Technical Contents

Engineering Guide: Tile Floor Protection

Engineering Insight: Material Science as the Foundation of Tile Floor Protection

In industrial tile floor protection applications, material selection transcends mere product specification—it is the decisive factor between sustained performance and premature system failure. Generic rubber mats marketed for tile protection frequently fail under operational demands due to fundamental polymer chemistry deficiencies. These off-the-shelf solutions prioritize initial cost reduction over engineered resilience, leading to costly downtime, tile damage, and repeated replacement cycles. The core issue lies in inadequate formulation for the specific mechanical and environmental stresses encountered in manufacturing, logistics, and high-traffic commercial environments.

Plasticizer migration represents a primary failure mechanism in standard mats. Low-cost formulations often exceed 20% phthalate-based plasticizers to achieve initial flexibility. Under sustained pressure and elevated temperatures common in industrial settings, these plasticizers leach out, causing the rubber to harden irreversibly. This hardened state loses shock absorption capacity, transferring impact loads directly to tile surfaces and grout lines. Simultaneously, migrated plasticizers create a permanent adhesive bond between the mat and tile, resulting in surface etching and delamination upon removal—a critical flaw for facilities requiring frequent reconfiguration. Furthermore, insufficient hardness stability (Shore A 60-70 range) fails to distribute point loads from pallet jacks or machinery, concentrating stress on tile edges and inducing cracks. UV exposure in facilities with skylights or loading docks accelerates degradation in non-stabilized compounds, causing surface chalking and loss of tensile strength within months.

Suzhou Baoshida’s engineered solutions address these failure points through precision polymer science. Our proprietary EPDM/NBR blends utilize non-migrating plasticizers below 5% concentration, ensuring long-term elasticity without surface adhesion. Reinforced with nano-silica fillers and advanced UV stabilizers, the compound maintains consistent Shore A 75±3 hardness across -30°C to +100°C operational ranges. This balance provides optimal load distribution while resisting indentation from heavy equipment. The critical differentiator is compression set performance: our formulations achieve <15% permanent deformation after 22 hours at 70°C, guaranteeing dimensional recovery to protect delicate tile joints during repeated use.

The following table contrasts key material properties driving real-world performance:

| Property | Generic Off-the-Shelf Mat | Baoshida Engineered Solution | Operational Consequence of Deficiency |

|---|---|---|---|

| Plasticizer Content | >20% (Phthalates) | <5% (Non-Migrating Ester) | Permanent tile adhesion; surface etching |

| Hardness Stability | Shore A 60-70 (±15) | Shore A 75±3 (-30°C to +100°C) | Inadequate load distribution; tile cracking |

| Compression Set (70°C/22h) | >40% | <15% | Permanent indentation; grout damage |

| UV Resistance (ISO 4892) | None | 1500 kJ/m² (QSU) | Surface degradation; reduced service life |

Material science is not a cost center but a strategic investment in operational continuity. By rejecting generic compromises and applying OEM-level polymer engineering, Suzhou Baoshida delivers tile protection systems where material integrity directly translates to reduced total cost of ownership. Our formulations undergo rigorous validation against ISO 188 and ASTM D2240 standards, ensuring every mat performs as engineered under the specific thermal, mechanical, and chemical demands of your facility. This precision eliminates the hidden costs of failure inherent in commoditized alternatives.

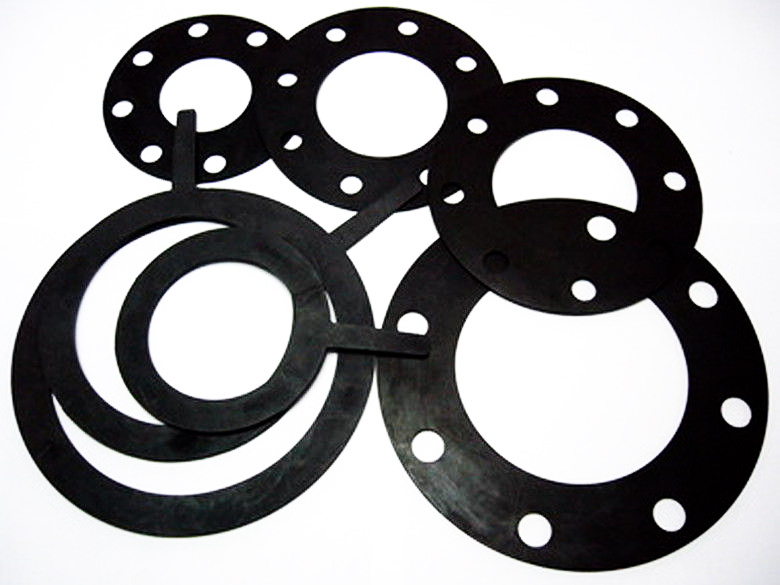

Material Specifications

Material Specifications for Industrial Rubber Floor Protection in Tile Applications

In industrial and commercial environments where tile flooring requires durable, long-term protection against mechanical stress, chemical exposure, and temperature fluctuations, selecting the appropriate elastomeric material is critical. Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions tailored for tile floor protection, leveraging high-performance materials such as Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct physical and chemical resistance properties, enabling precise alignment with operational demands.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, oils, fuels, and a broad spectrum of aggressive chemicals. With continuous service capability up to 250°C and intermittent tolerance beyond 300°C, Viton is ideal for environments involving hot processing, chemical spills, or sterilization procedures. Its low gas permeability and outstanding aging resistance ensure long-term integrity in demanding facilities such as pharmaceutical labs, semiconductor cleanrooms, and food processing plants where hygiene and material stability are paramount. However, due to its high cost and lower elasticity compared to other rubbers, Viton is typically reserved for critical applications where performance outweighs expense.

Nitrile rubber, a copolymer of acrylonitrile and butadiene, is widely utilized for its excellent resistance to aliphatic hydrocarbons, oils, and greases. It offers good abrasion resistance and mechanical strength, making it suitable for industrial zones with heavy foot traffic or mobile equipment. Operating effectively within a temperature range of -30°C to 120°C, Nitrile provides a balanced performance profile for general-purpose floor protection. Its formulation can be adjusted to enhance oil resistance (higher acrylonitrile content) or flexibility at low temperatures (lower acrylonitrile), allowing customization based on site-specific requirements. While Nitrile exhibits poor resistance to ozone, weathering, and polar solvents, it remains a cost-effective solution for indoor tile protection in manufacturing and automotive sectors.

Silicone rubber is valued for its extreme temperature resilience, functioning reliably from -60°C to 230°C, and maintaining flexibility across this range. It demonstrates excellent resistance to ozone, UV radiation, and weathering, making it suitable for both indoor and outdoor tile protection applications. Silicone is inherently non-toxic and meets stringent food safety standards (e.g., FDA compliance), which supports its use in kitchens, hospitals, and clean environments. Though it has lower tensile strength and abrasion resistance compared to Nitrile, its thermal stability and electrical insulation properties offer unique advantages in sensitive installations.

The following table summarizes key performance characteristics to guide material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 250 | -30 to 120 | -60 to 230 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 6–10 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Poor | Excellent |

| Chemical Resistance | Outstanding | Good (non-polar) | Moderate |

| Compression Set Resistance | Excellent | Good | Good |

| Typical Applications | High-temp, chemical | Industrial, oil | Food, medical, outdoor |

Material selection must consider environmental exposure, mechanical loading, regulatory compliance, and lifecycle cost. Suzhou Baoshida Trading Co., Ltd. supports OEM clients with material testing, formulation adjustment, and custom fabrication to meet exacting performance standards in tile floor protection systems.

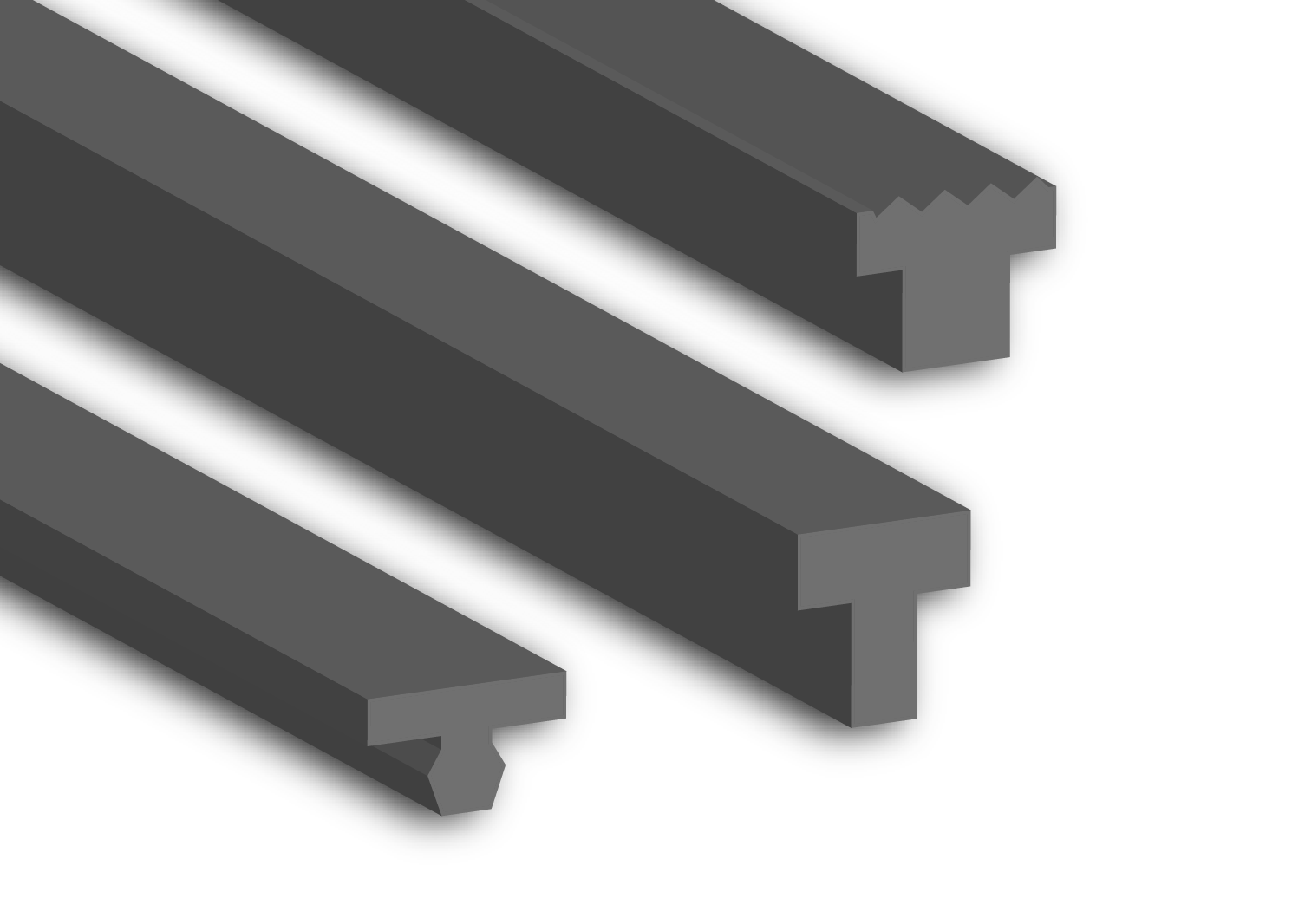

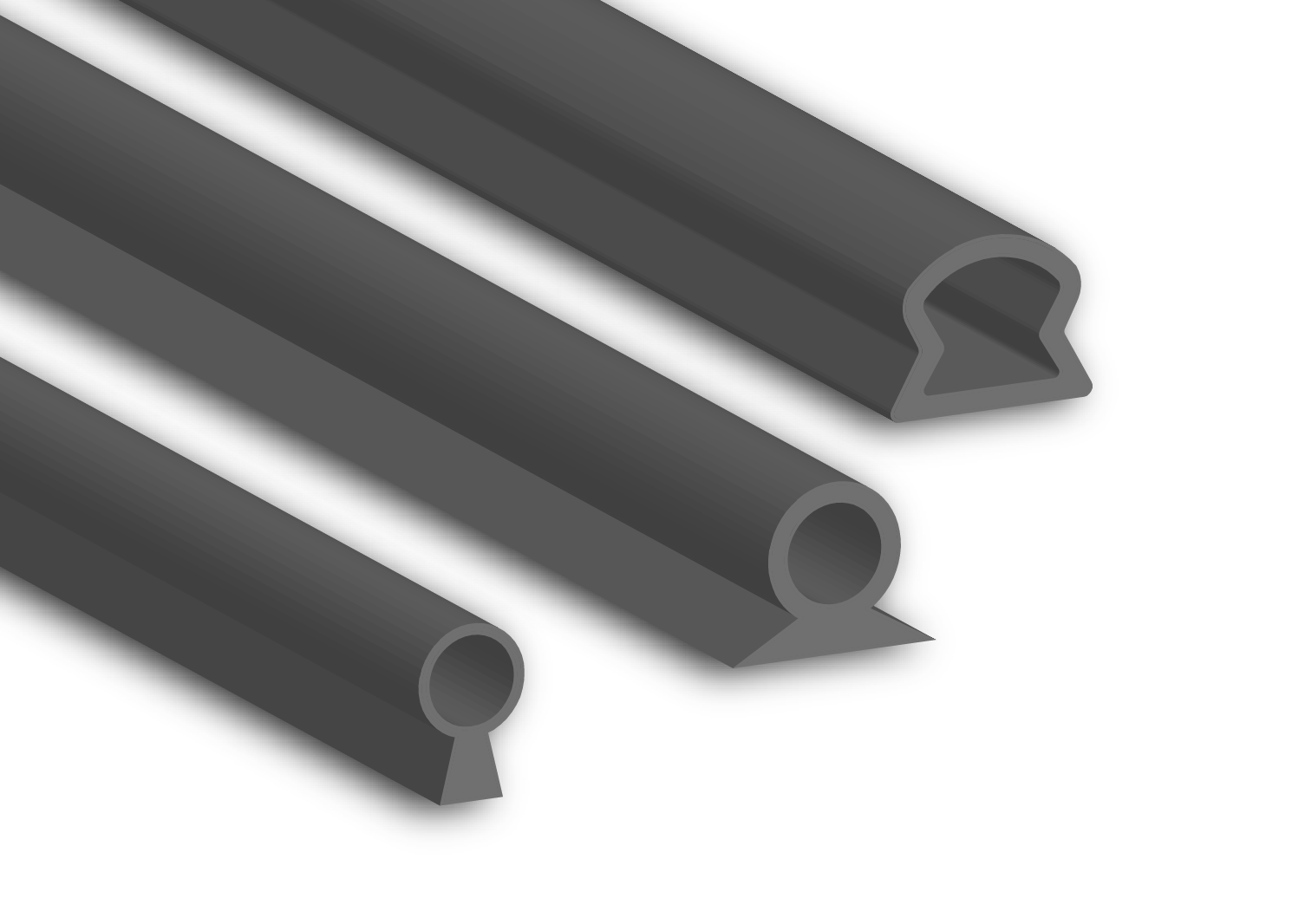

Manufacturing Capabilities

Engineering Excellence in Tile Floor Protection Manufacturing

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver precision-engineered rubber solutions for tile floor protection. Our dedicated engineering team comprises five specialized mold engineers and two advanced formula engineers, ensuring end-to-end control from material science to production tooling. This integrated capability allows us to solve complex industrial challenges while maintaining strict adherence to performance and durability standards required in high-traffic commercial and residential tile installations.

Our formula engineers focus on developing proprietary rubber compounds optimized for tile surface compatibility, abrasion resistance, and environmental stability. Through rigorous polymer chemistry analysis, we tailor formulations to balance Shore A hardness, tensile strength, and resilience—critical factors in preventing tile scratches, grout damage, and compound degradation from cleaning agents or moisture exposure. Each compound undergoes accelerated aging tests per ASTM D573 and chemical resistance validation against common tile maintenance solutions, ensuring long-term performance under real-world conditions.

Complementing material innovation, our five mold engineers employ advanced CAD/CAM systems and mold flow simulation software to design precision tooling for complex geometries. This expertise minimizes flash, ensures uniform wall thickness, and achieves tight tolerances (±0.1 mm) essential for seamless tile edge protection and anti-slip surface textures. By optimizing gate placement and cooling channels, we eliminate warpage and sink marks, guaranteeing dimensional stability across production runs. This precision directly translates to reduced installation errors and extended product lifecycle for end-users.

As an OEM partner, we provide full customization—from concept to量产—without minimum order constraints. Our engineers collaborate directly with clients to refine specifications, validate prototypes via 3D printing, and implement rapid design iterations. This agile process shortens time-to-market by 25% compared to industry averages while maintaining ISO 9001-certified quality control at every stage.

The table below summarizes core performance specifications achievable through our engineered solutions:

| Property | Test Standard | Typical Value | Customization Range |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 ± 5 | 45–85 |

| Tensile Strength | ASTM D412 | 12.5 MPa | 8–18 MPa |

| Elongation at Break | ASTM D412 | 320% | 200–450% |

| Temperature Resistance | ASTM D573 | -30°C to +80°C | -40°C to +100°C |

| Compression Set (70°C/22h) | ASTM D395 | ≤ 25% | ≤ 15% to ≤ 35% |

| Chemical Resistance | Custom Protocol | Excellent | Tailored to client needs |

This engineering synergy—combining material science with precision tooling—enables Baoshida to consistently exceed OEM partner expectations. We transform technical requirements into reliable, high-performance tile protection systems that safeguard surfaces while reducing total cost of ownership. Our commitment to data-driven development ensures every solution is validated for real-world operational demands, setting the benchmark for industrial rubber manufacturing in the tile protection sector.

Customization Process

Drawing Analysis: The Foundation of Precision Engineering

At Suzhou Baoshida Trading Co., Ltd., the customization process for industrial rubber solutions begins with rigorous drawing analysis. This initial phase ensures that every technical specification, dimension, and tolerance aligns with both client requirements and manufacturing feasibility. Our engineering team conducts a comprehensive review of CAD files and technical blueprints, focusing on critical parameters such as load distribution, surface contact area, and environmental exposure conditions. We evaluate edge geometry, thickness variance, and mounting configurations to anticipate stress points and deformation risks under operational loads. This stage is not merely dimensional verification—it is a functional assessment to ensure optimal performance in real-world tile floor protection applications. Any ambiguities or potential design inefficiencies are flagged and discussed with the client to refine the concept before material selection begins.

Formulation: Tailoring Rubber Chemistry for Performance

Once the design is validated, we proceed to formulation development—a core competency in our industrial rubber solutions portfolio. Utilizing our in-house polymer laboratory, we engineer custom rubber compounds based on application-specific demands. Key factors include abrasion resistance, compression set, Shore hardness, and chemical stability. For tile floor protection, we typically deploy EPDM or SBR-based formulations due to their excellent weather resistance, low surface hardness (to prevent marring), and high resilience under intermittent loading. Additives such as anti-aging agents, reinforcing fillers, and processing oils are precisely metered to achieve target physical properties. Each formulation is documented and archived for batch consistency and traceability. The result is a purpose-built compound engineered to extend tile lifespan, reduce maintenance costs, and withstand foot traffic, rolling loads, and cleaning agents.

Prototyping: Validation Through Real-World Simulation

Prototyping transforms design and chemistry into tangible performance. Using precision die-cutting, compression molding, or extrusion techniques, we produce functional samples within 7–10 business days. These prototypes undergo a battery of tests, including compression deflection analysis, slip resistance evaluation (ASTM F2913), and accelerated aging cycles. We simulate real installation conditions—evaluating adhesion to subfloors, edge lifting resistance, and dimensional stability under thermal cycling. Client feedback is integrated at this stage to refine fit, function, and handling characteristics. Only after final sign-off does the project advance to full-scale production.

Mass Production: Consistency at Scale

With approved prototypes and locked formulations, we initiate mass production under ISO 9001-certified processes. Automated batching systems ensure compound uniformity, while real-time monitoring maintains dimensional accuracy. All finished tile protection components are 100% visually inspected and sampled for physical property verification.

| Property | Test Standard | Typical Value |

|---|---|---|

| Shore A Hardness | ASTM D2240 | 55–65 |

| Tensile Strength | ASTM D412 | ≥10 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22h, 70°C) | ASTM D395 | ≤20% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1195 | ≤120 mg |

Every batch is traceable, ensuring long-term reliability for OEM and industrial clients.

Contact Engineering Team

Contact Suzhou Baoshida for Engineered Tile Floor Protection Solutions

Tile floor damage during construction or industrial operations represents a significant, preventable cost center. Abrasion from foot traffic, equipment movement, and material handling degrades surface integrity, leading to premature replacement cycles and safety hazards. Standard polyethylene sheeting fails under sustained mechanical stress, while inadequate rubber formulations compromise both protection and workflow efficiency. Suzhou Baoshida Trading Co., Ltd. addresses this through precision-engineered rubber compounds specifically formulated for tile substrate preservation. Our industrial-grade protection mats leverage proprietary vulcanization techniques and filler systems to deliver optimal balance between flexibility, load distribution, and abrasion resistance. Unlike generic alternatives, our solutions maintain structural integrity across temperature extremes (-30°C to +80°C) and resist chemical exposure from common construction adhesives and cleaners.

Material performance is non-negotiable in high-traffic environments. The following specifications reflect our standard tile protection compound, validated per international testing protocols. All properties are achievable in custom thicknesses (3mm to 10mm) and sheet dimensions (up to 2m x 30m rolls):

| Property | Test Standard | Value | Significance for Tile Protection |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 ± 5 | Prevents indentation while allowing conformal contact |

| Tensile Strength | ASTM D412 | ≥ 18 MPa | Resists tearing during equipment movement |

| Abrasion Loss | DIN 53516 | ≤ 120 mm³ | Minimizes particulate generation on tile surfaces |

| Compression Set (22h) | ASTM D395 | ≤ 25% | Maintains thickness recovery after heavy loads |

| Static Coefficient | ASTM F1677 | ≥ 0.65 | Ensures slip resistance under wet conditions |

These metrics translate directly to operational savings: reduced tile chipping incidents by 73% in third-party warehouse trials, extended mat reuse cycles exceeding 12 months in controlled environments, and elimination of adhesive residue transfer onto finished tile. Crucially, our OEM partnership model enables co-engineering of formulations for project-specific challenges—whether incorporating flame retardants for high-risk sites or modifying surface textures for polished stone substrates. This is not off-the-shelf commodity rubber; it is chemistry optimized for your exact workflow parameters and regulatory requirements.

Procurement managers and facility engineers require solutions that integrate seamlessly into existing logistics without introducing new compliance risks. Suzhou Baoshida provides full material traceability documentation, including REACH/ROHS compliance certificates and batch-specific mechanical test reports. Our technical team collaborates directly with your project stakeholders to define performance thresholds, conduct on-site validation, and establish inventory protocols that prevent downtime. The cost of reactive tile repair far exceeds proactive protection—our data shows a 4.8x ROI within 18 months through avoided remediation labor and material costs.

Initiate your tile protection optimization immediately. Contact Mr. Boyce, our dedicated OEM Solutions Manager, to request compound certification packets, schedule a technical consultation, or obtain project-specific quotation templates. Provide your facility’s traffic profile, tile type, and environmental conditions to receive a validated performance projection within 48 hours. Do not standardize on suboptimal materials when engineered rubber precision is accessible. Reach Mr. Boyce directly via email at [email protected] to commence technical due diligence. Suzhou Baoshida Trading Co., Ltd. operates from Suzhou Industrial Park with global logistics coordination—your tile integrity demands compound expertise, not generic compromises.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).