulations into reliable production. They design and validate specialized tooling for continuous extrusion or compression molding of thick profiles, focusing on precise temperature zoning, pressure distribution, and dwell time control critical for consistent density and dimensional accuracy across the entire 4 inch cross-section. Their expertise minimizes common thick-foam issues such as surface roughness, uneven expansion, or excessive trimming waste. This close collaboration between formula and mold engineering ensures the material’s inherent properties are fully realized in the final product geometry.

We operate as a true OEM partner, not merely a supplier. Our engineering team engages early in the client’s design phase, providing DFM (Design for Manufacturability) feedback specific to thick foam strip production. We support custom durometer ranges, specialized surface finishes (e.g., split, skived, or textured), and integration of functional elements like adhesive backing or fabric reinforcement within the 4 inch profile. Full material traceability, batch-specific certification, and rigorous in-process quality control are standard, ensuring every meter meets the agreed performance envelope.

The following table outlines the critical engineering specifications achievable for our standard 4 inch thick industrial foam strips:

| Specification Parameter | Typical Range/Value | Test Standard | Relevance for 4 Inch Thickness |

|---|---|---|---|

| Thickness | 4.00 ± 0.08 inches | ASTM D3574 | Critical dimensional tolerance for sealing integrity |

| Density | 8 – 25 lb/ft³ | ASTM D3574 | Impacts compression load, insulation value, weight |

| Compression Deflection | Customizable | ASTM D575 | Defines force required for sealing at target % compression |

| Compression Set (22h, 70°C) | ≤ 20% | ASTM D395 | Essential for long-term sealing force retention |

| Temperature Range | -40°C to +150°C (NBR) | ASTM D2240 | Material-specific performance envelope |

| Closed Cell Content | ≥ 90% | ASTM D2856 | Prevents fluid absorption, maintains buoyancy |

This integrated engineering capability, combining deep material science with precision tooling design and robust OEM processes, guarantees that Suzhou Baoshida’s 4 inch thick foam strips deliver the reliability and performance demanded by industrial sealing, insulation, and cushioning applications worldwide. We solve the inherent complexities of thick-section foam production to ensure your application succeeds.

Customization Process

Technical Customization Process for 4 Inch Thick Foam Strips

At Suzhou Baoshida Trading Co., Ltd., the customization of 4 inch thick foam strips follows a rigorous, science-driven methodology to ensure optimal performance in industrial applications. Our process begins with Drawing Analysis, where engineering teams evaluate customer-provided technical drawings or CAD models. This step includes verifying dimensional tolerances, cross-sectional profiles, and critical sealing or cushioning zones. We assess edge geometry, compression set requirements, and environmental exposure data such as UV, ozone, temperature extremes, and chemical contact. Accurate interpretation at this stage ensures alignment with OEM specifications and prevents downstream manufacturing deviations.

Following drawing validation, the Formulation phase initiates material development. Our rubber formula engineers select base polymers—commonly EPDM, NBR, silicone, or neoprene—based on the operational environment. For 4 inch thick foam strips, cell structure uniformity and compression recovery are paramount. We adjust blowing agents, crosslink density, and filler ratios to achieve target density (typically 0.3–0.6 g/cm³) while maintaining mechanical integrity. Additives such as flame retardants, anti-aging agents, and pigments are incorporated as required. The formulation is optimized using rheometry, TGA, and DSC analysis to confirm cure kinetics and thermal stability.

Prototyping is executed using continuous foam extrusion or batch autoclave foaming, depending on cross-section complexity and order volume. Physical samples are subjected to strict QC testing, including compression deflection (ASTM D575), tensile strength (ASTM D412), and accelerated aging (ASTM G154). Dimensional accuracy is verified using laser profilometry and coordinate measuring machines (CMM). Customer feedback is integrated at this stage, allowing for iterative refinement before release to mass production.

Mass Production leverages automated extrusion lines with in-line density monitoring and closed-loop temperature control. Each batch undergoes real-time quality checks, and final products are packaged per client logistics requirements—cut-to-length, coiled, or spooled. Full traceability is maintained via batch coding and material certificates (e.g., RoHS, REACH, UL).

The following table outlines typical technical specifications for custom 4 inch thick foam strips:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Thickness | 4 inch ± 0.125 inch | ASTM D3574 |

| Density | 0.3 – 0.6 g/cm³ | ASTM D3574 |

| Hardness (Shore A) | 15 – 40 | ASTM D2240 |

| Tensile Strength | ≥ 1.5 MPa | ASTM D412 |

| Elongation at Break | ≥ 150% | ASTM D412 |

| Compression Set (25%, 24h) | ≤ 20% | ASTM D3574 |

| Operating Temperature | -40°C to +150°C (varies by polymer) | UL 1581 |

| Cell Structure | Closed-cell or Open-cell (select) | Microscopy Analysis |

All parameters are adjustable per OEM requirements, with documentation provided for validation and compliance.

Contact Engineering Team

Precision Engineering for Industrial Foam Strip Applications

Suzhou Baoshida Trading Co., Ltd. delivers mission-critical rubber solutions engineered for demanding industrial environments. Our 4 inch thick foam strips exemplify rigorous material science, combining closed-cell structure integrity with consistent dimensional stability under thermal cycling and compression loads. These components are not generic commodities but precision-engineered elements designed for seamless integration into OEM production lines, sealing systems, and vibration-damping assemblies where failure is non-negotiable. We prioritize repeatability in cellular structure and force-deflection characteristics to ensure your end-product performance remains uncompromised across batch variations.

Material specifications define functional reliability in high-stakes applications. Below are the validated technical parameters for our standard 4 inch thick industrial foam strips, produced under ISO 9001-certified processes with full traceability.

| Parameter | Specification | Test Method |

|---|---|---|

| Thickness | 101.6 ± 1.5 mm | ASTM D3574 |

| Density | 95 ± 5 kg/m³ | ISO 845 |

| Compression Deflection | 95 ± 10 kPa @ 25% | ASTM D575 |

| Compression Set (22h/70°C) | ≤ 15% | ASTM D3574 Method B |

| Temperature Range | -40°C to +120°C | ISO 188 |

| Flame Resistance | UL 94 HF-1 | UL 94 |

These values represent baseline performance for our standard EPDM and silicone formulations. Customization is executed at the molecular level—adjusting polymer backbone chemistry, crosslink density, and additive packages—to meet unique operational demands such as chemical exposure resistance, low-temperature flexibility down to -65°C, or enhanced UV stability. Our engineering team collaborates directly with your R&D department to validate material behavior against your specific load profiles and environmental stressors, eliminating costly prototyping iterations.

Initiate technical consultation with Mr. Boyce, our dedicated OEM Relationship Manager, to resolve complex sealing or cushioning challenges. With 14 years of specialized experience in rubber compounding for automotive, aerospace, and industrial machinery sectors, Mr. Boyce translates your functional requirements into optimized material solutions. He oversees end-to-end project execution from formula development through to JIT delivery, ensuring alignment with your production schedules and quality gate protocols. His expertise in regulatory compliance—including FDA, REACH, and RoHS—guarantees seamless integration into global supply chains without certification delays.

Do not settle for off-the-shelf foam products with inconsistent cellular morphology. Suzhou Baoshida provides engineered certainty through data-driven formulation and process control. Contact Mr. Boyce immediately to discuss your 4 inch thick foam strip requirements. Forward your application details, performance targets, and volume projections to [email protected] for a technical feasibility assessment within 24 business hours. Specify your target compression load, environmental exposure conditions, and dimensional tolerances to receive a tailored proposal with accelerated sampling options. Partner with our team to transform material specifications into operational reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).