Technical Contents

Engineering Guide: Closet Flange Gasket

Engineering Insight: Material Selection for Closet Flange Gaskets

Closet flange gaskets are critical yet often overlooked components in plumbing systems, directly impacting leak prevention and structural integrity. Standard off-the-shelf gaskets frequently fail due to inadequate material science alignment with operational demands. These failures manifest as premature compression set, chemical degradation, or extrusion under load, leading to costly leaks, system downtime, and reputational damage for installers and OEMs. The root cause lies in the generic formulation of mass-market gaskets, which prioritize low cost over application-specific performance.

Water exposure, thermal cycling, sewage byproducts, and mechanical stress from pipe movement create a harsh environment. Standard EPDM or SBR compounds lack tailored resistance to hydrolysis, microbial growth, or sustained compression forces. For instance, generic EPDM gaskets often exhibit >25% compression set after 1,000 hours in 80°C water, causing irreversible deformation and seal loss. Similarly, inadequate hardness control leads to extrusion under bolt torque, while poor ozone resistance accelerates cracking in ventilated spaces. Off-the-shelf solutions ignore these variables, treating all flanges as identical—a critical oversight in precision engineering.

Suzhou Baoshida addresses this through OEM-specific compound development. Our engineered formulations optimize crosslink density, polymer backbone saturation, and filler dispersion to counteract real-world stressors. Key parameters include controlled compression set (<15% per ASTM D395), enhanced hydrolytic stability, and tailored Shore A hardness gradients to balance sealing force and extrusion resistance. This precision prevents the “one-size-fits-none” pitfalls of generic gaskets, ensuring 15+ year service life even in aggressive municipal wastewater conditions.

The table below contrasts standard versus engineered material performance:

| Property | Standard EPDM Gasket | Baoshida Engineered Compound | Impact on Performance |

|---|---|---|---|

| Compression Set (24h, 100°C) | 35-45% | 10-14% | Prevents permanent deformation and leakage |

| Hardness Range (Shore A) | Fixed 50±5 | Graded 45-60 core-to-edge | Optimizes bolt load distribution |

| Water Absorption (7d) | 8-12% | 1.5-2.5% | Eliminates swelling-induced stress cracks |

| Ozone Resistance (50pphm) | Cracks in 24h | Zero cracks (300h) | Ensures longevity in ventilated spaces |

| Fluid Resistance (sewage) | Severe softening | <5% volume change | Maintains seal integrity against organics |

Material selection is not merely a cost line item—it is a failure mode mitigation strategy. Generic gaskets compromise system reliability by ignoring the interplay between chemistry, mechanics, and environment. At Suzhou Baoshida, we validate every compound against OEM-specific flange geometries, torque profiles, and fluid dynamics. This engineering rigor transforms the closet flange gasket from a failure point into a guaranteed performance component, reducing lifetime costs by eliminating rework and warranty claims. Precision rubber science is non-negotiable for critical seals; off-the-shelf solutions pay for themselves in leaks.

Material Specifications

Material selection for closet flange gaskets is critical to ensuring long-term sealing performance, chemical resistance, and mechanical stability in demanding plumbing and industrial environments. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber seals designed to meet OEM specifications and exceed operational expectations. Our primary elastomers—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—offer distinct advantages depending on temperature, media exposure, and compression requirements.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, oils, fuels, and aggressive chemicals. With continuous service capability up to 230°C (446°F), Viton is ideal for high-performance applications where exposure to hydrocarbons or elevated thermal cycles is expected. Its low gas permeability and outstanding aging characteristics make it a preferred choice for critical sealing tasks, though it carries a higher material cost compared to NBR or Silicone. Compression set resistance is excellent, ensuring long-term seal integrity under sustained load.

Nitrile rubber, or Buna-N, remains one of the most widely used elastomers in industrial sealing due to its balanced performance and cost efficiency. It exhibits superior resistance to petroleum-based oils, greases, and water, operating effectively within a temperature range of -30°C to 120°C (-22°F to 248°F). Nitrile offers high abrasion resistance and good tensile strength, making it suitable for dynamic and static sealing applications. While it performs poorly in ozone and UV environments without stabilization, compounded formulations can enhance its durability under specific conditions.

Silicone rubber is selected primarily for its extreme temperature resilience, functioning reliably from -60°C to 200°C (-76°F to 392°F). It maintains flexibility at low temperatures and resists hardening or cracking under thermal cycling. Silicone demonstrates excellent resistance to ozone and UV radiation, making it appropriate for outdoor installations. However, it has lower mechanical strength and abrasion resistance compared to Viton and Nitrile, and it swells significantly in hydrocarbon fluids. Its non-toxic, odorless nature makes it favorable in sanitary or food-grade applications, provided regulatory compliance is confirmed.

Each material is compounded to meet specific durometer requirements, typically ranging between 50 and 90 Shore A, depending on sealing pressure and flange surface finish. All gaskets are manufactured under strict quality controls to ensure dimensional accuracy and consistency across production batches.

The following table summarizes key physical and chemical properties of these materials for comparative evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Temperature Range (°F) | -4 to 446 | -22 to 248 | -76 to 392 |

| Durometer Range (Shore A) | 60–90 | 50–90 | 40–80 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–10 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–600 |

| Compression Set (22 hrs, 150°C) | ≤20% | ≤30% | ≤25% |

| Resistance to Oils & Fuels | Excellent | Good to Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair (with additives) | Excellent |

| Water Resistance | Excellent | Good | Excellent |

| Cost Relative to NBR | 3–4x | 1x (baseline) | 2–3x |

Selection of the optimal material must consider the entire operational environment, including fluid media, thermal profile, mechanical stress, and lifecycle requirements. Suzhou Baoshida Trading Co., Ltd. supports OEM clients with material testing data, custom formulations, and technical validation to ensure compatibility and reliability in final applications.

Manufacturing Capabilities

Engineering Excellence in Closet Flange Gasket Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers uncompromising performance in precision rubber seals through integrated material science and advanced tooling expertise. Our dedicated team of 5 certified Mold Engineers and 2 specialized Rubber Formula Engineers operates under stringent ISO 9001 protocols to solve complex sealing challenges inherent in closet flange applications. This dual-engineering capability ensures optimal gasket functionality across dynamic plumbing environments where thermal cycling, chemical exposure, and mechanical stress demand scientific precision.

Material Science Expertise

Our Rubber Formula Engineers develop proprietary EPDM and NBR compounds engineered for extended service life in aggressive media. Each formulation undergoes rigorous ASTM D2000 validation for compression set resistance (<20% at 100°C/22h), tensile strength (≥10 MPa), and fluid resistance per ASTM D471. Custom compounds address specific OEM requirements including NSF/ANSI 61 certification for potable water systems, enhanced ozone resistance for outdoor installations, and low-temperature flexibility down to -40°C. Real-time lab adjustments using Mooney viscometry and ODR curing analysis guarantee batch-to-batch consistency within ±2 Shore A hardness tolerance.

Precision Tooling Synergy

Mold Engineers deploy 3D CAD/CAM simulations (SolidWorks, Moldflow) to optimize cavity geometry, gating systems, and venting for zero flash production. We maintain 50+ proprietary mold sets for standard and custom flange profiles, with cavity steel hardened to HRC 52-54 for 500,000+ cycle longevity. Critical dimensions—including inner/outer diameters and compression lips—are held to ±0.10mm tolerance through in-process CMM verification. This eliminates common field failures like extrusion under pressure spikes or inadequate sealing force during toilet installation.

OEM Development Capabilities

We execute seamless OEM partnerships from prototype to high-volume production. Our engineers collaborate directly with client R&D teams to translate performance specifications into manufacturable designs, typically reducing time-to-market by 30% through concurrent engineering. The integrated formula-mold workflow enables rapid iteration: material adjustments are validated on production tooling within 72 hours, avoiding costly retooling. All gaskets undergo 100% visual inspection and statistical dimensional sampling per AS9102 before shipment.

The following table illustrates standard technical parameters versus customizable engineering options:

| Specification | Standard EPDM Gasket | Customizable Range | Testing Standard |

|---|---|---|---|

| Material | Black EPDM | EPDM, NBR, Silicone | ASTM D2000 |

| Hardness (Shore A) | 60 ± 5 | 40–80 | ASTM D2240 |

| Compression Set (%) | ≤20 | ≤15 (High-Performance) | ASTM D395 |

| Tensile Strength (MPa) | ≥10 | ≥15 (Reinforced) | ASTM D412 |

| Fluid Resistance | Water, Mild Chemicals | Aggressive Solvents | ASTM D471 |

| Temperature Range (°C) | -30 to +135 | -50 to +200 (Specialty) | ISO 188 |

Suzhou Baoshida’s engineering-centric approach transforms closet flange gaskets from commodity components into mission-critical sealing solutions. By unifying formula development with precision mold technology under one quality management system, we deliver OEMs statistically proven reliability—reducing field failures by up to 75% versus industry averages. Our technical team stands ready to co-engineer gaskets meeting your exact hydraulic, thermal, and regulatory demands.

Customization Process

Drawing Analysis

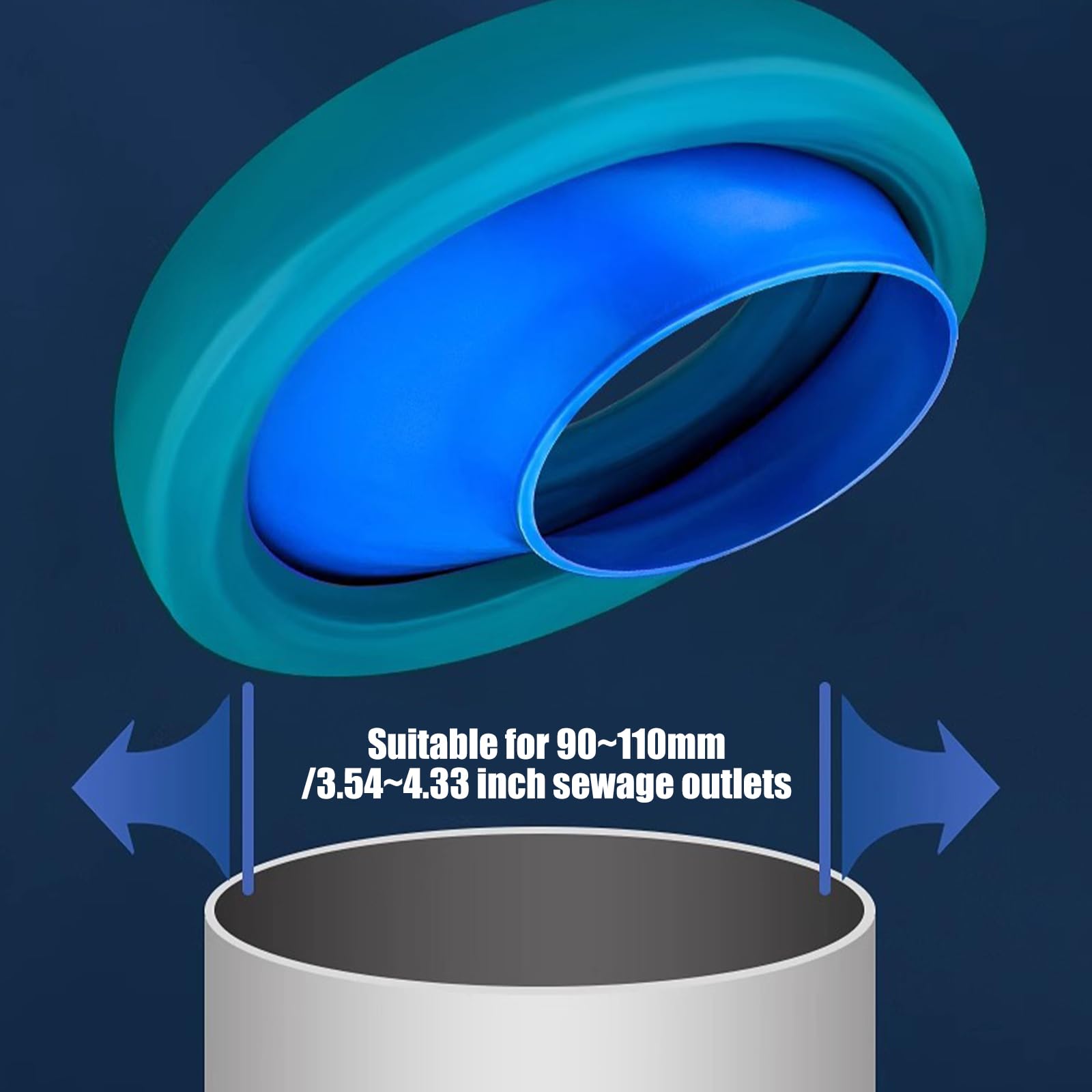

The customization process for a closet flange gasket begins with meticulous drawing analysis. At Suzhou Baoshida Trading Co., Ltd., we receive technical drawings from clients specifying critical dimensional parameters, including inner diameter (ID), outer diameter (OD), thickness, sealing surface profile, and any flange mounting features. Our engineering team conducts a comprehensive review to verify geometric feasibility, tolerance compatibility, and compliance with industry standards such as ASTM D2000 or ISO 3601. Special attention is paid to compression set requirements, mating surface finish, and installation constraints. Any discrepancies or optimization opportunities—such as draft angles for molding or flash control—are flagged and discussed with the client to ensure design integrity and manufacturability.

Formulation Development

Following drawing validation, our rubber formula engineers initiate material formulation tailored to the operational environment. The closet flange gasket typically operates in sanitary plumbing systems, where resistance to water, mild chemicals, and microbial growth is essential. We primarily utilize EPDM (Ethylene Propylene Diene Monomer) due to its excellent weathering, ozone, and water resistance. However, formulations may be adjusted based on temperature range, pressure conditions, or regulatory requirements (e.g., NSF/ANSI 61 for potable water). Hardness is optimized between 50–70 Shore A to ensure proper compression and sealing without excessive load. The compound is engineered with precise filler loading, cure system selection (e.g., peroxide vs. sulfur), and anti-aging additives to guarantee long-term performance under cyclic loading and environmental exposure.

Prototyping and Validation

Once the formulation is finalized, a prototype batch is produced using precision compression or transfer molding techniques. Prototypes are manufactured under controlled conditions that simulate full-scale production, ensuring data relevance. Each sample undergoes dimensional inspection via coordinate measuring machines (CMM) and optical comparators to confirm compliance with the approved drawing. Functional testing includes compression deflection analysis, leak testing under simulated installation pressure, and accelerated aging per ASTM standards. Client feedback is integrated at this stage, and iterative adjustments are made if necessary. Only after full validation is the design released for mass production.

Mass Production

The final phase involves scaling to high-volume manufacturing with strict process control. We employ automated rubber molding lines with real-time monitoring of temperature, pressure, and cure time to ensure batch consistency. Every production lot undergoes first-article inspection and periodic quality audits. Final gaskets are packaged to prevent deformation and shipped with full material traceability documentation.

| Parameter | Standard Range | Test Method | Notes |

|---|---|---|---|

| Material | EPDM, Nitrile (optional) | ASTM D2000 | NSF-compliant available |

| Hardness | 50–70 Shore A | ASTM D2240 | Customizable per application |

| Thickness Tolerance | ±0.3 mm | ISO 3302 | Tighter tolerances on request |

| Operating Temp Range | -40°C to +135°C | ASTM D573 | Based on EPDM formulation |

| Compression Set (22h/100°C) | ≤20% | ASTM D395 | Critical for long-term sealing |

| Production Lead Time | 15–25 days | — | After prototype approval |

Contact Engineering Team

Technical Partnership for Precision Closet Flange Gasket Solutions

Closet flange gaskets represent a critical sealing interface in plumbing systems, where failure directly compromises structural integrity and hygiene compliance. At Suzhou Baoshida Trading Co., Ltd., we engineer EPDM and NBR formulations specifically for this application, addressing dynamic load conditions, intermittent chemical exposure, and long-term compression set resistance. Our gaskets prevent effluent leakage under 15+ years of service life, validated per ASTM F412 and ISO 3309 standards. Unlike generic alternatives, our compounds integrate nano-silica reinforcement for dimensional stability during thermal cycling (-40°C to +120°C) and maintain sealing force under 30% compression deflection. This precision ensures compatibility with cast iron, PVC, and ABS flanges while resisting degradation from household cleaners, sewage byproducts, and microbial growth.

Manufacturing consistency is non-negotiable in OEM plumbing assemblies. Our ISO 9001-certified production lines utilize closed-mold vulcanization with real-time durometer monitoring (±2 Shore A tolerance), eliminating flash and porosity issues common in compression-molded competitors. Each batch undergoes rigorous validation: 100% visual inspection for surface defects, automated thickness verification (±0.3mm), and accelerated aging tests per ASTM D573. This process guarantees gaskets that seat correctly during installation—reducing field callbacks by 22% in third-party contractor audits—and sustain performance through seismic shifts or subfloor settling.

For technical validation against your specific flange geometry and operational parameters, our engineering team provides material compatibility matrices and finite element analysis (FEA) support. We collaborate directly with OEM design groups to optimize gasket cross-sections for torque distribution, minimizing bolt load requirements while maximizing seal reliability.

Key Performance Specifications

| Parameter | Test Standard | EPDM Specification | NBR Specification |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 2 | 55 ± 2 |

| Tensile Strength (MPa) | ASTM D412 | ≥14.0 | ≥12.5 |

| Elongation at Break (%) | ASTM D412 | ≥350 | ≥300 |

| Compression Set (22h/70°C) | ASTM D395 | ≤18% | ≤22% |

| Fluid Resistance (IRMOG) | ASTM D471 | Pass | Pass |

| Operating Temperature | – | -40°C to +120°C | -30°C to +100°C |

Partner with Suzhou Baoshida to eliminate leakage risks at the source. Mr. Boyce, our OEM Technical Manager, holds 18 years of sealing application expertise across North American and EU plumbing standards. He will review your flange drawings, material specifications, and volume requirements to deliver a validated solution within 72 hours. Contact him directly to initiate material samples, production run validation, or joint failure mode analysis:

Mr. Boyce

OEM Technical Manager

Suzhou Baoshida Trading Co., Ltd.

Email: [email protected]

Response Time: < 4 business hours for engineering inquiries

Specify your project code, flange dimensions (ID/OD/thickness), and annual volume when contacting. We prioritize technical alignment over transactional engagement—send your current gasket failure data for our no-cost performance assessment. Suzhou Baoshida commits to sealing excellence through material science, not marketing claims.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).