Technical Contents

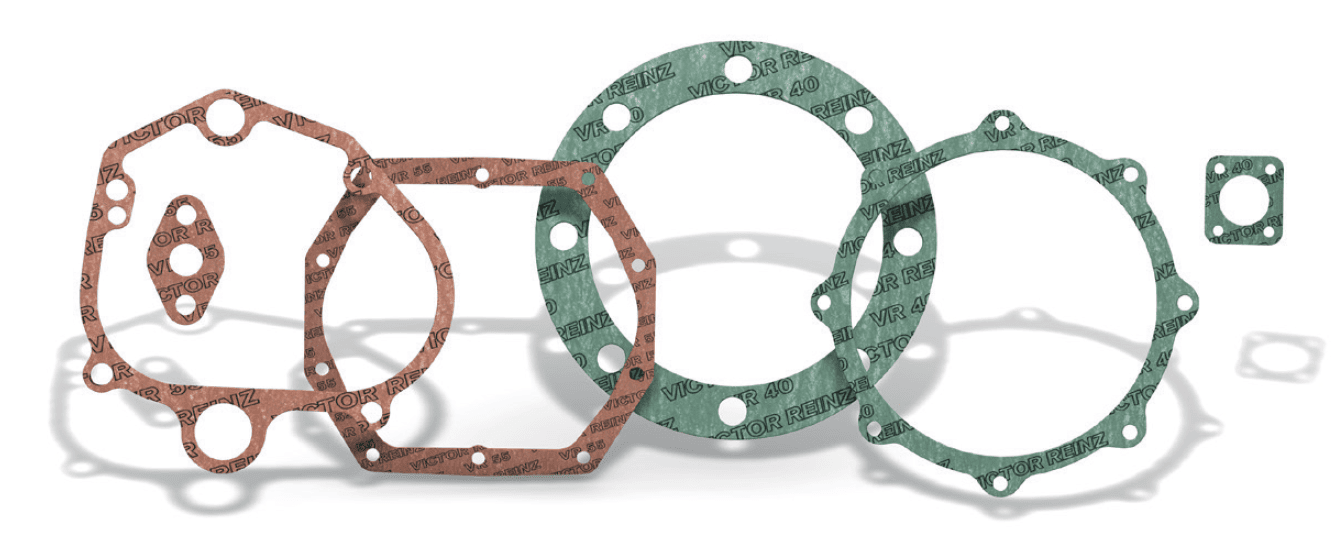

Engineering Guide: Victor Reinz Gasket

Engineering Insight: The Critical Role of Material Selection in Victor Reinz Gasket Performance

In the domain of precision rubber seals, the Victor Reinz gasket stands as a benchmark for reliability in high-stress mechanical environments. These gaskets are engineered to maintain integrity under extreme temperature fluctuations, pressure differentials, and exposure to aggressive chemical media. However, a common misconception in industrial procurement is that off-the-shelf gasket solutions can universally satisfy diverse operational demands. This assumption often leads to premature seal failure, unplanned downtime, and cascading mechanical damage. The root cause frequently lies in improper material selection—a variable that cannot be standardized without detailed system analysis.

Material selection for Victor Reinz gaskets is not a one-size-fits-all proposition. Each application imposes unique chemical, thermal, and mechanical stresses that must be mapped precisely to the elastomeric compound’s performance envelope. For instance, nitrile rubber (NBR) offers excellent resistance to oils and fuels but degrades rapidly in ozone-rich or high-temperature environments above 120°C. Conversely, fluorocarbon rubber (FKM) maintains stability up to 200°C and resists a broader range of chemicals, including acids and aromatic hydrocarbons, but comes at a higher cost and reduced flexibility at low temperatures.

Off-the-shelf gaskets are typically manufactured using generic material grades optimized for mass production, not performance specificity. These compromises become critical in applications such as internal combustion engines, turbocharger systems, or industrial compressors, where even minor seal degradation can result in leakage, loss of compression, or contamination of lubricants. Furthermore, dimensional tolerances and surface finish compatibility—often overlooked—interact with material behavior under compression set, affecting long-term sealing force retention.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific engineering over commoditized solutions. Our technical collaboration with OEMs begins with a full operational profile: temperature range, media exposure, flange type, bolt load, and cycle frequency. Only then can we recommend or supply a Victor Reinz gasket variant with a material composition that ensures lifecycle alignment with the host system.

The following table outlines common elastomers used in Victor Reinz gasket manufacturing and their key performance characteristics:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Hardness (Shore A) | Key Resistance Properties |

|---|---|---|---|---|

| NBR | -30 to +120 | 10–20 | 60–90 | Oils, fuels, water |

| FKM | -20 to +200 | 12–18 | 65–85 | Acids, aromatics, high heat |

| EPDM | -50 to +150 | 8–15 | 50–80 | Steam, oxygen, UV |

| ACM | -10 to +170 | 9–14 | 60–80 | Heat, oxidation, oils |

| VMQ | -60 to +180 | 6–10 | 40–80 | Extreme cold, silicone fluids |

Selecting the correct material is not merely a technical detail—it is a determinant of system reliability. Partnering with a supplier that understands the engineering science behind gasket performance ensures operational continuity and cost efficiency over the equipment lifecycle.

Material Specifications

Material Specifications for Precision Rubber Gaskets

Suzhou Baoshida Trading Co., Ltd. provides critical material specifications for industrial gasket applications, focusing on three elastomers commonly specified in Victor Reinz equivalents: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). These materials are engineered to meet stringent sealing demands across automotive, aerospace, and chemical processing sectors. Precision in material selection directly impacts gasket longevity, fluid compatibility, and operational safety. Each elastomer exhibits distinct thermal, chemical, and mechanical properties, necessitating rigorous evaluation against application parameters.

Viton (Fluoroelastomer, FKM) delivers exceptional resistance to high temperatures, aggressive chemicals, and non-polar fluids. Its molecular structure provides stability in continuous service up to 230°C, with intermittent exposure tolerance to 260°C. Viton excels in environments involving engine oils, fuels, acids, and hydraulic fluids, maintaining seal integrity under extreme pressure. However, it exhibits limited flexibility at sub-zero temperatures and higher material costs compared to alternatives. Compression set values typically remain below 25% after prolonged thermal aging, ensuring reliable resealing performance.

Nitrile (Acrylonitrile Butadiene Rubber, NBR) is the industry standard for cost-effective oil and fuel resistance. With acrylonitrile content dictating performance tiers, high-ACN grades withstand temperatures from -40°C to 120°C continuously. NBR demonstrates excellent abrasion resistance and tensile strength, making it ideal for dynamic sealing in hydraulic systems and fuel lines. Its primary limitations include poor ozone resistance and degradation above 125°C, where thermal oxidation accelerates. Standard hardness ranges from 50 to 90 Shore A, with compression set values of 15–30% after 70 hours at 100°C.

Silicone (Polysiloxane, VMQ) offers unparalleled flexibility across extreme temperatures, functioning reliably from -60°C to 230°C. It maintains elasticity in cryogenic applications and resists UV/ozone degradation, suiting outdoor and medical equipment use. However, silicone exhibits poor resistance to petroleum-based fluids and lower tensile strength than NBR or Viton. Its gas permeability necessitates careful evaluation in vacuum systems. Compression set performance is moderate (20–40% after aging), and reinforcement with silica fillers enhances mechanical properties for gasket applications.

The following table summarizes critical specifications for comparative analysis:

| Material | Temperature Range (°C) | Hardness Range (Shore A) | Key Strengths | Key Limitations |

|---|---|---|---|---|

| Viton (FKM) | -20 to 230 (continuous) | 60–90 | Extreme chemical resistance, high-temperature stability, low gas permeability | Poor low-temperature flexibility, high cost, limited steam resistance |

| Nitrile (NBR) | -40 to 120 (continuous) | 50–90 | Excellent oil/fuel resistance, abrasion resistance, cost efficiency | Moderate heat resistance, poor ozone/weathering resistance |

| Silicone (VMQ) | -60 to 230 (continuous) | 30–80 | Exceptional temperature range, UV/ozone stability, biocompatibility | Low tensile strength, poor hydrocarbon resistance, high gas permeability |

Selection must align with fluid exposure, thermal cycling, and mechanical stress profiles. Suzhou Baoshida Trading Co., Ltd. validates all materials against ASTM D2000 standards, ensuring dimensional stability and compression set compliance for OEM-critical applications. Consult our engineering team for application-specific formulation adjustments to optimize service life and sealing efficacy.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. maintains a core engineering team specialized in the development and production of high-precision rubber seals, including targeted expertise in Victor Reinz gasket replication and OEM equivalents. Our technical capability is anchored by a dedicated team of five mold engineers and two rubber formulation scientists, ensuring end-to-end control from material selection to final part geometry. This integrated approach enables us to meet stringent performance standards required in automotive, industrial, and heavy-duty applications.

Our mold engineering team specializes in precision tooling design for complex sealing profiles, including multi-layer steel (MLS), elastomer-coated metal, and non-asbestos composite gaskets. Utilizing advanced CAD/CAM software and CNC machining, we develop molds with tight tolerances (±0.05 mm) and optimized flow dynamics to ensure consistent part quality across high-volume production runs. Mold validation is conducted through iterative prototyping and dimensional inspection using coordinate measuring machines (CMM), guaranteeing conformity to original equipment specifications.

Complementing our tooling expertise, our two in-house rubber formulation engineers bring deep knowledge of polymer chemistry and material behavior under thermal, chemical, and mechanical stress. They are responsible for developing proprietary rubber compounds that match or exceed the performance of OEM materials used in Victor Reinz products. Our formulations are engineered for resistance to engine oils, coolants, exhaust gases, and extreme temperature cycles (-40°C to +250°C), with controlled compression set, tensile strength, and hardness profiles.

We operate a fully integrated R&D and production workflow that supports rapid OEM replication and custom seal development. Clients provide physical samples or technical drawings, and our team reverse-engineers both the geometric and material properties to produce functionally equivalent gaskets. This capability is particularly valuable for aftermarket support, legacy system maintenance, and cost-optimized replacements without compromising reliability.

Our engineering process emphasizes compatibility, durability, and manufacturability. Every new product undergoes rigorous functional testing, including pressure leak testing, thermal cycling, and long-term compression stress relaxation analysis. This ensures that our gaskets perform reliably under real-world operating conditions.

The following table outlines key technical specifications achievable through our engineering and production systems:

| Parameter | Capability Range |

|---|---|

| Material Types | NBR, EPDM, ACM, FKM, HT-EPDM, Graphite, Non-Asbestos Composites |

| Hardness (Shore A) | 50–90 |

| Temperature Resistance | -40°C to +250°C (dependent on compound) |

| Tolerance (Standard) | ±0.05 mm (critical sealing surfaces) |

| Compression Set (24h @ 150°C) | ≤25% (FKM), ≤30% (NBR/EPDM) |

| Production Volume Flexibility | 1,000 to 500,000 units per month |

| OEM Replication Lead Time | 15–25 days (from sample receipt to prototype) |

Suzhou Baoshida combines material science precision with advanced mold engineering to deliver technically robust gasket solutions tailored to OEM requirements. Our focus remains on performance equivalence, production scalability, and long-term sealing integrity.

Customization Process

Victor Reinz Gasket Customization: Precision Engineering Workflow

Suzhou Baoshida Trading Co., Ltd. executes Victor Reinz gasket customization through a rigorously controlled four-phase process, ensuring dimensional accuracy, material integrity, and functional reliability for demanding industrial applications. Our methodology adheres to ISO 9001 and IATF 16949 standards, integrating OEM specifications with advanced rubber science to eliminate field failure risks.

Drawing Analysis initiates the workflow. Our engineering team conducts granular review of client-provided technical drawings, focusing on geometric dimensioning and tolerancing (GD&T), surface finish requirements, and critical sealing zones. We cross-verify material callouts against operational parameters including temperature extremes, fluid exposure, and compression load. Any ambiguities in ISO 1127 or ASME Y14.5 annotations trigger immediate client consultation to prevent downstream deviations. This phase typically resolves 95% of potential fitment issues before material selection begins.

Formulation leverages Suzhou Baoshida’s proprietary compound database and OEM-approved polymer chemistries. Engineers select base elastomers—such as FKM, EPDM, or ACM—based on fluid compatibility charts and thermal stability thresholds. Key properties like durometer (Shore A 60–90), compression set (ASTM D395), and tensile strength are optimized via additive ratios of fillers, curatives, and stabilizers. Each formulation undergoes virtual simulation using Moldex3D to predict flow behavior and cure kinetics, minimizing trial iterations.

Prototyping validates the virtual model through physical testing. We produce 5–10 sample units via precision molding under controlled cavity pressures (±0.5 MPa) and cure cycles. Samples undergo dimensional inspection via CMM (accuracy ±0.005mm) and functional validation per SAE J2208 for leakage rates, compression force-deflection, and thermal cycling. Client approval requires ≤0.5% dimensional variance against nominal CAD data and zero fluid permeation at 1.5x operational pressure.

Mass Production commences only after prototype sign-off. We deploy automated molding lines with real-time SPC monitoring of barrel temperature, shot weight, and cure time. Every 50th unit undergoes destructive testing per ASTM D2000 standards, with full traceability via laser-etched batch codes. Final gaskets ship with CoC documentation certifying conformance to OEM-specified hardness, thickness tolerance (±0.1mm), and fluid resistance metrics.

Material performance specifications for common Victor Reinz gasket compounds are standardized below:

| Property | FKM 70 Durometer | EPDM 75 Durometer | ACM 80 Durometer |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -50 to +150 | -30 to +175 |

| Compression Set (ASTM D395) | ≤25% | ≤30% | ≤35% |

| Fluid Resistance (ASTM D471) | Excellent (Oils) | Excellent (Water) | Good (Oils) |

| Tensile Strength (MPa) | 12–18 | 8–14 | 9–15 |

| ASTM D2000 Classification | FC 744 | EA 745 | AG 744 |

This systematic approach ensures Victor Reinz gaskets meet exacting OEM performance criteria while maintaining Suzhou Baoshida’s zero-defect delivery commitment. All phases are documented in our PLM system for full auditability from RFQ to shipment.

Contact Engineering Team

For industrial manufacturers and OEMs requiring high-performance sealing solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the precision rubber seal sector. With extensive expertise in engineering and supplying Victor Reinz gaskets and equivalent performance-driven sealing products, we deliver reliability, consistency, and technical excellence tailored to demanding applications across automotive, powertrain, industrial machinery, and heavy-duty equipment sectors.

Our specialization in precision rubber seals ensures that every gasket meets stringent international standards for compression set resistance, thermal stability, chemical compatibility, and long-term sealing integrity. Whether you are sourcing for serial production, aftermarket replacement, or custom-engineered sealing solutions, Suzhou Baoshida provides full technical support, material traceability, and batch-controlled quality assurance. We work closely with global manufacturers to ensure dimensional accuracy, material compliance (including ASTM, ISO, and OEM-specific specifications), and rapid turnaround times without compromising performance.

Partnering with us means gaining access to a dedicated technical team fluent in both material science and application engineering. Our engineers support customers from initial material selection—such as NBR, EPDM, FKM, silicone, or specialty composites—to final product validation under real-world operating conditions. We offer comprehensive documentation, including material certificates, test reports, and compatibility analyses, ensuring full compliance with your manufacturing and safety requirements.

To streamline your procurement process, we maintain strategic inventory levels and flexible logistics solutions, enabling just-in-time delivery to support your production schedules. Our quality management system is aligned with ISO 9001 standards, and all products undergo rigorous in-house and third-party testing to ensure durability under high pressure, extreme temperatures, and aggressive media exposure.

Below is a representative specification profile for a typical Victor Reinz-grade rubber gasket produced to OEM-equivalent standards:

| Parameter | Specification |

|---|---|

| Material Type | NBR (Nitrile Butadiene Rubber) |

| Hardness (Shore A, 23°C) | 65 ± 5 |

| Tensile Strength | ≥12 MPa |

| Elongation at Break | ≥250% |

| Compression Set (22h, 100°C) | ≤25% |

| Operating Temperature Range | -30°C to +120°C (short peaks up to +150°C) |

| Fluid Resistance | Oil, fuel, water, glycol-based coolants |

| Thickness Tolerance | ±0.1 mm (per ISO 3302) |

| Surface Finish | Smooth, defect-free, die-cut or waterjet |

| Compliance | RoHS, REACH, ISO 9001 |

For technical inquiries, product specifications, or custom sealing solutions, contact Mr. Boyce, Rubber Formula Engineer & OEM Manager, directly at [email protected]. Mr. Boyce leads our technical client engagement team and provides expert consultation on material formulation, gasket design optimization, and rapid prototyping services. We respond to all inquiries within 24 business hours and offer sample submissions upon request.

Elevate your sealing performance with Suzhou Baoshida—where precision engineering meets industrial reliability. Contact us today to discuss your application requirements and discover how our Victor Reinz-grade gasket solutions can enhance your product integrity and production efficiency.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).