Technical Contents

Engineering Guide: Walk In Freezer Gasket

Engineering Insight: Material Selection in Walk-In Freezer Gaskets

The performance and longevity of a walk-in freezer gasket are fundamentally determined by material selection. In industrial refrigeration environments, where temperatures can range from -40°C to 10°C and mechanical stress from repeated door cycling is constant, the rubber compound must exhibit exceptional resilience, low-temperature flexibility, and resistance to aging. Off-the-shelf gaskets, typically formulated with generic EPDM or low-grade PVC blends, often fail prematurely due to inadequate formulation and lack of application-specific engineering. These failures manifest as cracking, hardening, compression set, and loss of sealing integrity—leading to energy inefficiency, frost buildup, and potential contamination risks in food storage and pharmaceutical applications.

At Suzhou Baoshida Trading Co., Ltd., we emphasize precision compounding tailored to operational parameters. Standard gaskets may meet basic dimensional tolerances but lack the molecular stability required for sustained performance under thermal cycling and exposure to cleaning agents. For instance, conventional EPDM formulations may degrade when exposed to ozone or UV during routine sanitation, while inferior plasticizers in PVC-based seals migrate over time, causing embrittlement. These material shortcomings are not immediately apparent during installation but become critical after 12–18 months of service, resulting in unplanned maintenance and downtime.

Our engineered rubber seals utilize high-purity, peroxide-cured EPDM compounds with optimized plasticizer systems and anti-aging additives. This formulation ensures consistent flexibility down to -50°C, superior resistance to ozone and microbial growth, and minimal compression set after prolonged compression (≤15% after 22 hours at 70°C per ASTM D395). The result is a gasket that maintains a hermetic seal over thousands of door cycles and extended service life—critical for compliance with HACCP, FDA, and ISO 21469 standards in sensitive environments.

Material performance is further validated through rigorous testing protocols, including accelerated aging, cold flex testing, and tensile retention analysis. Each compound is batch-certified to ensure repeatability and traceability, a standard practice in precision rubber manufacturing but often overlooked in mass-market alternatives.

The table below outlines key material specifications of our engineered freezer gasket compound compared to typical off-the-shelf alternatives:

| Property | Baoshida Engineered EPDM | Standard Off-the-Shelf EPDM/PVC |

|---|---|---|

| Temperature Range | -50°C to +100°C | -30°C to +70°C |

| Hardness (Shore A) | 60 ± 5 | 55–70 (variable) |

| Tensile Strength | ≥10 MPa | 6–8 MPa |

| Elongation at Break | ≥350% | 200–250% |

| Compression Set (22h, 70°C) | ≤15% | 25–40% |

| Ozone Resistance | Excellent (no cracking at 50 pphm) | Moderate to Poor |

| Low-Temp Flexibility (Brittle Point) | -55°C | -35°C |

In critical cold chain infrastructure, the gasket is not a commodity component—it is a precision seal integral to system efficiency and safety. Choosing a scientifically formulated material ensures operational reliability, reduces lifecycle costs, and supports compliance in regulated industries. At Baoshida, we engineer every gasket as a system-critical element, not an afterthought.

Material Specifications

Material Specifications for Walk-In Freezer Gasket Performance

Selecting the optimal elastomer for walk-in freezer gasket applications is critical for ensuring long-term thermal efficiency, structural integrity, and operational safety in cold chain environments. The extreme low-temperature exposure, frequent door cycling, and potential contact with cleaning agents demand materials exhibiting exceptional low-temperature flexibility, resistance to compression set, and durability against environmental factors. At Suzhou Baoshida Trading Co., Ltd., our precision rubber seal engineering focuses on three primary compounds proven for freezer gasket duty: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct performance profiles tailored to specific operational demands and budgetary constraints within the cold storage sector.

Viton (Fluoroelastomer) represents the premium solution for the most demanding ultra-low-temperature freezers, particularly those operating below -40°C or in environments requiring stringent chemical resistance. Its molecular structure provides unparalleled resistance to refrigerants, oils, and aggressive cleaning solvents common in pharmaceutical or food processing facilities. Viton maintains flexibility down to -50°C and exhibits the lowest compression set of the three materials at cryogenic temperatures, ensuring the gasket reliably regains its shape after repeated compression cycles to maintain an airtight seal. While its raw material cost is significantly higher, the extended service life and reduced maintenance frequency in critical applications often justify the investment for OEM freezer manufacturers.

Nitrile (Acrylonitrile Butadiene Rubber) serves as the industry-standard workhorse for general-purpose commercial and industrial freezers operating down to approximately -40°C. It offers an excellent balance of low-temperature flexibility, good resistance to fats, oils, and water-based cleaning solutions, and cost-effectiveness. Standard high-acrylonitrile NBR formulations provide adequate performance for most walk-in freezer applications above -30°C. However, its glass transition temperature limits flexibility below -40°C, increasing the risk of cracking and seal failure in deep-freeze environments. Nitrile remains the most economical choice for standard freezer installations where extreme cold is not a factor, and our optimized formulations enhance its low-temperature resilience for broader applicability.

Silicone (Polysiloxane) excels where extreme flexibility across a very wide temperature range (-60°C to +200°C) and superior ozone/UV resistance are paramount. Its inherent low glass transition temperature ensures exceptional sealing force retention even at cryogenic temperatures, minimizing air infiltration. Silicone demonstrates outstanding resistance to ozone cracking, a critical factor for gaskets exposed to ambient air during door openings. While generally more expensive than Nitrile and less chemically resistant to oils than Viton, its flexibility and weathering characteristics make it ideal for freezers in locations with high ambient ozone levels or where wide operational temperature swings occur. Processing requires specific expertise, which our OEM manufacturing process rigorously controls.

The following table details the comparative technical specifications essential for informed material selection in walk-in freezer gasket design:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range | -50°C to +200°C | -40°C to +100°C | -60°C to +200°C |

| Compression Set (ASTM D395, 22h @ 70°C) | Excellent (Lowest) | Good | Very Good |

| Low Temp Flex (ASTM D1329) | Outstanding (-50°C) | Good (-40°C) | Excellent (-60°C) |

| Ozone Resistance | Excellent | Poor to Fair | Excellent |

| Oil/Fuel Resistance | Outstanding | Very Good | Poor |

| Water/Cleaning Solvent Resistance | Excellent | Good | Excellent |

| Typical Freezer Application | Ultra-low temp (<-40°C), Pharma, Chemical exposure | Standard commercial/industrial (-40°C to 0°C) | Wide temp swing, High ozone areas, Extreme flexibility need |

| Relative Cost Factor | Highest | Lowest | Medium to High |

Material selection must align precisely with the freezer’s operational parameters and lifecycle cost expectations. Suzhou Baoshida Trading Co., Ltd. leverages extensive rubber compounding expertise and OEM manufacturing capabilities to deliver gaskets meeting exacting global standards for cold chain integrity. Consult our engineering team for application-specific formulation optimization.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Seal Development for Walk-In Freezer Gaskets

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in precision rubber seals is anchored in deep material science expertise and advanced mold design proficiency. We maintain a dedicated team of five certified mold engineers and two specialized rubber formulation engineers, enabling full in-house control from concept to production. This integrated approach ensures that every walk-in freezer gasket we manufacture meets exacting performance standards for thermal efficiency, compression recovery, and long-term durability under extreme conditions.

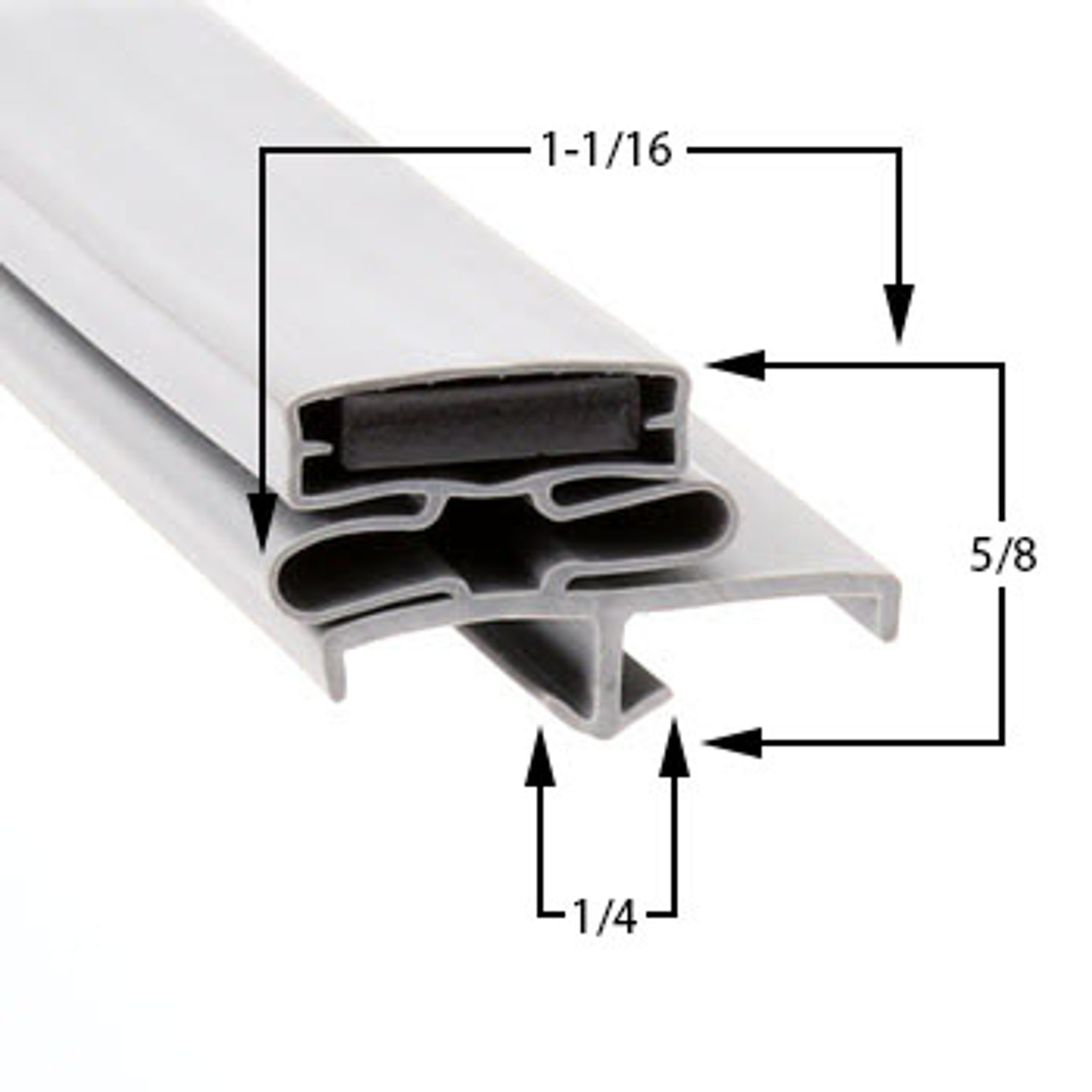

Our mold engineers utilize state-of-the-art CAD/CAM software, including SolidWorks and AutoCAD, to develop precision-engineered molds with tight tolerances (±0.1 mm). Each design undergoes rigorous simulation for flow dynamics, shrinkage prediction, and stress distribution, minimizing trial iterations and accelerating time-to-market. The team specializes in multi-cavity and family mold configurations, optimizing production efficiency while maintaining consistency across complex gasket profiles. With extensive experience in both injection and compression molding processes, our engineers ensure seamless scalability from prototype to high-volume manufacturing.

Complementing mold design is our proprietary rubber formulation capability. Our two formula engineers hold advanced degrees in polymer chemistry and have over 15 combined years of industrial R&D experience. They develop custom EPDM, silicone, and neoprene compounds tailored to the operational demands of commercial refrigeration systems. Key performance targets include low-temperature flexibility down to -50°C, ozone and UV resistance, and compliance with FDA and RoHS standards. Each formulation is subjected to accelerated aging tests, compression set analysis (ASTM D395), and thermal cycling validation to ensure reliability over 10+ year service life.

We offer full OEM support, including reverse engineering of legacy gaskets, 3D scanning of existing profiles, and performance benchmarking against original equipment specifications. Our engineering team collaborates directly with OEM clients to co-develop gasket solutions that enhance energy efficiency, reduce door closing force, and improve sealing integrity across variable temperature zones.

The following table outlines key technical specifications achievable through our engineering platform:

| Parameter | Standard Performance | Test Method |

|---|---|---|

| Temperature Range | -50°C to +120°C | ASTM D1329 |

| Compression Set (22 hrs, 70°C) | ≤20% | ASTM D395 |

| Tensile Strength | ≥8.0 MPa | ASTM D412 |

| Elongation at Break | ≥300% | ASTM D412 |

| Hardness (Shore A) | 55–75 | ASTM D2240 |

| Ozone Resistance | No cracking (200 pphm) | ASTM D1149 |

| Flame Retardancy | Optional (UL94 HF-1) | UL94 |

This combination of advanced tooling, material science, and OEM-centric development makes Suzhou Baoshida a trusted engineering partner for walk-in freezer gasket solutions in global commercial refrigeration markets.

Customization Process

Customization Process for Walk-In Freezer Gaskets

At Suzhou Baoshida Trading Co., Ltd., our customization process for walk-in freezer gaskets integrates material science with precision engineering to ensure optimal thermal sealing performance under extreme conditions. This four-phase workflow guarantees compliance with OEM specifications while addressing the unique challenges of commercial refrigeration environments.

Drawing Analysis

We initiate with rigorous dimensional and functional assessment of client-provided CAD drawings or physical samples. Critical parameters include door frame geometry, compression depth requirements, and installation clearance tolerances. Our engineers cross-reference these against ISO 3302-1 standards for rubber dimensional accuracy and validate thermal expansion coefficients relative to the freezer’s operational temperature range. Any discrepancies in sealing surface continuity or stress concentration points are flagged for collaborative redesign prior to material selection. This phase ensures the gasket geometry will maintain uniform contact pressure across the entire door perimeter after repeated cycling.

Formulation Development

Material selection is driven by the freezer’s minimum operating temperature and regulatory requirements. Our proprietary EPDM compounds dominate this segment due to exceptional low-temperature flexibility down to -50°C and ozone resistance. The rubber formula is engineered with precision filler ratios and crosslink density adjustments to achieve target hardness (65±5 Shore A) and compression set resistance. Critical additives include specialized antidegradants to prevent hardening during prolonged exposure to ammonia-based refrigerants. Every formulation undergoes ASTM D2000 classification validation, with compound certificates provided for traceability.

Prototyping & Validation

Prototype gaskets are extruded using production-grade tooling and subjected to accelerated lifecycle testing. We simulate 10,000 door cycles at -40°C while monitoring seal integrity via vacuum decay testing. Key performance metrics include compression set after 72 hours at low temperature and tensile retention after thermal aging. Prototypes failing to meet ≤15% compression set at -40°C undergo iterative compound refinement. Client approval requires documented evidence of compliance with all critical specifications prior to tooling sign-off.

Mass Production

Full-scale manufacturing leverages automated extrusion lines with real-time laser micrometry for dimensional control. Each batch undergoes inline hardness testing and visual inspection per AQL 1.0 standards. Final validation includes third-party certification for FDA 21 CFR 177.2600 compliance where food contact is required. We maintain lot traceability from raw material certificates through finished goods, with production data logs available for OEM audit.

Critical Performance Specifications

| Property | Target Value | Test Method | Criticality |

|---|---|---|---|

| Temperature Range | -50°C to +100°C | ASTM D1329 | Essential |

| Compression Set (72h) | ≤15% at -40°C | ASTM D395 Method B | Critical |

| Hardness (Shore A) | 65 ± 5 | ASTM D2240 | Essential |

| Tensile Strength | ≥10 MPa | ASTM D412 | Critical |

| Ozone Resistance | No cracks @ 50pphm | ASTM D1149 | Essential |

This structured methodology ensures every gasket delivers consistent energy efficiency and longevity, directly supporting our OEM partners’ reliability targets in demanding commercial freezer applications. Rigorous validation at each phase eliminates field failure risks while maintaining cost efficiency in high-volume production.

Contact Engineering Team

Contact Suzhou Baoshida for High-Performance Walk-In Freezer Gaskets

At Suzhou Baoshida Trading Co., Ltd., we specialize in the engineering and supply of precision rubber seals designed for demanding commercial and industrial refrigeration environments. Our walk-in freezer gaskets are manufactured to exacting standards, ensuring optimal thermal efficiency, airtight sealing, and long-term durability under extreme temperature cycling. As a trusted OEM partner, we combine advanced material science with rigorous quality control to deliver gasket solutions that meet or exceed original equipment specifications.

If you are sourcing reliable, high-performance freezer door seals for original equipment manufacturing, retrofit projects, or bulk replacement programs, our technical team is ready to support your requirements. We understand that even minor sealing inefficiencies can lead to significant energy loss, compressor strain, and premature system failure. That is why our gaskets are formulated using high-grade EPDM and silicone compounds, offering superior resistance to ozone, UV exposure, moisture, and temperature extremes ranging from -50°C to +150°C.

We offer custom molding capabilities for non-standard profiles, variable lengths, and application-specific durometer ratings. Whether you require magnetic insertion strips, multi-lip sealing geometries, or FDA-compliant materials for food service environments, Suzhou Baoshida delivers tailored solutions with fast turnaround and consistent batch-to-batch repeatability.

To ensure seamless integration into your production or maintenance workflow, we provide full technical documentation, material certifications (including RoHS and REACH compliance), and on-demand testing reports for tensile strength, compression set, and low-temperature flexibility.

For immediate assistance with product selection, sample requests, or volume pricing, contact Mr. Boyce, our dedicated OEM Account Manager. With over 15 years of experience in rubber sealant applications for refrigeration systems, Mr. Boyce provides technical guidance and responsive supply chain support to manufacturers across North America, Europe, and Southeast Asia.

Reach out today to discuss your walk-in freezer gasket needs and discover how Suzhou Baoshida can enhance the reliability and energy efficiency of your refrigeration units.

| Specification | Value |

|---|---|

| Material Options | EPDM, Silicone, Thermoplastic Rubber (TPR) |

| Temperature Range | -50°C to +150°C |

| Durometer (Shore A) | 40–80 ±5 |

| Compression Set (22 hrs, 70°C) | ≤20% |

| Tensile Strength | ≥7.5 MPa |

| Elongation at Break | ≥250% |

| Color Options | Black, White, Gray, Custom (Pantone Match) |

| Custom Profiles | Available (CAD/3D Model Support) |

| Certifications | RoHS, REACH, FDA (select grades) |

Contact Mr. Boyce directly at [email protected] to request samples, technical data sheets, or a customized quotation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).