Technical Contents

Engineering Guide: Rubber Trays

Engineering Insight: The Critical Role of Material Selection in Rubber Tray Performance

In industrial applications, rubber trays serve as essential components in material handling, part curing, chemical containment, and transport systems. Despite their seemingly simple design, the performance and longevity of rubber trays are profoundly influenced by material selection. A common misconception is that any rubber compound can suffice for general-purpose trays. However, off-the-shelf solutions frequently fail under real-world operational conditions due to inadequate resistance to thermal cycling, chemical exposure, mechanical stress, or compression set.

The failure of generic rubber trays often stems from a one-size-fits-all approach to formulation. Standard trays made from low-cost natural rubber or basic SBR (styrene-butadiene rubber) may appear cost-effective initially but degrade rapidly when exposed to oils, ozone, elevated temperatures, or repeated loading. In contrast, engineered rubber compounds such as Nitrile (NBR), EPDM, Viton (FKM), or silicone offer targeted performance characteristics that align with specific industrial environments.

For instance, NBR excels in oil and fuel resistance, making it ideal for automotive and machining applications where trays contact lubricants or hydraulic fluids. EPDM demonstrates superior resistance to steam, water, and weathering, rendering it suitable for autoclave curing or outdoor exposure. Silicone maintains integrity across extreme temperatures (-60°C to +230°C), critical in thermal processing lines. Fluorocarbon-based materials like FKM provide unmatched chemical inertness in semiconductor or pharmaceutical manufacturing where purity and resistance to aggressive solvents are non-negotiable.

Beyond chemical compatibility, mechanical properties must be evaluated. Hardness (measured in Shore A), tensile strength, elongation at break, and compression set directly affect load-bearing capacity, dimensional stability, and service life. A tray that deforms under continuous load or cracks after repeated thermal cycles introduces contamination risks and unplanned downtime.

Custom formulation allows precise tuning of these properties. At Suzhou Baoshida Trading Co., Ltd., we prioritize application-specific engineering, analyzing operational parameters to select or develop rubber compounds that ensure reliability, safety, and cost efficiency over the product lifecycle.

The table below compares key rubber materials used in industrial tray manufacturing:

| Material | Temperature Range (°C) | Key Resistance Properties | Typical Applications |

|---|---|---|---|

| NBR (Nitrile) | -30 to +120 | Oil, fuel, abrasion | Machining, automotive parts handling |

| EPDM | -50 to +150 | Steam, water, ozone, weathering | Autoclave trays, outdoor conveyance |

| Silicone | -60 to +230 | Extreme heat, cold, UV | Thermal curing, food-grade handling |

| FKM (Viton) | -20 to +200 | Acids, solvents, halogens | Semiconductor, pharmaceutical processing |

| Natural Rubber | -50 to +80 | Abrasion, low-temperature flexibility | General-purpose, light-duty transport |

In conclusion, the selection of rubber material is not a secondary consideration—it is the foundation of functional tray design. Off-the-shelf trays often overlook these critical variables, leading to premature failure. Precision engineering, grounded in material science, ensures optimal performance in demanding industrial environments.

Material Specifications

Material Specifications for Industrial Rubber Trays

Selecting the appropriate elastomer for rubber trays is critical in industrial applications where performance under stress directly impacts operational reliability. At Suzhou Baoshida Trading Co., Ltd., we engineer rubber trays to exacting OEM standards, prioritizing chemical compatibility, thermal stability, and mechanical resilience. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent three high-performance materials, each suited to distinct environmental challenges. Viton excels in extreme chemical and thermal environments, Nitrile offers optimal resistance to oils and fuels, while Silicone provides unparalleled flexibility across wide temperature ranges with biocompatibility. Material selection must align with fluid exposure, temperature cycling, load requirements, and regulatory constraints to prevent premature failure.

The comparative analysis below details essential specifications for each material. Key parameters include continuous service temperature limits, resistance to common industrial agents, tensile strength, elongation at break, and compression set values after aging. These metrics determine suitability for sectors such as semiconductor manufacturing, automotive fluid handling, pharmaceutical processing, and food-grade conveyance.

| Material | Temperature Range (°C) | Chemical Resistance | Key Mechanical Properties | Typical Industrial Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 (short-term to 300) | Exceptional resistance to acids, bases, hydrocarbons, jet fuels, and ozone. Moderate resistance to ketones and esters. | Tensile: 10-15 MPa; Elongation: 150-300%; Low compression set (<20% after 70h at 200°C) | Chemical transfer trays, semiconductor wafer carriers, aerospace fluid containment |

| Nitrile (NBR) | -40 to +120 (short-term to 150) | Superior resistance to oils, greases, aliphatic hydrocarbons, and water. Poor resistance to ozone, ketones, and chlorinated solvents. | Tensile: 15-25 MPa; Elongation: 200-500%; Compression set: 25-40% after 70h at 100°C | Automotive oil pans, hydraulic component trays, industrial lubricant handling systems |

| Silicone (VMQ) | -60 to +230 (short-term to 260) | Good resistance to water, alcohols, and mild acids. Poor resistance to concentrated acids, fuels, and non-polar solvents. | Tensile: 6-10 MPa; Elongation: 400-800%; Compression set: 15-25% after 70h at 200°C | Medical device sterilization trays, food processing conveyors, electronics insulation carriers |

Viton’s fluorocarbon backbone delivers unmatched stability in aggressive chemical baths but incurs higher material costs. Nitrile balances cost-effectiveness with robust oil resistance, though its vulnerability to ozone necessitates protective additives in outdoor applications. Silicone’s inertness and flexibility make it ideal for repeated thermal cycling and sterile environments, though its lower tensile strength requires thicker cross-sections for load-bearing trays. Compression set values are particularly critical for sealing trays; values exceeding 30% typically indicate inadequate recovery, leading to leakage in gasketed systems.

Suzhou Baoshida optimizes compound formulations by adjusting polymer grades, filler types (e.g., silica for tear resistance), and cure systems to meet client-specific ASTM D2000 or ISO 3601 requirements. For instance, peroxide-cured Silicone enhances high-temperature resilience, while hydrogenated Nitrile (HNBR) extends service life in dynamic oil exposure. We rigorously validate all materials through accelerated aging tests per ISO 188 and chemical immersion per ASTM D471. Precise material selection, grounded in these specifications, ensures rubber trays maintain dimensional stability and functional integrity throughout their operational lifecycle, minimizing downtime and replacement costs for industrial partners.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. delivers comprehensive engineering capabilities in the field of industrial rubber solutions, with a specialized focus on the design, formulation, and production of high-performance rubber trays for demanding OEM applications. Our technical foundation is built upon a dedicated team of seven core engineers—five mold design specialists and two advanced rubber formulation experts—working in synergy to ensure every component meets exacting functional, environmental, and lifecycle requirements.

Our mold engineering team brings extensive experience in precision tooling for compression, transfer, and injection molding processes. Each engineer applies finite element analysis (FEA) and mold flow simulation to optimize cavity design, venting, gating, and ejection systems. This proactive approach minimizes defects such as flash, voids, or incomplete fills, ensuring dimensional stability and repeatability across high-volume production runs. All molds are constructed using hardened tool steels with protective coatings where necessary, supporting long service life under continuous industrial use.

Complementing mold design is our in-house rubber formulation capability. Our two senior formula engineers specialize in compounding elastomers tailored to specific mechanical, thermal, and chemical exposure conditions. Whether the application requires resistance to oils, ozone, high temperatures, or repeated compression set, we develop custom formulations using NR, SBR, NBR, EPDM, silicone, and FKM base polymers. Each compound is rigorously tested for tensile strength, elongation, hardness (Shore A), compression set, and aging characteristics before approval.

Our integrated OEM service model enables end-to-end project ownership—from initial concept and 3D modeling to prototyping, material validation, and serial production. We work directly with client specifications or reverse-engineer existing components to improve performance and reduce total cost of ownership. All developments are supported by full documentation, including material certifications (e.g., ROHS, REACH), first article inspection reports, and process capability (Cp/Cpk) data.

The following table outlines typical performance specifications achievable for our engineered rubber trays, depending on material and design:

| Property | NBR (Nitrile) | EPDM | Silicone | FKM (Viton®) |

|---|---|---|---|---|

| Hardness Range (Shore A) | 50–90 | 50–85 | 40–80 | 60–80 |

| Tensile Strength (MPa) | 12–20 | 10–18 | 6–10 | 10–15 |

| Elongation at Break (%) | 250–450 | 200–400 | 200–600 | 150–250 |

| Operating Temperature Range (°C) | -30 to +120 | -50 to +150 | -60 to +200 | -20 to +250 |

| Fluid Resistance | Excellent (oils, fuels) | Good (water, steam) | Moderate | Outstanding (aggressive chemicals) |

| Compression Set (70 hrs, 100°C) | 15–25% | 20–30% | 10–20% | 10–18% |

This technical depth, combined with strict ISO-compliant manufacturing controls, positions Suzhou Baoshida as a trusted engineering partner for OEMs across automotive, electronics, energy, and industrial equipment sectors. We are equipped to deliver rubber trays that perform reliably in the most challenging environments.

Customization Process

Rubber Tray Customization Process at Suzhou Baoshida Trading Co., Ltd.

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, four-phase customization workflow for industrial rubber trays, ensuring dimensional precision, material performance, and production scalability meet exact OEM specifications. This structured approach minimizes iteration cycles and guarantees end-product reliability in demanding applications.

Drawing Analysis

Initial engagement commences with comprehensive technical drawing review. Our engineering team scrutinizes GD&T callouts, critical dimensions, draft angles, and parting line feasibility against moldability constraints. We validate tolerance stacks against ISO 2768-mK standards and assess potential undercuts or ejection challenges. Client application data—load requirements, chemical exposure, temperature profiles, and lifecycle expectations—are cross-referenced with the geometry. Any ambiguities or potential weaknesses, such as thin sections prone to flash or inadequate venting zones, are flagged immediately for collaborative resolution prior to material selection.

Formulation

Material science drives performance. Based on the validated application parameters from Drawing Analysis, our rubber chemists select the optimal base polymer system. Key considerations include resistance to oils (NBR), ozone/weathering (EPDM), or broad chemical compatibility (FKM). Critical physical properties are engineered through precise compounding of curatives, fillers, plasticizers, and protective additives. Cure kinetics are optimized for the client’s production cycle time. The table below summarizes typical specification targets for common industrial tray formulations.

| Property | NBR Example | EPDM Example | Test Standard |

|---|---|---|---|

| Hardness (Shore A) | 60 ± 5 | 70 ± 5 | ASTM D2240 |

| Tensile Strength (MPa) | ≥ 15.0 | ≥ 12.0 | ASTM D412 |

| Elongation at Break (%) | ≥ 300 | ≥ 250 | ASTM D412 |

| Temp Range (°C) | -30 to +120 | -50 to +150 | Client Spec |

| Compression Set (%) | ≤ 25 | ≤ 30 | ASTM D395 B |

Prototyping

A dedicated low-volume production run using client-approved tooling steel molds generates functional prototypes. Each tray undergoes stringent first-article inspection against the original CAD model using CMM verification. Physical testing validates the formulated compound’s performance under simulated service conditions—load deflection, chemical immersion, thermal cycling, and fatigue resistance. Dimensional stability data and surface finish quality are documented. Client feedback on prototype functionality triggers final micro-adjustments to the compound recipe or mold parameters before release.

Mass Production

Upon formal sign-off, the validated process transitions to high-volume manufacturing under Suzhou Baoshida’s ISO 9001-certified quality management system. Production batches utilize the exact compound formulation and cure profiles established during prototyping. In-process controls monitor key parameters: raw material lot traceability, mixing homogeneity, mold temperature uniformity, and cure state via rheometry. Final trays undergo 100% visual inspection and statistical dimensional sampling per AQL 1.0. Comprehensive material certification and production logs accompany every shipment, ensuring full traceability and compliance with the client’s industrial supply chain requirements. This seamless handoff from prototype to production guarantees consistent part performance at scale.

Contact Engineering Team

For industrial manufacturers seeking high-performance rubber trays tailored to demanding production environments, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in precision rubber solutions. With years of engineering expertise and a deep understanding of material science, we specialize in the design, formulation, and production of custom rubber trays that meet exacting industry standards. Our products are engineered to withstand thermal cycling, chemical exposure, mechanical stress, and prolonged operational cycles—critical requirements in sectors such as automotive, electronics, semiconductor handling, and industrial automation.

Our rubber trays are manufactured using advanced compounding techniques, ensuring optimal resilience, dimensional stability, and resistance to compression set. Whether you require trays for high-temperature curing processes, ESD-safe environments, or oil-resistant applications, we formulate with materials including silicone, EPDM, nitrile (NBR), and fluororubber (FKM) to match your operational demands. Every tray is produced under strict quality control protocols, with batch traceability, Shore hardness calibration, and full compliance documentation available upon request.

To ensure seamless integration into your production lines, we offer complete customization—from precise cavity layouts and load-bearing geometries to color coding and surface texturing. Our engineering team collaborates directly with clients to analyze application parameters, enabling us to deliver trays that enhance process efficiency, reduce part damage, and extend service life.

Below are representative technical specifications for our standard industrial rubber trays. Custom configurations are available upon engineering review.

| Property | Value |

|---|---|

| Material Options | Silicone, EPDM, NBR, FKM, Neoprene |

| Hardness Range (Shore A) | 40–90 ±5 |

| Temperature Resistance | -40°C to +250°C (material-dependent) |

| Tensile Strength | ≥8 MPa (ASTM D412) |

| Elongation at Break | ≥200% |

| Compression Set (22 hrs, 70°C) | ≤20% |

| Electrical Resistivity (ESD variants) | 10^5 – 10^9 Ω·cm |

| Standard Tolerances | ±0.3 mm (molded), ±0.5 mm (cut) |

| Color Options | Black, red, blue, green, custom |

| Regulatory Compliance | RoHS, REACH, FDA (upon request) |

Partnering with Suzhou Baoshida means gaining access to end-to-end technical support—from initial concept and material selection to prototyping, validation, and volume production. We operate certified manufacturing facilities with in-house tooling capabilities, ensuring rapid turnaround and consistent quality across all order scales.

For detailed technical consultation or to request a sample batch for evaluation, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer, directly at [email protected]. Mr. Boyce leads our application engineering team and specializes in material formulation optimization for industrial tooling and handling systems. He will work closely with your engineering staff to define performance criteria, recommend suitable elastomers, and deliver a solution that aligns precisely with your operational requirements.

At Suzhou Baoshida, we don’t just supply rubber trays—we engineer performance-driven components that elevate your manufacturing reliability. Reach out today to begin the technical dialogue.

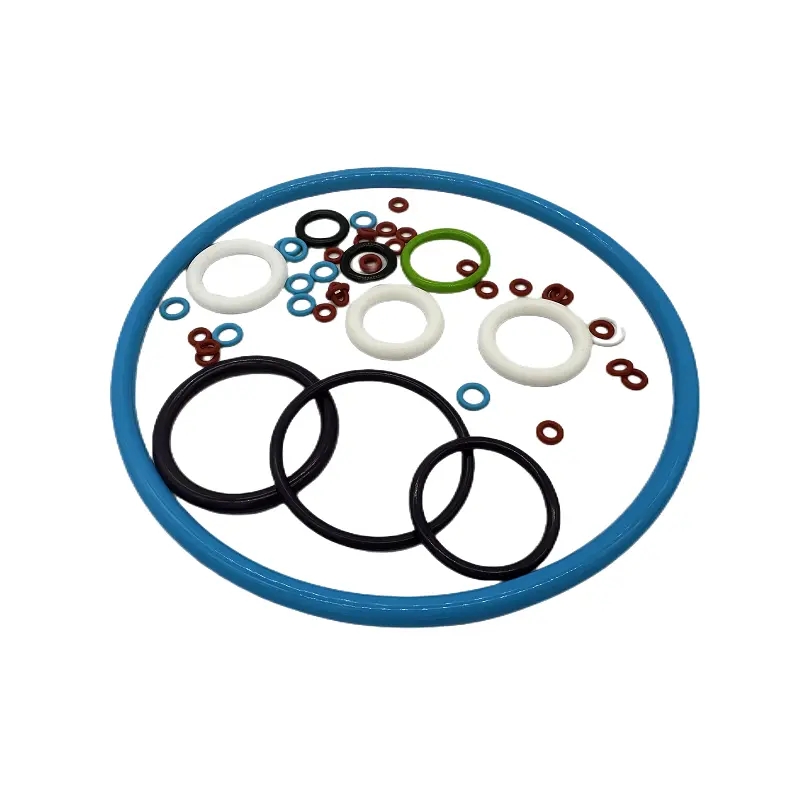

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).