Technical Contents

Engineering Guide: Garage Door Side Weather Stripping

Material Selection: The Core Determinant of Weather Strip Longevity

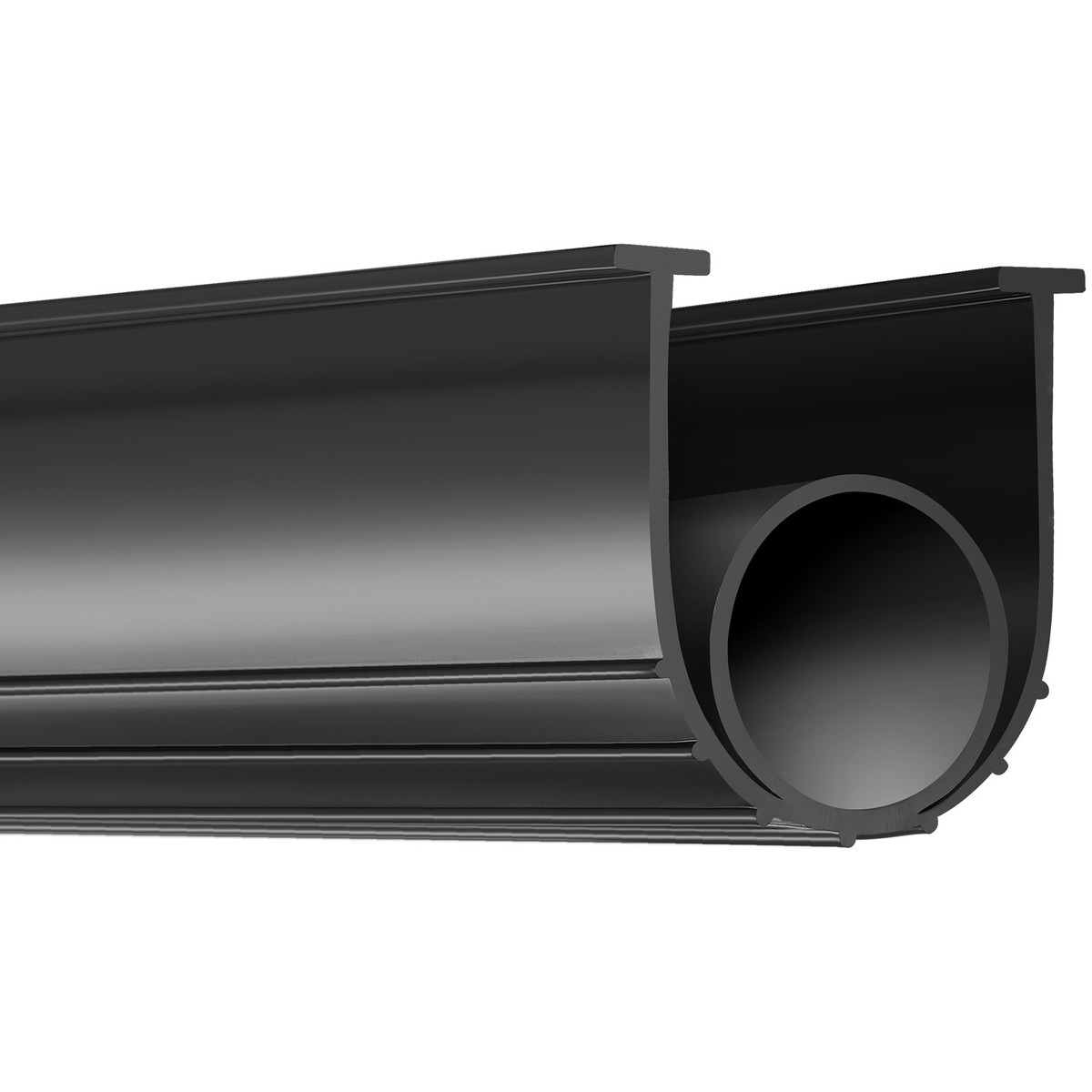

Garage door side weather stripping operates under extreme mechanical and environmental stress. Standard off-the-shelf solutions frequently fail prematurely due to inadequate material formulation, leading to air infiltration, energy loss, and costly warranty claims. The critical oversight lies in treating weather stripping as a commodity rather than an engineered component. Generic extrusions often utilize basic EPDM compounds optimized for cost, not performance. These formulations lack resilience against thermal cycling, UV degradation, and repeated compression, causing irreversible polymer chain scission and surface cracking within 12–18 months.

The primary failure mode stems from poor compression set resistance. Garage doors cycle daily, compressing the strip against the frame. Low-grade rubber loses its elastic recovery capacity, resulting in permanent deformation. This creates gaps that compromise thermal efficiency and allow moisture ingress. Additionally, standard compounds exhibit insufficient low-temperature flexibility. Below -20°C, generic EPDM hardens significantly, reducing sealing force and increasing wind noise. UV exposure further accelerates surface embrittlement through ozone attack, a factor rarely mitigated in non-technical formulations.

Suzhou Baoshida addresses these flaws through precision-tailored elastomer systems. Our engineered TPE compounds incorporate advanced stabilizers and dynamic vulcanization, ensuring consistent sealing force across 50,000+ compression cycles. Proprietary antioxidant packages prevent UV/ozone degradation, while optimized plasticizer systems maintain flexibility down to -40°C. This scientific approach eliminates the false economy of off-the-shelf products, directly correlating to extended service life and reduced total cost of ownership for OEMs.

The performance gap is quantifiable through key material parameters:

| Property | Generic Off-the-Shelf EPDM | Suzhou Baoshida Engineered TPE |

|---|---|---|

| Hardness (Shore A) | 70 ± 5 | 65 ± 3 |

| Temp Range (°C) | -20 to 100 | -40 to 120 |

| Compression Set (70°C, 22h) | 35% | 18% |

| Tensile Strength (MPa) | 8.5 | 12.0 |

| Elongation at Break (%) | 250 | 450 |

This data underscores why material science dictates real-world reliability. The engineered TPE’s lower compression set ensures gap-free sealing after years of use, while superior elongation prevents tearing during installation or thermal expansion. Suzhou Baoshida’s formulations undergo accelerated aging per ASTM D2240 and ISO 188, validating performance beyond industry minimums. For OEMs, specifying precision-engineered weather stripping isn’t an incremental cost—it’s a strategic investment in product integrity and customer satisfaction. Our technical team collaborates directly with manufacturers to calibrate compounds to specific climate zones and door mechanics, transforming a common failure point into a competitive differentiator.

Material Specifications

Material selection is a critical factor in the performance and longevity of garage door side weather stripping. At Suzhou Baoshida Trading Co., Ltd., we specialize in industrial rubber solutions engineered for durability, environmental resistance, and consistent sealing performance. For garage door applications, three elastomers stand out due to their balanced properties: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material offers distinct advantages depending on operating conditions such as temperature range, chemical exposure, and mechanical stress.

Viton is a fluorocarbon-based rubber renowned for its exceptional resistance to high temperatures, ozone, and a broad range of chemicals, including oils, fuels, and solvents. This makes Viton an ideal choice for industrial or commercial environments where exposure to aggressive substances is likely. Its continuous service temperature can reach up to 230°C, with short-term excursions even higher. However, Viton is typically more expensive than other elastomers and may not be necessary for standard residential applications.

Nitrile rubber, or acrylonitrile butadiene rubber (NBR), is one of the most widely used materials in sealing applications due to its excellent resistance to petroleum-based oils and fuels, good abrasion resistance, and cost-effective manufacturing. It performs reliably in temperature ranges from -30°C to 100°C, making it well-suited for typical garage environments. Nitrile also demonstrates strong tensile strength and compression set resistance, ensuring long-term shape retention and effective sealing under constant pressure.

Silicone rubber (VMQ) offers outstanding performance in extreme temperature conditions, with a service range extending from -60°C to 200°C. It exhibits excellent resistance to UV radiation, ozone, and weathering, making it highly suitable for exterior applications exposed to sunlight and fluctuating climates. While silicone has relatively lower mechanical strength compared to Nitrile or Viton, its flexibility at low temperatures and non-reactive nature provide significant benefits in residential and temperature-sensitive settings.

The following table summarizes key physical and chemical properties of these materials for direct comparison in garage door side weather stripping applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 100 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor to Fair |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Compression Set Resistance | Excellent | Good | Fair to Good |

| Typical Applications | Industrial, high-heat, chemical exposure | General sealing, residential/commercial garages | Extreme cold/heat, outdoor weathering |

Selecting the appropriate material requires a thorough understanding of the operational environment. Suzhou Baoshida Trading Co., Ltd. provides customized rubber profiles tailored to specific performance demands, ensuring optimal sealing efficiency and service life.

Manufacturing Capabilities

Engineering Excellence in Garage Door Weather Stripping Solutions

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver precision-engineered garage door side weather stripping that meets stringent industrial and environmental demands. Our integrated engineering team—comprising five dedicated mould engineers and two specialized rubber formula engineers—ensures every component is optimized for performance, durability, and seamless integration into OEM production lines. This multidisciplinary approach eliminates common failure points such as compression set, ozone degradation, and inconsistent sealing under thermal cycling.

Our formula engineers focus on molecular-level material innovation, developing proprietary EPDM and TPE compounds tailored to garage door applications. Through rigorous ASTM D2000 and ISO 37 testing, we achieve optimal balance between low-temperature flexibility down to -50°C and heat resistance up to 150°C. Critical properties like compression set (≤ 25% after 70 hours at 100°C) and tensile strength (≥ 10 MPa) are systematically enhanced using advanced vulcanization systems and nano-reinforced fillers. This eliminates premature hardening or cracking in extreme climates, directly extending product service life.

The mould engineering team utilizes 3D CAD/CAM (SolidWorks, Moldflow) to refine extrusion and splicing tooling geometries. Finite element analysis (FEA) validates thermal uniformity across complex profiles, preventing weld line weaknesses and dimensional drift. Each design undergoes iterative prototyping with real-time feedback from our in-house extrusion lines, ensuring ±0.15 mm dimensional tolerance for consistent door alignment and wind-load resistance. This precision minimizes assembly friction and prevents air/water infiltration at critical junctions.

As a certified OEM partner, we manage end-to-end development from concept to量产. Our process integrates client specifications with material science and tooling physics, reducing time-to-market by 30% through concurrent engineering. All compounds are free of hazardous phthalates and comply with REACH/ROHS, while our ISO 9001-certified facility guarantees traceability from raw material lot to finished strip.

Critical Performance Specifications for Garage Door Side Weather Stripping

| Property | Test Standard | Target Value | Significance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 | Optimal balance: seal integrity vs. door operation force |

| Compression Set (22h/70°C) | ASTM D395 | ≤ 18% | Prevents permanent deformation and gap formation |

| Tensile Strength | ISO 37 | ≥ 12 MPa | Resists tearing during installation and use |

| Low-Temperature Flexibility | ASTM D1329 | Pass at -45°C | Eliminates brittleness in freezing conditions |

| Ozone Resistance (50 pphm) | ASTM D1149 | No cracks (48h) | Ensures longevity in outdoor exposure |

This engineering synergy enables us to solve complex sealing challenges while maintaining cost efficiency. Clients receive weather stripping that exceeds industry benchmarks for energy efficiency (reducing HVAC leakage by ≥ 40%) and acoustic insulation (STC 25+). By embedding material science and precision tooling into every OEM project, Suzhou Baoshida delivers not just components, but guaranteed system performance for global garage door manufacturers.

Customization Process

Customization Process for Garage Door Side Weather Stripping

At Suzhou Baoshida Trading Co., Ltd., our engineering workflow for custom garage door side weather stripping follows a rigorous, science-driven sequence to ensure dimensional accuracy, environmental resilience, and long-term sealing performance. Every project begins with Drawing Analysis, where our technical team evaluates client-provided CAD files or technical sketches. This phase focuses on cross-sectional geometry, tolerance specifications (±0.1 mm standard), installation interface compatibility, and compression set requirements. We assess groove fit, flange engagement, and deflection behavior under operational conditions to preempt field failures.

Following drawing validation, the Formulation stage is initiated. Our rubber chemists select base polymers based on environmental exposure data—such as UV intensity, temperature extremes (–40°C to +120°C), and chemical resistance needs. For standard residential applications, EPDM (Ethylene Propylene Diene Monomer) is preferred due to its superior ozone and weather resistance. For industrial or high-temperature environments, silicone or fluorocarbon (FKM) compounds may be engineered. Additives including carbon black (for UV stability), plasticizers (for low-temperature flexibility), and sulfur-based curatives (for crosslink density) are precisely metered. Shore A hardness is tuned between 55 and 75 to balance sealing force and ease of door movement.

Once the compound is finalized, Prototyping commences using precision extrusion and continuous vulcanization (CV) lines. Short-run samples (typically 10–50 meters) are produced under production-intent conditions. These prototypes undergo dimensional verification via coordinate measuring machines (CMM) and performance testing, including compression deflection (ASTM D575), accelerated aging (ASTM D573), and ozone resistance (ASTM D1149). Clients receive physical samples with full material test reports (MTRs) for field evaluation.

Upon approval, we transition to Mass Production. Our automated extrusion lines operate under strict process control (SPC), with inline laser gauging ensuring cross-sectional consistency. Each production batch undergoes full traceability—batch-coded raw materials, cure monitoring via rheometry, and 100% visual inspection. Final packaging includes moisture-resistant wrapping and barcoded labeling for inventory management.

Our end-to-end process ensures that every meter of weather stripping meets exact OEM specifications, delivering reliable sealing performance over 10,000+ door cycles.

Material and Performance Specifications

| Property | EPDM Standard | Silicone Option | FKM Option | Test Standard |

|---|---|---|---|---|

| Shore A Hardness | 60 ± 5 | 65 ± 5 | 70 ± 5 | ASTM D2240 |

| Tensile Strength | ≥ 10 MPa | ≥ 8 MPa | ≥ 12 MPa | ASTM D412 |

| Elongation at Break | ≥ 300% | ≥ 400% | ≥ 250% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤ 25% | ≤ 20% | ≤ 15% | ASTM D395 |

| Temperature Range | –40°C to +120°C | –60°C to +200°C | –20°C to +230°C | — |

| Ozone Resistance | Excellent | Good | Excellent | ASTM D1149 |

Contact Engineering Team

Optimizing Garage Door Side Weather Stripping Performance Through Precision Rubber Engineering

The sealing performance of garage door side weather stripping is fundamentally determined by the molecular architecture and compounding precision of the elastomer. Standardized thermoplastic or generic rubber profiles often fail under cyclic compression, UV exposure, and extreme temperature fluctuations, leading to premature compression set, hardening, or loss of resilience. At Suzhou Baoshida Trading Co., Ltd., we address these industrial challenges through custom-formulated EPDM and silicone compounds engineered for dimensional stability and long-term sealing integrity. Our proprietary vulcanization processes optimize cross-link density to maintain consistent force decay profiles across 50,000+ compression cycles, ensuring reliable barrier performance against wind, moisture, and particulate ingress in commercial and residential applications.

As an OEM partner, we integrate material science with manufacturing scalability. Our ISO 9001-certified production lines utilize precision extrusion dies with ±0.15 mm tolerance control, coupled with continuous microwave curing systems that eliminate surface porosity. This eliminates common field failures such as edge tearing during installation or groove misalignment due to inconsistent durometer profiles. We collaborate with clients to tailor polymer backbones for specific climatic zones—enhancing ozone resistance for desert environments or low-temperature flexibility for sub-arctic regions—while meeting ASTM D2000 and EN 12817 standards.

Below are critical performance specifications for our standard garage door side weather stripping compounds. All values are validated per ASTM D2240, D412, and D395 protocols:

| Material Type | Hardness (Shore A) | Temp Range (°C) | Compression Set (22h/70°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Applications |

|---|---|---|---|---|---|---|

| High-Performance EPDM | 65 ± 5 | -50 to +135 | ≤ 25% | ≥ 10.5 | ≥ 350 | Coastal, high-UV regions |

| Standard EPDM | 55 ± 5 | -40 to +120 | ≤ 30% | ≥ 9.0 | ≥ 400 | Temperate climates |

| Low-Temp Silicone | 50 ± 5 | -60 to +200 | ≤ 20% | ≥ 6.5 | ≥ 500 | Arctic commercial facilities |

These compounds undergo rigorous dynamic fatigue testing in our Suzhou R&D facility, simulating 10 years of operational stress in accelerated aging chambers. We provide full material traceability via batch-specific certificates of conformance, including MFR, gel content, and extractables data for regulatory compliance.

Partner with Suzhou Baoshida to resolve persistent weather stripping failures through engineered elastomer solutions. Our technical team will conduct a free application analysis—submit your dimensional drawings, environmental requirements, and failure mode data for a customized compound recommendation. Mr. Boyce, our OEM Program Manager, specializes in translating engineering specifications into production-ready profiles with rapid prototyping capabilities. Initiate your project with an engineer-to-engineer consultation to discuss material selection, tooling optimization, and volume production scheduling. Contact Mr. Boyce directly at [email protected] with subject line “Garage Door Weather Stripping OEM Inquiry” for priority technical review. We respond to all engineering inquiries within 4 business hours with actionable data—not generic sales templates. Elevate your product reliability through rubber science, not trial-and-error substitution.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).