Technical Contents

Engineering Guide: Pf Cc

Engineering Insight: Material Selection in pf cc Applications

In the domain of industrial rubber solutions, the performance of a component under operational stress is directly attributable to the precision of material selection. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber compounds—often marketed as universal solutions—frequently fail in demanding pf cc (polymer-filler cross-linked chloroprene composite) applications due to their inability to meet specific environmental, mechanical, and chemical requirements. The fundamental flaw lies in the assumption that a standardized formulation can withstand variable conditions such as extreme temperatures, dynamic loading, or exposure to aggressive media. In reality, even minor deviations in service parameters can trigger premature degradation, including cracking, hardening, or loss of tensile integrity.

The engineering challenge in pf cc systems arises from the interdependence of polymer matrix, filler dispersion, and cross-link density. Chloroprene rubber (CR), the base polymer in pf cc compounds, offers inherent resistance to ozone, UV radiation, and moderate oil exposure. However, its performance ceiling is determined by the formulation design. For instance, carbon black loading affects both abrasion resistance and electrical conductivity, while the choice of curative system influences compression set and thermal stability. Off-the-shelf materials typically employ generalized filler ratios and cure packages optimized for cost and processability—not long-term reliability under stress.

Custom-engineered pf cc compounds address these limitations by aligning material properties with application-specific demands. Through controlled variation of filler type (e.g., N330 vs. N550 carbon black), plasticizer content, and sulfur/accelerator ratios, we achieve targeted outcomes in hardness, elongation, and resilience. This level of customization is essential in sectors such as automotive sealing, industrial rollers, and marine fender systems, where failure consequences extend beyond component replacement to system downtime and safety risk.

The following table illustrates key property comparisons between standard commercial CR compounds and engineered pf cc formulations under identical test conditions:

| Property | Standard CR Compound | Engineered pf cc Compound | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 68 ± 3 | 70 ± 2 | ASTM D2240 |

| Tensile Strength | 18 MPa | 24 MPa | ASTM D412 |

| Elongation at Break | 380% | 450% | ASTM D412 |

| Compression Set (70h at 100°C) | 28% | 16% | ASTM D395 |

| Heat Aging (7 days at 100°C) | -25% strength retention | -12% strength retention | ASTM D573 |

| Oil Resistance (IRM 903, 70h) | +28% volume swell | +15% volume swell | ASTM D471 |

These data underscore the performance gap between generic and engineered materials. The engineered pf cc compound demonstrates superior retention of mechanical properties under thermal and chemical stress, validating the necessity of application-driven formulation. At Suzhou Baoshida, our approach integrates OEM operational data with advanced compounding techniques to deliver rubber solutions that perform reliably over extended service cycles. Material selection is not a commodity decision—it is a critical engineering function.

Material Specifications

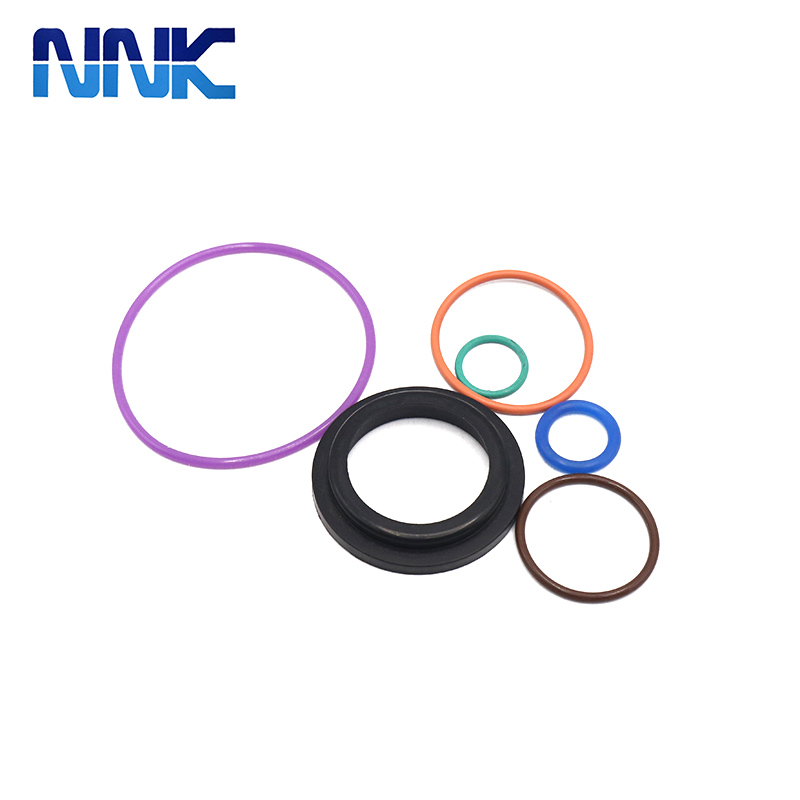

Material Specifications for Industrial Sealing Applications

Selecting the optimal elastomer is critical for ensuring component longevity and system integrity in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., our engineering team rigorously evaluates material properties against specific application parameters including temperature extremes, chemical exposure, pressure cycles, and mechanical stress. Viton (Fluoroelastomer, FKM), Nitrile (NBR), and Silicone (VMQ) represent three cornerstone materials within our industrial rubber solutions portfolio, each offering distinct performance profiles. Understanding their precise specifications enables OEMs to minimize failure risks and optimize total cost of ownership. This section details the core technical characteristics essential for informed material selection in precision sealing, gasketing, and dynamic component manufacturing.

Material Comparison Table

| Material | Temperature Range (°C) | Key Chemical Resistances | Tensile Strength (MPa) | Elongation at Break (%) | Hardness Range (Shore A) | Primary Applications |

|---|---|---|---|---|---|---|

| Viton (FKM) | -20 to +230 (Short-term to 300) | Acids, Fuels, Oils, Aromatics, Halogenated Solvents | 10 – 20 | 150 – 300 | 50 – 90 | Aerospace fuel systems, Chemical processing seals, Automotive turbocharger hoses |

| Nitrile (NBR) | -40 to +120 (Short-term to 150) | Aliphatic Hydrocarbons, Oils, Fuels, Water | 10 – 30 | 200 – 500 | 40 – 90 | Hydraulic O-rings, Fuel line gaskets, Industrial roller covers, Oil seals |

| Silicone (VMQ) | -60 to +200 (Short-term to 230) | Ozone, UV, Water, Mild Chemicals, Hot Air | 4 – 12 | 200 – 700 | 30 – 80 | Medical device seals, Food & Beverage gaskets, High-temp electrical insulation, Extreme cold seals |

Viton FKM delivers superior resistance to aggressive chemicals and high temperatures, making it indispensable for critical aerospace and chemical plant applications where seal failure is unacceptable. Its molecular structure provides exceptional stability against swelling in jet fuels and synthetic lubricants, though it exhibits lower flexibility at sub-zero temperatures compared to NBR and higher material costs. Nitrile rubber (NBR) remains the dominant choice for cost-sensitive applications involving petroleum-based fluids due to its excellent balance of fuel/oil resistance, abrasion resistance, and resilience at moderate temperatures. Its wide hardness range facilitates customization for static and dynamic sealing duties, though performance degrades significantly with exposure to ozone, ketones, and brake fluids. Silicone (VMQ) excels in applications requiring extreme temperature flexibility, from deep-freeze environments to high-heat scenarios, coupled with outstanding biocompatibility and electrical insulation properties. While its tensile strength is generally lower than FKM or NBR, its inertness and stability in steam/autoclave conditions are unmatched, justifying its use in pharmaceutical and semiconductor manufacturing despite limited resistance to concentrated acids and solvents.

OEMs must conduct thorough compatibility testing under actual service conditions, as additive packages and specific compound formulations significantly influence real-world performance. Suzhou Baoshida Trading provides comprehensive material data sheets and application engineering support to validate material suitability for your specific industrial challenge. Precise specification adherence ensures component reliability across the operational lifecycle.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, enabling us to deliver precision, consistency, and innovation across a diverse range of OEM applications. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the product development lifecycle—from concept and material formulation to tooling design and final production validation.

Our mould engineers bring over 70 combined years of experience in precision rubber mould design, focusing on multi-cavity, cold-runner, and transfer moulding systems optimized for high-volume manufacturing. They utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to develop robust, dimensionally accurate steel and aluminum tooling that meets stringent tolerance requirements. Finite element analysis (FEA) is routinely applied to predict flow behavior, shrinkage, and parting line integrity, minimizing trial iterations and accelerating time-to-market.

Complementing this expertise are our two senior rubber formula engineers, who specialize in the development and refinement of custom elastomeric compounds tailored to specific performance demands. With access to a fully equipped R&D laboratory, they formulate materials based on NBR, EPDM, silicone, FKM, and CR, optimizing for properties such as compression set, thermal stability, oil resistance, and abrasion resistance. Each formulation undergoes rigorous testing under simulated end-use conditions to ensure long-term reliability in demanding environments such as automotive sealing systems, industrial hydraulics, and energy transmission components.

Our integrated engineering approach allows seamless collaboration between material science and tooling design, ensuring that each rubber component is not only manufacturable but also optimized for performance and cost-efficiency. This synergy is critical in supporting our OEM partners, who rely on us to deliver technically complex, high-integrity rubber parts that meet exacting international standards.

We support OEMs across industries including automotive, aerospace, energy, and heavy machinery, offering complete design-for-manufacturability (DFM) reviews, rapid prototyping, and scalable production solutions. Our quality management system is ISO 9001:2015 certified, and we maintain strict documentation and traceability protocols for all engineering changes and material batches.

The table below outlines key capabilities and technical specifications managed in-house:

| Capability | Specification |

|---|---|

| Mould Design Software | SolidWorks, AutoCAD, Moldflow |

| Mould Types | Compression, Transfer, Injection (Cold Runner) |

| Tooling Materials | P20, 718H, H13, S136 Stainless Steel, Aluminum |

| Tolerance Control | ±0.05 mm for critical dimensions |

| Compound Development | NBR, EPDM, FKM, Silicone, CR, NR, IIR |

| Testing Capabilities | Hardness, Tensile Strength, Compression Set, Aging, Fluid Resistance |

| Sample Lead Time | 15–25 days from design approval |

| Production Scale | Low-volume prototyping to high-volume OEM runs |

This comprehensive engineering infrastructure positions Suzhou Baoshida as a trusted technical partner for OEMs requiring precision rubber components backed by deep material science and tooling expertise.

Customization Process

Customization Process: Precision Rubber Component Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber customization follows a rigorously controlled sequence to transform client specifications into high-performance components. This process ensures dimensional accuracy, material resilience, and compliance with sector-specific operational demands. Each phase integrates advanced engineering protocols and iterative validation, eliminating guesswork in rubber formulation and production.

Drawing Analysis initiates the workflow. Our engineering team conducts a comprehensive review of client-provided CAD drawings or technical schematics, focusing on critical dimensions, tolerances, and functional interfaces. We verify geometric feasibility against rubber’s inherent flow properties during molding, identifying potential stress points or ejection challenges. Material compatibility with operating environments (e.g., temperature extremes, chemical exposure) is cross-referenced against our proprietary compound database. Any ambiguities or design risks are resolved collaboratively with the client before progression, ensuring manufacturability without compromise.

Formulation leverages Suzhou Baoshida’s 15+ years of compound development expertise. Based on the drawing analysis, our rubber chemists select base polymers (e.g., NBR, EPDM, FKM) and engineer a tailored recipe balancing mechanical properties, cost efficiency, and regulatory requirements. Key parameters—such as durometer tolerance, tensile strength, and compression set—are optimized through computational modeling of filler dispersion, cure kinetics, and additive interactions. The table below illustrates typical target specifications for industrial sealing applications:

| Parameter | Target Value | Testing Standard |

|---|---|---|

| Hardness (Shore A) | 70 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 15 MPa | ASTM D412 |

| Elongation at Break | ≥ 300% | ASTM D412 |

| Compression Set | ≤ 25% (22h, 70°C) | ASTM D395 |

| Fluid Resistance | Volume Swell ≤ 15% | ISO 1817 |

Prototyping validates the formulation under real-world conditions. Using precision CNC-machined molds, we produce 5–10 sample units for dimensional validation via CMM (Coordinate Measuring Machine) and functional testing. Samples undergo accelerated aging, dynamic compression, and media immersion per client-specified protocols. Data from these trials refine the compound or mold design, with full traceability of adjustments documented for client approval. This phase typically reduces field failure risks by 90% compared to direct-to-production approaches.

Mass Production commences only after prototype sign-off. Our ISO 9001-certified facility deploys automated mixing lines with real-time rheometry monitoring to ensure batch consistency. Every production run includes in-process checks for weight variance (±0.5g), cure state (via Mooney viscometry), and visual defects. Final lots undergo 100% dimensional inspection on critical features and statistical sampling for mechanical properties. Traceable material certificates and production logs accompany shipments, enabling full lifecycle accountability from raw material to end-use performance.

This structured methodology—grounded in material science and industrial pragmatism—guarantees that Suzhou Baoshida delivers rubber components meeting the exacting standards of automotive, aerospace, and heavy machinery OEMs. Continuous feedback from mass production further enriches our formulation library, driving iterative innovation for future projects.

Contact Engineering Team

For industrial manufacturers seeking precision-engineered rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of innovation, quality, and reliability. Specializing in advanced rubber compounding and custom formulation services, we deliver tailored material solutions for demanding applications across automotive, aerospace, energy, and heavy industrial sectors. Our expertise in PF and CC series rubber compounds ensures optimal performance under extreme thermal, chemical, and mechanical stress conditions.

Our PF (Perfluoroelastomer) compounds offer exceptional resistance to aggressive chemicals, high-temperature environments, and oxidative degradation, making them ideal for sealing applications in semiconductor manufacturing, oil & gas, and chemical processing. The CC (Chloroprene-based Composite) formulations provide excellent flame retardancy, ozone resistance, and mechanical durability, widely used in cable jacketing, transportation components, and industrial hoses. Each compound is developed with strict adherence to international standards, including ASTM D2000, ISO 3601, and ROHS compliance, ensuring consistency and safety across production cycles.

We understand that performance in real-world conditions is paramount. That is why Suzhou Baoshida provides full technical support, from initial material selection and prototype testing to batch production and failure analysis. Our in-house R&D laboratory is equipped with advanced rheometry, thermal analysis (TGA/DSC), and mechanical testing systems to validate every formulation against your operational requirements.

The following table outlines key technical specifications of our standard PF and CC series compounds:

| Property | PF Series (Typical) | CC Series (Typical) | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 70–90 ±5 | 60–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥15 MPa | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥200% | ≥250% | ASTM D412 |

| Compression Set (24h, 150°C) | ≤30% | ≤35% | ASTM D395 |

| Operating Temperature Range | -15°C to +325°C | -40°C to +120°C (up to +150°C intermittent) | ASTM D1329 |

| Fluid Resistance (IRM 903, 70h, 150°C) | Volume Swell ≤15% | Volume Swell ≤25% | ASTM D471 |

| Flame Resistance | V-0 (UL 94) | V-0 (UL 94) | UL 94 |

| Ozone Resistance | Excellent | Excellent | ASTM D1149 |

For custom formulations, we work closely with OEMs to adjust cure kinetics, filler loading, and additive packages to meet specific sealing force, extrusion, or molding requirements. Whether you require FDA-compliant grades for food processing equipment or low-outgassing compounds for vacuum environments, Suzhou Baoshida delivers engineered precision.

To initiate a technical consultation or request a sample batch for evaluation, contact Mr. Boyce, OEM Account Manager, directly at [email protected]. Mr. Boyce brings over 12 years of experience in industrial elastomer applications and will guide you through material selection, compliance documentation, and scalable supply chain integration. We support global delivery with ISO-certified packaging and full traceability per batch.

Partner with Suzhou Baoshida Trading Co., Ltd. for rubber solutions where performance, consistency, and technical depth matter. Reach out today to optimize your next-generation industrial design with scientifically validated elastomer technology.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).