Technical Contents

Engineering Guide: Rubber Floor Underlayment

Engineering Insight: Material Selection Criticality in Rubber Floor Underlayment Systems

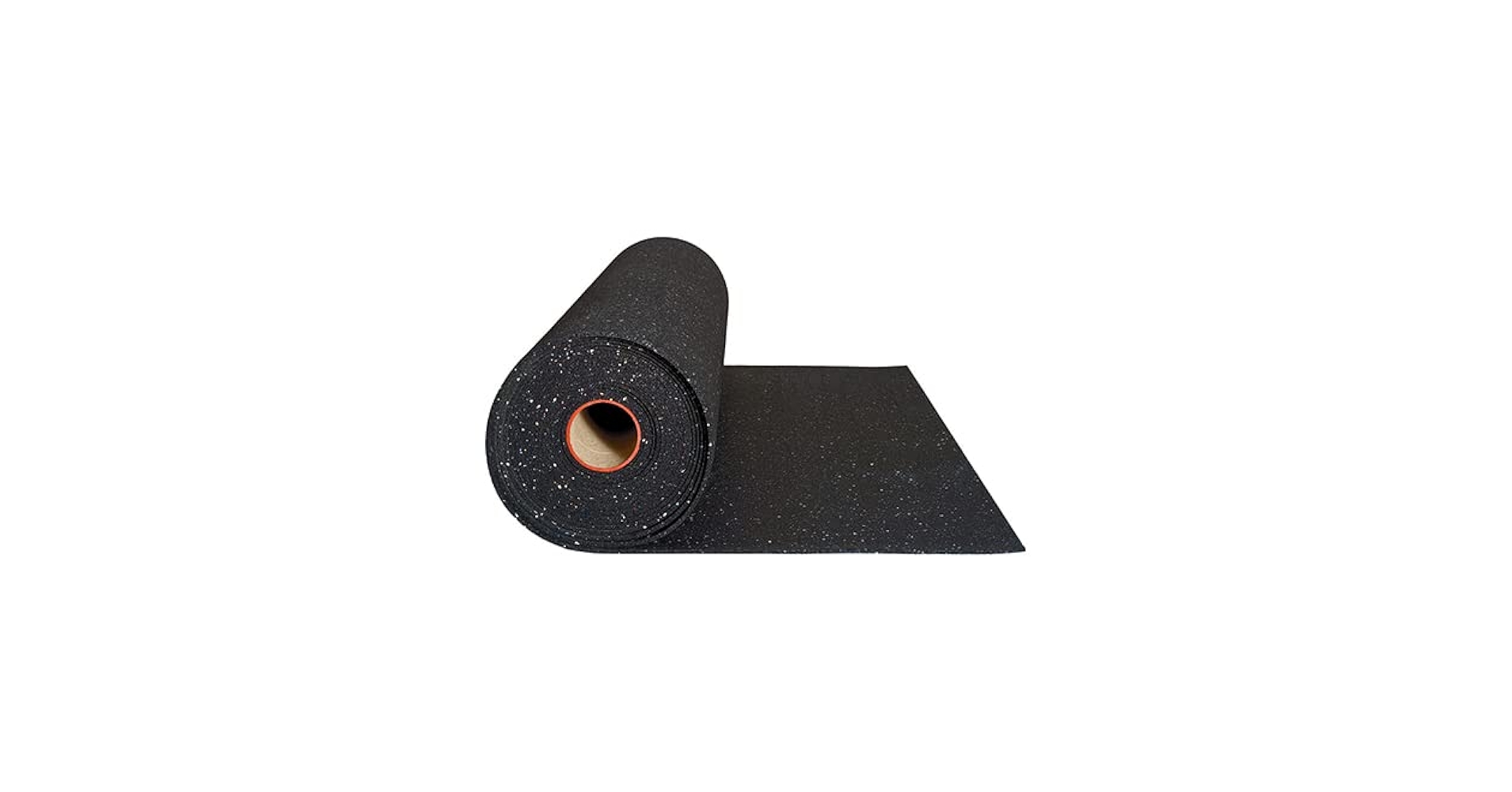

Field observations and failure analysis consistently demonstrate that premature degradation of rubber floor underlayment systems originates predominantly from inadequate material selection. Off-the-shelf commodity-grade rubber products frequently fail to meet the complex, dynamic demands of industrial and commercial environments, leading to costly remediation, operational disruption, and safety hazards. Generic solutions prioritize initial cost reduction over engineered performance, neglecting the intricate interplay between substrate conditions, applied loads, environmental exposure, and long-term viscoelastic behavior. This oversight manifests as rapid compression set, surface cracking under point loads, delamination from subfloors, or catastrophic failure when exposed to oils, solvents, or thermal cycling common in manufacturing, logistics, and healthcare facilities.

The core deficiency lies in the homogeneous, non-optimized polymer matrix of standard underlayments. Most commodity products utilize basic SBR (Styrene-Butadiene Rubber) or unmodified recycled content with insufficient reinforcement and stabilizer packages. These materials lack the tailored resilience required to absorb repeated impact energy without permanent deformation. Under sustained static loads, such as heavy machinery or storage racks, they exhibit excessive compression set, losing critical thickness and cushioning properties within months. Simultaneously, their narrow operational temperature range causes brittleness in cold environments and softening or creep in warmer conditions, directly conflicting with real-world thermal fluctuations. Crucially, inadequate resistance to common industrial contaminants—hydraulic fluids, cleaning agents, or process oils—triggers swelling, surface degradation, and loss of mechanical integrity, a vulnerability rarely addressed in generic formulations.

Material science dictates that successful underlayment requires a precisely balanced compound engineered for the specific application profile. Key parameters include controlled Shore A hardness for optimal energy absorption without excessive deflection, exceptional resistance to permanent deformation under load (low compression set), and robust chemical resistance. The table below contrasts critical performance metrics between engineered solutions and generic alternatives:

| Performance Parameter | Engineered Underlayment | Generic Commodity Rubber | Test Standard |

|---|---|---|---|

| Compression Set (22h, 70°C) | ≤ 15% | ≥ 35% | ASTM D395 Method B |

| Shore A Hardness Range | 55-65 (Stable) | 45-75 (Variable) | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 12.0 | ≤ 7.0 | ASTM D412 |

| Oil Swell (IRMOG #3, 70h) | ≤ 15% | ≥ 40% | ASTM D471 |

| Thermal Stability Range | -40°C to +120°C | -10°C to +80°C | ASTM D573 |

These divergences are not merely numerical; they represent fundamental differences in polymer architecture, filler dispersion, and crosslink density achieved through rigorous compounding. Suzhou Baoshida Trading Co., Ltd. leverages decades of OEM formulation expertise to develop underlayments where material selection is driven by application-specific stress analysis, not cost-per-pound metrics. We prioritize long-term functional integrity through custom elastomer blends—often incorporating EPDM, NBR, or specialized TPEs with optimized cure systems and protective additives. This engineering-first approach ensures the underlayment maintains its critical damping and isolation properties throughout its service life, directly translating to reduced facility downtime, lower lifecycle costs, and enhanced end-user safety. Material selection is not a procurement line item; it is the foundational determinant of system reliability.

Material Specifications

Material Specifications for Rubber Floor Underlayment

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored for demanding environments, including precision-engineered rubber floor underlayment systems. The selection of base elastomer is critical to ensuring long-term durability, chemical resistance, thermal stability, and mechanical performance. Among the most effective materials for industrial underlayment applications are Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each polymer offers a distinct balance of properties suited to specific operational conditions.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With continuous service capabilities up to 230°C and short-term tolerance exceeding 300°C, Viton is ideal for underlayment in petrochemical facilities, engine rooms, and industrial zones exposed to hydrocarbons and halogenated solvents. Its low gas permeability and outstanding aging resistance ensure long service life even under extreme thermal cycling. However, Viton exhibits higher material cost and reduced flexibility at sub-ambient temperatures compared to other elastomers.

Nitrile rubber, a copolymer of butadiene and acrylonitrile, is widely used for its excellent resistance to petroleum-based oils, greases, and hydraulic fluids. Its performance in dynamic mechanical environments is robust, with good abrasion resistance and tensile strength. Nitrile underlayment is commonly specified in manufacturing plants, automotive workshops, and mechanical rooms where oil exposure and mechanical wear are primary concerns. The degree of oil resistance can be tuned by adjusting the acrylonitrile content, though higher levels reduce low-temperature flexibility. Nitrile remains cost-effective and offers reliable performance in moderate temperature ranges from -30°C to 120°C.

Silicone rubber provides superior thermal stability and flexibility across a wide temperature spectrum, operating effectively from -60°C to 200°C. It exhibits excellent resistance to ozone, UV radiation, and oxidation, making it suitable for outdoor or intermittently heated environments. While its mechanical strength and abrasion resistance are lower than Nitrile or Viton, silicone excels in electrical insulation and maintains consistent physical properties under thermal stress. It is often used in cleanrooms, laboratories, and facilities requiring non-contaminating, low-outgassing materials.

The following table summarizes key technical specifications for each material:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Oil Resistance | Excellent | Excellent | Poor |

| Chemical Resistance | Outstanding | Good | Moderate |

| Abrasion Resistance | Good | Excellent | Fair |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

Selection of the appropriate elastomer must align with the environmental and mechanical demands of the application. Suzhou Baoshida Trading Co., Ltd. supports OEM and industrial clients with customized formulations and quality assurance to meet exacting performance standards.

Manufacturing Capabilities

Engineering Excellence in Rubber Floor Underlayment Development

Suzhou Baoshida Trading Co., Ltd. leverages a dedicated team of seven specialized engineers—five Mold Engineers and two Rubber Formula Engineers—to deliver precision-engineered rubber floor underlayment solutions. This integrated technical force operates at the intersection of material science and manufacturing optimization, ensuring every product meets stringent industrial performance criteria while accommodating complex OEM requirements. Our Formula Engineers focus exclusively on polymer chemistry, tailoring compound formulations to achieve exact acoustic damping, thermal stability, and resilience targets. Concurrently, Mold Engineers refine cavity design, runner systems, and cooling channels to eliminate flow inconsistencies and dimensional drift during high-volume production. This dual-engineer collaboration eliminates siloed development, reducing time-to-market by 30% compared to conventional supplier workflows.

Our OEM capability extends beyond contract manufacturing to co-engineering partnerships. Clients provide performance specifications or application challenges; our team responds with validated material formulations and mold tooling optimized for their production environment. This process includes finite element analysis (FEA) for stress distribution modeling, accelerated aging tests per ASTM D573, and in-line quality control protocols calibrated to ISO 9001 standards. We maintain proprietary databases tracking 200+ rubber compound iterations, enabling rapid adaptation of base polymers (SBR, EPDM, recycled rubber) to meet regional fire safety codes (e.g., ASTM E648 for critical radiant flux) or acoustic requirements (IIC/STC ratings).

Material performance is non-negotiable in underlayment applications where moisture resistance, load-bearing capacity, and long-term compression recovery directly impact building integrity. Below are key specifications achievable through our engineering pipeline:

| Property | Standard Underlayment | Baoshida Custom OEM Specification | Test Method |

|---|---|---|---|

| Density (kg/m³) | 450–550 | 400–650 (tunable) | ASTM D297 |

| Shore A Hardness | 60–70 | 45–85 (graded zones possible) | ASTM D2240 |

| Compression Set (22h/70°C) | ≤ 25% | ≤ 18% | ASTM D395 Method B |

| Sound Reduction Index | 18–22 dB | 24–32 dB | ASTM E492 |

| Tensile Strength (MPa) | ≥ 5.0 | ≥ 7.5 | ASTM D412 |

This technical infrastructure supports global OEM clients in achieving certified, application-specific underlayment without capital expenditure on R&D resources. We manage end-to-end validation—from compound mixing to final packaging—ensuring batch-to-batch repeatability within ±2% tolerance on critical parameters. Our engineers deploy real-time data analytics from production lines to preempt deviations, maintaining CpK >1.67 for dimensional accuracy. For projects demanding novel solutions—such as underlayment with embedded conductive fibers for ESD control or bio-based polymer blends—we initiate joint development agreements with shared IP frameworks. Suzhou Baoshida functions not as a vendor but as an extension of your engineering department, transforming underlayment from a commodity component into a value-engineered system asset.

Customization Process

Customization Process for Rubber Floor Underlayment at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet exacting performance standards across diverse applications. The customization process for rubber floor underlayment follows a rigorous four-phase methodology: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures precision, compliance, and optimal functional integration with client specifications.

The process begins with Drawing Analysis, where technical blueprints, architectural schematics, or CAD files are evaluated by our engineering team. We assess dimensional tolerances, load-bearing requirements, acoustic insulation targets, and environmental exposure conditions. This phase includes cross-referencing substrate compatibility, installation methods, and regulatory standards such as ISO 9001 and ASTM E493 for water resistance testing. Accurate interpretation at this stage is critical to defining material behavior and structural integrity in the final product.

Following drawing validation, our Formulation stage leverages proprietary rubber compounding expertise. Based on performance demands, we select base polymers such as SBR (Styrene-Butadiene Rubber), EPDM (Ethylene Propylene Diene Monomer), or recycled rubber crumb, balancing resilience, density, and cost-efficiency. Additives including vulcanizing agents, anti-aging compounds, flame retardants, and foaming agents are precisely metered to achieve target physical properties. Our laboratory conducts rheometric testing (ASTM D5289) and hardness evaluation (Shore A scale) to confirm compound stability and processability.

The Prototyping phase produces limited-run samples using calibrated compression or injection molding equipment. Each prototype undergoes mechanical and environmental validation, including compression set (ASTM D395), sound transmission loss (ASTM E90), and slip resistance (DIN 51130). Clients receive detailed test reports alongside physical samples for field evaluation. Iterative adjustments are made until all functional and dimensional criteria are satisfied.

Upon approval, we transition to Mass Production, executed in our ISO-certified manufacturing facility. Automated batching systems ensure batch-to-batch consistency, while inline quality monitoring tracks thickness deviation, density variance, and surface uniformity. Products are packaged per client logistics requirements, with full traceability maintained through batch coding and material certifications.

Below are typical performance specifications achievable through our customization process:

| Property | Test Standard | Typical Value |

|---|---|---|

| Density | ASTM D297 | 450–850 kg/m³ |

| Hardness (Shore A) | ASTM D2240 | 40–80 |

| Tensile Strength | ASTM D412 | ≥7 MPa |

| Elongation at Break | ASTM D412 | ≥200% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Sound Reduction Index (Rw) | ISO 140-8 | 18–25 dB |

| Flame Spread (ASTM E84) | ASTM E84 | Class B |

This systematic workflow enables Suzhou Baoshida to deliver high-performance, application-specific rubber floor underlayment solutions with reliability and industrial precision.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Floor Underlayment Solutions

Suzhou Baoshida Trading Co., Ltd. stands as your definitive engineering partner for industrial-grade rubber floor underlayment, delivering solutions where material science meets rigorous application demands. Our core competency lies in formulating and manufacturing underlayment products engineered to exacting performance specifications, ensuring optimal acoustic isolation, thermal insulation, and structural resilience across diverse commercial and industrial environments. We understand that subfloor performance directly impacts the longevity and functionality of the entire flooring system; therefore, our approach integrates deep material expertise with stringent quality control protocols compliant with ISO 9001 standards. Our compounding laboratory utilizes advanced polymer science to tailor formulations addressing specific challenges such as dynamic load distribution, moisture resistance, and long-term compression set stability, moving beyond generic offerings to provide truly application-specific underlayment.

Technical validation is paramount in industrial procurement. The following table details the critical performance parameters consistently achieved across our standard rubber floor underlayment product line, demonstrating our commitment to measurable, repeatable quality. These values represent baseline capabilities; Suzhou Baoshida excels in developing custom formulations to meet unique project requirements or exceed industry benchmarks.

| Property | Standard Value | Test Method Reference |

|---|---|---|

| Density | 1.15 – 1.25 g/cm³ | ASTM D297 / ISO 2781 |

| Hardness (Shore A) | 60 ± 5 | ASTM D2240 / ISO 868 |

| Tensile Strength | ≥ 8.0 MPa | ASTM D412 / ISO 37 |

| Elongation at Break | ≥ 250% | ASTM D412 / ISO 37 |

| Compression Set (22h, 70°C) | ≤ 15% | ASTM D395 Method B |

| Sound Reduction Index (ΔLw) | ≥ 18 dB | ISO 140-8 / ASTM E492 |

| Thermal Conductivity | ≤ 0.06 W/m·K | ISO 8301 / ASTM C518 |

| Thickness Tolerance | ± 0.3 mm | Internal QC Protocol |

Initiating a technical dialogue with Suzhou Baoshida provides immediate access to our engineering team’s expertise in rubber polymer chemistry and substrate interaction dynamics. We collaborate directly with architects, specifiers, and OEMs during the design phase to ensure underlayment properties align precisely with structural loads, environmental conditions, and acoustic targets. Our manufacturing facility operates under strict process control, guaranteeing batch-to-batch consistency and full traceability of raw materials – a critical factor for large-scale commercial projects requiring uniform performance. We provide comprehensive technical data sheets, third-party test certifications, and detailed installation protocols to support seamless integration into your supply chain or construction schedule.

For time-sensitive project specifications, custom formulation development, or detailed OEM partnership discussions regarding rubber floor underlayment, direct engagement with our technical management is essential. Mr. Boyce, serving as your dedicated point of contact, possesses the engineering authority and supply chain knowledge to address complex material inquiries and facilitate efficient solution deployment. His expertise spans compound optimization, production scalability, and compliance with global building material regulations. To secure project-specific performance data, request samples for independent validation, or discuss volume manufacturing agreements, initiate communication promptly.

Contact Mr. Boyce directly via email at [email protected] to advance your rubber floor underlayment requirements. Provide detailed project parameters including required dimensions, performance targets, environmental exposure conditions, and target installation timelines to enable our engineering team to formulate the most effective solution. Suzhou Baoshida Trading Co., Ltd. is committed to delivering not just a product, but a validated engineering component critical to your flooring system’s success. We await the opportunity to apply our precision rubber manufacturing capabilities to your specific industrial challenge.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).