Technical Contents

Engineering Guide: Flapper Door

Engineering Insight: Material Selection in Flapper Door Performance

In industrial applications, the flapper door functions as a critical flow control mechanism, commonly deployed in wastewater systems, pneumatic conveyors, and chemical processing units. While often perceived as a simple mechanical component, the performance and longevity of a flapper door are profoundly influenced by material selection. Off-the-shelf rubber components frequently fail in demanding environments due to a lack of customization in polymer formulation and reinforcement architecture. These generic solutions are typically engineered for nominal operating conditions and do not account for variables such as chemical exposure, temperature cycling, abrasion, or dynamic stress fatigue.

The core failure mechanisms in standard flapper doors include swelling due to fluid incompatibility, cracking from ozone or UV exposure, and mechanical degradation from repeated impact and flexing. For instance, natural rubber (NR) may offer excellent resilience and low compression set under ambient conditions but rapidly deteriorates when exposed to oils, ozone, or elevated temperatures. Similarly, ethylene propylene diene monomer (EPDM) exhibits strong resistance to steam and polar fluids but performs poorly in contact with hydrocarbons. Using such materials without chemical compatibility analysis leads to premature seal failure, leakage, and unplanned downtime.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific elastomer engineering. Our approach begins with a comprehensive assessment of the operational environment—fluid type, concentration, temperature range, pressure cycles, and mechanical loading. Based on this data, we select or compound rubber materials that balance mechanical integrity with environmental resistance. For example, fluorocarbon rubber (FKM) is preferred in high-temperature, oil-rich environments, while nitrile butadiene rubber (NBR) with high acrylonitrile content offers optimal resistance to aliphatic hydrocarbons. For severe abrasion conditions, we integrate reinforced composites with textile or aramid cord plies to enhance tensile strength and tear resistance.

Custom compounding also allows for the optimization of cure systems, filler types, and plasticizers to improve performance metrics such as compression set, rebound resilience, and low-temperature flexibility. This level of precision ensures that the flapper door maintains a reliable seal over thousands of cycles, even under fluctuating loads and harsh media.

The table below outlines common elastomers used in flapper door applications, highlighting their key performance characteristics.

| Material | Temperature Range (°C) | Key Chemical Resistances | Key Limitations | Typical Use Case |

|---|---|---|---|---|

| NBR | -30 to +100 | Oils, fuels, aliphatic hydrocarbons | Poor ozone & weather resistance | Pneumatic systems, fuel handling |

| EPDM | -50 to +150 | Steam, water, acids, alkalis | Swells in oils and hydrocarbons | Water treatment, HVAC |

| FKM | -20 to +200 | Aromatic hydrocarbons, acids, oils | Poor low-temperature flexibility | Chemical processing, high-temp seals |

| NR | -50 to +70 | Abrasion, tearing, resilience | Poor oil & ozone resistance | Low-stress mechanical seals |

| CR | -30 to +100 | Ozone, weather, flame resistance | Moderate oil resistance | Outdoor industrial equipment |

Material selection is not a secondary consideration—it is the foundation of flapper door reliability. Standardized rubber components may offer short-term cost savings, but they compromise system integrity and increase lifecycle costs. At Baoshida, we deliver engineered rubber solutions that align precisely with operational demands, ensuring durability, compliance, and performance in the most challenging industrial environments.

Material Specifications

Material Specifications for Flapper Door Sealing Components

Flapper doors in industrial fluid control systems demand elastomeric materials capable of enduring cyclic flexing, chemical exposure, and thermal extremes while maintaining dimensional stability. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science rigor to ensure zero leakage and extended service life. Our formulations for Viton, Nitrile, and Silicone are engineered to ASTM D2000 standards, with compounding tailored to specific operational stressors. Viton (FKM) excels in high-temperature hydrocarbon environments due to its fluorocarbon backbone, resisting swelling in sour gas (H₂S), crude oil, and aggressive solvents up to 250°C. Its low compression set (≤20% at 200°C/70h) prevents seal relaxation under constant load, critical for flapper doors in oilfield choke manifolds. Nitrile (NBR) offers optimal cost-performance balance for hydraulic and fuel systems, with acrylonitrile content (34–50%) tuned to maximize resistance to aliphatic hydrocarbons and lubricants. Standard grades withstand -30°C to 125°C, though hydrogenated NBR (HNBR) extends this to 150°C with superior abrasion resistance for high-cycle applications. Silicone (VMQ) provides unmatched thermal stability from -60°C to 230°C and exceptional flexibility at cryogenic temperatures, ideal for pharmaceutical or food-grade flapper doors exposed to steam sterilization. However, its lower tensile strength necessitates reinforcement for high-pressure differentials, and it exhibits poor resistance to concentrated acids and hydrocarbons.

Material selection must align with fluid compatibility, temperature profiles, and mechanical stress. Viton is non-negotiable for H₂S-rich environments per NACE MR0175, while Nitrile dominates cost-sensitive automotive and industrial hydraulics. Silicone remains the sole viable option for repeated autoclave cycles but requires careful design to mitigate extrusion under pressure. All compounds undergo Baoshida’s accelerated aging protocols, including 1,000-hour compression set testing at maximum operating temperature and dynamic fatigue validation to 500,000 cycles.

Comparative Material Properties for Flapper Door Applications

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +125 | -60 to +230 |

| Tensile Strength (MPa) | 12–18 | 15–25 | 6–10 |

| Compression Set (70h/70°C) | ≤15% | ≤25% | ≤20% |

| Key Chemical Resistance | Aromatics, H₂S, acids | Aliphatic fuels, oils | Steam, ozone, water |

| Key Limitations | Poor brake fluids, ketones | Limited ozone/weathering | Low tear strength, hydrocarbons |

| Typical ASTM Grade | FK 7075 | NBR 7070 | VMQ 6065 |

Baoshida’s OEM partnership includes material validation against your exact fluid media via immersion testing per ISO 1817. We recommend Viton for upstream oil/gas flapper doors, NBR for general industrial fluid power, and Silicone for biopharmaceutical flow control—always coupled with finite element analysis of stress distribution. Contact our engineering team to co-develop a compound specification sheet for your application’s critical parameters.

Manufacturing Capabilities

Engineering Excellence in Flapper Door Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of high-performance flapper doors. With a dedicated team of five certified mould engineers and two specialized rubber formula engineers, we integrate material science with precision engineering to deliver OEM-grade components tailored to demanding operational environments.

Our mould engineers bring over 60 combined years of experience in designing complex rubber-to-metal bonded systems. They utilize advanced CAD/CAM software—SolidWorks, AutoCAD, and Moldflow—to simulate flow dynamics, optimize part geometry, and ensure consistent cycle times. This enables us to produce flapper door moulds with tight tolerances (±0.1 mm) and superior surface finish, critical for sealing performance and longevity. Each design undergoes rigorous finite element analysis (FEA) to predict stress distribution and fatigue life under dynamic loading conditions typical in wastewater, chemical processing, and HVAC applications.

Complementing this mechanical expertise is our in-house rubber formulation team. Our two formula engineers specialize in developing custom elastomer compounds that meet specific resistance requirements—be it to ozone, hydrocarbons, or extreme temperatures. Using a systematic approach based on ASTM D2000 standards, they formulate materials from EPDM, NBR, Viton, and neoprene, adjusting cure systems, filler content, and plasticizers to achieve target hardness (40–90 Shore A), compression set (<20% at 70°C for 70 hrs), and tensile strength (>10 MPa). This control over raw material properties ensures that every flapper door performs reliably under real-world service conditions.

Our OEM capabilities are built on this dual expertise. We support clients from concept to mass production, offering full technical collaboration including 3D modelling, prototype validation, and DFM (Design for Manufacturability) feedback. Whether adapting an existing design or developing a new flapper door for a proprietary system, we maintain strict confidentiality and compliance with ISO 9001:2015 protocols. Tooling is manufactured in-house or through trusted partners with EDM and CNC machining precision, ensuring repeatability across batches.

All flapper doors are tested for dimensional accuracy, adhesion strength (peel test >5 kN/m), and functional performance in simulated flow chambers before shipment. We also provide full material traceability and test reports upon request.

Key Technical Specifications of Standard Flapper Door Components

| Parameter | Specification |

|---|---|

| Material Options | EPDM, NBR, Viton, Neoprene, SBR |

| Hardness Range | 40–90 Shore A |

| Temperature Resistance | -40°C to +200°C (depending on compound) |

| Tolerance | ±0.1 mm (critical dimensions) |

| Adhesion Strength | >5 kN/m (rubber-to-metal bond) |

| Compression Set (70 hrs, 70°C) | <20% |

| Standard Compliance | ASTM D2000, ISO 3302, ISO 2768 |

With vertically integrated engineering and material development, Suzhou Baoshida delivers flapper door solutions that combine durability, precision, and performance—engineered for industry, built for the long term.

Customization Process

Customization Process for Flapper Door Components

At Suzhou Baoshida Trading Co., Ltd., our flapper door customization adheres to a rigorously defined engineering workflow, ensuring optimal performance in demanding industrial environments. This process eliminates guesswork through data-driven validation at every phase, directly translating client specifications into reliable rubber solutions.

Drawing Analysis

Engineering commences with comprehensive GD&T verification of client-supplied drawings, cross-referencing critical dimensions against ISO 17480 flapper door standards. Finite element analysis (FEA) simulates dynamic stress points under operational pressure differentials, identifying potential fatigue zones. We validate seal interface geometry against mating surfaces to prevent leakage paths, while assessing material thickness tolerances for compression set resilience. Non-conformities trigger collaborative engineering change proposals before progression.

Material Formulation

Based on fluid exposure, temperature extremes, and mechanical load profiles, our rubber compounding team selects base polymers and additives. For hydrocarbon-rich environments, hydrogenated nitrile butadiene rubber (HNBR) formulations with tailored filler systems achieve superior abrasion resistance. Steam or hot water applications utilize peroxide-cured EPDM compounds with controlled crosslink density. Each batch undergoes Mooney viscosity and cure kinetics testing to ensure processing consistency, targeting Shore A hardness within ±3 points of the specification.

Prototyping and Validation

Precision-molded prototypes undergo accelerated aging tests per ASTM D2000 standards, including 72-hour exposure to specified media at maximum operating temperature. Functional validation includes cyclic fatigue testing to 500,000 operations under simulated backpressure, with leakage rates measured via helium mass spectrometry. Compression set is quantified per ASTM D395 Method B after 22 hours at 100°C. Only prototypes meeting all dimensional and performance criteria advance to production.

Controlled Mass Production

Serial production implements statistical process control (SPC) with real-time monitoring of key parameters: cure time, mold temperature, and durometer. Every lot undergoes 100% visual inspection per ISO 3302-1 tolerances, with random samples subjected to tensile strength, elongation, and fluid resistance retesting. Traceability is maintained via laser-etched batch codes linked to raw material certificates and process logs, ensuring full compliance with ISO 9001:2015 requirements.

Critical Material Specifications

The following table outlines standard compound options for flapper doors, with formulations adjustable to meet project-specific demands.

| Material Grade | Hardness (Shore A) | Temp Range (°C) | Fluid Resistance | Compression Set (%) |

|---|---|---|---|---|

| NBR-70 | 68–72 | -30 to +120 | Oils, fuels | ≤25 @ 70°C/24h |

| EPDM-50 | 48–52 | -50 to +150 | Steam, glycols | ≤20 @ 150°C/70h |

| FKM-80 | 78–82 | -20 to +230 | Aggressive chemicals | ≤15 @ 200°C/70h |

This structured approach guarantees flapper doors that maintain sealing integrity across 10,000+ operational cycles, minimizing downtime in critical fluid control systems. Suzhou Baoshida Trading Co., Ltd. partners with OEMs to transform engineering requirements into validated rubber components through uncompromising scientific methodology.

Contact Engineering Team

For industrial manufacturers seeking precision-engineered rubber components, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of high-performance flapper door solutions. With extensive expertise in industrial rubber formulations and OEM manufacturing, we deliver components designed to meet the rigorous demands of fluid control, sealing, and directional flow applications across sectors including wastewater management, automotive systems, chemical processing, and marine engineering.

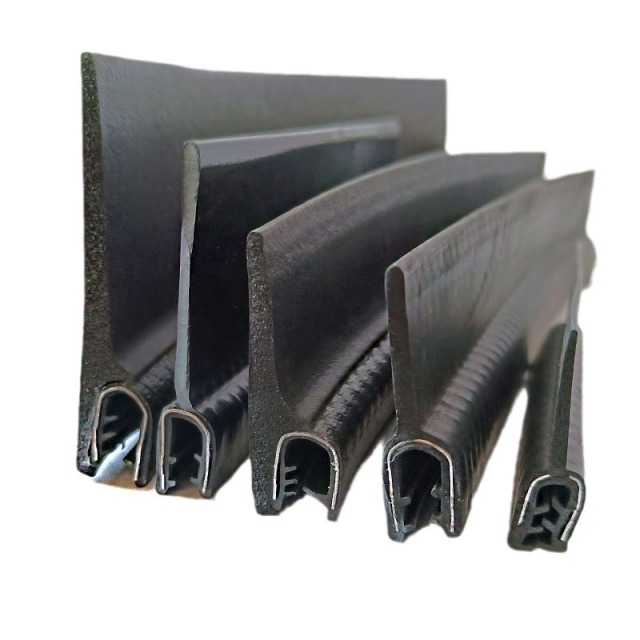

Our flapper doors are engineered for optimal durability, chemical resistance, and fatigue life under repeated cyclic loading. Utilizing advanced elastomer compounds such as EPDM, Nitrile (NBR), Neoprene, and FKM, we tailor material selection to the operational environment—ensuring long-term reliability in both high-temperature and corrosive conditions. Each flapper door is manufactured using precision molding techniques, guaranteeing dimensional accuracy, consistent wall thickness, and superior sealing performance.

Suzhou Baoshida maintains strict quality control protocols in alignment with ISO standards, conducting comprehensive testing for compression set, tensile strength, hardness, and fluid resistance. Our engineering team collaborates directly with clients to optimize design parameters, including hinge flexibility, seat sealing geometry, and backpressure tolerance. Whether you require a standard configuration or a fully customized solution, we support rapid prototyping, tooling development, and scalable production runs to meet your volume and delivery requirements.

Below are representative technical specifications for our standard flapper door series. Custom dimensions and materials are available upon request.

| Parameter | Specification Range |

|---|---|

| Material Options | NBR, EPDM, Neoprene, FKM, SBR |

| Hardness (Shore A) | 50–80 ±5 |

| Operating Temperature | -40°C to +150°C (depending on compound) |

| Standard Diameters | 25 mm to 300 mm |

| Pressure Rating | Up to 10 bar (custom up to 25 bar) |

| Flange Type | Flat face, Raised face, or custom |

| Hinge Design | Integral molded hinge or bonded joint |

| Color | Black, red, green, or custom per request |

| Certifications | ROHS, FDA (upon request), ISO 9001 |

To initiate a technical consultation or request a quotation for flapper door components, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads material formulation and client engineering integration, ensuring that every solution is scientifically optimized for performance and manufacturability. With direct oversight of production and quality assurance, he provides technical continuity from concept to delivery.

Reach out via email at [email protected] to discuss your application requirements, share CAD files, or request sample submissions. We respond to all inquiries within 24 business hours and offer multilingual support for global OEM partnerships. For time-sensitive projects, expedited development and shipping options are available.

Partner with Suzhou Baoshida for flapper door solutions grounded in rubber science, industrial precision, and responsive manufacturing service.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).