Technical Contents

Engineering Guide: Led Strip Diffuser Flexible

Engineering Insight: Material Selection in LED Strip Diffuser Flexibility

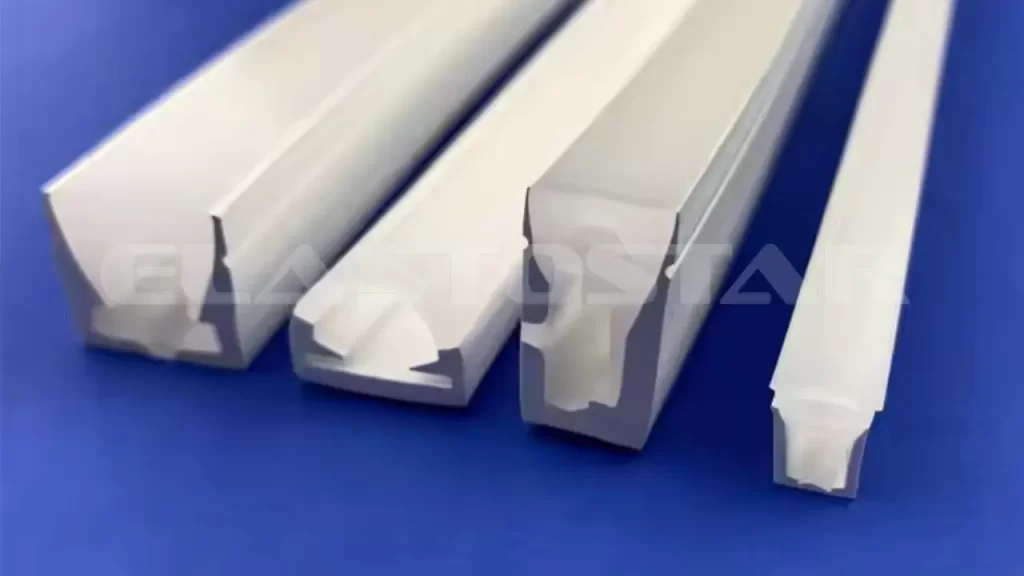

In the precision-driven domain of industrial lighting solutions, the performance of an LED strip diffuser is not solely determined by optical design—it hinges critically on material science. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf diffuser profiles, while cost-attractive, frequently fail under real-world operational conditions due to inadequate material selection. These failures manifest as yellowing, warping, reduced light transmission, and mechanical degradation, particularly in environments exposed to thermal cycling, UV radiation, or chemical contaminants.

The core issue lies in the polymer matrix. Standard diffusers often employ low-grade polycarbonate (PC) or polymethyl methacrylate (PMMA) without proper stabilization. These materials may offer initial clarity and flexibility, but they lack the molecular resilience required for sustained performance. For instance, unstabilized PC undergoes photo-oxidative degradation when exposed to UV light, leading to discoloration and embrittlement. Similarly, PMMA exhibits poor impact resistance and thermal stability, limiting its use in high-intensity or elevated-temperature applications.

In contrast, engineered thermoplastic elastomers (TPE) and modified silicone-rubber composites provide superior balance between optical diffusion, mechanical flexibility, and environmental resistance. These materials are formulated with UV absorbers, thermal stabilizers, and light-scattering additives that maintain optical integrity over extended service life. Moreover, their inherent flexibility allows for seamless integration into curved or irregular mounting surfaces—critical in architectural and industrial design.

A key differentiator is the diffusion mechanism. Homogeneous dispersion of diffusing agents within the polymer matrix ensures uniform luminance without hotspots. Off-the-shelf solutions often rely on surface texturing alone, which degrades with abrasion and offers inconsistent light distribution. In contrast, volume-diffused profiles made from high-performance rubber-modified polymers deliver consistent photometric performance across variable operating conditions.

We validate material performance through accelerated aging tests, including 1,000-hour UV exposure (per ISO 4892-2), thermal cycling from -40°C to 85°C, and humidity resistance at 85% RH. Only materials sustaining >90% light transmission and <5% dimensional change under these conditions are approved for production.

The following table outlines comparative material performance for LED strip diffuser applications:

| Material | Light Transmission (%) | Operating Temp Range (°C) | UV Resistance | Flexural Modulus (MPa) | Yellowing Index (after 1k hrs UV) |

|---|---|---|---|---|---|

| Standard PMMA | 92 | -20 to 70 | Low | 3,000 | 18.5 |

| Standard PC | 88 | -40 to 110 | Moderate | 2,400 | 12.3 |

| Modified TPE-Rubber Composite | 85 | -50 to 120 | High | 800 | 4.1 |

| Silicone-PC Hybrid | 87 | -60 to 150 | Very High | 600 | 2.8 |

Material selection is not a compromise between cost and quality—it is a strategic engineering decision that defines product reliability. At Suzhou Baoshida, we prioritize formulation precision to ensure our diffusers meet the mechanical, thermal, and optical demands of industrial applications where failure is not an option.

Material Specifications

Material Specifications for LED Strip Diffuser Applications

Selecting the optimal elastomer for LED strip diffusers requires rigorous evaluation of thermal stability, optical clarity, mechanical resilience, and chemical compatibility. At Suzhou Baoshida Trading Co., Ltd., we prioritize materials that maintain structural integrity under continuous thermal cycling while ensuring uniform light diffusion. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent industry-standard solutions, each engineered for distinct operational environments. Viton excels in high-temperature resistance and hydrocarbon exposure, making it suitable for industrial lighting in automotive or chemical processing settings. Nitrile offers cost-effective resilience against oils and fuels but exhibits limitations in UV and extreme-temperature stability. Silicone delivers superior optical transmission and flexibility across broad temperature ranges, ideal for precision architectural or medical-grade lighting where clarity and longevity are non-negotiable. All materials undergo stringent ASTM D2000 testing for compression set, tensile strength, and elongation to guarantee OEM compliance.

Material Comparison Table

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +250 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 10–15 | 15–25 | 6–12 |

| Elongation at Break (%) | 150–300 | 200–500 | 400–800 |

| Hardness (Shore A) | 50–90 | 40–90 | 30–80 |

| Optical Clarity | Translucent (60–70%) | Opaque | Transparent (90%+) |

| Key Chemical Resistance | Fuels, acids, oils | Oils, fuels | Ozone, UV, water |

| Cost Efficiency | High | Low | Medium |

Viton’s fluoropolymer backbone ensures exceptional resistance to thermal degradation and aggressive chemicals, though its higher density may marginally reduce light diffusion efficiency compared to alternatives. Nitrile balances affordability with robust mechanical properties but requires UV stabilizers for outdoor deployment, as prolonged sunlight exposure accelerates surface cracking. Silicone remains the benchmark for optical performance, with negligible yellowing after 5,000+ hours of UV exposure and minimal thermal contraction. Its platinum-cured variants meet ISO 10993 biocompatibility standards, extending applicability to sterile environments.

For high-lumen-density LED arrays generating sustained heat above 150°C, Viton or high-temperature Silicone variants are mandatory to prevent delamination. Nitrile suffices for low-power indoor strips under 80°C but necessitates thicker cross-sections to compensate for lower thermal conductivity. Suzhou Baoshida’s OEM formulations optimize filler dispersion—such as silica for Silicone or carbon black for NBR—to enhance diffuser homogeneity without compromising Shore A tolerances (±3 points). All compounds are extrusion-processed to ±0.1mm dimensional accuracy, ensuring seamless integration with aluminum heat sinks and polycarbonate housings. Partner with our engineering team to validate material selection against your thermal load profiles and regulatory frameworks.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance LED strip diffuser flexible profiles. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we maintain full in-house control over the entire product development cycle—from conceptual design to final production validation. This integrated engineering approach ensures precision, repeatability, and rapid time-to-market for custom OEM solutions.

Our mould engineers bring over a decade of cumulative experience in precision extrusion die design and thermoplastic elastomer (TPE) profile tooling. Utilizing advanced CAD/CAM software and CNC machining, they develop optimized extrusion dies that guarantee dimensional accuracy, consistent wall thickness, and superior optical clarity in diffuser profiles. Each die is rigorously tested and fine-tuned to accommodate material flow dynamics and thermal expansion characteristics, ensuring long-term stability and minimal scrap rates during high-volume production.

Complementing this expertise are our two rubber formula engineers, who specialize in tailoring TPE compounds to meet exact optical, mechanical, and environmental requirements. By adjusting polymer base ratios, filler content, and light-diffusing additives, we engineer materials that achieve precise haze transmission, UV resistance, and thermal stability (up to 105°C continuous exposure). These formulations are developed in-house using a systematic Design of Experiments (DOE) methodology, allowing us to balance flexibility, tensile strength, and luminous diffusion efficiency for each application.

Our OEM capabilities are built on this dual foundation of material science and precision tooling. We support clients from prototype to mass production, offering custom cross-sectional designs, co-extrusion options (e.g., dual hardness or UV-blocking layers), and compliance with RoHS, REACH, and UL94-V0 standards. Whether the requirement is for milky white diffusion, transparent edge blending, or flame-retardant performance, our team delivers engineered solutions optimized for both function and manufacturability.

All development stages are supported by on-site testing facilities, including tensile strength analysis, Shore A hardness measurement, thermal aging chambers, and luminous transmittance evaluation using integrating spheres. This enables rapid iteration and validation, reducing development lead time by up to 40% compared to external engineering partnerships.

We maintain strict process control through standardized work instructions, first article inspection (FAI), and Statistical Process Control (SPC) during production. This disciplined engineering framework ensures that every meter of LED strip diffuser flexible meets the highest standards of quality, consistency, and optical performance.

| Parameter | Standard Performance | Customizable Range |

|---|---|---|

| Material Base | TPE, Silicone, PVC | TPE (preferred for flexibility & clarity) |

| Hardness (Shore A) | 70 ±5 | 50–90 |

| Tensile Strength | ≥8 MPa | Up to 12 MPa |

| Elongation at Break | ≥450% | Up to 600% |

| Operating Temperature | -40°C to +105°C | Extended range available |

| Light Transmittance (Diffused) | 85–92% | 70–95% (adjustable haze) |

| Flame Rating | UL94-V0 (optional) | UL94-V2, HF-1 available |

| OEM Customization | Full profile & material design | Yes, including co-extrusion |

Customization Process

Customization Process for LED Strip Diffuser Flexible Components

Suzhou Baoshida Trading Co., Ltd. implements a rigorous four-stage customization protocol for LED strip diffuser flexible components, ensuring optimal optical performance and mechanical reliability in industrial applications. This process begins with comprehensive Drawing Analysis, where engineering teams dissect client-provided technical schematics to validate dimensional tolerances, geometric conformity, and interface compatibility. Critical parameters such as wall thickness uniformity, curvature radii, and mounting feature geometries undergo GD&T verification against ISO 2768-mK standards. Any deviations from manufacturable specifications are resolved collaboratively with the client prior to progression, eliminating downstream rework risks.

Subsequent Formulation development leverages our proprietary rubber compounding expertise. Material scientists select base polymers—typically SEBS or TPU variants—based on required flexibility, thermal stability, and light diffusion characteristics. Precise additive ratios are engineered to achieve target transmittance levels while incorporating UV stabilizers, optical diffusers, and flame-retardant agents. Each formulation is validated through spectral analysis to confirm 85–92% luminous transmittance across 400–700 nm wavelengths and Shore A hardness consistency within ±3 points. The table below summarizes key customizable properties:

| Property | Standard Range | Testing Method |

|---|---|---|

| Hardness (Shore A) | 55–85 | ASTM D2240 |

| Light Transmittance | 85%–92% | ASTM D1003 |

| Operating Temperature | -40°C to +120°C | ISO 188 |

| Tensile Strength | 8–15 MPa | ASTM D412 |

| Elongation at Break | 300%–600% | ASTM D412 |

Prototyping follows strict phase-gate validation. Two iterative prototype batches are produced using CNC-machined molds, with each unit subjected to optical bench testing for luminance uniformity and mechanical stress cycling. Clients receive detailed performance dossiers including photometric distribution curves and accelerated aging data. Only upon written client approval—confirming compliance with IESNA LM-79-19 metrics—does the project advance to Mass Production.

Our mass production phase operates under ISO 9001:2015-certified workflows with real-time SPC monitoring. Automated extrusion lines maintain ±0.1 mm dimensional control, while inline spectrophotometers continuously verify transmittance consistency. Every production lot undergoes 100% visual inspection and batch-traceable material certification. Suzhou Baoshida’s closed-loop feedback system ensures continuous process refinement, delivering OEM-grade diffusers with ≤0.5% defect rates and on-time shipment reliability exceeding 99.2%. This end-to-end precision engineering guarantees seamless integration into high-density LED arrays while meeting stringent industrial durability requirements.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber components, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of engineered elastomeric solutions. Specializing in precision rubber profiles, seals, gaskets, and custom extrusions, our expertise extends to supporting advanced lighting systems through innovative rubber-based diffuser integration. As a trusted OEM partner in the industrial rubber sector, we deliver materials engineered for durability, optical diffusion efficiency, and long-term environmental resistance—critical attributes in modern LED strip applications requiring flexible, seamless light distribution.

Our technical team, led by Mr. Boyce, provides end-to-end support from material selection to prototype validation and volume production. Whether you are designing linear lighting for architectural installations, industrial equipment, or consumer appliances, Suzhou Baoshida ensures that every rubber diffuser profile meets stringent performance benchmarks. Our formulations are optimized for UV stability, heat resistance, and optical clarity, ensuring minimal light scattering and uniform luminance across the entire length of the LED strip. With in-house compounding, precision extrusion, and rigorous QC protocols, we maintain tight tolerances and consistent batch-to-batch repeatability.

We understand that flexibility, adhesion compatibility, and installation ease are paramount in dynamic lighting environments. Our flexible diffuser profiles are designed to conform to curved substrates while maintaining structural integrity and optical performance under thermal cycling and mechanical stress. Additionally, our rubber materials can be tailored to meet flame retardancy standards (UL94, RoHS, REACH) and operate reliably across a wide temperature range.

To support your engineering and procurement teams, we offer comprehensive technical documentation, sample provisioning, and rapid prototyping services. Our goal is to streamline integration into your existing manufacturing workflows while enhancing product reliability and aesthetic quality.

For immediate technical consultation or to initiate a project collaboration, contact Mr. Boyce directly at [email protected]. Include your application requirements, volume forecasts, and material specifications to receive a tailored response within 24 business hours. We respond to all inquiries with detailed engineering feedback and commercial terms aligned with global supply chain standards.

Below are key technical specifications for our standard flexible LED strip diffuser rubber profiles:

| Property | Value | Test Method |

|---|---|---|

| Hardness (Shore A) | 60 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 8.0 MPa | ASTM D412 |

| Elongation at Break | ≥ 250% | ASTM D412 |

| Operating Temperature Range | -40°C to +120°C | Internal |

| Light Transmittance (1mm thick) | ≥ 85% (400–700 nm) | ASTM D1003 |

| UV Resistance | 1,000+ hrs (Xenon Arc, ASTM G155) | ASTM G155 |

| Flame Rating | UL94 V-0 (optional) | UL94 |

| Custom Colors | Available (Pantone Matching) | — |

Partner with Suzhou Baoshida Trading Co., Ltd. to elevate your LED lighting performance through scientifically engineered rubber diffuser solutions. Contact Mr. Boyce today to discuss your next-generation design.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).