Technical Contents

Engineering Guide: 1 1 4 Square Tubing

Engineering Insight: Material Science Imperatives for 1.25 Inch Square Tubing

The designation “1 1 4 square tubing” specifies a critical dimensional profile: 1.25 inch outer dimensions with a square cross-section. In industrial fluid handling, pneumatic systems, and structural sealing applications, this geometry demands precise material science alignment. Off-the-shelf rubber tubing frequently fails under operational stress due to generic polymer formulations that ignore application-specific chemical, thermal, and mechanical loads. Standard extruded products prioritize cost over performance, utilizing base polymers like unmodified EPDM or SBR with inadequate filler systems. These compounds lack the tailored resilience required for dynamic compression, fluid compatibility, or extended service life, leading to premature degradation such as extrusion, cracking, or permeation failure.

Material selection must address three non-negotiable parameters. First, dimensional stability under pressure: square tubing experiences concentrated stress at corners, necessitating uniform durometer and wall thickness to prevent ovalization. Second, fluid resistance must be validated against specific media—not just generic “oil resistance.” Hydrocarbon exposure, for instance, requires NBR with ≥34% acrylonitrile content or hydrogenated alternatives like HNBR to avoid swelling-induced seal loss. Third, thermal cycling performance demands polymers with low compression set (≤20% per ASTM D395) at operational extremes. Generic tubing often exceeds 35% set, causing permanent deformation and leakage after repeated thermal excursions.

Ozone and UV exposure further differentiate engineered solutions. Standard tubing using non-antiozoned rubbers develops surface cracks within weeks in outdoor environments, while custom compounds integrate paraffinic waxes and tertiary amines for crack resistance. Crucially, wall thickness tolerance must be held to ±0.005 inch—not the ±0.015 inch common in commodity stock—to ensure consistent sealing force across the square profile’s edges.

The table below contrasts critical specifications between generic and engineered 1.25 inch square tubing:

| Property | Generic Tubing | Baoshida Engineered Solution |

|---|---|---|

| ID/OD Tolerance | ±0.015 inch | ±0.005 inch |

| Durometer Range | Fixed 70±5 Shore A | Custom 50–90 Shore A |

| Fluid Resistance (ASTM D471) | Swelling: ≤35% in IRM 903 | Swelling: ≤15% in IRM 903 |

| Temp Range | -20°F to +250°F | -65°F to +300°F |

| Elongation at Break | ≥200% | ≥350% |

These deviations explain why off-the-shelf tubing fails in high-cycle or aggressive-media applications. Material science must precede geometry: a 1.25 inch square profile is only as reliable as its polymer backbone. Suzhou Baoshida Trading Co., Ltd. engineers compounds using accelerated aging protocols and finite element analysis to simulate corner stress distribution, ensuring dimensional fidelity under load. Custom curing systems and silica-silane reinforcement further enhance fatigue resistance—proving that in precision sealing, the rubber formulation is never incidental. For mission-critical systems, engineered material selection is the non-negotiable foundation of operational integrity.

Material Specifications

Material Specifications for 1 1 4 Square Tubing in Industrial Rubber Applications

Suzhou Baoshida Trading Co., Ltd. provides high-performance rubber square tubing solutions engineered for precision and reliability in demanding industrial environments. The 1 1 4 square tubing designation refers to a cross-sectional dimension of 1 inch by 1 inch with a wall thickness of 1/4 inch, commonly used in sealing, damping, and protective applications across automotive, aerospace, chemical processing, and semiconductor industries. The performance of this tubing is critically dependent on the elastomer selected, with Viton, Nitrile (NBR), and Silicone representing three of the most widely specified materials due to their distinct chemical and thermal properties.

Viton, a fluorocarbon-based rubber, offers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It maintains structural integrity in continuous service temperatures up to 200°C (392°F), with short-term exposure tolerance reaching 250°C (482°F). This makes Viton ideal for applications involving engine compartments, fuel systems, and chemical exposure where long-term stability is paramount. Its low gas permeability and excellent aging characteristics further enhance reliability in sealed environments.

Nitrile rubber, or Buna-N, is a cost-effective solution optimized for resistance to petroleum-based oils, greases, and hydraulic fluids. It performs reliably in temperature ranges from -30°C to 100°C (-22°F to 212°F), with certain formulations extending low-temperature flexibility down to -50°C. Nitrile exhibits good abrasion resistance and mechanical strength, making it suitable for dynamic sealing applications such as pneumatic systems and industrial machinery where oil resistance is critical but extreme heat is not a factor.

Silicone rubber excels in extreme temperature applications, functioning effectively from -60°C to 230°C (-76°F to 446°F). It offers excellent resistance to ozone, UV radiation, and weathering, making it ideal for outdoor and high-purity environments such as medical devices and food processing. While silicone has lower tensile strength and abrasion resistance compared to Viton and Nitrile, its flexibility across a wide thermal range and compliance with FDA and USP Class VI standards make it a preferred choice for non-oil-related high-temperature or sanitary applications.

Selection of the appropriate material must consider fluid compatibility, thermal exposure, mechanical stress, and regulatory requirements. Suzhou Baoshida ensures all 1 1 4 square tubing products meet stringent dimensional tolerances and material certifications per ASTM D2000 and ISO 3302 standards.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 short-term) | -30 to 100 (-50 low-temp grade) | -60 to 230 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Excellent (petroleum oils, greases) | Poor (oils), Good (water, alcohols) |

| Compression Set Resistance | Excellent | Good | Moderate |

| UV/Ozone Resistance | Excellent | Fair | Excellent |

| Tensile Strength (MPa) | 10–15 | 10–20 | 5–8 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| FDA Compliance | Limited grades | No | Yes (specific formulations) |

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for 1 1 4 Square Tubing

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver engineered rubber solutions for demanding industrial applications, specifically excelling in the production of precision 1 1 4 square tubing. Our core strength resides in a dedicated team of seven specialized engineers: five Mould Engineers and two Rubber Formula Engineers. This integrated team operates beyond standard manufacturing, focusing on material science and tooling precision critical for complex geometries like square tubing where consistent wall thickness, sharp corners, and dimensional stability are non-negotiable. Our Formula Engineers meticulously develop and validate custom elastomer compounds, optimizing for specific client requirements such as extreme temperature resistance, chemical exposure, compression set, or tensile strength. Simultaneously, our Mould Engineers utilize advanced CAD/CAM and mold flow analysis to design and refine tooling that ensures uniform material distribution, minimizes flash, and achieves the tight tolerances demanded by square cross-section profiles, directly impacting product longevity and performance in sealing or structural roles.

Our OEM capabilities represent a seamless extension of this engineering rigor. We function as a true development partner, managing the entire process from initial concept and material selection through prototyping, rigorous validation testing, and full-scale production. This closed-loop workflow, governed by stringent ISO 9001 protocols, guarantees traceability and consistency. Clients benefit from our capacity to handle low-volume, high-complexity runs alongside high-volume production, all within our controlled manufacturing environment. We excel at translating technical specifications into reliable, repeatable outputs, significantly reducing time-to-market and mitigating risks associated with material failure or dimensional variance in critical applications such as fluid handling systems, gasketing, or protective conduit.

Material performance is paramount for 1 1 4 square tubing operating under stress. The table below outlines key customizable parameters achievable through our formula development and process control:

| Parameter | Standard Range | Customizable | Test Method |

|---|---|---|---|

| Hardness (Shore A) | 30 – 90 | Yes | ASTM D2240 |

| Temperature Range | -60°C to +250°C | Yes | ASTM D573 |

| Tensile Strength | 5.0 – 25.0 MPa | Yes | ASTM D412 |

| Elongation at Break | 150% – 700% | Yes | ASTM D412 |

| Compression Set | ≤ 25% (22h, 70°C) | Optimized | ASTM D395 |

| Dimensional Tolerance | ±0.1mm (critical faces) | Achieved | ISO 2768-m |

This technical foundation enables us to solve complex client challenges. For instance, when a major automotive supplier required square tubing resistant to aggressive biofuels at elevated temperatures, our Formula Engineers developed a proprietary FKM variant, while the Mould Engineering team refined the tooling to prevent corner degradation during curing, resulting in a 40% increase in service life versus the incumbent solution. We do not merely supply rubber; we engineer validated performance. Partnering with Suzhou Baoshida ensures your 1 1 4 square tubing meets exacting functional demands through science-driven material formulation, precision tooling, and comprehensive OEM execution, delivering reliability you can measure in reduced failure rates and extended product lifecycle.

Customization Process

Customization Process for 1 1 4 Square Rubber Tubing

At Suzhou Baoshida Trading Co., Ltd., the customization of 1 1 4 square rubber tubing begins with a rigorous engineering workflow designed to meet precise industrial requirements. Our process ensures dimensional accuracy, material compatibility, and performance reliability under operational stress. The sequence follows four critical stages: Drawing Analysis, Formulation Development, Prototyping, and Mass Production.

The first stage, Drawing Analysis, involves a detailed review of customer-provided technical drawings or CAD models. Engineers assess critical dimensions, tolerances, surface finish requirements, and any special features such as wall thickness uniformity or corner radii. The 1 1 4 square tubing specification—referring to a nominal outer dimension of 1.25 inches per side—is validated against industry standards and manufacturing feasibility. Any discrepancies or design limitations are communicated to the client for optimization prior to material selection.

Following drawing validation, the Formulation stage begins. Our rubber formulation team selects elastomer compounds based on application demands such as temperature range, chemical exposure, compression set resistance, and mechanical load. Common base materials include NBR (nitrile butadiene rubber), EPDM (ethylene propylene diene monomer), and silicone, each offering distinct advantages in different environments. Additives are precisely metered to enhance UV resistance, flame retardancy, or abrasion performance. The final compound is documented and archived for batch traceability.

Once the formulation is approved, we proceed to Prototyping. A short production run is conducted using calibrated extrusion and continuous vulcanization lines to produce sample lengths of the 1 1 4 square tubing. These prototypes undergo dimensional verification via coordinate measuring machines (CMM) and physical testing including durometer hardness, tensile strength, and elongation at break. Samples are submitted to the client for functional evaluation in their specific assembly or sealing application.

Upon successful prototype approval, the project transitions into Mass Production. Our automated extrusion lines operate under strict process controls, with real-time monitoring of temperature profiles, line speed, and cure parameters. Each production batch is subject to in-process quality checks and final inspection before packaging. We maintain full documentation for ISO compliance and support just-in-time delivery logistics for OEM integration.

The following table outlines key technical specifications commonly associated with customized 1 1 4 square rubber tubing:

| Parameter | Standard Value | Tolerance | Test Method |

|---|---|---|---|

| Outer Dimension | 1.25 in (31.75 mm) | ±0.008 in (±0.20 mm) | ISO 3302-1 |

| Wall Thickness | Custom (typ. 0.125–0.250 in) | ±0.005 in (±0.13 mm) | ISO 3302-1 |

| Hardness Range | 50–90 Shore A | ±5 Shore A | ASTM D2240 |

| Operating Temperature | -40°C to +150°C (varies by compound) | — | ASTM D1329 |

| Tensile Strength | ≥10 MPa | — | ASTM D412 |

| Elongation at Break | ≥250% | — | ASTM D412 |

This structured approach ensures that every custom 1 1 4 square rubber tubing solution meets the highest standards of performance, consistency, and industrial applicability.

Contact Engineering Team

Precision Rubber Extrusion Solutions for Industrial Structural Components

Suzhou Baoshida Trading Co., Ltd. specializes in engineered rubber extrusion profiles for critical industrial applications, including structural reinforcement components. While the designation “1 1 4 square tubing” typically references metal fabrication, our expertise lies in producing high-integrity 1x1x4 inch rubber extrusion profiles designed to interface with or replace rigid structural elements in dynamic systems. These profiles deliver vibration damping, thermal insulation, chemical resistance, and sealing performance where metal tubing alone cannot meet operational demands. Confusion between metal and elastomeric components often leads to suboptimal system design; our team ensures precise material selection and dimensional accuracy for seamless integration into your assembly.

Our proprietary rubber formulations undergo rigorous finite element analysis (FEA) to validate performance under compressive, tensile, and torsional loads. Standard 1x1x4 inch profiles are manufactured to ISO 3302-1 M2 tolerances, with cross-sectional consistency critical for load distribution in gasketing, shock absorption, and environmental sealing applications. Below are key specifications for our baseline industrial-grade extrusion:

| Parameter | Specification Detail | Testing Standard |

|---|---|---|

| Cross-Section Dimensions | 1.000″ x 1.000″ x 0.250″ wall thickness | ISO 3302-1 M2 |

| Material Options | EPDM, NBR, Silicone, HNBR, CR | ASTM D2000 |

| Durometer Range | 40–90 Shore A | ASTM D2240 |

| Tensile Strength | 1,500–3,200 psi (varies by compound) | ASTM D412 |

| Elongation at Break | 250–600% | ASTM D412 |

| Compression Set (70h/70°C) | ≤25% | ASTM D395 |

| Production Capacity | 500–2,000 meters per production run | Internal QC Protocol |

These profiles are not generic off-the-shelf items but engineered solutions. We address challenges such as ozone degradation in outdoor hydraulic systems, fuel resistance in mobile equipment, and thermal cycling stability in aerospace substrates through custom polymer science. Our ISO 9001:2015-certified facility utilizes closed-loop extrusion monitoring to maintain ±0.005″ dimensional control, ensuring repeatability across 10,000+ meter orders. Clients benefit from accelerated prototyping—typically 7–10 days from CAD submission to physical sample—supported by in-house compound development labs that optimize cure kinetics and filler dispersion for your specific operating environment.

For mission-critical applications where material failure compromises system integrity, Suzhou Baoshida provides OEMs with full technical stewardship. Our engineers collaborate directly with your design team to refine extrusion geometry, validate finite element models, and certify performance against SAE, MIL, or customer-specific standards. We eliminate the guesswork in elastomer selection through accelerated aging protocols that simulate 5+ years of field exposure in 4 weeks, delivering data-driven recommendations for longevity.

Initiate your project with validated engineering support. Contact Mr. Boyce, our dedicated OEM Technical Manager, to discuss material compatibility, tolerance optimization, or rapid prototyping for 1x1x4 inch rubber extrusion profiles. Provide your application’s pressure, temperature, and fluid exposure parameters for a targeted compound recommendation within 24 hours. Email [email protected] with subject line “1x1x4 Profile Engineering Query” to receive a formal quotation inclusive of material certification, dimensional reports, and production lead time analysis. Suzhou Baoshida ensures your structural elastomer components perform as engineered—not as compromises.

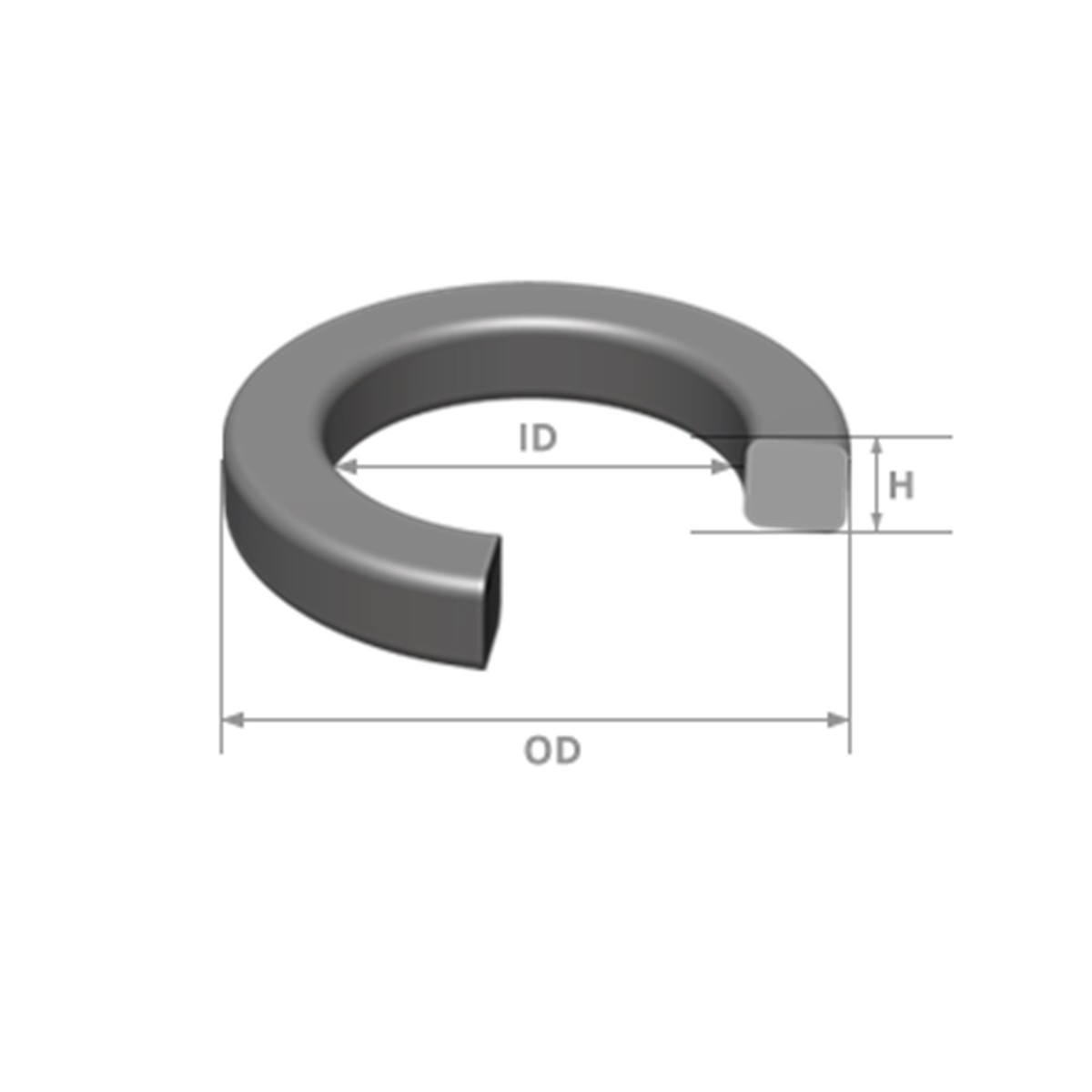

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).