Technical Contents

Engineering Guide: Rubber Cutting Edge

Engineering Insight: Material Selection for Rubber Cutting Edge Applications

In high-precision industrial environments, the term “rubber cutting edge” denotes components operating under extreme mechanical, thermal, and chemical stressors where failure is not an option. Off-the-shelf elastomer solutions frequently underperform because they prioritize cost and general usability over application-specific engineering. Generic compounds lack the tailored polymer morphology required to resist simultaneous challenges like high-frequency cyclic loading, aggressive media exposure, and dimensional stability at operational extremes. This mismatch leads to premature compression set, extrusion, chemical degradation, or catastrophic seal failure—costing OEMs downtime, warranty claims, and reputational damage.

Material selection must begin with a granular analysis of the operational envelope. Standard NBR or EPDM formulations fail when exposed to modern biofuels, ozone concentrations exceeding 50 ppb, or temperatures beyond -40°C to +120°C. Critical applications demand engineered compounds where polymer backbone saturation, crosslink density, and filler dispersion are optimized at the molecular level. For instance, aerospace hydraulic seals require fluorosilicone elastomers with peroxide curing to withstand Skydrol® fluids at -55°C, while semiconductor wafer handling mandates ultra-pure FFKM with <1 ppb outgassing. Compromising on these parameters results in micro-cracking, fluid ingress, or particle shedding that contaminates sensitive processes.

The table below illustrates why off-the-shelf materials fall short in cutting-edge scenarios compared to precision-engineered alternatives.

| Property | Off-the-Shelf Compound Range | Critical Application Requirement | Failure Consequence |

|---|---|---|---|

| Compression Set (ASTM D395) | 25–40% after 70 hrs @ 100°C | <15% after 1,000 hrs @ 150°C | Seal leakage, loss of clamping force |

| Abrasion Resistance (ASTM D2228) | 120–180 mm³ loss | <80 mm³ loss | Edge erosion, particulate generation |

| Fluid Resistance (ASTM D471) | Swell >25% in hydraulic fluid | Swell <8% in synthetic ester | Seal extrusion, pressure drop |

| Temperature Range | -30°C to +120°C | -55°C to +230°C | Brittleness at low T, thermal runaway at high T |

Suzhou Baoshida Trading Co., Ltd. addresses these gaps through OEM-centric material science. Our process starts with dissecting the client’s duty cycle—mapping pressure spikes, media chemistry, and dynamic movement profiles—then developing proprietary polymer matrices. We utilize high-purity peroxide-cured HNBR for oilfield downhole tools requiring H₂S resistance, or custom ACM compounds for EV battery thermal interface materials needing non-flammability per UL 94 V-0. Every formulation undergoes accelerated life testing against real-world stressors, not just baseline ASTM standards.

Generic rubber solutions treat all edges as identical. True cutting-edge performance demands materials engineered at the molecular level for the specific edge case. Partnering with an OEM-focused supplier ensures elastomers that don’t just meet specifications but deliver reliability where failure is measured in microseconds. This precision is non-negotiable for industries where rubber components are the final barrier against system collapse.

Material Specifications

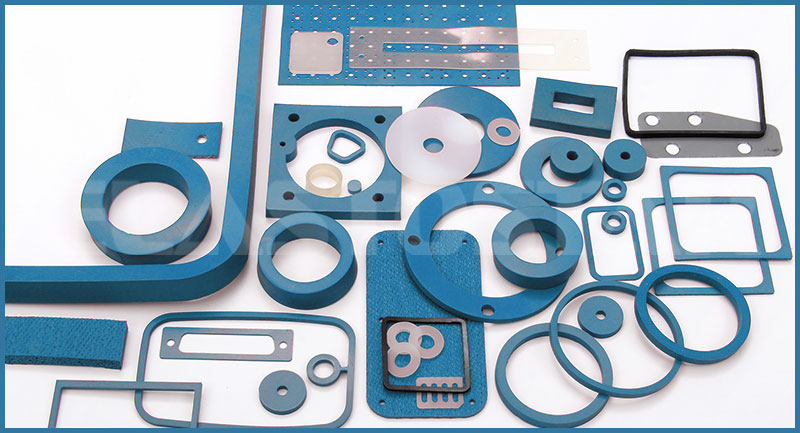

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions engineered for precision, durability, and reliability in demanding environments. Our rubber cutting edge products are formulated using advanced elastomeric compounds, each selected for specific operational requirements. Among the most widely utilized materials are Viton, Nitrile (NBR), and Silicone, each offering distinct advantages in temperature resistance, chemical compatibility, mechanical strength, and sealing performance. Understanding the material properties is essential for optimizing performance in industrial applications such as hydraulic systems, automotive components, aerospace seals, and chemical processing equipment.

Viton, a fluorocarbon-based elastomer (FKM), is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With continuous service capabilities up to 230°C and intermittent exposure tolerance beyond 260°C, Viton is ideal for extreme environments where thermal and chemical degradation are primary concerns. Its low permeability and excellent aging characteristics make it a preferred choice for critical sealing applications in the aerospace, petrochemical, and semiconductor industries.

Nitrile rubber, or Buna-N, offers superior resistance to petroleum-based oils, greases, and fuels, making it one of the most commonly used elastomers in industrial and automotive sealing systems. It exhibits good abrasion resistance and tensile strength, with an operational temperature range of -30°C to 120°C. While not suitable for prolonged exposure to ozone or UV radiation, Nitrile provides a cost-effective, high-performance solution for dynamic and static seals in hydraulic and fuel delivery systems.

Silicone rubber (VMQ) excels in extreme temperature applications, with serviceability from -60°C to 200°C, and short-term resilience down to -100°C in specialized grades. It demonstrates excellent resistance to ozone, UV radiation, and weathering, making it ideal for outdoor and medical applications. While its mechanical strength and oil resistance are lower than Viton or Nitrile, silicone offers outstanding electrical insulation properties and biocompatibility, supporting use in medical devices, food processing, and high-voltage insulation.

The selection of the appropriate elastomer depends on the specific environmental and mechanical demands of the application. Suzhou Baoshida Trading Co., Ltd. ensures precise material formulation, quality control, and custom engineering support to match the right rubber compound to your industrial needs.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 (up to 260 intermittent) | -30 to 120 | -60 to 200 (down to -100 intermittent) |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 200–300 | 200–500 | 200–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Very Good | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

| Common Applications | Aerospace, chemical seals, semiconductor | Automotive seals, hydraulic systems | Medical devices, food processing, electrical insulation |

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions Through Integrated Expertise

Suzhou Baoshida Trading Co., Ltd. delivers industry-leading rubber component manufacturing through a synergistic fusion of formula science and precision mould engineering. Our dedicated team comprises five certified Mould Engineers and two specialized Rubber Formula Engineers, uniquely positioned to address complex material and geometric challenges inherent in high-performance industrial applications. This integrated approach ensures seamless translation from raw compound design to final part production, eliminating the siloed workflows that compromise quality at competitors.

Our Formula Engineers pioneer custom elastomer formulations tailored to extreme operational demands, including temperature resilience from -60°C to 300°C, chemical resistance against aggressive media, and dynamic mechanical properties for fatigue-critical applications. Each compound undergoes rigorous validation through ASTM D2000 testing protocols, accelerated aging cycles, and finite element analysis (FEA) simulation to predict real-world behavior. This scientific rigor prevents field failures in sectors like automotive sealing systems, where a single formulation flaw can cascade into multi-million-dollar recalls.

Complementing this, our Mould Engineering team leverages advanced CAD/CAM suites (SolidWorks, Moldflow) to design tooling that achieves micron-level tolerances while optimizing cycle times and material yield. We specialize in multi-cavity precision moulds for complex geometries—including micro-extruded profiles, bonded assemblies, and zero-flash components—ensuring repeatability across volumes from prototyping to 500,000+ annual units. Critical to this is our concurrent engineering process: mould designers collaborate with formula specialists during the initial phase to align cavity flow dynamics with compound viscosity profiles, preventing defects like knit lines or incomplete cures.

As a certified OEM partner, we manage end-to-end production under ISO 9001 and IATF 16949 frameworks, providing full documentation traceability from raw material certificates to first-article inspection reports. Clients benefit from reduced time-to-market through our rapid tooling iterations—achieving mould modifications in 72 hours—and dedicated production cells that isolate sensitive projects from contamination risks. This capability is proven in supplying Tier-1 automotive hydraulic seals requiring 0.02mm dimensional stability and aerospace vibration dampeners meeting AMS-7259 specifications.

The table below quantifies our core engineering parameters versus industry benchmarks:

| Parameter | Suzhou Baoshida Capability | Standard Industry Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.02 mm | ±0.05 mm |

| Material Hardness Range | 20–90 Shore A | 30–80 Shore A |

| Mould Cycle Time Reduction | 15–25% | 5–10% |

| Compound Validation Tests | 12+ per formulation | 5–7 per formulation |

| OEM Project Lead Time | 8–10 weeks (prototype) | 12–16 weeks (prototype) |

This engineering cohesion—where material science and tooling precision operate as a unified system—enables Suzhou Baoshida to solve previously intractable challenges in fluid handling, energy absorption, and dynamic sealing. We transform OEM specifications into defect-free production realities, ensuring every rubber component meets the uncompromising standards of modern industrial machinery. Partner with us to convert material innovation into measurable operational advantage.

Customization Process

Customization Process for Rubber Cutting Edges at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to the exacting demands of modern manufacturing. Our structured customization process ensures precision, durability, and compatibility across diverse operating environments. This process consists of four critical stages: Drawing Analysis, Formulation, Prototyping, and Mass Production.

The first phase, Drawing Analysis, begins with a comprehensive review of the client’s technical specifications and application requirements. Our engineering team evaluates dimensional tolerances, load conditions, environmental exposure (e.g., temperature, chemicals, abrasion), and mechanical constraints. We verify geometric integrity using CAD-based modeling tools and conduct feasibility assessments to identify potential design optimizations. This step ensures that the final product aligns with both functional performance and manufacturability standards.

Following drawing validation, we proceed to Formulation. Our rubber chemists develop a custom elastomer compound based on the operational profile of the cutting edge. Factors such as hardness, tensile strength, compression set, and resistance to oils, ozone, or extreme temperatures are meticulously balanced. We utilize a range of base polymers—including NBR, EPDM, Viton (FKM), and silicone—each selected for specific performance attributes. Additives such as reinforcing fillers, antioxidants, and curing agents are precisely dosed to achieve the target physical and chemical properties.

Once the formulation is finalized, we enter the Prototyping phase. Using precision molding techniques such as compression, transfer, or injection molding, we produce a limited batch of sample components. These prototypes undergo rigorous laboratory testing, including hardness measurement, tensile testing, aging resistance, and dynamic performance simulation. Clients are provided with test reports and physical samples for field evaluation. Feedback is integrated into any necessary design or material refinements before approval for scale-up.

The final stage is Mass Production, executed in our ISO-certified manufacturing facility. We deploy automated molding lines, real-time quality monitoring, and statistical process control (SPC) to ensure batch-to-batch consistency. Every rubber cutting edge is inspected for dimensional accuracy and surface integrity prior to packaging. Our production capacity supports both medium and high-volume orders with reliable lead times and full traceability.

The table below outlines typical performance specifications achievable through our customization process:

| Property | Test Method | Typical Range |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 50–90 |

| Tensile Strength | ASTM D412 | 8–25 MPa |

| Elongation at Break | ASTM D412 | 200–600% |

| Compression Set (70°C, 22h) | ASTM D395 | ≤25% |

| Operating Temperature | — | -40°C to +250°C (FKM) |

| Fluid Resistance | ASTM D471 | Oil, water, acids, ozone |

Through this disciplined, science-driven approach, Suzhou Baoshida delivers rubber cutting edges that meet the highest industrial standards—engineered for performance, validated for reliability, and built for longevity.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Cutting Edge Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber formulation and OEM manufacturing, delivering quantifiable performance for cutting-edge applications. Our engineering team specializes in resolving complex material challenges where standard elastomers fail—addressing demands for extreme abrasion resistance, chemical stability, thermal endurance, and micron-level dimensional accuracy. When your project requires rubber components operating at the physical limits of material science, direct engagement with our technical OEM management ensures optimal solution design from inception to量产. Generic supplier relationships cannot replicate the precision engineering required for high-stakes rubber cutting edge applications; only a partner with deep compound expertise and process control mastery delivers consistent, failure-resistant performance.

The table below summarizes critical parameters where our engineered rubber formulations achieve industry-leading results, directly impacting your product’s operational lifespan and reliability. These specifications are not theoretical ideals but validated outputs from our ISO 9001-certified production systems, tailored to your exacting requirements.

| Parameter | Specification Range | Application Impact |

|---|---|---|

| Hardness (Shore A) | 30–95 | Optimized for dynamic load distribution |

| Temperature Resistance | -60°C to +300°C | Sustained performance in extreme cycles |

| Tensile Strength | 15–40 MPa | Critical for high-stress cutting interfaces |

| Compression Set (70h) | ≤15% @ 100°C | Ensures long-term sealing integrity |

| Abrasion Loss (DIN) | ≤65 mm³ | Maximizes component service life |

Initiate collaboration by contacting Mr. Boyce, our dedicated OEM Manager, who possesses 12 years of hands-on experience in rubber compound development for automotive, semiconductor, and heavy machinery sectors. His technical authority spans raw material selection, vulcanization kinetics optimization, and tolerance-bound molding processes—ensuring your cutting edge specifications translate into flawless physical components. Email [email protected] with your project’s material performance targets, environmental stressors, and dimensional constraints. Include any existing failure analysis data or CAD geometry for accelerated prototyping. Mr. Boyce will coordinate our formulation chemists and process engineers to deliver a validated solution pathway within 72 hours, not generic product catalogs.

Do not compromise on the material foundation of your cutting edge technology. Suzhou Baoshida’s OEM partnership model eliminates the guesswork in rubber component performance through data-driven compound engineering and rigorous in-house validation testing. Every specification we commit to is backed by ASTM/ISO test reports and batch traceability to raw material lots. Contact Mr. Boyce immediately to schedule a technical consultation—provide your target operating parameters, and we will present a customized compound formulation strategy with quantifiable performance projections. In precision rubber manufacturing, the margin for error is measured in microns; trust only a partner whose expertise operates at that scale. Initiate your project with engineering certainty.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).