Technical Contents

Engineering Guide: Carbon Fibre Packing

Engineering Insight: The Critical Role of Material Selection in Carbon Fibre Packing

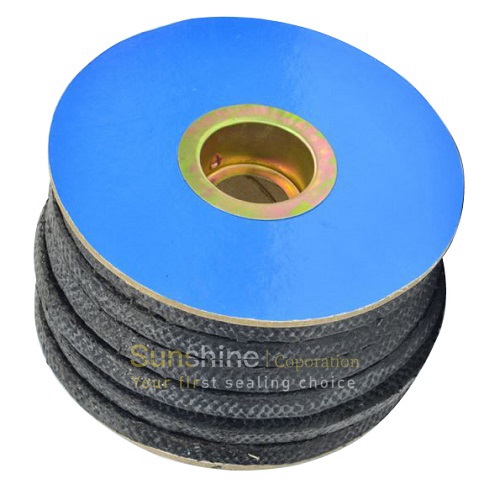

In the domain of industrial sealing solutions, carbon fibre packing stands out for its exceptional thermal conductivity, low thermal expansion, and high mechanical strength under extreme conditions. However, the performance of carbon fibre packing is not inherent to the material alone—it is fundamentally dictated by precise material selection and engineered compatibility with operational parameters. Off-the-shelf solutions, while appealing for their availability and lower initial cost, frequently fail to meet the rigorous demands of dynamic industrial environments due to oversimplified design assumptions and inadequate customization.

Carbon fibre, when used in packing applications, is often combined with various impregnants such as PTFE, graphite, or inorganic fillers to enhance lubricity, chemical resistance, or thermal stability. The effectiveness of these combinations depends on the specific media being sealed, operating temperature, shaft speed, and pressure differentials. For instance, a packing ring formulated for low-friction water pumps may degrade rapidly in a high-temperature chemical reactor due to incompatible polymer binders. This mismatch underscores why standardized products are ill-suited for mission-critical applications.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific engineering. Our rubber and composite formulations are developed in alignment with OEM requirements and field data, ensuring that each packing solution is optimized for longevity and reliability. Off-the-shelf alternatives typically employ generic fibre weaves and fixed resin systems, which lack adaptability. In contrast, engineered carbon fibre packing involves tailored braid structures, controlled fibre orientation, and selective impregnation processes that collectively resist extrusion, minimise wear, and maintain sealing integrity under cyclic loads.

Another critical factor is chemical compatibility. Carbon fibre itself is chemically inert, but the matrix or binder can be vulnerable to hydrolysis, oxidation, or solvent attack. For example, PTFE-impregnated packs perform well in acidic environments but may decompose at temperatures exceeding 260°C, releasing corrosive byproducts. In alkaline or oxidizing services, graphite or ceramic-modified systems are preferable. Without proper material vetting, premature failure modes such as packing extrusion, shaft scoring, or fugitive emissions become inevitable.

We recommend a systematic evaluation of service conditions before selecting any sealing solution. The table below outlines key performance parameters for common carbon fibre packing variants used in industrial applications.

| Material Variant | Max Temp (°C) | Pressure Rating (bar) | Shaft Speed (m/s) | Chemical Resistance Profile | Typical Application |

|---|---|---|---|---|---|

| Carbon + PTFE | 260 | 20 | 15 | Acids, alcohols, water | Pumps, mixers, valves |

| Carbon + Graphite | 450 (inert) | 30 | 20 | Steam, alkalis, molten metals | High-temp valves, reactors |

| Carbon + Ceramic Fillers | 600 | 35 | 18 | Oxidizing agents, hot air | Furnace doors, expansion joints |

| Carbon + Inorganic Binder | 300 | 25 | 12 | Solvents, oils, moderate acids | Chemical processing equipment |

Standardized carbon fibre packing fails not because the base material is inadequate, but because it is misapplied. True performance stems from engineered precision—matching material architecture to operational physics. At Suzhou Baoshida, we deliver not just components, but engineered assurance.

Material Specifications

Material Specifications for Carbon Fiber Packing Solutions

Carbon fiber reinforced packing demands precise elastomer selection to balance mechanical resilience, thermal stability, and chemical compatibility. At Suzhou Baoshida Trading Co., Ltd., our formulations integrate high-purity carbon fiber with premium elastomeric matrices to achieve optimal sealing performance under extreme industrial conditions. Material choice directly impacts service life, particularly in dynamic applications involving high pressure, aggressive media, or wide temperature excursions. Below we detail critical specifications for Viton (FKM), Nitrile (NBR), and Silicone (VMQ) compounds used in our carbon fiber packing systems. Each material undergoes rigorous ASTM D2000 validation to ensure consistency in hardness, tensile strength, and compression set—key parameters for maintaining seal integrity during prolonged operation.

The comparative analysis below highlights performance thresholds essential for OEM integration. All values reflect standard-grade compounds; custom formulations are available to address specific fluid compatibility or temperature requirements.

| Material | Temperature Range (°C) | Key Chemical Resistance | Hardness (Shore A) | Tensile Strength (MPa) | Compression Set (70h/100°C) |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | Excellent: Hydrocarbons, acids, steam, oils | 70–90 | 10–18 | ≤25% |

| Nitrile (NBR) | -30 to 120 | Excellent: Aliphatic hydrocarbons, water, hydraulic fluids | 50–90 | 10–20 | ≤30% |

| Silicone (VMQ) | -60 to 200 | Excellent: Water, ozone, oxygen; Poor: Ketones, steam | 40–80 | 5–10 | ≤20% |

Viton excels in high-temperature chemical environments, such as refinery valve stems handling aromatic solvents or sour gas. Its fluorocarbon structure provides unmatched resistance to swelling in aggressive media, though cost considerations may limit use in non-critical applications. Nitrile remains the industrial workhorse for hydraulic and pneumatic systems due to its balance of oil resistance, abrasion tolerance, and cost efficiency. However, ozone exposure and elevated temperatures above 120°C necessitate alternative solutions. Silicone offers superior low-temperature flexibility and biocompatibility for pharmaceutical or food-grade packing but exhibits lower tensile strength and vulnerability to hydrocarbon degradation.

Critical selection criteria must prioritize the dominant operational stressor. For instance, NBR is optimal for mobile hydraulic equipment where cost and oil resistance dominate, while Viton is non-negotiable for chemical processing seals exposed to chlorinated solvents above 150°C. Silicone’s compression set advantage suits static seals in cryogenic applications but requires reinforcement for dynamic use. Suzhou Baoshida’s OEM engineering team collaborates with clients to validate material suitability against actual service profiles, including fluid immersion testing per ASTM D471 and thermal aging per ASTM D573. This data-driven approach prevents premature seal failure and aligns with ISO 9001-certified manufacturing protocols governing our carbon fiber packing production. Understanding these material boundaries ensures optimal lifecycle performance in demanding industrial sealing applications.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Carbon Fibre Packing Solutions

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and manufacturing of high-performance carbon fibre packing. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the product development lifecycle—from concept and material formulation to precision moulding and final validation.

Our formula engineers focus on tailoring elastomeric compounds to meet the demanding thermal, chemical, and mechanical requirements typical in sealing applications involving carbon fibre packing. Leveraging advanced polymer science and rigorous testing protocols, they optimize formulations for resilience under extreme temperatures, resistance to aggressive media, and long-term compression set performance. This scientific approach ensures that each compound is not only compliant with industry standards but also engineered for application-specific durability and efficiency.

Complementing this, our five mould engineers bring precision and scalability to the manufacturing process. They specialize in designing and refining injection and compression moulds with micron-level accuracy, ensuring consistent geometry, tight tolerances, and repeatable part quality across production batches. Utilizing CAD/CAM software and CNC machining, they rapidly prototype and iterate tooling to support both custom designs and high-volume OEM production.

Our integrated engineering workflow enables seamless collaboration between material science and tooling design, reducing time-to-market and enhancing product performance. This synergy is critical when serving OEM clients who demand reliability, traceability, and customization in their sealing solutions.

We support full OEM manufacturing services, including private labeling, technical documentation, and co-engineering partnerships. Our facility adheres to ISO 9001 quality management standards, ensuring every carbon fibre packing component meets stringent international requirements for performance and consistency.

Below is a summary of our core technical capabilities relevant to carbon fibre packing production:

| Parameter | Specification |

|---|---|

| In-House Engineering Team | 5 Mould Engineers, 2 Rubber Formula Engineers |

| Material Development | Custom elastomer formulations (NBR, EPDM, FKM) |

| Mould Design & Fabrication | CAD/CAM-based, CNC-machined steel moulds |

| Tolerance Control | ±0.05 mm for critical dimensions |

| Production Process | Injection moulding, compression moulding |

| OEM Service Capabilities | Full customization, private labeling, co-design |

| Quality Standards | ISO 9001 certified, batch traceability |

| Testing Capabilities | Compression set, hardness, thermal aging, chemical resistance |

Through this robust engineering infrastructure, Suzhou Baoshida delivers technically advanced, application-optimized carbon fibre packing solutions that meet the evolving demands of global industrial markets.

Customization Process

Carbon Fibre Packing Customization Process: Precision Engineering for Demanding Sealing Applications

At Suzhou Baoshida Trading Co., Ltd., our carbon fibre packing customization process ensures optimal performance in high-temperature, high-pressure industrial environments. This rigorous four-stage methodology integrates material science with precision manufacturing to meet exact OEM specifications. We begin with comprehensive Drawing Analysis, where our engineering team dissects client-provided technical schematics and GD&T callouts. Critical parameters such as cross-sectional tolerances, groove dimensions, and operational media contact surfaces are validated against ISO 3601 sealing standards. This phase identifies potential extrusion gaps, thermal expansion variables, and chemical exposure risks, establishing the foundation for a failure-resistant design.

Subsequent Formulation development leverages our proprietary rubber compounding expertise. Based on the operational profile—temperature range, chemical exposure, and dynamic stress requirements—we select base polymers (e.g., FKM, PTFE-modified NBR) and engineer carbon fibre reinforcement ratios. Our lab precisely calibrates filler dispersion, vulcanization kinetics, and fibre orientation to achieve target mechanical properties while mitigating common failure modes like thermal degradation or compression set. Each formulation undergoes iterative rheological testing to confirm processability and final-part integrity.

Prototyping transforms validated formulations into functional samples. Using client-approved tooling, we produce small-batch prototypes under controlled production conditions. These undergo empirical validation per ASTM F38 and DIN 28090 standards, including compression resistance, leakage rate quantification, and dynamic friction analysis. Client feedback on prototype performance in actual equipment guides micro-adjustments to material composition or dimensional tolerances, ensuring seamless integration into the end application.

Upon prototype sign-off, Mass Production commences under stringent statistical process control. Each production lot is traceable via batch-coded raw materials, with real-time monitoring of curing temperature profiles, press tonnage, and dimensional consistency. Final inspection includes 100% visual checks for surface defects and抽样 testing per AQL 1.0 for critical dimensions. This closed-loop system guarantees repeatability, with all carbon fibre packing units certified to ISO 9001:2015 quality management protocols.

Key Performance Specifications for Carbon Fibre Packing

| Parameter | Test Standard | Typical Value Range | Significance |

|---|---|---|---|

| Density | ASTM D297 | 1.45–1.65 g/cm³ | Indicates fibre loading consistency |

| Tensile Strength | ASTM D412 | 12–18 MPa | Resistance to extrusion forces |

| Compression Set (24h/200°C) | ASTM D395 | ≤ 25% | Critical for long-term seal retention |

| Max. Continuous Temp. | ISO 2230 | -20°C to +300°C | Defines operational envelope |

| Friction Coefficient | DIN 53535 | 0.12–0.18 | Minimizes wear in dynamic applications |

This structured workflow—grounded in material science and industrial pragmatism—delivers carbon fibre packing solutions that enhance equipment uptime and reduce lifecycle costs for global OEM partners. Suzhou Baoshida’s commitment to engineering precision ensures every custom component meets the uncompromising demands of modern industrial sealing.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Carbon Fibre Packing Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to the rigorous demands of modern manufacturing, sealing, and mechanical systems. Our expertise extends to the development and supply of carbon fibre packing, a critical sealing material engineered for extreme conditions involving high temperature, pressure, and chemical exposure. As a trusted OEM partner, we combine precision material science with scalable production to meet the exacting standards of global industrial clients.

Carbon fibre packing is widely used across industries such as petrochemical processing, power generation, pulp and paper, and marine engineering due to its exceptional tensile strength, low thermal expansion, and resistance to wear and creep. Our formulations integrate high-purity carbon fibres with advanced elastomeric binders and performance additives such as PTFE, graphite, or aramid for optimized friction control, thermal conductivity, and chemical inertness. Each product is manufactured under strict quality control protocols to ensure dimensional consistency, long service life, and compliance with international sealing standards.

We understand that sealing applications are highly application-specific. Whether you require braided carbon fibre packing for rotary shafts, valve stems, or pump seals, our engineering team works closely with clients to customize fibre architecture, braid density, lubrication treatment, and cross-sectional geometry. Our R&D capabilities allow us to match OEM specifications precisely, ensuring seamless integration into existing systems and minimizing downtime during maintenance cycles.

To support global procurement needs, Suzhou Baoshida offers scalable supply chains, batch traceability, and technical documentation including material safety data sheets (MSDS), certificates of conformance, and performance test reports. We serve Tier-1 suppliers and end-users across Asia, Europe, and North America, providing just-in-time logistics and responsive technical service.

For immediate assistance with carbon fibre packing selection, customization, or volume procurement, contact Mr. Boyce, OEM Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over a decade of experience in industrial sealing solutions and leads client engagement for strategic manufacturing partnerships. He is available to discuss technical specifications, sample requests, and qualification processes for new applications.

Reach out via email at [email protected] to initiate a technical consultation or request a material data package. Our team responds to all inquiries within 24 business hours. For urgent matters, please indicate “Priority – Carbon Fibre Packing” in the subject line to ensure expedited handling.

Below are representative specifications for our standard carbon fibre packing grades:

| Property | CF-100 (Standard) | CF-200 (Reinforced) | CF-300 (High-Temp) |

|---|---|---|---|

| Fibre Type | Carbon | Carbon + Aramid | Carbon + Graphite |

| Temperature Range | -200°C to +280°C | -200°C to +300°C | -200°C to +600°C |

| Pressure Resistance | 20 MPa | 25 MPa | 30 MPa |

| Shaft Speed (max) | 15 m/s | 18 m/s | 12 m/s |

| Chemical Resistance | Excellent | Excellent | Outstanding |

| Lubrication | PTFE Impregnated | PTFE + Grease | Self-Lubricating |

Partner with Suzhou Baoshida for technically superior, application-optimized carbon fibre packing solutions engineered for reliability and performance. Contact Mr. Boyce today to advance your sealing technology.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).