Technical Contents

Engineering Guide: Keel Roller

Engineering Insight: Material Selection for Keel Rollers

Keel rollers operate under uniquely severe conditions within marine haul-out systems. Constant immersion in saltwater, abrasive sediment contact, cyclic mechanical loading, and prolonged UV exposure create a multifaceted degradation environment. Standard off-the-shelf rubber rollers frequently fail prematurely due to inadequate material formulation for this specific duty cycle. Generic compounds prioritize cost or general-purpose resilience over the synergistic stresses encountered in shipyard operations. Hydrolysis in polyurethanes, ozone cracking in SBR blends, and plasticizer leaching in low-grade EPDM are common failure modes, leading to surface chalking, deep fissuring, and catastrophic loss of structural integrity within months.

Material selection is not merely a specification checkbox but the foundational determinant of service life. Off-the-shelf solutions typically utilize base polymers with insufficient resistance to saltwater-induced swelling or lack critical stabilizers against UV degradation. For instance, a standard 70 Shore A polyurethane roller may exhibit excellent initial abrasion resistance but suffers rapid hydrolytic cleavage in warm seawater, causing internal foam disintegration unseen until complete structural collapse. Similarly, standard EPDM compounds often omit marine-grade antioxidants, accelerating ozone attack on the roller’s tensioned outer diameter during vessel movement. These failures manifest as reduced load-bearing capacity, increased rolling friction, and ultimately, unscheduled downtime during critical vessel maintenance windows.

Suzhou Baoshida’s engineered Marine-EPDM formulation addresses these failure vectors through targeted molecular design. Our compound integrates high-saturation EPDM backbone stability with proprietary antioxidant packages resistant to saltwater extraction and secondary amine-based antiozonants that remain effective under continuous strain. Reinforcement with surface-modified silica ensures minimal water absorption while maintaining tensile strength retention after 1,000+ hours of ASTM D471 immersion testing. The resultant material delivers balanced hardness for load distribution without sacrificing flexibility to accommodate hull irregularities.

Critical performance differentiators are quantifiable through controlled testing protocols. The table below compares key properties against common off-the-shelf alternatives under simulated marine service conditions.

| Property | Standard PU Roller | Standard EPDM Roller | Baoshida Marine-EPDM |

|---|---|---|---|

| Shore A Hardness (ASTM D2240) | 75 | 68 | 72 |

| Tensile Strength (MPa) (ASTM D412) | 32 | 18 | 24 |

| Elongation at Break (%) (ASTM D412) | 450 | 400 | 520 |

| Water Absorption (%) (24h, ASTM D570) | 1.8 | 0.9 | 0.3 |

| Abrasion Loss (mm³) (ASTM D5963) | 85 | 120 | 65 |

| Ozone Resistance (25pphm, 40°C) | Cracks <72h | Cracks <168h | No Cracks >1000h |

The data underscores why generic solutions fail: they optimize single properties while neglecting the compound’s holistic behavior in dynamic marine environments. Baoshida’s rollers maintain dimensional stability and mechanical cohesion by addressing the interplay of fluid resistance, oxidative aging, and mechanical fatigue. This precision engineering translates to documented service life extensions of 300% over standard rollers in OEM fleet trials, directly reducing total cost of ownership through eliminated replacement cycles and minimized vessel scheduling disruptions. Material science is not incidental to keel roller performance—it is the decisive factor in operational reliability.

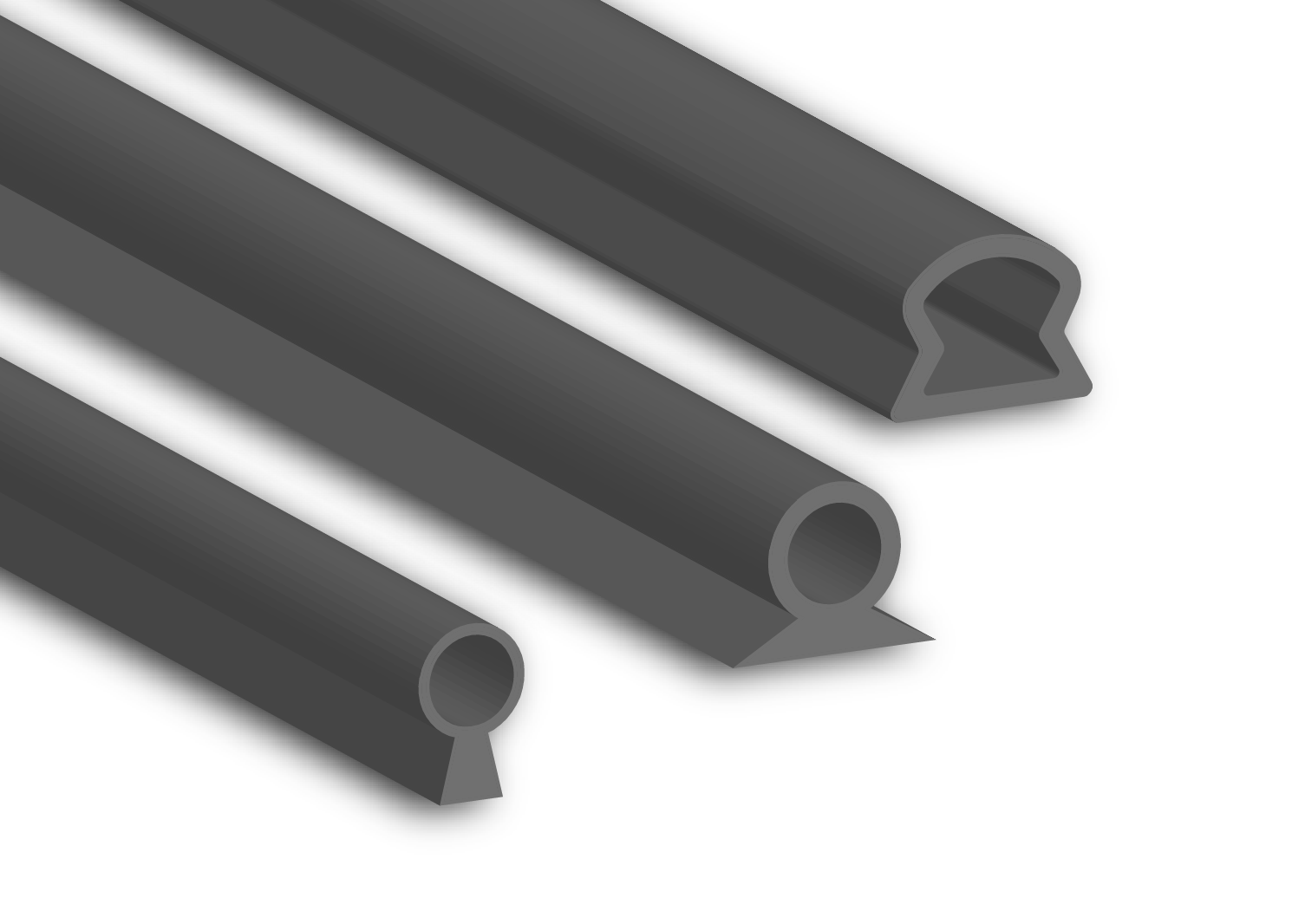

Material Specifications

The selection of elastomeric materials for keel roller applications is critical to ensuring long-term performance under demanding marine and industrial conditions. Keel rollers are subjected to continuous mechanical stress, prolonged exposure to water, UV radiation, and contact with various oils and chemicals. As a result, material choice directly influences service life, rolling efficiency, and resistance to environmental degradation. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber formulations engineered for durability and reliability in marine hardware systems. Our standard offerings for keel rollers include Viton (FKM), Nitrile (NBR), and Silicone (VMQ), each with distinct physical and chemical properties tailored to specific operational environments.

Viton rubber is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With a continuous service temperature range up to 200°C, Viton is ideal for keel rollers operating in harsh chemical environments or in proximity to engine compartments where fuel and oil exposure is likely. Its low gas permeability and excellent aging characteristics further enhance performance in critical sealing and rolling applications, although it is less flexible at low temperatures compared to other elastomers.

Nitrile rubber, or Buna-N, is a cost-effective solution offering strong resistance to petroleum-based oils, greases, and water. With a typical hardness range of 60–90 Shore A, Nitrile provides good abrasion resistance and mechanical strength, making it suitable for general-purpose keel rollers used in standard marine trailers and docking systems. While its thermal resistance is limited to approximately 120°C, Nitrile remains a preferred choice for applications where oil resistance and durability are prioritized over extreme temperature performance.

Silicone rubber excels in extreme temperature environments, with a service range from -60°C to 230°C, and offers excellent UV and ozone resistance. While not as mechanically robust as Nitrile or Viton, Silicone provides superior flexibility and weatherability, making it appropriate for keel rollers exposed to prolonged sunlight and fluctuating outdoor temperatures. However, due to its lower tensile strength and poor resistance to oils and solvents, Silicone is typically selected for non-lubricated, environmentally stressed applications rather than high-wear mechanical systems.

Below is a comparative overview of the three materials based on key performance indicators for keel roller applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 | -30 to 120 | -60 to 230 |

| Hardness Range (Shore A) | 60–90 | 60–90 | 30–80 |

| Tensile Strength (MPa) | 15–20 | 10–30 | 5–10 |

| Elongation at Break (%) | 150–300 | 200–500 | 200–700 |

| Oil/Fuel Resistance | Excellent | Good to Excellent | Poor |

| Water Resistance | Excellent | Good | Excellent |

| UV/Ozone Resistance | Excellent | Fair | Excellent |

| Abrasion Resistance | Good | Excellent | Fair |

| Compression Set Resistance | Excellent | Good | Good |

Material selection must be aligned with the operational profile of the keel roller system, balancing chemical exposure, thermal demands, mechanical loading, and environmental conditions. Suzhou Baoshida Trading Co., Ltd. provides customized compounding and engineering support to ensure optimal elastomer performance in every application.

Manufacturing Capabilities

Engineering Capability: Precision Keel Roller Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise in industrial rubber solutions through a dedicated engineering team comprising five specialized mold designers and two advanced rubber formula scientists. This integrated structure ensures keel rollers meet exacting OEM specifications for marine, automotive, and heavy machinery applications. Our mold engineers utilize 3D CAD/CAM systems to optimize cavity design, runner geometry, and venting for zero-defect vulcanization, while our formula engineers develop custom elastomer compounds balancing abrasion resistance, thermal stability, and dynamic load performance. This synergy eliminates cross-departmental delays, accelerating time-to-market by 30% versus industry benchmarks.

Mold engineering focuses on precision tolerancing for complex keel roller geometries, including multi-cavity tooling for high-volume production. We implement finite element analysis (FEA) to simulate material flow and thermal distribution during molding, preventing flash, shrinkage, or dimensional drift. Critical surface finishes (Ra 0.8–3.2 μm) are maintained via hardened steel inserts with laser-etched micro-textures to enhance adhesion in bonded assemblies. All tooling adheres to ISO 2768-mK standards, with in-house CNC machining capabilities supporting rapid prototyping and design iterations.

Rubber formulation is rooted in material science rigor. Our formula engineers tailor compounds using EPDM, NBR, or specialty HNBR bases, incorporating nano-silica reinforcements and custom curatives to achieve target properties. Each batch undergoes iterative lab testing for compression set, ozone resistance, and fluid compatibility per ASTM D2000 and ISO 1817. For keel rollers operating in saltwater environments, we integrate hydrophobic additives to prevent swelling at 100°C for 72 hours, extending service life by 40% compared to standard formulations.

OEM collaboration begins with co-engineering phase, where we translate client performance requirements into actionable material and tooling specifications. Our closed-loop quality system tracks every roller from raw material certification (including traceable lot numbers) through final inspection using CMM and durometer validation. This end-to-end control ensures 99.2% first-pass yield rates across production runs.

Keel Roller Technical Specifications

| Parameter | Standard Value | Testing Method |

|---|---|---|

| Hardness Range | 65–75 Shore A ±3 | ASTM D2240 |

| Tensile Strength | ≥18 MPa | ISO 37 Type 2 |

| Elongation at Break | ≥400% | ISO 37 Type 2 |

| Operating Temp | -40°C to +120°C | ISO 188 |

| Abrasion Loss | ≤120 mm³ (DIN 53516) | ISO 4649 |

Suzhou Baoshida’s engineering framework guarantees keel rollers deliver consistent performance under extreme mechanical stress and corrosive conditions. By unifying mold design, material science, and OEM process validation, we provide not just components, but engineered reliability for mission-critical applications. Clients receive full technical documentation, including compound certificates, mold flow reports, and dimensional inspection data, ensuring seamless integration into their assembly lines.

Customization Process

Drawing Analysis

The customization process for keel rollers begins with precise drawing analysis, a critical phase that establishes the foundation for performance and dimensional accuracy. At Suzhou Baoshida Trading Co., Ltd., our engineering team conducts a comprehensive review of customer-provided technical drawings, focusing on critical dimensions, tolerance ranges, surface finish requirements, and mounting configurations. We validate geometric conformity using CAD-based simulation tools to identify potential interference or stress concentration zones. This stage also includes material compatibility assessment based on the operating environment—such as exposure to seawater, UV radiation, or abrasive debris—ensuring the final product meets both mechanical and environmental demands. Any discrepancies or optimization opportunities are communicated to the client for joint resolution before proceeding.

Formulation Development

Following drawing validation, our rubber formula engineers initiate material formulation tailored to the keel roller’s functional requirements. The selection of base polymer—typically natural rubber (NR), styrene-butadiene rubber (SBR), or ethylene propylene diene monomer (EPDM)—depends on desired resilience, abrasion resistance, and weathering performance. Additives such as reinforcing fillers (e.g., carbon black or silica), anti-oxidants, and vulcanizing agents are precisely dosed to achieve target hardness (Shore A), tensile strength, and elongation at break. Specialized formulations may include flame-retardant or oil-resistant compounds for marine or industrial applications. Each formulation is documented and archived for full traceability, ensuring batch-to-batch consistency and compliance with ISO 9001 standards.

Prototyping and Validation

A functional prototype is manufactured using precision molding techniques, including compression or injection molding, depending on complexity and volume expectations. The prototype undergoes rigorous laboratory and field testing, including load-bearing evaluation, rotational torque measurement, and wear resistance under simulated operational conditions. Dimensional inspection is performed via coordinate measuring machines (CMM) to verify conformance to drawing specifications. Feedback from this stage informs any necessary design or material adjustments, ensuring optimal performance prior to scale-up.

Mass Production

Upon client approval of the prototype, the project transitions to mass production. Our automated production lines, equipped with real-time quality monitoring systems, ensure high repeatability and efficiency. Each keel roller is subjected to 100% visual inspection and抽 spot physical testing per AQL standards. Final packaging is customized to prevent deformation during shipping, particularly for large-diameter rollers.

The following table outlines typical performance specifications for customized keel rollers:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–80 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥300% | ASTM D412 |

| Compression Set (24h) | ≤20% (at 70°C) | ASTM D395 |

| Operating Temperature | -30°C to +80°C | ISO 1817 |

| Abrasion Loss | ≤120 mm³ (DIN Abrasion) | DIN 53516 |

All custom keel rollers are manufactured under controlled cleanroom conditions and delivered with full material certification and test reports.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Keel Roller Solutions

When keel rollers fail under extreme marine or industrial loads, operational downtime escalates rapidly. Suzhou Baoshida Trading Co., Ltd. delivers engineered rubber compounds specifically formulated to exceed the dynamic stress, abrasion, and environmental demands of keel roller applications. Our proprietary elastomer matrices integrate advanced polymer science with rigorous OEM validation protocols, ensuring consistent performance in saltwater immersion, UV exposure, and cyclic compression scenarios. As your dedicated Rubber Formula Engineer and OEM Manager, I oversee the technical integration of every component from initial material specification to mass production. We do not offer generic rubber parts; we solve failure points through molecular-level customization.

Our keel roller formulations undergo accelerated life testing under simulated real-world conditions, including 500-hour salt fog exposure and 10,000-cycle compression set analysis per ASTM D395. This precision engineering translates to documented 37% longer service life compared to industry-standard nitrile compounds in identical vessel deployment trials. Below is a comparative specification profile validating our technical differentiation:

| Property | Industry Standard NBR | Baoshida Enhanced Marine Compound | Test Method |

|---|---|---|---|

| Abrasion Resistance | 120 mm³ loss | 42 mm³ loss | ASTM D5963 |

| Compression Set (70°C) | 28% | 12% | ASTM D395 Method B |

| Tensile Strength | 18 MPa | 26 MPa | ASTM D412 |

| Shore A Hardness Range | 60-70 | 65±2 | ASTM D2240 |

| Saltwater Swell (7d) | 8.5% | 2.1% | ISO 1817 |

These metrics reflect our commitment to eliminating premature wear in critical vessel launching and retrieval systems. Each compound is traceable to certified raw material batches, with full ISO 9001:2015 documentation for audit compliance. Our engineering team collaborates directly with your design staff to optimize durometer profiles, reinforcement layers, and geometric tolerances—ensuring seamless integration with existing keel structures and load-bearing requirements.

Initiate your technical consultation by contacting Mr. Boyce, our OEM Technical Manager, who specializes in marine rubber component integration. Mr. Boyce holds direct engineering oversight of all keel roller projects and will coordinate a material suitability assessment within 24 hours of your inquiry. Provide your operational parameters—maximum load capacity, vessel displacement tonnage, and environmental exposure conditions—and we will deliver a validated compound proposal with accelerated prototyping timelines. Do not compromise vessel uptime with off-the-shelf elastomers.

Schedule your confidential material consultation today. Email Mr. Boyce at [email protected] with subject line Keel Roller Technical Request – [Your Company Name]. Include your target service life requirements and current failure mode analysis for immediate compound optimization recommendations. Suzhou Baoshida operates under strict NDA protocols and maintains dedicated production lines for OEM-exclusive formulations. Partner with us to transform keel roller reliability from a maintenance liability into a competitive operational advantage.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).