Technical Contents

Engineering Guide: Roofing Rubber

Engineering Insight: Material Selection in Roofing Rubber Applications

In industrial roofing systems, the selection of rubber materials is not a matter of convenience—it is a decisive engineering parameter that governs longevity, performance under stress, and resistance to environmental degradation. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf rubber solutions frequently underperform because they are designed for generalized applications, not the specific mechanical, thermal, and chemical conditions encountered in commercial and industrial roofing environments.

Roofing rubber must endure prolonged UV exposure, extreme temperature fluctuations, moisture, ozone, and mechanical stress from wind uplift and foot traffic. Generic elastomers often lack the formulation sophistication to maintain structural integrity under these combined stressors. For example, standard EPDM compounds may exhibit adequate UV resistance but fail prematurely due to poor tensile recovery or inadequate resistance to ponding water containing industrial pollutants. Similarly, recycled rubber content in economical blends can introduce inconsistencies in crosslink density, accelerating aging and reducing service life.

The failure of non-engineered rubber solutions manifests in cracking, hardening, loss of elasticity, and seam delamination—issues that compromise waterproofing and lead to costly repairs or full-system replacement. These failures are not random; they are predictable outcomes of mismatched material properties and operational demands.

At the core of successful roofing rubber performance is precise polymer selection and compounding. Ethylene Propylene Diene Monomer (EPDM) remains a benchmark due to its exceptional weatherability and thermal stability. However, performance can be further optimized through controlled diene content, filler dispersion, and vulcanization systems. For aggressive environments, advanced formulations incorporating chlorinated polyethylene (CM) or thermoplastic vulcanizates (TPV) offer enhanced chemical resistance and processing efficiency.

Material thickness, tensile strength, and elongation at break are not standalone metrics—they must be evaluated in context. A high elongation value means little if the material cannot recover or if it degrades rapidly under UV exposure. Therefore, holistic testing under simulated service conditions is essential.

Below is a comparative analysis of key rubber materials used in industrial roofing applications:

| Property | EPDM (Standard) | EPDM (High-Performance) | Chlorinated Polyethylene (CM) | Thermoplastic Vulcanizate (TPV) |

|---|---|---|---|---|

| Tensile Strength (MPa) | 7–9 | 10–12 | 8–10 | 10–14 |

| Elongation at Break (%) | 300–400 | 450–550 | 350–450 | 400–600 |

| Service Temperature Range (°C) | -50 to +135 | -50 to +150 | -30 to +130 | -40 to +140 |

| UV Resistance | Excellent | Excellent | Good | Very Good |

| Ozone Resistance | Excellent | Excellent | Excellent | Excellent |

| Water & Steam Resistance | Excellent | Excellent | Very Good | Excellent |

| Chemical Resistance | Moderate | Good | Excellent | Good |

The data illustrates that while standard EPDM meets basic requirements, high-performance variants and alternative polymers offer measurable advantages in demanding applications. Material selection must be guided by site-specific factors: geographic climate, building use, expected maintenance cycles, and exposure to pollutants.

At Suzhou Baoshida Trading Co., Ltd., we provide engineered rubber solutions tailored to the operational lifecycle of each roofing system. Our formulations are validated through accelerated aging tests and real-world performance tracking, ensuring reliability beyond the limitations of commodity-grade products. In roofing, as in all industrial applications, the right material is not the cheapest one—it is the one that delivers sustained performance with minimal lifecycle cost.

Material Specifications

Material Specifications: Critical Selection Criteria for Roofing Rubber Applications

Selecting the appropriate elastomer for roofing systems demands rigorous evaluation of environmental stressors, including prolonged UV exposure, thermal cycling, chemical resistance, and mechanical durability. At Suzhou Baoshida Trading Co., Ltd., we prioritize material integrity to ensure decades-long service life in demanding architectural and industrial roofing scenarios. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent three cornerstone materials, each engineered for distinct operational envelopes. Misalignment between material properties and application requirements directly compromises seal integrity, leading to premature failure and costly remediation. Understanding their precise technical boundaries is non-negotiable for OEMs and specifiers.

The comparative analysis below adheres strictly to ASTM D2000 classification standards and accelerated aging protocols per ISO 188. Data reflects typical compounded formulations optimized for roofing extrusions, membranes, and gasketing.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 (ASTM D412) | 10–18 (ASTM D412) | 6–10 (ASTM D412) |

| Elongation at Break (%) | 150–250 | 200–450 | 200–600 |

| Shore A Hardness | 60–80 | 50–90 | 30–80 |

| Compression Set (B) (%) | ≤25 (24h, 150°C) | ≤35 (70h, 100°C) | ≤20 (22h, 200°C) |

| Key Resistance Attributes | Extreme heat, ozone, fuels, acids | Aliphatic oils, hydraulic fluids, water | UV, ozone, weathering, steam |

| Primary Roofing Applications | Chemical plant roofs, high-temperature exhaust seals | Drainage systems, mechanical joint seals | Expansion joints, glazing gaskets, solar panel mounts |

Viton excels where extreme thermal stability and chemical aggression coexist, such as industrial facilities processing solvents or acids. Its fluoropolymer backbone resists swelling in hydrocarbon exposure but commands a premium cost. Nitrile remains the economical workhorse for general-purpose roofing seals exposed to water, greases, or moderate oil contact; acrylonitrile content directly scales oil resistance but inversely affects low-temperature flexibility. Silicone dominates in weather-severe environments due to unparalleled UV/ozone resistance and consistent performance from Arctic to desert climates, though its lower tensile strength necessitates careful profile design for high-load zones.

OEM selection must prioritize the dominant stress factor: chemical exposure mandates Viton, hydraulic fluid contact favors high-acrylonitrile NBR, while long-term weatherability without thermal extremes justifies silicone. Suzhou Baoshida provides material certification dossiers and accelerated aging test reports for each compound batch, ensuring traceability to ASTM/ISO benchmarks. Partner with our engineering team to validate material suitability against your specific roofing system’s operational profile—never compromise on elastomer specification when structural integrity is at stake.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering engineered performance materials tailored for demanding applications such as roofing systems. Our engineering capability is anchored in a dedicated team of technical specialists, including five certified mould engineers and two advanced rubber formulation scientists. This multidisciplinary expertise enables us to provide fully integrated OEM services—from concept and compound design to precision moulding and final product validation.

Our mould engineering team brings extensive experience in designing and optimizing rubber component tooling for roofing applications, where dimensional stability, weather resistance, and long-term sealing performance are critical. These engineers utilize advanced CAD/CAM software and finite element analysis (FEA) to simulate compression, thermal expansion, and environmental aging, ensuring that every mould delivers repeatable, high-integrity parts. With in-house tooling oversight, we maintain tight control over cycle times, part consistency, and defect mitigation, directly supporting scalable production for OEM partners.

Complementing our mould design strength is our proprietary rubber formulation capability. Our two senior formula engineers specialize in elastomer chemistry, focusing on EPDM, SBR, and high-silica natural rubber blends optimized for roofing environments. They develop compounds that meet rigorous performance benchmarks, including UV resistance, low-temperature flexibility (down to -50°C), water absorption rates, and long-term compression set. Each formulation is subjected to accelerated aging tests, Shore A hardness profiling, and tensile fatigue analysis to ensure field reliability under extreme climatic conditions.

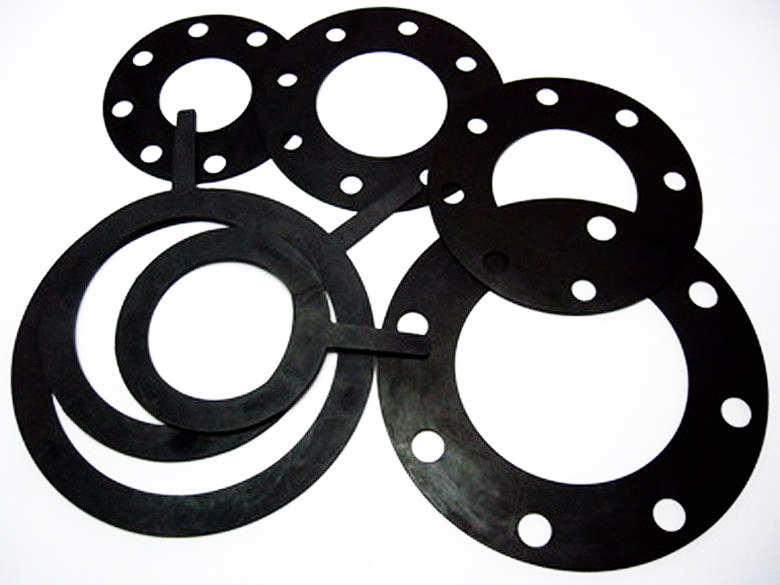

As an OEM partner, Suzhou Baoshida provides end-to-end manufacturing support, including material selection, DFM (Design for Manufacturability) feedback, prototype development, and batch traceability. We work directly with roofing system designers to customize rubber profiles, gaskets, flashing components, and sealants that integrate seamlessly into modular or built-up roofing assemblies. Our production lines are equipped for high-volume compression and transfer moulding, with full QA/QC protocols aligned with ISO 9001 standards.

The following table outlines key technical specifications achievable through our engineering and manufacturing platform:

| Property | Test Standard | Typical Performance |

|---|---|---|

| Hardness Range (Shore A) | ASTM D2240 | 40 – 80 ±5 |

| Tensile Strength | ASTM D412 | 8 – 18 MPa |

| Elongation at Break | ASTM D412 | 250% – 500% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -50°C to +120°C |

| Water Absorption (7 days) | ISO 2781 | <1.5% |

| UV Resistance | ASTM G154 | Pass (3000h cycles) |

By combining advanced material science with precision engineering, Suzhou Baoshida ensures that every rubber component we produce meets the structural and environmental demands of modern roofing systems. Our OEM framework is built on collaboration, technical transparency, and performance accountability—making us a trusted partner in industrial rubber innovation.

Customization Process

Roofing Rubber Customization Process: Precision Engineering from Concept to Production

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions for roofing applications follow a rigorously defined customization pathway. This systematic approach ensures the final product meets exact structural, environmental, and longevity requirements critical for commercial and industrial roofing systems. We manage all OEM manufacturing partners to guarantee adherence to this protocol, eliminating performance uncertainty.

The process initiates with comprehensive Drawing Analysis. Our engineering team meticulously reviews architectural and structural drawings, focusing on roof geometry, slope, anticipated load stresses, thermal expansion coefficients, and substrate compatibility. Critical factors such as seam configuration, penetration details, and expected service life under specific regional UV exposure and temperature extremes are quantified. This phase identifies non-negotiable performance parameters, forming the technical foundation for material development. Assumptions are invalidated; only measurable engineering data guides subsequent stages.

This data directly informs the Formulation stage. Our rubber chemists develop proprietary compound recipes using premium EPDM or TPO base polymers, selecting curatives, fillers, stabilizers, and UV inhibitors to achieve the precise balance of properties defined in the drawing analysis. Formulation targets include exceptional weathering resistance, optimal tensile strength for wind uplift resistance, controlled flexibility at low temperatures, and long-term dimensional stability. Every additive ratio is optimized through computational modeling before physical batching, ensuring molecular-level performance alignment with the project’s environmental profile.

Validated formulations proceed to Prototyping. Small-batch production under controlled OEM conditions generates sample membranes. These undergo accelerated aging tests per ASTM standards, including cyclic thermal testing (-40°C to +85°C), QUV exposure (3000+ hours), and mechanical stress analysis. Physical samples are also subjected to real-world simulation: seam peel strength, puncture resistance, and adhesion to specified substrates are rigorously measured. Client validation of prototype performance data and physical samples is mandatory before progression. This phase confirms the formulation withstands the actual operational stresses identified during drawing review.

Upon prototype approval, seamless transition to Mass Production occurs under our stringent OEM management. Production batches utilize dedicated mixing lines with real-time rheometry monitoring to ensure compound consistency. Each batch undergoes full quality control verification against the approved prototype specifications. Traceability is absolute, with raw material lot numbers and process parameters documented for every square meter produced. Final inspection includes 100% visual examination for surface defects and random抽样 testing of critical physical properties, guaranteeing uniformity across the entire project volume.

Key performance specifications consistently targeted for roofing membranes are summarized below, reflecting industry standards and Suzhou Baoshida’s engineering benchmarks:

| Property | Target Value (EPDM/TPO) | Test Standard |

|---|---|---|

| Tensile Strength (MPa) | ≥ 7.5 / ≥ 12.0 | ASTM D412 Type C |

| Elongation at Break (%) | ≥ 300 / ≥ 250 | ASTM D412 |

| Tear Resistance (kN/m) | ≥ 25.0 / ≥ 20.0 | ASTM D1004 |

| Low Temperature Flexibility | -40°C Pass | ASTM D1938 |

| Accelerated Weathering | 3000+ hrs QUV-B Pass | ASTM G154 |

| Heat Aging Resistance | ΔTensile ≤ 15% | ASTM D573 |

This disciplined four-stage process, managed with scientific precision from Suzhou Baoshida, transforms architectural intent into a durable, high-performance roofing solution. We deliver not just rubber, but engineered assurance against environmental degradation and structural failure.

Contact Engineering Team

For industrial manufacturers and construction material suppliers seeking high-performance roofing rubber solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global supply chain. As a specialized provider of industrial rubber products, we deliver engineered materials designed for durability, weather resistance, and long-term structural integrity. Our roofing rubber formulations are developed to meet the rigorous demands of commercial, residential, and industrial roofing applications, providing exceptional UV resistance, thermal stability, and tensile strength under extreme environmental conditions.

Our technical team at Suzhou Baoshida applies deep expertise in elastomer science to customize rubber compounds tailored to specific performance criteria. Whether you require EPDM, SBR, or specialty synthetic blends, our formulations are optimized for seamless integration into roofing membranes, flashing components, expansion joints, and waterproofing systems. Every batch undergoes stringent quality control protocols to ensure consistency, adhesion performance, and compliance with international standards.

Partnering with Suzhou Baoshida means gaining access to precision-engineered rubber materials backed by responsive technical support and scalable production capacity. We work closely with OEMs, fabricators, and distributors to deliver cost-effective, high-quality solutions with reliable lead times and global logistics coordination.

Below is a representative specification profile for one of our standard roofing rubber compounds, illustrating the performance metrics achievable through our formulation expertise:

| Property | Test Method | Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥350% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Temperature Range | — | -40°C to +120°C |

| Specific Gravity | ASTM D297 | 1.25 ± 0.05 |

| Flame Resistance | UL 94 | HB Rated |

| Water Absorption (24 hrs) | ASTM D570 | ≤0.5% |

These values are indicative and can be adjusted based on client requirements. Custom durometers, conductive or non-conductive variants, colored compounds, and enhanced ozone resistance are available upon request.

To discuss your specific roofing rubber needs or request material samples and technical data sheets, contact Mr. Boyce directly. As the dedicated OEM Manager at Suzhou Baoshida Trading Co., Ltd., Mr. Boyce provides technical consultation, quotation support, and project coordination for international clients. He ensures that every engagement is handled with engineering precision and commercial efficiency.

Contact Mr. Boyce at [email protected] to initiate a technical discussion, submit a material inquiry, or request a customized formulation proposal. Include your application details, volume requirements, and performance expectations to receive a targeted solution. Our team responds promptly to all technical inquiries and supports client collaboration across time zones and regulatory environments.

Suzhou Baoshida Trading Co., Ltd. is committed to advancing industrial rubber technology through science-driven formulation and customer-centric service. Let us supply the material foundation for your next generation of high-performance roofing systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).