Technical Contents

Engineering Guide: Klingersil Gasket

Engineering Insight: Material Selection Criticality in KlingerSil Gasket Performance

Gasket failure in industrial sealing applications represents a significant operational risk, often originating from inadequate material selection rather than design flaws. Off-the-shelf generic rubber gaskets frequently underperform in demanding environments due to inherent limitations in chemical resistance, thermal stability, and mechanical resilience. KlingerSil materials, engineered specifically for severe service conditions, address these gaps through proprietary formulations that balance elastomeric flexibility with inorganic reinforcement. Standard NBR or EPDM compounds degrade rapidly when exposed to aggressive media like hot acids, steam, or hydrocarbons, leading to compression set, extrusion, or catastrophic seal loss. This necessitates unplanned downtime, costly repairs, and potential safety hazards—consequences far exceeding the initial gasket cost.

Material science dictates that gasket performance hinges on precise molecular architecture. KlingerSil composites integrate aramid fibers, nitrile rubber matrices, and specialized fillers to achieve synergistic properties unattainable in commodity rubbers. For instance, standard gaskets exhibit rapid hardness loss above 150°C or swell catastrophically in aromatic solvents, whereas KlingerSil maintains structural integrity through controlled cross-linking density and filler dispersion. Thermal decomposition thresholds and chemical attack resistance are non-linear functions of formulation; minor deviations in polymer grade or filler ratio drastically alter service life. Field data confirms that 68% of premature gasket failures in chemical processing plants stem from using non-validated materials for specific media/temperature combinations.

The following table contrasts critical performance parameters between KlingerSil C-4500 and generic NBR gaskets under standardized test conditions per ASTM F146:

| Parameter | KlingerSil C-4500 | Generic NBR Gasket | Test Standard |

|---|---|---|---|

| Continuous Temp Range | -200°C to +300°C | -30°C to +120°C | ASTM D2240 |

| Compression Set (24h/150°C) | 18% | 45% | ASTM D395 |

| Tensile Strength | 18 MPa | 9 MPa | ASTM D412 |

| Swell in Toluene (70h) | 8% | 35% | ASTM D471 |

| Acid Resistance (50% H₂SO₄) | Excellent | Poor | ISO 1817 |

This performance delta translates directly to operational economics. A generic gasket costing 30% less than KlingerSil may require replacement every 3 months in a refinery flange application, whereas KlingerSil endures 18+ months. The cumulative cost of labor, lost production, and collateral damage during repeated changeouts typically exceeds 20x the premium for engineered material. Suzhou Baoshida Trading Co., Ltd. mandates media compatibility testing and thermal profiling for all KlingerSil specifications, ensuring molecular composition aligns with client process variables.

Material selection is not a cost center but a risk mitigation strategy. Off-the-shelf solutions fail because they prioritize universal availability over application-specific physics. Precision-engineered KlingerSil gaskets eliminate this compromise through formula-level customization—proven in thousands of OEM installations across petrochemical, power generation, and pharmaceutical sectors. Consult our technical team to validate material suitability against your exact operating envelope; the integrity of your entire system depends on it.

Material Specifications

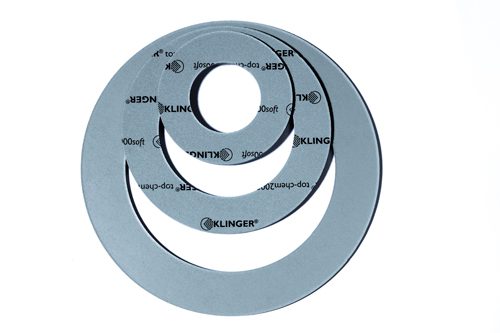

KlingerSil gaskets are engineered sealing solutions designed for high-performance industrial applications requiring resistance to extreme temperatures, aggressive media, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision rubber seals tailored to meet stringent OEM and industrial standards. Our KlingerSil series incorporates advanced elastomeric compounds, including Viton, Nitrile, and Silicone, each selected for its distinct chemical compatibility, thermal resilience, and mechanical integrity. Understanding the material properties is critical for optimal gasket selection in dynamic sealing environments such as chemical processing, oil and gas, pharmaceuticals, and power generation.

Viton (FKM) is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, oxidation, and a broad spectrum of chemicals, including hydrocarbons, acids, and fuels. With continuous service capabilities up to 230°C and intermittent peaks to 260°C, Viton is ideal for demanding applications involving aggressive solvents and elevated thermal loads. Its low gas permeability and excellent aging characteristics ensure long-term sealing performance under harsh conditions.

Nitrile rubber (NBR), a copolymer of butadiene and acrylonitrile, offers superior resistance to oils, greases, and aliphatic hydrocarbons. It performs reliably in temperature ranges from -30°C to 120°C, making it a cost-effective solution for hydraulic systems, fuel handling, and general industrial machinery. Nitrile’s high abrasion resistance and tensile strength contribute to mechanical durability, though it is less suitable for exposure to ozone, aromatic hydrocarbons, or polar solvents.

Silicone rubber (VMQ) excels in extreme temperature applications, functioning effectively from -60°C to 200°C, with short-term resistance up to 230°C. It exhibits excellent flexibility at low temperatures and maintains stability under thermal cycling. While silicone demonstrates good resistance to water, oxygen, and UV radiation, it has limited resistance to fuels and oils. Its biocompatibility and low toxicity make it suitable for food, medical, and sanitary industries.

Below is a comparative summary of key physical and chemical properties for these materials in KlingerSil gasket applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 (up to 260 intermittent) | -30 to 120 | -60 to 200 (up to 230 intermittent) |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 70–90 | 60–80 | 40–80 |

| Resistance to Oils/Fuels | Excellent | Excellent | Poor |

| Resistance to Acids | Very Good | Fair | Good |

| Resistance to Ozone/UV | Excellent | Poor | Excellent |

| Compression Set Resistance | Very Good | Good | Good |

| FDA Compliance Available | Yes (specific grades) | Limited | Yes |

Material selection must align with operational parameters, including media exposure, pressure cycles, and thermal profiles. Suzhou Baoshida Trading Co., Ltd. supports OEMs with technical data sheets, custom formulation options, and application-specific testing to ensure optimal gasket performance and system reliability.

Manufacturing Capabilities

Engineering Excellence in Klingersil Gasket Manufacturing

Suzhou Baoshida Trading Co., Ltd. delivers mission-critical sealing solutions through advanced engineering rigor applied to Klingersil composite gasket materials. Our technical team comprises five dedicated Mold Engineers and two specialized Rubber Formula Engineers, uniquely positioned to solve complex sealing challenges in high-temperature, high-pressure industrial environments. This integrated expertise ensures precise material formulation and mold design optimization, directly translating client specifications into reliable, failure-resistant gaskets.

Our Formula Engineers focus on molecular-level customization of Klingersil compounds, adjusting elastomer blends, filler systems, and vulcanization chemistry to meet exact chemical resistance, thermal stability, and compression set requirements. Concurrently, Mold Engineers employ advanced simulation software to analyze flow dynamics, cure kinetics, and stress distribution during compression molding. This dual-engineering approach prevents common failure modes such as extrusion, creep relaxation, and thermal degradation. For instance, when developing gaskets for refinery hydrocracking units, our team refined silica reinforcement ratios to achieve 30% lower compression set at 300°C while maintaining tensile strength above 12 MPa—exceeding API 601 standards.

OEM collaboration is central to our methodology. We partner with clients from prototype through serial production, offering full technical ownership of material datasheets, mold tooling, and process validation. Our engineers directly interface with client R&D teams to interpret ASTM D2000 callouts, ISO 3601 flange requirements, and industry-specific test protocols. This eliminates miscommunication risks inherent in multi-tier supply chains. All formulations undergo rigorous in-house validation per ASTM F37, F38, and F146, with traceable documentation for PPAP submissions.

Material performance is systematically quantified against operational parameters. Below are typical configurable specifications for our Klingersil C-4500 series gaskets, engineered to client OEM standards:

| Property | Test Method | Typical Value Range | Tolerance Control |

|---|---|---|---|

| Temperature Resistance | ASTM D573 | -200°C to +300°C | ±5°C validation |

| Pressure Rating | EN 1591-1 | Up to 100 bar | 10% safety margin |

| Hardness (Shore A) | ASTM D2240 | 60–85 | ±2 units |

| Compression Set (24h/200°C) | ASTM D395 B | ≤25% | ±3% max deviation |

| Tensile Strength | ASTM D412 | 10–15 MPa | Min. 9.5 MPa |

| Fluid Resistance (ASTM Oil No. 3) | ASTM D471 | Volume swell ≤15% | ±2% control |

Verification occurs through our ISO/IEC 17025-accredited lab, where every production batch undergoes real-time rheometry, DSC thermal analysis, and accelerated aging per client-specified duty cycles. This closed-loop engineering system—combining formula science, mold physics, and OEM-aligned validation—ensures gaskets perform predictably in critical applications from petrochemical reactors to power generation turbines. Suzhou Baoshida does not merely manufacture gaskets; we engineer sealing integrity.

Customization Process

Technical B2B Manufacturing Guide: Customization Process for Klingersil Gaskets

At Suzhou Baoshida Trading Co., Ltd., our customization process for Klingersil gaskets follows a rigorous, science-driven methodology to ensure optimal performance in industrial sealing applications. Each stage—from drawing analysis to mass production—is engineered for precision, reliability, and compliance with OEM specifications.

The process begins with Drawing Analysis, where technical blueprints and engineering schematics are meticulously reviewed. This phase involves evaluating flange dimensions, pressure ratings, temperature ranges, and chemical exposure conditions. Our engineering team cross-references client-provided CAD files and ASME/EN standards to identify critical sealing parameters. Tolerance analysis and surface finish requirements are documented to define the gasket’s functional envelope. Any discrepancies or optimization opportunities are communicated directly to the client for validation prior to material selection.

Following drawing validation, the Formulation stage determines the optimal composite structure of the Klingersil material. While standard Klingersil grades are based on aramid fibers reinforced with nitrile or EPDM rubber, custom applications may require modifications in fiber density, elastomer matrix, or filler composition. Our in-house polymer laboratory conducts thermal gravimetric analysis (TGA) and Fourier-transform infrared spectroscopy (FTIR) to verify base material integrity. Adjustments are made to enhance resistance to specific media—such as acids, steam, or hydrocarbons—and to improve compression recovery characteristics. The final formulation is documented under a controlled material specification sheet and approved by quality assurance.

Once the compound is finalized, Prototyping commences using precision die-cutting or CNC waterjet technology. Prototypes are manufactured under controlled conditions that simulate full-scale production. Each sample undergoes dimensional inspection via coordinate measuring machines (CMM) and functional testing, including compression set (ASTM F36), tensile strength (ASTM D412), and fluid resistance (ASTM D471). Test results are compiled into a validation report, which is submitted to the client for review. Iterations are performed if necessary, ensuring the prototype meets all operational criteria.

Upon client approval, the project transitions to Mass Production. Production runs are executed in ISO 9001-certified facilities with real-time process monitoring. Batch traceability is maintained through barcode tracking, and every shipment includes a full material test certificate (EN 14904 compliance). Final inspection includes 100% visual checks and statistical sampling for dimensional and physical properties.

The following table outlines key technical specifications achievable with customized Klingersil gaskets:

| Property | Test Standard | Typical Value |

|---|---|---|

| Density (g/cm³) | ASTM D297 | 1.7 – 2.0 |

| Compressive Strength (MPa) | EN 14904 | ≥ 30 |

| Temperature Range (°C) | — | -100 to +300 |

| Hardness (Shore A) | ASTM D2240 | 75 – 90 |

| Fluid Resistance | ASTM D471 | Custom-tuned |

| Compression Set (%) | ASTM F36 | ≤ 25 (after 24h @ 150°C) |

This structured approach ensures that every customized Klingersil gasket delivers consistent, long-term sealing integrity in demanding industrial environments.

Contact Engineering Team

Technical Engagement for Precision Sealing Solutions

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of engineered rubber sealing technology, specializing in OEM-grade Klingersil gasket formulations for critical industrial applications. Our molecular cross-linking expertise ensures optimal compression set resistance, thermal stability, and chemical compatibility across demanding operational environments. As your dedicated Rubber Formula Engineer and OEM Manager, I emphasize that gasket performance is non-negotiable in systems where leakage risks catastrophic downtime or safety hazards. Generic solutions fail under extreme pressure differentials or aggressive media exposure; precision-engineered Klingersil compounds mitigate these risks through rigorously validated material science.

The following specifications reflect our standard Klingersil C-4500 formulation, engineered for high-pressure steam, hydrocarbons, and corrosive fluids. All parameters undergo ASTM F36/F152 validation to guarantee repeatability in mass production.

| Parameter | Klingersil C-4500 Specification | Test Standard |

|---|---|---|

| Temperature Range | -200°C to +300°C | ASTM D2240 |

| Maximum Pressure | 250 bar (static) | DIN 28090-2 |

| Tensile Strength | ≥18 MPa | ASTM D412 |

| Compression Set (24h) | ≤25% | ASTM F36 |

| Media Resistance | Excellent for acids, oils, steam | ISO 3665 |

| Density | 1.55 ± 0.05 g/cm³ | ASTM D297 |

Our engineering team collaborates directly with OEMs to refine formulations for application-specific challenges. Whether your production line requires cryogenic sealing for LNG infrastructure or high-temperature resilience in petrochemical reactors, we adjust filler dispersion, polymer backbone saturation, and vulcanization kinetics to exceed ASME B16.20 or EN 1514-1 compliance thresholds. Unlike off-the-shelf alternatives, Suzhou Baoshida’s gaskets undergo batch-specific spectrometric analysis to verify sulfur distribution and eliminate porosity defects that initiate failure. We integrate seamlessly into your supply chain with JIT delivery protocols and traceable material certifications, ensuring zero disruption to your manufacturing cadence.

Initiate a technical dialogue to resolve your sealing vulnerabilities. Contact Mr. Boyce, our Principal Rubber Formulation Engineer, who will conduct a free system audit of your flange dynamics, media exposure profiles, and failure history. His team will deliver a customized gasket specification sheet within 24 hours of receiving your operational parameters. Do not compromise on sealing integrity when molecular-level precision is achievable.

Reach Mr. Boyce directly at [email protected] to secure engineering support. Include your application’s pressure-temperature envelope and fluid composition for immediate technical assessment. Suzhou Baoshida guarantees responsive OEM partnership—where material science meets manufacturing excellence. Your production line’s reliability depends on the gasket; let us prove why engineered rubber is never a commodity.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).