Technical Contents

Engineering Guide: 625 Inconel Sheet

Engineering Insight: 625 Inconel Sheet in Demanding Industrial Environments

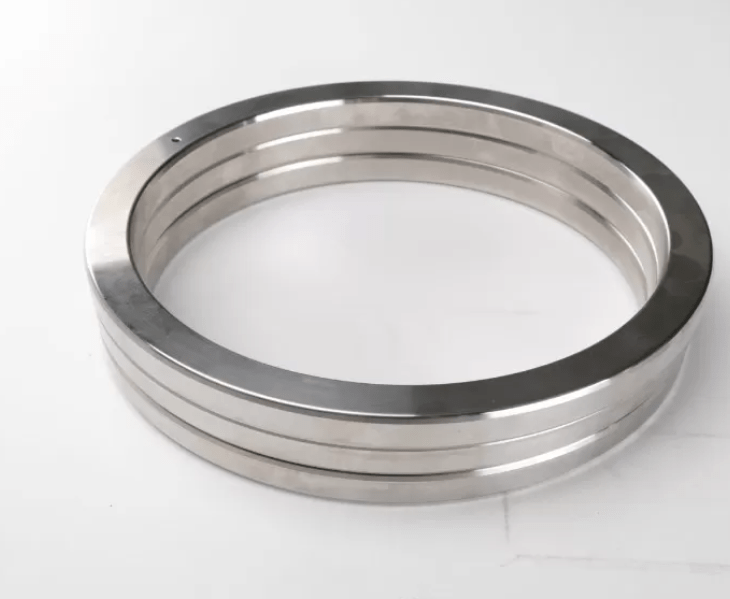

Material selection is a foundational element in the design and performance of industrial components exposed to extreme thermal, chemical, and mechanical stress. Among high-performance alloys, Inconel 625 stands out for its exceptional resistance to oxidation, corrosion, and creep deformation at elevated temperatures. While Suzhou Baoshida Trading Co., Ltd. specializes in industrial rubber solutions, we recognize that system integrity often depends on the compatibility and performance of metallic substrates such as 625 Inconel sheet. In complex sealing, gasketing, and fluid handling systems, the interaction between elastomeric components and high-alloy materials like Inconel 625 can determine the operational lifespan and reliability of the entire assembly.

Standard off-the-shelf materials frequently fail in aggressive industrial applications due to inadequate resistance to thermal cycling, chloride-induced stress corrosion cracking, or exposure to acidic or alkaline media. Conventional stainless steels or lower-grade nickel alloys may initially appear cost-effective but degrade rapidly under sustained high-temperature conditions or in environments containing sulfur compounds, halogens, or high-pressure steam. In contrast, Inconel 625 maintains structural integrity in service temperatures up to 1800°F (980°C) and exhibits outstanding resistance to pitting and crevice corrosion in chloride-rich environments—conditions commonly found in petrochemical processing, offshore platforms, and aerospace systems.

The inherent stability of Inconel 625 stems from its nickel-chromium-molybdenum-niobium composition, which forms a robust, self-healing oxide layer that protects against environmental degradation. This characteristic is particularly critical when integrating rubber seals or linings, where micro-leakage or interfacial breakdown can initiate catastrophic failure. Off-the-shelf components often neglect the need for metallurgical compatibility, leading to galvanic corrosion, thermal mismatch, or premature joint fatigue. Precision-engineered Inconel 625 sheets ensure dimensional stability and surface consistency, enabling reliable bonding with fluoropolymers or high-temperature elastomers such as FFKM or PTFE-based systems.

For OEMs and industrial system designers, the decision to specify Inconel 625 is not merely about material cost but total cost of ownership. Reduced maintenance cycles, extended service life, and enhanced safety margins justify the initial investment, particularly in mission-critical applications.

| Property | Value |

|---|---|

| Alloy Designation | Inconel 625 (UNS N06625) |

| Nickel Content | ≥58% |

| Chromium Content | 20.0–23.0% |

| Molybdenum Content | 8.0–10.0% |

| Niobium + Tantalum | 3.15–4.15% |

| Tensile Strength (Annealed) | ≥930 MPa |

| Yield Strength (0.2% Offset) | ≥415 MPa |

| Elongation | ≥30% |

| Density | 8.44 g/cm³ |

| Melting Range | 1290–1350°C |

| Maximum Service Temperature | ~980°C (1800°F) |

At Suzhou Baoshida Trading Co., Ltd., we advocate for holistic material integration, ensuring that both metallic and polymeric components are engineered to perform synergistically under real-world operating conditions.

Material Specifications

Material Specifications for Industrial Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber compounds tailored for extreme industrial environments. While Inconel 625 sheet metal serves critical roles in high-temperature structural applications, our core expertise lies in elastomeric sealing and insulation solutions. This section details key rubber materials—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—optimized for compatibility with systems where Inconel 625 components may operate, such as chemical processing, aerospace, and energy infrastructure. Each compound undergoes rigorous ASTM D2000 classification and OEM validation to ensure dimensional stability, chemical inertness, and longevity under operational stress.

Viton fluorocarbon rubber delivers exceptional resistance to aggressive media, including fuels, oils, and acids at temperatures ranging from -20°C to +230°C. Its low gas permeability and stability in ozone-rich environments make it ideal for dynamic seals in turbine engines and chemical reactors. Nitrile rubber excels in petroleum-based fluid applications, with a functional range of -40°C to +120°C. Its high abrasion resistance and cost efficiency suit hydraulic systems and automotive fuel handling. Silicone rubber offers unparalleled thermal flexibility (-60°C to +200°C) and biocompatibility, critical for pharmaceutical processing and high-purity semiconductor manufacturing. All materials are compounded to meet ISO 3601 flange standards and FDA 21 CFR 177.2600 for indirect food contact where applicable.

The comparative analysis below outlines critical performance parameters for informed material selection. Data reflects standard grades; custom formulations for enhanced tensile strength, low-temperature flexibility, or plasma resistance are available per OEM specifications.

| Material | Temperature Range (°C) | Key Chemical Resistance | Compression Set (ASTM D395, 22h/150°C) | Primary Industrial Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Aromatic hydrocarbons, acids, jet fuels | ≤25% | Aerospace seals, chemical valve stems, sour gas environments |

| Nitrile (NBR) | -40 to +120 | Aliphatic hydrocarbons, hydraulic fluids | ≤30% | Automotive O-rings, fuel injectors, industrial hydraulics |

| Silicone (VMQ) | -60 to +200 | Water, steam, alcohols, oxidizing agents | ≤20% | Medical device gaskets, semiconductor wafer handling, food processing seals |

Material selection must account for simultaneous exposure to thermal cycling, pressure differentials, and media concentration. For instance, Viton maintains integrity in 98% sulfuric acid at 150°C where NBR degrades rapidly, while Silicone outperforms both in repeated steam sterilization cycles. Baoshida’s engineering team conducts application-specific validation using ISO 1817 immersion testing and dynamic seal simulation to prevent premature failure. All compounds are manufactured under IATF 16949 protocols with traceable lot documentation, ensuring compliance with global OEM quality mandates. Partner with our technical team to optimize material performance against your operational parameters.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, integrating advanced material science with precision engineering to deliver high-performance components tailored to demanding environments. While our core expertise lies in rubber formulation and elastomer system integration, we bring exceptional value to cross-material applications, including those involving high-temperature alloys such as INCONEL® 625 sheet. Our engineering team collaborates closely with OEM partners to develop hybrid sealing, gasketing, and protective systems where rubber-to-metal interfaces must perform under extreme thermal, chemical, and mechanical stress.

Our engineering capability is anchored by a dedicated team of five mould engineers and two specialized rubber formula engineers. This technical staff is responsible for end-to-end development—from concept and material selection to tooling design, prototyping, and validation. When integrating INCONEL 625 sheet into composite assemblies, our engineers assess interfacial compatibility, thermal expansion differentials, and long-term durability under operational loads. We focus on optimizing bonding techniques between elastomers and high-nickel alloys, ensuring reliable adhesion through proprietary surface treatments and adhesive primers engineered in-house.

As an OEM solutions provider, Suzhou Baoshida supports custom manufacturing across low-, medium-, and high-volume production runs. We maintain strict process control through ISO-compliant workflows and employ advanced simulation tools to predict performance in service conditions. Our formula engineers develop elastomer compounds—such as FKM, FFKM, ACM, and high-temperature silicone—that are specifically designed to complement the corrosion resistance and thermal stability of INCONEL 625. These compounds are tested in conjunction with metal substrates to validate performance in environments involving high-pressure steam, aggressive chemicals, or sustained elevated temperatures.

We provide full documentation, including material traceability, process validation reports, and compliance with international standards (ASTM, ISO, DIN). Our OEM clients benefit from rapid turnaround on prototypes, design for manufacturability (DFM) feedback, and scalable production capacity backed by strategic raw material sourcing and in-house tooling fabrication.

The following table outlines key technical parameters relevant to INCONEL 625 sheet and its integration with elastomeric components in industrial applications.

| Property | INCONEL 625 Sheet | Typical Elastomer Interface (FKM/FFKM) | Notes |

|---|---|---|---|

| Melting Range | 1290–1350 °C | Decomposition >400 °C (FKM) | Thermal mismatch managed via design |

| Tensile Strength | ≥930 MPa | 12–20 MPa | Structural support provided by metal |

| Corrosion Resistance | Excellent (oxidizing & reducing media) | High (FKM/FFKM) | Synergistic performance in chemical seals |

| Coefficient of Thermal Expansion | ~13 µm/m·°C | 170–200 µm/m·°C | Requires compliant bonding or gasket design |

| Maximum Continuous Use Temp | 980 °C | 250–327 °C (depending on grade) | Elastomer limits system interface temperature |

| Common Applications | Aerospace, marine, chemical processing | Seals, gaskets, flange pads | Used in hybrid component assemblies |

Through precise material pairing and engineering rigor, Suzhou Baoshida enables robust, mission-critical solutions where INCONEL 625 sheet interfaces with advanced rubber systems. Our OEM partnerships are built on technical transparency, innovation, and repeatable quality.

Customization Process

Customization Process for Rubber Components with 625 Inconel Sheet Interfaces

Suzhou Baoshida Trading Co., Ltd. specializes in engineered rubber solutions designed to interface precisely with high-performance substrates like 625 Inconel sheet. Our customization process ensures optimal sealing, vibration damping, and chemical resistance in extreme environments where Inconel 625 is specified. This begins with rigorous drawing analysis to decode critical interface parameters. We scrutinize dimensional tolerances, surface finish requirements (Ra ≤ 0.8 μm for Inconel bonding), thermal expansion coefficients, and fluid exposure profiles. Misalignment in these factors risks premature seal failure due to Inconel’s high stiffness and thermal stability. Our engineers cross-verify client CAD models against ASME B16.20 and NORSOK M-710 standards to preempt assembly conflicts.

Formulation follows, targeting compatibility with Inconel 625’s operational envelope. Standard rubber compounds fail under conditions where Inconel excels (e.g., 980°C continuous service). We develop perfluoroelastomer (FFKM) or high-purity FKM blends with tailored filler systems to withstand oxidizing acids, chlorides, and thermal cycling inherent in Inconel applications. Key adjustments include optimizing crosslink density to counter Inconel’s CTE of 13 μm/m·°C and incorporating adhesion promoters for direct bonding to passivated Inconel surfaces. All formulations undergo ASTM D2000 classification validation against client-specified temperature, fluid, and compression set limits.

Prototyping validates real-world performance. We fabricate 3–5 sample sets using precision molding, then subject them to simulated service conditions: thermal shock cycling from -196°C to 315°C, H₂S/CO₂ exposure per NACE MR0175, and dynamic compression testing per ASTM F36. Critical metrics include interfacial adhesion strength (minimum 12 kN/m per ISO 813) and compression set after 72 hours at 288°C. Client feedback on prototype fitment and leakage rates triggers iterative refinements before tooling sign-off.

Mass production leverages statistical process control (SPC) with ±0.05 mm dimensional accuracy. Each batch undergoes 100% visual inspection per ISO 3601 and random FTIR verification of compound integrity. Traceability links every rubber component to certified Inconel sheet mill test reports (ASTM B446), ensuring full compliance with aerospace, chemical processing, or energy sector mandates.

Rubber Compound Specifications for 625 Inconel Interfaces

| Property | FFKM Standard Grade | FKM High-Temp Grade | Test Standard | Inconel 625 Requirement Match |

|---|---|---|---|---|

| Continuous Temp Range | -15°C to 327°C | -20°C to 288°C | ASTM D573 | Matches 980°C metal limit |

| Compression Set (288°C) | ≤ 25% | ≤ 35% | ASTM D395 | Critical for thermal cycling |

| H₂SO₄ Resistance (75%) | Excellent | Good | ASTM D471 | Resists acid exposure |

| Adhesion to Inconel | 18 kN/m | 10 kN/m | ISO 813 | Exceeds 12 kN/m minimum |

| CTE Compatibility | 145–165 ppm/°C | 170–190 ppm/°C | ASTM E831 | Aligns with 13 ppm/°C metal |

This systematic approach guarantees rubber components that maximize the longevity and safety of 625 Inconel sheet assemblies, reducing lifecycle costs for OEM partners in demanding industrial sectors.

Contact Engineering Team

For industrial manufacturers seeking high-performance materials capable of withstanding extreme environments, 625 Inconel sheet remains a critical solution in aerospace, chemical processing, marine engineering, and high-temperature industrial systems. At Suzhou Baoshida Trading Co., Ltd., we specialize in the supply of premium-grade 625 Inconel sheets, precision-finished and rigorously tested to meet international ASTM, AMS, and ISO standards. Our expertise extends beyond metal supply—we integrate advanced industrial rubber solutions to support sealing, gasketing, and thermal insulation applications where Inconel interfaces with elastomeric systems. This synergy between high-temperature alloys and engineered rubber compounds ensures long-term reliability in demanding operational conditions.

Our 625 Inconel sheets are manufactured using high-purity nickel-chromium-molybdenum-niobium alloy, offering exceptional resistance to oxidizing and reducing environments, pitting, crevice corrosion, and stress-corrosion cracking. Whether you require cold-rolled sheets for structural integrity or hot-rolled variants for high-formability applications, we maintain a comprehensive inventory with precise dimensional control and full material traceability. Each batch undergoes spectrographic analysis and mechanical testing to guarantee consistent performance under thermal cycling up to 1800°F (980°C) and exposure to aggressive media such as chloride ions and acidic compounds.

Below are key technical specifications for our standard 625 Inconel sheet offerings:

| Property | Specification |

|---|---|

| Material Standard | ASTM B637, AMS 5597, ISO 15156 |

| Composition (Nominal) | Ni: 58%, Cr: 20-23%, Mo: 8-10%, Nb+Ta: 3.15-4.15% |

| Tensile Strength (min) | 1035 MPa |

| Yield Strength (0.2% offset, min) | 415 MPa |

| Elongation (min) | 30% in 50mm |

| Density | 8.44 g/cm³ |

| Melting Range | 1290–1350°C |

| Available Thickness | 0.5 mm to 25 mm |

| Surface Finish | Hot-rolled, Annealed, Pickled or Passivated |

| Tolerances | ASTM A480 or customer-specific |

Suzhou Baoshida Trading Co., Ltd. operates at the intersection of advanced materials science and industrial application engineering. Our technical team collaborates with OEMs and MRO providers to develop integrated solutions, including rubber-to-metal bonded components that utilize 625 Inconel substrates for durability in dynamic sealing environments. We provide custom cutting, forming, and surface treatment services, ensuring rapid turnaround for project-critical deliveries.

For immediate assistance with 625 Inconel sheet procurement or technical consultation on material compatibility with elastomeric systems, contact Mr. Boyce at Suzhou Baoshida Trading Co., Ltd. Direct inquiries to [email protected]. Mr. Boyce brings over 15 years of experience in industrial material sourcing and is available to support specification reviews, sample requests, and volume supply agreements tailored to your production schedule. Partner with a supplier who understands the precision demands of high-integrity industrial systems. Reach out today to ensure your next project meets the highest standards in performance and reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).