Technical Contents

Engineering Guide: As568 Size Chart

Engineering Insight: AS568 Size Chart and the Critical Role of Material Selection

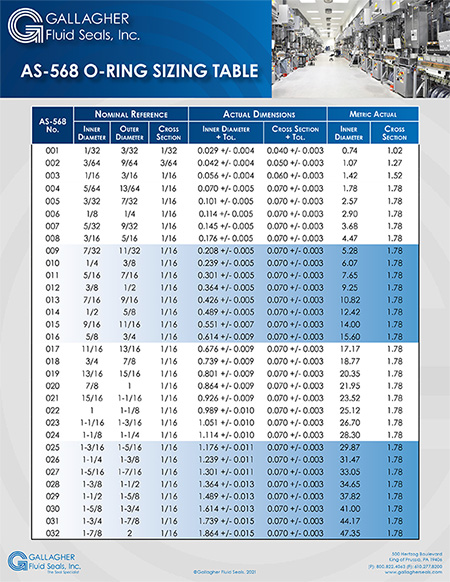

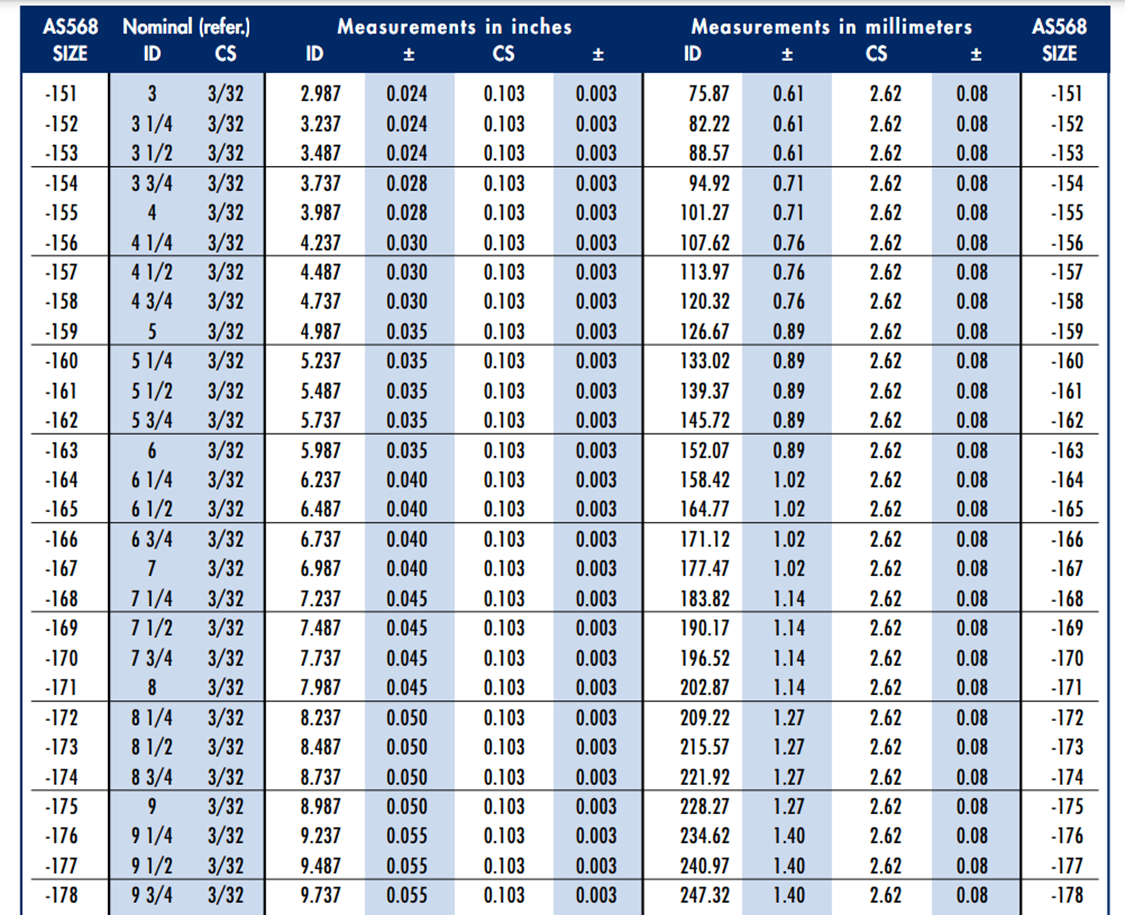

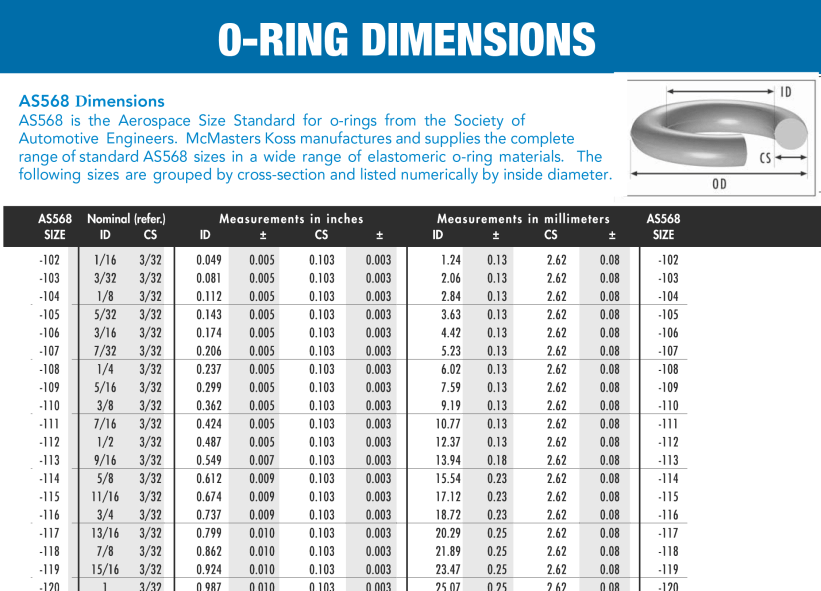

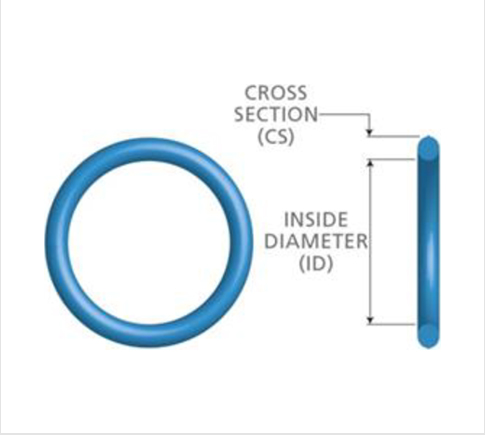

The AS568 size chart is a standardized reference for O-ring dimensions, widely adopted across aerospace, automotive, and industrial sectors. While it provides precise inner diameter, cross-section, and tolerance specifications, adherence to dimensional standards alone does not guarantee performance or longevity in real-world applications. The failure of off-the-shelf O-rings in demanding environments often stems not from dimensional inaccuracy but from inappropriate material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize that engineering success lies in matching both size and material to the operational environment.

Standardized dimensions ensure interchangeability, but material properties dictate chemical resistance, thermal stability, compression set, and mechanical resilience. For example, an NBR O-ring conforming to AS568A-014 may fit perfectly in a hydraulic system, yet degrade rapidly when exposed to high-temperature synthetic lubricants. Conversely, an FKM O-ring of the same AS568 size may excel in high-heat, chemically aggressive environments but fail in dynamic applications due to higher stiffness and lower resilience.

Off-the-shelf solutions are typically optimized for cost and availability, not for specific operational stressors. Common failure modes—extrusion, hardening, cracking, or swelling—are frequently traced to material incompatibility rather than dimensional mismatch. A one-size-fits-all approach neglects variables such as fluid media, temperature cycling, pressure surges, and surface finish, all of which influence seal performance.

At Baoshida, we advocate for engineered material selection based on application-specific data. Our industrial rubber solutions leverage advanced elastomers including EPDM, FKM, NBR, Silicone, and Aflas, each selected for targeted performance attributes. We support OEMs with material compatibility testing and accelerated life cycle analysis to ensure that the chosen O-ring not only fits per AS568 but also survives and performs under actual service conditions.

The following table outlines common elastomers used in AS568 O-rings, with key performance characteristics:

| Material | Temperature Range (°C) | Fluid Resistance | Compression Set | Typical Applications |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 | Good for oils, fuels | Moderate | Hydraulics, pneumatics |

| FKM (Viton®) | -20 to +200 | Excellent for oils, acids, fuels | Low | Aerospace, chemical processing |

| EPDM | -50 to +150 | Excellent for water, steam, brake fluids | Low | HVAC, water systems |

| Silicone | -60 to +200 | Poor for hydrocarbons | Moderate | Medical, food-grade, electrical |

| Aflas® | -20 to +200 | Excellent for acids, bases, steam | Low | Petrochemical, sour gas environments |

Understanding the limitations of generic O-rings is essential for reliability. True sealing integrity requires a dual focus: dimensional compliance with AS568 and intelligent material engineering. At Suzhou Baoshida Trading Co., Ltd., we deliver both—precision manufacturing and application-driven material science.

Material Specifications

Material Specifications for AS568 Standard O-Rings

Precision sealing performance under diverse industrial conditions necessitates rigorous material selection aligned with AS568 dimensional standards. While AS568 strictly governs cross-sections and inside diameters, the elastomer compound dictates chemical compatibility, thermal resilience, and mechanical endurance. Suzhou Baoshida Trading Co., Ltd. emphasizes that material choice is an independent engineering decision critical to seal longevity. Below we detail three premier compounds for AS568 O-rings: Viton® (FKM), Nitrile (NBR), and Silicone (VMQ), referencing ASTM D2000 and ISO 3601 standards.

Viton® fluoroelastomers deliver exceptional resistance to high temperatures, aerospace fuels, hydraulic fluids, and aggressive chemicals. Continuous service is viable from -20°C to +204°C with intermittent peaks up to 232°C. Its saturated fluorocarbon backbone prevents swelling in non-polar media like jet fuels and mineral oils but exhibits vulnerability to ketones, amines, and hot hydrofluoric acid. Standard hardness ranges between 70–90 Shore A. This material is indispensable for aerospace, semiconductor, and chemical processing applications where failure is unacceptable.

Nitrile rubber remains the industry benchmark for cost-effective resistance to petroleum-based oils, greases, and aliphatic hydrocarbons. Operating effectively between -40°C and +121°C, NBR formulations adjust acrylonitrile (ACN) content to balance fuel resistance versus low-temperature flexibility. Typical hardness spans 50–90 Shore A. Limitations include poor ozone/weathering resistance and degradation in polar solvents like acetone or chlorinated hydrocarbons. NBR dominates automotive, hydraulics, and general industrial sealing where exposure involves engine oils or transmission fluids.

Silicone elastomers excel in extreme temperature stability from -55°C to +230°C and offer outstanding resistance to ozone, UV, and steam. Biocompatibility makes VMQ suitable for pharmaceutical and food-grade applications per FDA 21 CFR 177.2600. However, silicone exhibits low tensile strength, poor abrasion resistance, and susceptibility to swelling in petroleum derivatives. Standard hardness is 40–80 Shore A. Use cases include medical devices, bake ovens, and outdoor electrical insulation where thermal range outweighs mechanical demands.

The comparative specifications below guide material selection against application parameters

| Property | Viton® (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +204 | -40 to +121 | -55 to +230 |

| Fluid Resistance | Jet fuels, acids | Petroleum oils | Water, steam |

| Hardness Range (Shore A) | 70–90 | 50–90 | 40–80 |

| Tensile Strength (MPa) | 10–15 | 15–25 | 5–8 |

| Compression Set (ASTM D395) | <20% @ 200°C | <30% @ 100°C | <25% @ 200°C |

| Key Limitation | Ketones, amines | Ozone, polar solvents | Petroleum, tears |

Engineers must validate material compatibility against specific media, temperatures, and dynamic stresses. Suzhou Baoshida provides AS568 O-rings in all three compounds with full traceability to ASTM D2000 classification codes. Consult our technical team for application-specific formulation adjustments to optimize seal life in critical OEM systems. Material selection remains the cornerstone of reliable sealing—dimensions alone cannot compensate for compound mismatch.

Manufacturing Capabilities

Engineering Excellence in Precision Rubber Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and production of AS568 standard O-rings. With a dedicated team of five specialized mould engineers and two advanced formula engineers, we maintain full in-house control over the entire development cycle—from concept and material formulation to precision tooling and high-volume manufacturing. This integrated approach ensures that every product meets the exacting dimensional and performance standards required by global industries such as aerospace, automotive, and fluid power systems.

Our team of mould engineers brings over 60 combined years of experience in precision rubber mould design. They utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to develop highly accurate, multi-cavity moulds that ensure tight tolerances and consistent part geometry. Each AS568 O-ring mould is engineered to comply with the Aerospace Standard AS568C, which defines 369 standard sizes across inside diameter, cross-section, and tolerance bands. Our engineers optimize gating, venting, and parting line configurations to minimize flash and dimensional variation, ensuring that every O-ring meets ISO 3601 and SAE AS568 compliance requirements.

Complementing our mould expertise, our two rubber formulation engineers specialize in elastomer chemistry and material performance under extreme conditions. They develop custom and standard compounds tailored to meet specific application demands, including resistance to temperature extremes, ozone, UV, hydraulic fluids, and aggressive chemicals. Our formula development process includes rigorous testing for compression set, tensile strength, elongation, and hardness (Shore A), ensuring that each compound not only fits the AS568 size but also performs reliably in its intended environment.

We offer comprehensive OEM services, enabling clients to co-develop application-specific O-rings with full confidentiality and technical support. Our OEM process includes material selection, prototype tooling, first article inspection (FAI) reporting, and production scaling—all under ISO 9001-certified quality management systems. With rapid prototyping capabilities and a responsive engineering team, we reduce time-to-market while maintaining the highest standards of quality and repeatability.

The following table outlines key technical specifications we support under the AS568 standard:

| Parameter | Specification Range | Standard Compliance |

|---|---|---|

| AS568 Sizes Available | #001 to #949 | AS568C, ISO 3601 |

| Cross-Section (inches) | 0.040″ to 0.275″ | ±0.003″ to ±0.005″ tolerance |

| Inside Diameter (inches) | 0.029″ to 25.976″ | Per AS568C tables |

| Hardness Range (Shore A) | 40 to 90 | ASTM D2240 |

| Operating Temperature | -65°F to +450°F (-54°C to +232°C) | Material-dependent |

| Materials | NBR, EPDM, FKM, Silicone, CR, NR | ASTM D1418 |

Our engineering-driven approach ensures that Suzhou Baoshida delivers not just standard O-rings, but precision-engineered sealing solutions built for performance, reliability, and long-term durability.

Customization Process

AS568 Size Chart Customization: Precision Engineering Workflow

Suzhou Baoshida Trading Co., Ltd. implements a rigorously controlled customization process for AS568 standard O-rings, ensuring dimensional accuracy and material performance meet aerospace, automotive, and industrial fluid system demands. The AS568 standard defines 369 standardized sizes with strict cross-section and inner diameter tolerances; deviation compromises sealing integrity under pressure, temperature, or chemical exposure. Our four-phase workflow eliminates design-to-production risks through scientific validation.

Drawing Analysis

This phase mandates dimensional verification against AS568A specifications. Engineering cross-references client drawings to validate size code alignment, tolerance bands per AS568A Table 1, and application-specific requirements (e.g., groove dimensions per SAE AS4716). Critical parameters include cross-section tolerance (±0.004″ for sizes ≤0.139″), inner diameter limits, and surface finish (Ra ≤0.4 µm). Non-conformities trigger collaborative redesign with clients to prevent assembly failures or extrusion gaps.

Formulation

Material science drives compound development. Based on fluid compatibility (per ASTM D471), temperature range (-55°C to +230°C), and compression set targets (<20% per ASTM D395), our lab selects base polymers (FKM, EPDM, NBR) and additives. Shore A hardness is calibrated to AS568-specified ranges (e.g., 70±5 for standard aerospace grades). Each formulation undergoes spectrometry and rheometry to confirm cure kinetics, ensuring uniform cross-linking during molding.

Prototyping

Low-volume prototypes (5–10 units) are molded using precision transfer presses with cavity-specific tooling. Dimensional validation employs coordinate measuring machines (CMM) to verify AS568 tolerances at three radial points. Simultaneously, samples undergo accelerated aging, fluid immersion, and compression stress relaxation testing. Failure analysis identifies root causes—e.g., insufficient cure time causing excessive set—before tooling finalization.

Mass Production

Approved tooling enters ISO 9001-certified production with real-time SPC monitoring. Every lot undergoes 100% visual inspection and statistical dimensional sampling per ANSI/ASQ Z1.4. Cross-section and ID measurements are logged against AS568 benchmarks. Final validation includes traceable material certificates (ASTM D2000 line callouts) and package-level conformance to MIL-PRF-83248. This closed-loop system guarantees <0.1% defect rates in serial production.

AS568 Key Dimensional Specifications

| Size Code | Cross-Section (inches) | ID Tolerance (inches) | Application Example |

|———–|————————|————————|——————————|

| 101 | 0.040 ±0.003 | +0.007 / -0.000 | Fuel system connectors |

| 214 | 0.103 ±0.004 | +0.015 / -0.000 | Hydraulic actuators |

| 322 | 0.275 ±0.006 | +0.030 / -0.000 | Heavy equipment manifolds |

Suzhou Baoshida’s adherence to AS568 tolerancing—coupled with material formulation expertise—ensures O-rings perform reliably in critical sealing applications. Our process transforms client specifications into certified, production-ready components without dimensional or chemical compromise.

Contact Engineering Team

For industrial manufacturers and engineering teams requiring precision rubber components, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in delivering high-performance sealing solutions. Our expertise in industrial rubber technology ensures that every product, from custom-molded seals to standardized O-rings conforming to the AS568 size chart, meets exacting dimensional and material specifications. As a leading supplier in the global rubber components market, we combine rigorous quality control with responsive technical support to serve OEMs, automotive manufacturers, aerospace contractors, and industrial equipment producers.

The AS568 standard is a critical reference in the design and procurement of O-rings, defining 369 dash sizes across three cross-sectional diameters (1/16″, 3/32″, and 1/8″) with precise inside diameter tolerances. At Suzhou Baoshida, we maintain full compliance with this specification, enabling seamless interchangeability and reliable sealing performance across hydraulic, pneumatic, and static applications. Our inventory includes all standard AS568 sizes in multiple elastomer compounds, including Nitrile (NBR), Fluorocarbon (FKM/Viton®), Silicone (VMQ), Ethylene Propylene (EPDM), and Neoprene (CR), each selected for resistance to temperature extremes, chemical exposure, and mechanical stress.

To ensure optimal performance, we recommend verifying material compatibility with operating conditions such as fluid media, pressure cycles, and environmental exposure. Our engineering team provides technical consultation to assist in compound selection, hardness grading (ranging from 50 to 90 Shore A), and custom fabrication for non-standard configurations. Whether you require low-volume prototyping or high-volume production runs, our supply chain is optimized for on-time delivery and consistent dimensional accuracy.

Below is a representative sample of commonly used AS568 sizes and their dimensional specifications:

| Dash Size | Inside Diameter (in) | Cross Section (in) | Outside Diameter (in) | Volume (in³) |

|---|---|---|---|---|

| -001 | 0.029 | 0.040 | 0.109 | 0.0004 |

| -012 | 0.104 | 0.070 | 0.244 | 0.0018 |

| -102 | 0.489 | 0.070 | 0.629 | 0.0071 |

| -214 | 1.341 | 0.139 | 1.619 | 0.0356 |

| -326 | 3.094 | 0.280 | 3.654 | 0.1782 |

All dimensions are measured per AS568C revision standards, with tolerances adhering to ±0.003″ for inside diameter and ±0.002″ for cross section in standard-grade O-rings. Tighter tolerances are available for critical sealing applications.

For technical inquiries, material data sheets, or volume pricing on AS568-compliant O-rings, contact Mr. Boyce at [email protected]. As OEM Manager and Rubber Formula Engineer, Mr. Boyce leads our technical sales division, providing direct engineering support and customized elastomer formulation services. Suzhou Baoshida Trading Co., Ltd. is committed to delivering industrial rubber solutions that meet the highest standards of reliability, performance, and technical precision. Reach out today to discuss your sealing requirements and receive prompt, expert guidance tailored to your application.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).