Technical Contents

Engineering Guide: Window Channel

Material Selection in Window Channel Engineering: A Precision Imperative

In the domain of automotive and industrial sealing systems, the window channel stands as a deceptively simple component with complex functional demands. Often overlooked, its performance directly influences user experience, acoustic insulation, weather resistance, and long-term durability. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary consideration—it is the cornerstone of reliable window channel performance. Off-the-shelf rubber profiles frequently underperform because they are engineered for generalized applications, not the precise thermal, mechanical, and environmental conditions of specific installations.

The failure of generic window channels typically manifests in premature cracking, loss of tensile strength, compression set, or adhesion breakdown. These issues arise when base elastomers are mismatched to operational stressors. For instance, a standard EPDM formulation may resist UV and ozone degradation but exhibit poor low-temperature flexibility, leading to brittleness in cold climates. Conversely, a high-acrylate NBR compound may deliver excellent oil resistance but degrade under prolonged sunlight exposure—unsuitable for exterior glazing systems.

True engineering efficacy begins with a granular understanding of service conditions: temperature range, dynamic movement frequency, exposure to chemicals or UV radiation, and required friction coefficient. At Baoshida, we deploy a systems approach to elastomer formulation, tailoring polymer backbone, plasticizer type, filler loading, and vulcanization chemistry to the application. For high-cycle automotive windows, we optimize for low compression set and consistent Shore A hardness (typically 60–70) to maintain sealing force over 100,000+ operations. For industrial enclosures exposed to hydraulic fluids, we formulate with hydrogenated nitrile (HNBR) to resist swelling and maintain dimensional stability.

Furthermore, compatibility with adjacent materials—glass, metal guides, plastic trims—dictates surface energy and lubricity requirements. A poorly matched coefficient of friction leads to binding or excessive wear. Our proprietary surface-modified compounds integrate internal lubricants and mold-release agents that ensure smooth actuation without external silicone application, reducing maintenance and contamination risk.

The following table illustrates comparative performance characteristics of common elastomers used in window channel applications:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Advantages | Limitations |

|---|---|---|---|---|---|

| EPDM | -50 to +150 | 12–18 | 300–500 | Excellent UV/ozone resistance, good heat stability | Poor oil/fuel resistance |

| NBR | -30 to +100 | 10–15 | 250–400 | Good oil/fuel resistance, low compression set | Moderate UV resistance |

| HNBR | -40 to +170 | 20–30 | 300–450 | High thermal stability, excellent mechanical properties | Higher cost |

| Silicone | -60 to +200 | 6–10 | 200–400 | Exceptional temperature range, good flexibility | Lower tensile strength, higher friction |

Generic solutions fail because they standardize across variables that demand customization. At Baoshida, we reject one-size-fits-all formulations. Our engineered rubber compounds are developed through application-specific analysis, ensuring that every window channel performs reliably under real-world conditions—because in industrial sealing, precision isn’t optional; it’s mandatory.

Material Specifications

Material Specifications for Automotive Window Channel Seals

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions for automotive window channel seals, where material selection directly impacts sealing integrity, durability, and operational lifespan. Our formulations prioritize resistance to environmental stressors, mechanical fatigue, and fluid exposure inherent in dynamic window mechanisms. Three elastomers dominate this application: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each offers distinct performance profiles aligned with specific operational demands.

Viton (FKM) excels in extreme environments requiring resistance to high temperatures, oils, and aggressive chemicals. Its fluorocarbon structure maintains elasticity between -20°C and 230°C, with tensile strength typically exceeding 15 MPa. Viton exhibits minimal swelling in brake fluids, transmission oils, and ozone-rich atmospheres, making it ideal for engine-bay-proximate channels or luxury vehicles with stringent longevity requirements. However, its higher raw material cost necessitates justification through severe operational conditions.

Nitrile (NBR) remains the industry standard for cost-sensitive applications demanding robust oil and fuel resistance. Operating effectively from -30°C to 120°C, NBR achieves tensile strengths of 10–20 MPa and elongation at break >300%. Its acrylonitrile content directly correlates with oil resistance; formulations with 34% ACN balance cost and performance for most passenger vehicle window channels. While susceptible to ozone degradation and limited high-temperature resilience, NBR’s abrasion resistance and compression set properties (typically <30% at 70°C) ensure reliable sealing under repeated cycling.

Silicone (VMQ) delivers unparalleled temperature stability (-60°C to 260°C) and UV/ozone resistance, critical for sunroof channels or regions with extreme climate variance. Though tensile strength is moderate (6–8 MPa), its low compression set (<20% at 150°C) guarantees consistent sealing force retention. Silicone’s hydrophobic nature resists water ingress but limits adhesion to metal channels without primers. Its lower abrasion resistance compared to NBR necessitates reinforcement for high-cycle applications, yet its biocompatibility and color stability support premium interior-facing seals.

The comparative analysis below details critical parameters per ASTM D2000 standards:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 260 |

| Tensile Strength (MPa) | 15–20 | 10–20 | 6–8 |

| Elongation at Break (%) | 200–300 | 300–500 | 300–600 |

| Hardness (Shore A) | 65–85 | 50–90 | 40–80 |

| Fluid Resistance | Excellent (oils, fuels, acids) | Excellent (oils, fuels) | Poor (oils, fuels); Excellent (water, steam) |

| Compression Set (70h/100°C) | <25% | <30% | <20% |

Suzhou Baoshida’s OEM engineering team validates material selection against client-specific duty cycles, including door slam dynamics, acoustic requirements, and regional environmental exposure. We optimize compound formulations—adjusting filler systems, crosslink density, and additive packages—to achieve target hardness (60–80 Shore A), low-temperature flexibility, and adhesion to coated steel substrates. Prototyping and accelerated aging per ISO 188 protocols ensure field performance meets Tier 1 automotive durability benchmarks. Material choice ultimately balances lifecycle cost against functional criticality; NBR suffices for standard applications, while Viton or Silicone addresses thermal/chemical extremes. Our technical partnership ensures seamless integration into automated assembly lines with consistent dimensional stability.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capacity in industrial rubber solutions is anchored in deep technical expertise and a disciplined approach to OEM manufacturing. With a dedicated team comprising five specialized mould engineers and two advanced rubber formula engineers, we maintain full in-house control over the design-to-production lifecycle of window channel systems. This integrated engineering structure enables us to deliver precision-engineered rubber profiles that meet exacting automotive and industrial performance standards.

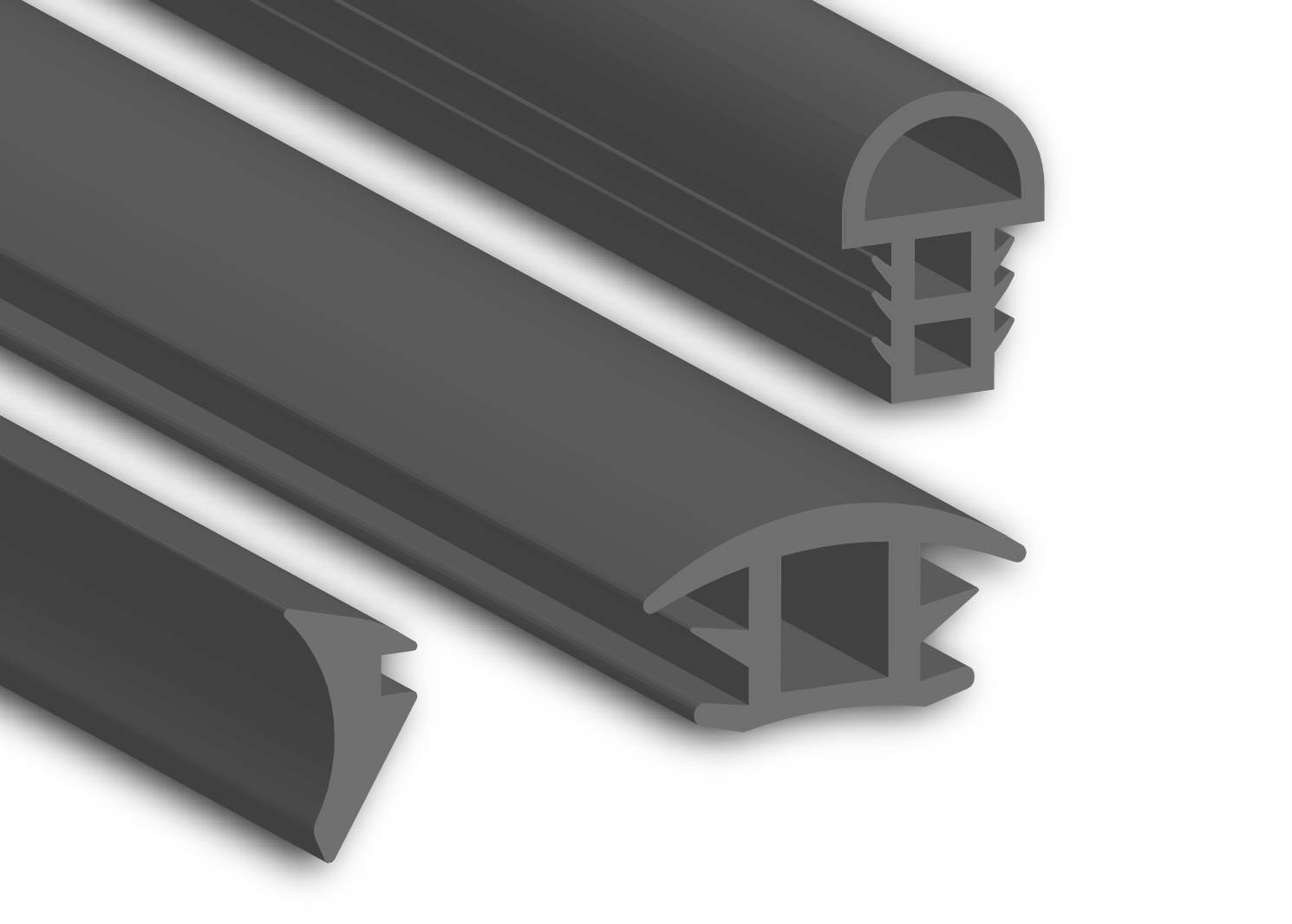

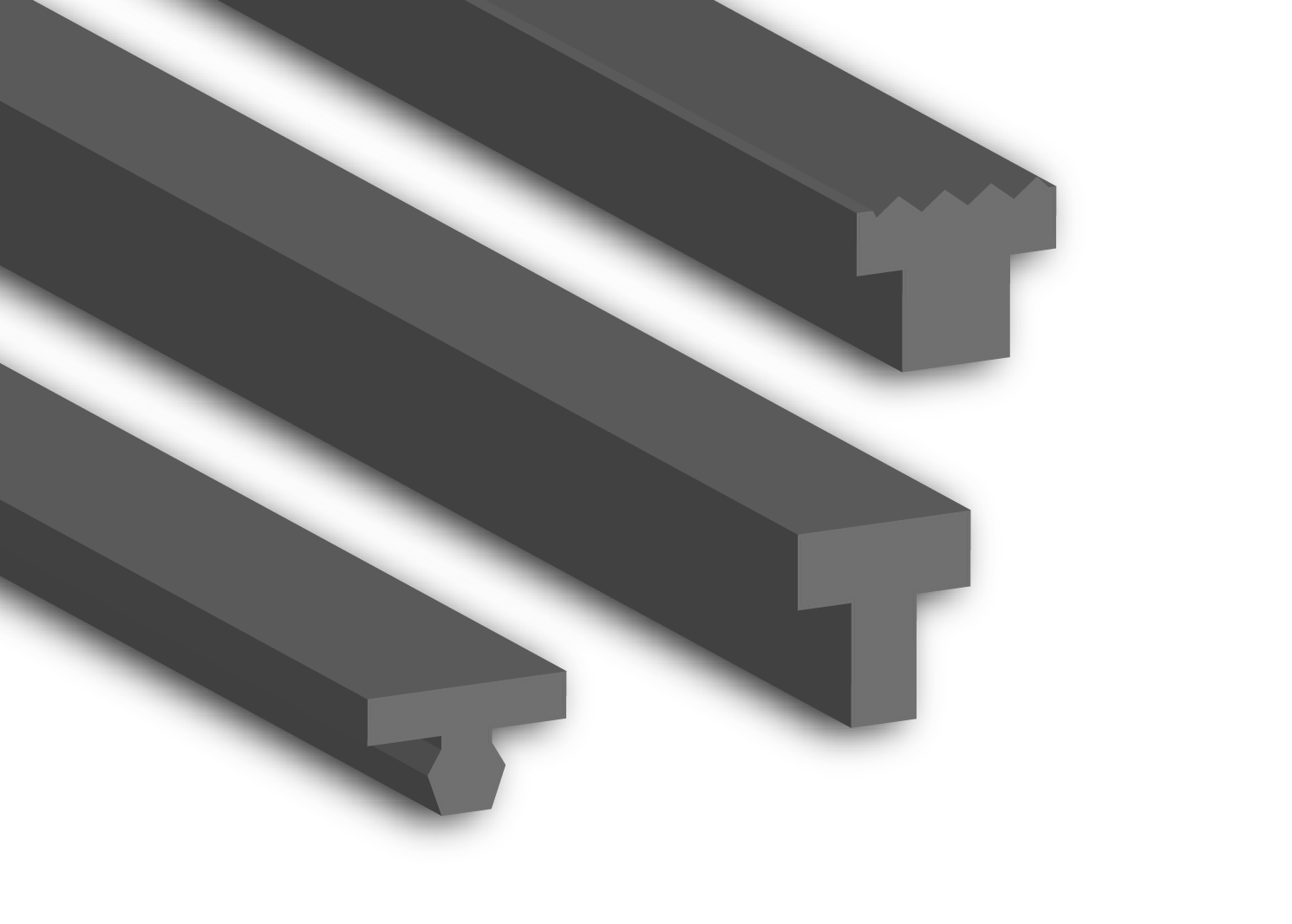

Our mould engineers possess extensive experience in the design, simulation, and optimization of extrusion and splicing tooling for complex window channel geometries. Utilizing advanced CAD/CAM software and finite element analysis (FEA), they ensure dimensional accuracy, material flow efficiency, and long-term tool durability. This capability allows us to support rapid prototyping, tolerance validation, and seamless transition from concept to mass production. Every window channel profile is engineered to maintain consistent cross-sectional integrity, critical for sealing performance, glass glide functionality, and noise reduction.

Complementing our tooling expertise, our two rubber formulation engineers bring specialized knowledge in elastomer chemistry, particularly in EPDM, TPE, and silicone-based compounds. They develop custom formulations tailored to specific OEM requirements, including resistance to UV degradation, ozone exposure, extreme temperatures (ranging from -40°C to +120°C), and compression set. These formulations are rigorously tested in-house for tensile strength, elongation at break, hardness (Shore A), and adhesion performance to glass and metal substrates. Our lab facilities support full ASTM and ISO-compliant testing, ensuring long-term reliability under real-world operating conditions.

We specialize in OEM window channel manufacturing, serving Tier-1 automotive suppliers and industrial equipment manufacturers across Asia, Europe, and North America. Our OEM capabilities include confidential product development, co-engineering support, and full documentation traceability (including material data sheets, process FMEAs, and PPAP submissions). We maintain strict IP protection protocols and support dual-sourcing strategies through scalable production lines equipped with automated extrusion, microwave curing, and robotic handling systems.

The combination of advanced formulation science and precision mould engineering allows us to produce window channels with superior sealing performance, extended service life, and consistent surface finish. Whether for automotive side windows, sunroofs, or industrial enclosures, our engineering team ensures every product meets the functional and regulatory demands of modern applications.

Typical Window Channel Material Specifications

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 9.0 MPa |

| Elongation at Break | ASTM D412 | ≥ 300% |

| Compression Set (24h @ 70°C) | ASTM D395 | ≤ 25% |

| Operating Temperature Range | — | -40°C to +120°C |

| Adhesion Strength to Glass | Internal Test | ≥ 80 N/cm |

| UV and Ozone Resistance | ASTM G154 / D1149 | Pass (1000h) |

This engineering-led approach ensures that Suzhou Baoshida delivers not just components, but technically validated solutions for demanding window sealing applications.

Customization Process

Customization Process for Precision Window Channel Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our window channel customization process integrates rigorous material science with precision engineering to deliver OEM-compliant rubber profiles. This structured workflow ensures dimensional accuracy, environmental resilience, and seamless integration into automotive or architectural assemblies. The process begins with comprehensive drawing analysis, where our engineering team deconstructs client specifications to identify critical-to-quality parameters. We validate tolerances, cross-section geometry, and mating surface requirements against industry standards such as ISO 3302-1 for rubber dimensional accuracy. Concurrently, we assess installation forces and dynamic stress points to preempt field failures. This phase includes collaborative reviews with clients to resolve ambiguities, ensuring alignment on performance expectations before material selection commences.

Material formulation follows as the cornerstone of functional reliability. Leveraging our proprietary compound database and accelerated aging protocols, we tailor elastomer chemistry to the operational environment. Key considerations include UV resistance for exterior applications, low-temperature flexibility down to -50°C, and resistance to ozone degradation. Our EPDM and TPE formulations are optimized for Shore A hardness between 60–80 to balance sealing force and ease of window movement. Critical additives—such as peroxide curing systems for thermal stability or nano-silica reinforcements for tear strength—are precisely dosed using statistical process control. Each formulation undergoes dynamic mechanical analysis (DMA) to verify viscoelastic behavior across temperature cycles, ensuring consistent performance in extreme climates.

Prototyping transitions theoretical specifications into physical validation. We employ multi-cavity aluminum molds for rapid iteration, producing samples within 15 business days. Every prototype undergoes stringent dimensional verification via CMM (Coordinate Measuring Machine) against the original CAD model, with deviations tracked to ±0.05 mm tolerance. Functional testing includes 50,000-cycle durability trials on window regulators, compression set evaluation per ASTM D395, and adhesion strength checks for multi-component channels. Client feedback at this stage drives micro-adjustments to compound viscosity or profile geometry, minimizing rework in production.

Mass production deployment integrates real-time quality gates. Our Suzhou facility utilizes 120–1500T hydraulic presses with closed-loop temperature control, maintaining ±1°C consistency during vulcanization. In-line laser micrometers monitor extrusion profiles continuously, while every batch undergoes third-party validation for tensile strength, elongation, and specific gravity per ASTM D2240. Traceability is enforced through serialized lot coding, linking raw material certificates to finished goods. This end-to-end control reduces client time-to-market by 30% while ensuring zero non-conformities in high-volume automotive programs.

Critical Material Specifications for Window Channel Applications

| Material Type | Tensile Strength (MPa) | Temperature Range (°C) | Compression Set (%), 22h @ 70°C | Shore A Hardness |

|---|---|---|---|---|

| Standard EPDM | 8.0–10.5 | -50 to +150 | ≤ 25 | 65–75 |

| High-Performance TPE | 10.0–14.0 | -45 to +135 | ≤ 20 | 70–80 |

| Baoshida Arctic-Grade EPDM | 9.5–12.0 | -60 to +140 | ≤ 18 | 60–70 |

| Baoshida UV-Stable TPE | 11.0–15.0 | -50 to +125 | ≤ 22 | 75–85 |

This systematic approach—from drawing scrutiny to serial production—ensures our window channels meet the exact mechanical, chemical, and lifecycle demands of global OEMs while adhering to IATF 16949 quality frameworks.

Contact Engineering Team

Contact Suzhou Baoshida for Premium Window Channel Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber manufacturing, specializing in high-performance window channel systems for automotive, construction, and transportation applications. With years of engineering expertise and a commitment to material science innovation, we deliver window channel profiles that meet the most stringent OEM requirements. Our products are designed for optimal sealing performance, UV resistance, compression set durability, and long-term weatherability—critical factors in maintaining structural integrity and user comfort across dynamic environmental conditions.

Our window channel extrusions are precision-engineered using advanced EPDM, silicone, and thermoplastic vulcanizate (TPV) compounds, ensuring compatibility with glass movement, thermal expansion, and acoustic insulation demands. Whether you require custom durometer ratings, co-extruded stiffening inserts, or colored trims with UV stabilizers, our R&D team collaborates closely with clients to develop application-specific profiles that enhance both function and aesthetics.

To support global supply chains, Suzhou Baoshida maintains ISO 9001-certified production facilities equipped with state-of-the-art extrusion lines, automated cutting systems, and in-house tooling capabilities. This vertical integration enables rapid prototyping, consistent batch-to-batch quality, and scalable production volumes tailored to your project timeline.

For technical collaboration or sourcing inquiries, we invite you to contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over a decade of experience in rubber component supply chain management and serves as the primary liaison between engineering teams and international clients. He is available to discuss material specifications, compliance documentation (including RoHS, REACH, and UL certifications), DFMEA support, and logistics coordination for JIT delivery models.

Below are standard technical parameters for our most commonly requested window channel profiles. Custom dimensions and compounds are available upon request.

| Property | Test Method | Typical Value |

|---|---|---|

| Material | — | EPDM, Silicone, or TPV |

| Hardness (Shore A) | ASTM D2240 | 55–80 ±5 |

| Tensile Strength | ASTM D412 | ≥8.0 MPa |

| Elongation at Break | ASTM D412 | ≥250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Operating Temperature Range | — | -40°C to +150°C |

| Color Options | — | Black, Gray, Beige, Custom (Pantone Match) |

| Standard Tolerances | ISO 3302 | Class M2 or M3 |

All profiles undergo rigorous QC screening, including dimensional verification, adhesion testing for co-extruded substrates, and dynamic durability cycling under simulated operational loads. We support CAD/CAM file submissions (STEP, IGES, DXF) for tooling development and offer DFM feedback within 48 hours of receipt.

To initiate a technical consultation or request a sample kit, contact Mr. Boyce directly at [email protected]. Include your project specifications, annual volume estimates, and any regulatory requirements to expedite the evaluation process. Our team responds to all inquiries within one business day. Partner with Suzhou Baoshida for engineered rubber solutions that deliver precision, reliability, and performance—every time.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).