Technical Contents

Engineering Guide: Rubber Seal Manufacturer

Engineering Insight: The Critical Role of Material Selection in Precision Rubber Seals

In the field of industrial sealing solutions, material selection is not merely a design consideration—it is the foundation of performance, longevity, and system reliability. As a trusted rubber seal manufacturer, Suzhou Baoshida Trading Co., Ltd. emphasizes that off-the-shelf elastomer components frequently fail in demanding environments due to inadequate material compatibility with operational conditions. These failures often manifest as premature degradation, leakage, extrusion, or loss of sealing force—issues that are preventable through precise material engineering.

Standard rubber seals, typically fabricated from generic compounds such as SBR or low-grade NBR, are designed for broad applicability rather than specific performance. While cost-effective for low-stress applications, they lack the tailored resistance required in environments involving extreme temperatures, aggressive chemicals, high pressure, or dynamic mechanical stress. For example, exposure to hydraulic fluids, aromatic hydrocarbons, or ozone can rapidly degrade unsuitable elastomers, leading to cracking, swelling, or hardening. In contrast, engineered materials like FKM, EPDM, or HNBR provide targeted resistance profiles that align with the chemical and thermal demands of the application.

At Suzhou Baoshida, we approach material selection as a science-driven process. Each sealing application is evaluated based on fluid type, temperature range, pressure load, compression set requirements, and dynamic movement. This enables us to match the optimal elastomer formulation to the operational environment, ensuring long-term integrity and minimizing total cost of ownership. Custom compounding allows for fine-tuning of hardness, tensile strength, and resilience—parameters that directly affect seal performance and service life.

The failure of off-the-shelf seals often stems from a one-size-fits-all approach that neglects these variables. A seal that performs adequately during initial testing may degrade within weeks under real-world conditions if the base polymer is not chemically resistant or thermally stable. In critical systems such as hydraulic cylinders, pneumatic actuators, or automotive powertrains, such failures can lead to costly downtime, safety hazards, and reputational damage.

To illustrate the performance variance across elastomers, the following table outlines key material properties relevant to industrial sealing applications.

| Material | Temperature Range (°C) | Fluid Resistance | Compression Set | Typical Applications |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 (+125 short-term) | Good for oils, fuels | Moderate | General-purpose hydraulic seals |

| FKM (Viton®) | -20 to +200 (+250 short-term) | Excellent for oils, acids, fuels | Excellent | Aerospace, automotive, chemical processing |

| EPDM | -50 to +150 | Excellent for water, steam, brake fluids | Good | HVAC, water systems, steam valves |

| HNBR | -40 to +150 (+170 short-term) | Very good for oils, ozone | Excellent | Automotive timing belts, oilfield equipment |

| Silicone | -60 to +200 | Poor for hydrocarbons | Fair | Electrical insulation, food-grade seals |

Material selection is not a compromise between cost and performance—it is an investment in reliability. As a precision rubber seal manufacturer, Suzhou Baoshida Trading Co., Ltd. is committed to delivering engineered solutions that exceed the limitations of generic alternatives.

Material Specifications

Material Specifications for Precision Rubber Seals

As a leading OEM partner in precision rubber sealing solutions, Suzhou Baoshida Trading Co., Ltd. prioritizes material science rigor to ensure optimal performance across industrial applications. Our engineering team meticulously selects elastomers based on chemical exposure, thermal demands, and mechanical stress parameters. Below we detail critical specifications for Viton (FKM), Nitrile (NBR), and Silicone (VMQ), the cornerstone materials for high-integrity seals in automotive, aerospace, and fluid handling systems. All formulations comply with ASTM D2000 and ISO 37 standards, with custom compounding available to meet stringent OEM requirements.

Viton (FKM) delivers exceptional resistance to aggressive chemicals, including fuels, oils, and acids, due to its 66% fluorine content. It operates reliably from -20°C to +230°C continuous service temperature, with short-term peaks up to 300°C. Its low gas permeability and outstanding ozone/weathering resistance make it ideal for aerospace fuel systems and chemical processing seals. Compression set values remain below 25% after 70 hours at 200°C, ensuring long-term sealing force retention.

Nitrile (NBR) remains the industry standard for petroleum-based fluid applications, offering cost-effective resilience in hydraulic and automotive fuel systems. With acrylonitrile content ranging from 34% to 45%, it balances oil resistance and low-temperature flexibility. Standard grades function from -30°C to +120°C, though hydrogenated variants (HNBR) extend this to +150°C. NBR exhibits excellent abrasion resistance and tensile strength but requires careful evaluation for ozone exposure in outdoor installations.

Silicone (VMQ) excels in extreme temperature applications, maintaining elasticity from -60°C to +200°C. Its biocompatibility and FDA compliance suit medical and food-grade seals, while inherent flame resistance benefits aerospace interiors. Though limited in fuel/oil resistance, silicone provides superior electrical insulation and UV stability. Specialized fluorosilicone (FVMQ) grades enhance hydrocarbon resistance while retaining wide thermal range.

The comparative analysis below summarizes key performance metrics for rapid OEM material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 12–20 | 15–25 | 5–12 |

| Compression Set (70°C/22h) | ≤25% | ≤20% | ≤20% |

| Fuel Resistance | Excellent | Good | Poor |

| Acid Resistance | Excellent | Fair | Fair |

| Ozone Resistance | Excellent | Poor | Excellent |

| Key Applications | Jet fuel systems, chemical pumps | Hydraulic seals, O-rings | Medical devices, oven gaskets |

Suzhou Baoshida’s OEM engineering team collaborates with clients to validate material selection against specific fluid compatibility charts and dynamic stress conditions. We provide full traceability via material test reports (MTRs) and accelerated aging data per ASTM D573. For critical applications, our formula development lab tailors durometer (50–90 Shore A), filler systems, and cure chemistry to exceed operational lifespans. Partner with us to transform material specifications into sealing reliability.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our precision rubber seal manufacturing process. With a dedicated team comprising five experienced mould engineers and two specialized rubber formula engineers, we deliver technically robust, application-specific sealing solutions tailored to meet the exacting demands of global OEMs. Our integrated engineering approach ensures seamless alignment between material science, tooling design, and production scalability.

Our two in-house rubber formula engineers possess deep expertise in polymer chemistry and elastomer compounding. They are responsible for developing custom rubber formulations that meet precise performance criteria such as temperature resistance, chemical compatibility, compression set, and mechanical durability. Whether the application demands silicone for high-temperature environments, FKM for aggressive chemical exposure, or EPDM for weather resistance, our formulation team optimizes each compound to deliver consistent performance under real-world operating conditions. This level of material control allows us to support OEMs in industries ranging from automotive and aerospace to medical devices and industrial machinery.

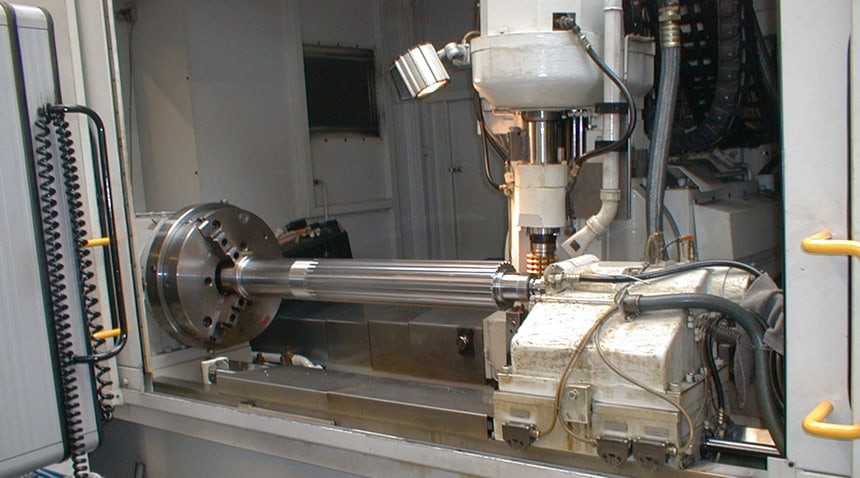

Complementing our formulation expertise, our five mould engineers bring advanced precision to the tooling phase. Utilizing state-of-the-art CAD/CAM software, including SolidWorks and AutoCAD, they design and refine moulds with micron-level accuracy. Their deep understanding of flow dynamics, shrinkage behavior, and demoulding mechanics ensures high repeatability, minimal flash, and extended tool life. All moulds undergo rigorous validation through prototype testing and dimensional inspection before moving to full-scale production.

Our OEM capabilities are built on a foundation of technical collaboration and confidentiality. We work directly with client engineering teams to co-develop seals from concept to mass production. This includes design for manufacturability (DFM) reviews, prototype sampling, material qualification, and full documentation traceability. Our facility supports both small-batch custom runs and high-volume production, with full process control through SPC and First Article Inspection (FAI) protocols.

The integration of material formulation and precision tooling enables us to consistently achieve tight tolerances and superior part consistency. Below are typical performance specifications achievable across our product lines.

| Property | Typical Range | Test Standard |

|---|---|---|

| Hardness (Shore A) | 30–90 | ASTM D2240 |

| Tensile Strength | 8–22 MPa | ASTM D412 |

| Elongation at Break | 200–600% | ASTM D412 |

| Compression Set (70h, 70°C) | ≤25% | ASTM D395 |

| Operating Temperature | -40°C to +250°C (material dependent) | — |

| Dimensional Tolerance (mm) | ±0.05 to ±0.2 | ISO 3302-1 (Class M2–M3) |

This engineering synergy—between compound development and precision moulding—positions Suzhou Baoshida as a trusted technical partner for OEMs requiring reliable, high-performance rubber seals.

Customization Process

Precision Rubber Seal Customization Process: From Concept to Production

At Suzhou Baoshida Trading Co., Ltd., our customization process for precision rubber seals integrates rigorous engineering protocols with OEM-centric collaboration. This methodology ensures seamless translation of client specifications into high-performance sealing solutions, adhering strictly to ISO 3601 and ASTM D2000 standards. The process comprises four interdependent phases, each validated through cross-functional engineering reviews.

Drawing Analysis initiates the workflow. Our engineering team conducts a comprehensive assessment of client-provided technical drawings, focusing on critical dimensions, geometric tolerances (GD&T), and surface finish requirements. We verify sealing interface compatibility, compression set parameters, and environmental exposure conditions. Any ambiguities in material callouts or functional constraints trigger immediate client consultation to prevent downstream deviations. This phase culminates in a formal drawing approval, locking critical-to-quality (CTQ) attributes for subsequent stages.

Formulation Development leverages Suzhou Baoshida’s proprietary material science database. Based on the validated drawing requirements, our rubber formula engineers select polymer backbones (e.g., NBR, FKM, EPDM) and optimize compound composition. Key variables include filler reinforcement, plasticizer selection, and cure system kinetics to achieve target compression set, tensile strength, and fluid resistance. The table below illustrates typical formulation adjustments for common industrial scenarios:

| Material Type | Hardness Range (Shore A) | Temperature Resistance (°C) | Fluid Compatibility |

|---|---|---|---|

| Standard NBR | 50–90 | -30 to +120 | Oils, water, aliphatic hydrocarbons |

| High-Acrylate FKM | 60–85 | -20 to +200 | Aggressive fuels, brake fluids, acids |

| Peroxide-Cured EPDM | 55–80 | -50 to +150 | Steam, polar solvents, phosphate esters |

Prototyping employs precision compression or injection molding under controlled conditions mirroring mass production tooling. Prototypes undergo accelerated aging tests per ASTM D573, fluid immersion per ISO 1817, and dynamic sealing performance validation. Dimensional conformity is verified via CMM (Coordinate Measuring Machine) against the approved drawing. Client feedback on prototype functionality typically necessitates ≤2 iterative refinements before final sign-off.

Mass Production commences only after formal prototype approval. Suzhou Baoshida implements statistical process control (SPC) with real-time monitoring of cure time, mold temperature, and material batch consistency. Every production lot undergoes 100% visual inspection and抽样 (sampling) per ANSI/ASQ Z1.4 for critical dimensions. Full traceability—from raw material certificates to final test reports—is maintained via our ERP system, ensuring compliance with automotive IATF 16949 and aerospace AS9100 requirements.

This structured approach minimizes time-to-market while guaranteeing that every seal meets the exact operational demands of hydraulic systems, automotive powertrains, or industrial machinery. Suzhou Baoshida’s engineering rigor transforms client specifications into failure-resistant sealing performance, backed by OEM-level quality accountability.

Contact Engineering Team

For over a decade, Suzhou Baoshida Trading Co., Ltd. has stood at the forefront of precision rubber seal manufacturing, serving global industries with engineered elastomeric solutions that meet the most stringent performance demands. Our expertise lies in the development and production of custom rubber seals for automotive, aerospace, industrial machinery, medical devices, and fluid handling systems. With advanced compounding technology, in-house tooling capabilities, and rigorous quality control protocols, we ensure every seal delivers optimal resilience, chemical resistance, and dimensional accuracy under extreme operating conditions.

Our engineering team specializes in material selection across a broad spectrum of elastomers, including Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), Silicone (VMQ), Fluorocarbon (FKM), and Butyl (IIR), tailored precisely to your application’s temperature range, media exposure, and mechanical stress requirements. Whether you require static or dynamic sealing solutions, low-temperature flexibility, or resistance to aggressive fluids such as oils, fuels, or sterilization agents, Suzhou Baoshida provides scientifically validated formulations and precision molding processes to exceed expectations.

We understand that in high-performance environments, seal failure is not an option. That is why our manufacturing process integrates ISO 9001-certified quality systems, real-time process monitoring, and comprehensive post-production testing—including compression set, tensile strength, hardness, and volume swell analysis—to guarantee consistency and reliability across every production batch.

Below is a representative specification range for our standard high-performance rubber seals:

| Property | NBR | EPDM | FKM | VMQ |

|---|---|---|---|---|

| Temperature Range (°C) | -30 to +125 | -50 to +150 | -20 to +200 | -60 to +200 |

| Fuel/Oil Resistance | Excellent | Poor | Excellent | Good |

| Ozone/UV Resistance | Fair | Excellent | Excellent | Excellent |

| Compression Set (22 hrs, 150°C) | ≤25% | ≤20% | ≤15% | ≤20% |

| Hardness Range (Shore A) | 50–90 | 50–85 | 60–90 | 40–80 |

All compounds can be customized to meet ASTM D2000 or OEM-specific material specifications. We support rapid prototyping, DFM analysis, and full-scale production with short lead times and competitive unit pricing.

To ensure seamless collaboration and technical alignment, we invite direct engagement with our lead engineer and OEM account manager, Mr. Boyce. With extensive experience in rubber formulation and industrial sealing applications, Mr. Boyce serves as the primary technical liaison for all custom development projects and high-volume manufacturing programs.

For immediate assistance, technical consultation, or to request a material data sheet and sample kit, please contact Mr. Boyce at [email protected]. We respond to all inquiries within 12 business hours and offer virtual engineering meetings to review drawings, performance requirements, and production timelines. At Suzhou Baoshida, we are committed to delivering not just rubber seals—but engineered sealing performance that enhances your product reliability and operational efficiency. Reach out today to begin your next precision sealing solution.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).