Technical Contents

Engineering Guide: Shore Durometer Hardness Tester

Engineering Insight: The Critical Role of Material Selection in Shore Durometer Hardness Testers

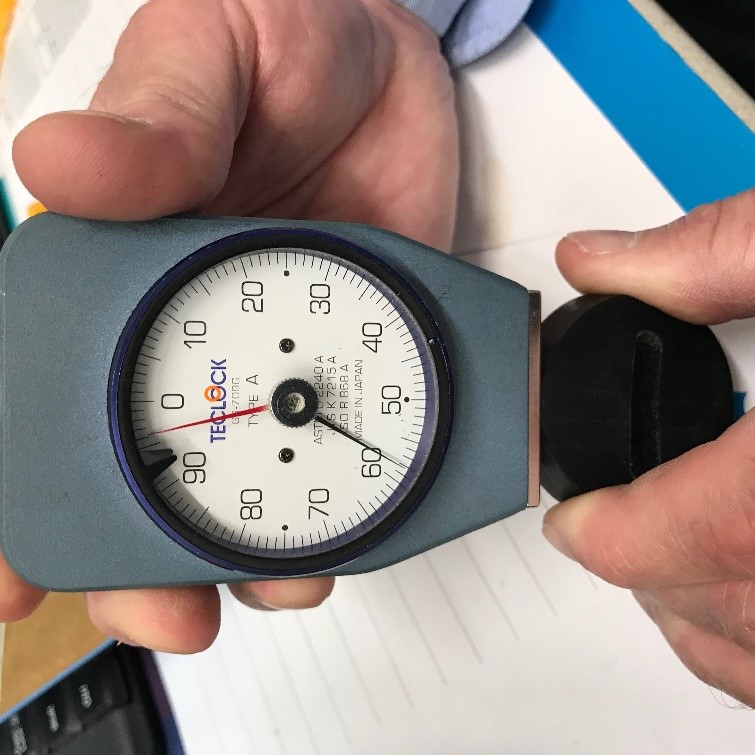

In industrial rubber manufacturing and quality assurance, the accuracy and repeatability of hardness measurements are foundational to product performance and compliance. The Shore durometer hardness tester, a primary instrument for quantifying elastomeric resistance to indentation, must be engineered with precision that extends beyond mechanical design—material selection is paramount. Off-the-shelf solutions often fail in demanding production environments due to compromises in material integrity, leading to measurement drift, mechanical fatigue, and inconsistent calibration.

The Shore durometer operates on a spring-loaded indenter mechanism that applies a defined force to the rubber surface. Any deformation or wear in the indenter tip, plunger housing, or base anvil directly affects measurement outcomes. Standard commercial testers frequently employ lower-grade stainless steels or plated alloys to reduce manufacturing costs. These materials, while adequate for light-duty or laboratory use, exhibit higher susceptibility to abrasion, corrosion, and dimensional instability under repeated industrial use. For instance, a zinc-coated plunger rod may corrode when exposed to processing oils or cleaning solvents, introducing friction variance that alters spring force dynamics.

At Suzhou Baoshida Trading Co., Ltd., we prioritize high-purity hardened tool steels for critical components such as the indenter needle and anvil surface. These materials maintain Rockwell hardness ratings above HRC 58, ensuring resistance to micro-wear over thousands of test cycles. Additionally, our housings utilize anodized aerospace-grade aluminum alloys, which provide optimal rigidity-to-weight ratios while resisting thermal expansion. This thermal stability is crucial in environments where ambient temperature fluctuates, as dimensional changes in the frame can skew indentation depth readings.

Another often-overlooked factor is elastomeric sealing. Many generic testers omit internal seals, allowing dust and moisture ingress that degrades internal spring performance. Our engineered solutions incorporate fluorocarbon (FKM) O-rings rated for industrial contaminants, preserving internal mechanics and extending recalibration intervals.

The following table outlines key material specifications in our industrial-grade Shore A and Shore D testers compared to typical off-the-shelf models:

| Component | Suzhou Baoshida Industrial Tester | Typical Off-the-Shelf Model |

|---|---|---|

| Indenter Needle | Tungsten carbide, polished to Ra ≤ 0.1 µm | Chrome-plated steel, Ra ≤ 0.8 µm |

| Plunger Shaft | 17-4 PH stainless steel, H9 tolerance | Zinc-plated mild steel |

| Anvil Surface | Hardened 440C stainless, ground flatness ≤ 0.002 mm | Mild steel with epoxy coating |

| Housing | 6061-T6 aluminum, anodized Type III | ABS plastic or stamped steel |

| Spring Mechanism | ASTM A313 stainless steel, pre-compressed | Carbon steel, non-stabilized |

| Sealing | FKM O-rings, IP65-rated enclosure | No internal seals |

Material selection directly governs long-term metrological reliability. In high-throughput rubber production—where Shore hardness correlates with compression set, tensile strength, and sealing performance—using substandard testing equipment introduces unacceptable risk. Suzhou Baoshida’s engineering approach ensures that every material choice aligns with the operational demands of industrial rubber manufacturing, delivering consistent, traceable hardness data across the product lifecycle.

Material Specifications

Material Specifications for Shore Durometer Hardness Testing in Industrial Sealing Applications

Accurate Shore A durometer hardness measurement is fundamental for validating the performance characteristics of elastomeric sealing components. This parameter directly influences critical properties such as compression set resistance, sealing force, extrusion resistance, and dynamic fatigue life. Selecting the appropriate base polymer with a hardness profile optimized for the operational environment ensures long-term reliability and prevents premature seal failure. At Suzhou Baoshida Trading Co., Ltd., we rigorously characterize Viton (FKM), Nitrile (NBR), and Silicone (VMQ) compounds to provide OEMs with materials meeting exacting dimensional and functional specifications. Understanding the inherent property ranges of these elastomers is essential for correlating measured Shore A values with real-world application demands, particularly concerning chemical exposure, temperature extremes, and mechanical stress.

Viton fluoroelastomers are specified for the most demanding chemical and high-temperature environments. These compounds typically achieve Shore A hardness values between 50 and 90, offering a balance of flexibility and structural integrity. Viton excels in resisting aggressive fuels, oils, acids, and bases, maintaining functionality continuously up to 200°C and withstanding intermittent peaks near 250°C. This thermal stability makes it indispensable for aerospace, automotive fuel systems, and chemical processing seals where NBR or Silicone would rapidly degrade. Nitrile rubber remains the dominant choice for general-purpose oil and fuel resistance due to its cost-effectiveness and robust mechanical properties. Standard NBR formulations span Shore A 40 to 90, providing excellent resilience against petroleum derivatives, aliphatic hydrocarbons, and hydraulic fluids. Its operational temperature range is generally limited to -30°C to +100°C, though specialized hydrogenated NBR (HNBR) variants can extend the upper limit to approximately 150°C, broadening its utility in demanding automotive and industrial applications. Silicone rubber is selected primarily for its exceptional low-temperature flexibility and high-temperature stability, coupled with good electrical insulation. Shore A hardness for standard VMQ compounds ranges from 30 to 80. Silicone withstands continuous exposure from -60°C to +200°C and handles brief excursions to 250°C. While exhibiting good resistance to water, ozone, and weathering, its performance against oils, fuels, and solvents is significantly inferior to Viton or NBR, limiting its use to applications like medical devices, food processing, and high/low-temperature gaskets where chemical exposure is minimal.

The following table summarizes key comparative specifications for these critical elastomers:

| Material | Typical Shore A Range | Continuous Temp Range (°C) | Key Chemical Resistances | Primary Application Focus |

|---|---|---|---|---|

| Viton (FKM) | 50 – 90 | -20 to +200 | Fuels, Oils, Acids, Bases, Aromatics | Aerospace, Chemical Processing, High-Temp Automotive |

| Nitrile (NBR) | 40 – 90 | -30 to +100 (HNBR: +150) | Petroleum Oils, Fuels, Hydraulic Fluids | Automotive Seals, General Industrial Hydraulics |

| Silicone (VMQ) | 30 – 80 | -60 to +200 | Water, Ozone, Weathering, Steam | Medical Devices, Food Processing, Extreme Temp Gaskets |

Suzhou Baoshida Trading Co., Ltd. provides comprehensive technical support to OEM partners, ensuring Shore hardness specifications are precisely defined within the optimal performance envelope of each elastomer. Our material formulations are engineered to deliver consistent durometer values critical for dimensional stability and sealing force prediction under operational loads. Collaborating with our engineering team guarantees material selection aligns with your specific environmental challenges and functional requirements.

Manufacturing Capabilities

Engineering Excellence in Rubber Material Testing and OEM Development

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in precision applications involving Shore durometer hardness testing. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver technically robust, application-specific solutions tailored to the exacting demands of global OEMs. Our integrated approach ensures that material formulation, tooling design, and final product performance are aligned from concept to production.

Our formula engineers possess deep expertise in polymer chemistry and elastomer behavior, enabling precise control over rubber hardness, resilience, compression set, and environmental resistance. This proficiency is critical when developing materials for Shore A and Shore D durometer applications, where even minor deviations can impact sealing performance, wear life, or component fit. By leveraging advanced testing protocols and real-time durometer validation, we ensure that every compound meets defined hardness specifications across varying temperatures and service conditions.

Complementing our material science capabilities, our five in-house mould engineers specialize in precision tooling for rubber injection, compression, and transfer moulding. They utilize 3D CAD modeling and finite element analysis (FEA) to optimize cavity design, gate placement, and venting—factors that directly influence the consistency of hardness readings in finished parts. This synergy between formulation and tooling ensures repeatability, minimizes batch variation, and supports high-volume OEM production with stringent QC requirements.

We support full OEM service offerings, including private-label manufacturing, custom formulation development, and hardness-specific material certification. Our production lines are calibrated to meet international standards such as ASTM D2240 and ISO 868, ensuring traceable and reliable Shore hardness measurements. Whether clients require soft elastomers (30–60 Shore A) for sealing applications or rigid compounds (60–90 Shore D) for industrial components, our engineering team delivers compliant, performance-optimized solutions.

The following table outlines our standard testing and formulation capabilities relevant to Shore durometer hardness evaluation:

| Parameter | Specification Range | Testing Standard | Equipment Used |

|---|---|---|---|

| Hardness Scale | Shore A, Shore D | ASTM D2240, ISO 868 | Digital Durometer (Type A/D) |

| Measurable Range | 10–100 Shore A, 20–90 Shore D | ISO 48-4 | Zwick Roell H09 |

| Temperature Range for Testing | -20°C to +80°C | ISO 188 | Environmental Chambers |

| Sample Thickness | ≥6 mm (preferred) | ASTM D2240 | Precision Micrometers |

| Repeatability Tolerance | ±0.5 Shore Units | Internal QA Protocol | Calibrated Test Stands |

Through rigorous process control, scientific formulation, and engineering integration, Suzhou Baoshida Trading Co., Ltd. ensures that every rubber component meets the precise hardness and performance criteria demanded by advanced manufacturing sectors. Our OEM partnerships benefit from transparent development cycles, full documentation, and scalable production—all underpinned by a culture of technical precision.

Customization Process

Customization Process for Shore Durometer Hardness Testers: Engineering Precision from Concept to Volume

At Suzhou Baoshida Trading Co., Ltd., our customization process for Shore durometer hardness testers integrates rigorous polymer science with industrial manufacturing discipline. This phased methodology ensures elastomer components meet exact application demands while adhering to global standards like ASTM D2240 and ISO 48-4. We prioritize material-performance alignment at every stage to eliminate field failures and optimize lifecycle costs for OEM partners.

Drawing Analysis initiates the workflow with a deep technical review of client specifications. Our engineers scrutinize geometric tolerances, surface finish requirements, and environmental exposure conditions (e.g., temperature range, chemical contact). Critical attention is given to dimensional stability under load, as minor deviations in specimen thickness directly impact Shore readings. We identify potential tolerance stacking risks and propose design refinements to ensure test repeatability, such as optimizing edge radii to prevent indentation artifacts during measurement.

Formulation leverages our 15-year expertise in elastomer compounding. Based on the validated design parameters, we select base polymers (EPDM, NBR, silicone, or FKM) and engineer the cure system, filler dispersion, and plasticizer ratios to achieve target hardness. For instance, a hydraulic seal requiring 70±3 Shore A demands precise silica-to-carbon black ratios and controlled peroxide crosslinking to resist compression set while maintaining durometer consistency across -40°C to 150°C. Every formulation undergoes predictive modeling for cure kinetics and hardness drift before physical prototyping.

Prototyping employs ISO 17483-certified molding processes to produce 3–5 validation units per iteration. Each prototype undergoes multi-axis durometer testing at 15s, 30s, and 60s dwell times to capture creep behavior, alongside accelerated aging per ASTM D573. We correlate hardness data with tensile strength and elongation to verify molecular network integrity. Client feedback on prototype performance triggers formulation or process adjustments, typically resolving >95% of variables within two iterations.

Mass Production activates our IATF 16949-certified production line with real-time statistical process control. Hardness is monitored hourly using calibrated ZwickRoell testers, with data logged against lot-specific material certificates. We implement first-article inspection (FAI) per AS9102 and in-process checks for critical dimensions affecting durometer accuracy. Final validation includes third-party hardness certification reports, ensuring every batch meets the contractual hardness profile before shipment.

The following table summarizes critical hardness-performance relationships guiding our customization:

| Hardness Range (Shore A) | Tolerance Band | Typical Industrial Applications | Key Material Considerations |

|---|---|---|---|

| 30–40 | ±2 | Seals for low-pressure fluid systems | High resilience, low filler loading to prevent extrusion |

| 50–70 | ±3 | Hydraulic/pneumatic seals, gaskets | Balanced oil resistance and compression set performance |

| 80–95 | ±2 | Conveyor belts, printing rollers | Reinforced with aramid fibers for abrasion resistance |

| 90+ (Shore D) | ±1 | Automotive bushings, industrial rollers | Requires FKM/FFKM for thermal stability above 200°C |

This structured approach de-risks elastomer component deployment by anchoring hardness specifications to functional requirements. Suzhou Baoshida’s engineering-led workflow transforms client drawings into validated production solutions, guaranteeing durometer consistency that directly translates to end-product reliability in demanding industrial environments.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Shore Durometer Hardness Testing Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-accuracy industrial rubber testing instrumentation tailored for manufacturers, quality control laboratories, and R&D facilities. Our core expertise lies in Shore durometer hardness testers—critical tools for ensuring material consistency, compliance, and performance across automotive, aerospace, medical device, and industrial component sectors. As your trusted OEM partner in rubber solutions, we offer not only precision-engineered testing equipment but also technical support, calibration services, and customized configurations to meet your exact operational demands.

The Shore durometer hardness test remains a fundamental metric in polymer science, providing a quantitative measure of a material’s resistance to indentation. Selecting the correct durometer scale and instrument type is essential for maintaining product integrity and meeting international standards such as ASTM D2240 and ISO 868. Our range includes digital and analog models calibrated for Shore A, Shore D, and Shore 00 scales, each designed for specific material classes—from soft silicone seals to rigid thermoplastic elastomers.

We understand that industrial environments demand durability, repeatability, and traceable accuracy. Our testers are manufactured under strict quality control protocols, featuring hardened indenters, precision springs, and corrosion-resistant housings. Each unit undergoes individual calibration verification, with optional NIST-traceable certification available upon request. Whether you require benchtop models for lab use or portable handheld units for field inspections, Suzhou Baoshida provides the right solution with minimal downtime and maximum reliability.

For technical inquiries, product selection guidance, or volume procurement support, we invite you to contact Mr. Boyce, our dedicated OEM and technical sales manager. With over 15 years of experience in rubber testing instrumentation, Mr. Boyce provides expert consultation to help you integrate the correct hardness testing methodology into your production workflow. He supports clients in specification alignment, regulatory compliance, and after-sales service coordination, ensuring a seamless experience from initial inquiry to long-term deployment.

Below is a summary of our standard Shore durometer hardness tester specifications:

| Parameter | Specification |

|---|---|

| Measurement Scales | Shore A, Shore D, Shore 00 |

| Accuracy | ±1.0 Shore units |

| Repeatability | ±0.5 Shore units |

| Indentation Force (Shore A) | 8.06 N (822 gf) at full scale |

| Display Type | Digital LCD with backlight / Analog dial |

| Data Output | USB/RS-232 (digital models) |

| Calibration Standard | ASTM D2240, ISO 868 |

| Operating Temperature | 15–35°C |

| Power Supply | 2×AAA batteries or USB power (digital) |

| Housing Material | Anodized aluminum with anti-slip rubber grip |

To discuss your application requirements or request a product demonstration, contact Mr. Boyce directly at [email protected]. We respond to all technical and commercial inquiries within 12 business hours. As a global supplier, Suzhou Baoshida supports English, German, French, and Mandarin communication, with logistics coverage across North America, Europe, Southeast Asia, and the Middle East. Partner with us for reliable, precision-driven hardness testing solutions built for industrial excellence.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).