Technical Contents

Engineering Guide: Window Seel

Engineering Insight: Window Seal Material Selection Criticality

Window seals represent a deceptively complex engineering challenge where material science directly dictates functional longevity. Off-the-shelf rubber compounds frequently fail in demanding architectural applications due to inadequate resistance to cumulative environmental stressors. Standard commodity EPDM formulations prioritize initial cost reduction over sustained performance, ignoring critical interactions between UV exposure, thermal cycling, compression set, and chemical exposure. These formulations typically utilize generic polymer grades with unoptimized filler systems and antioxidant packages, leading to premature hardening, cracking, or loss of sealing force within 2–3 years. Field failures manifest as water ingress, air leakage, and structural noise—issues directly traceable to insufficient molecular crosslink density and polymer backbone stability under real-world conditions.

The core deficiency lies in non-customized material design. OEMs selecting generic seals overlook that window systems operate under unique load profiles: constant compression against rigid frames, cyclic thermal expansion (-40°C to +120°C), and prolonged ozone exposure at altitude. Commodity EPDM often exceeds 25% compression set after 70°C aging per ASTM D395, causing permanent deformation and seal gap formation. Simultaneously, inadequate carbon black dispersion accelerates UV degradation, while insufficient antiozonant migration leads to surface crazing. These failures incur rework costs exceeding 300% of initial material savings, damaging OEM brand integrity.

Suzhou Baoshida addresses this through proprietary EPDM compounding focused on dynamic resilience. Our engineered solutions integrate high-saturation terpolymers with controlled diene content (<4.5%), nano-structured silica fillers for reinforcement homogeneity, and synergistic antioxidant systems designed for 25+ year service life. Material properties are validated against application-specific stress models, not generic ASTM benchmarks. Below is a comparative analysis of critical performance metrics:

| Property | Off-the-Shelf EPDM | Baoshida Engineered EPDM | Test Standard |

|---|---|---|---|

| Compression Set (70°C/22h) | 25–35% | 8–12% | ASTM D395 Method B |

| Tensile Strength Retention (150°C/72h) | 45–55% | 82–88% | ASTM D573 |

| Ozone Resistance (50pphm, 40°C) | Cracks at 20% strain | No cracks at 30% strain | ASTM D1149 |

| Shore A Hardness Change (UV, 500h) | +15–20 points | +3–5 points | SAE J1960 |

This performance delta stems from our closed-loop development process: we analyze extrusion profiles, installation tolerances, and regional climate data to tailor cure systems and polymer architectures. For example, seals destined for coastal installations receive enhanced salt-fog resistance via quaternary amine additives, while alpine applications utilize cryogenic modifiers preventing glass adhesion below -40°C. Material selection is never transactional—it is the foundation of system integrity.

OEMs must recognize that window seals are engineered components, not consumables. Partnering with a specialist rubber formulator ensures material properties align with structural dynamics and environmental exposure, eliminating field failures at the molecular level. Suzhou Baoshida delivers this precision through OEM-integrated material science, transforming seals from failure points into reliability assets.

Material Specifications

Suzhou Baoshida Trading Co., Ltd. provides high-performance industrial rubber solutions tailored for precision applications, including window seals in automotive, aerospace, and architectural systems. The performance and longevity of a window seal are directly influenced by the elastomer selected, as each material exhibits unique chemical, thermal, and mechanical properties. Viton, Nitrile (NBR), and Silicone represent three of the most widely specified elastomers for sealing applications due to their reliability under demanding service conditions. Understanding the comparative characteristics of these materials enables OEMs and system integrators to make informed material selections based on environmental exposure, temperature range, and fluid compatibility.

Viton, a fluorocarbon rubber (FKM), offers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It maintains structural integrity in continuous service temperatures up to 230°C and performs reliably in intermittent exposures up to 260°C. This makes Viton an optimal choice for aerospace and high-performance automotive window seals where exposure to jet fuel, lubricants, and extreme thermal cycling is expected. However, Viton is less flexible at low temperatures, with a lower service limit around -20°C, and carries a higher material cost compared to alternatives.

Nitrile rubber (NBR) is a cost-effective solution for applications involving petroleum-based fluids and moderate heat. With a service temperature range from -30°C to 120°C, NBR provides excellent abrasion resistance and good compression set performance. It is commonly used in automotive window seals exposed to engine oils and hydraulic fluids. While NBR offers strong mechanical durability, its performance degrades when exposed to ozone, UV radiation, and polar solvents, limiting its use in outdoor or high-oxidation environments without protective additives.

Silicone rubber (VMQ) excels in extreme temperature applications, with a functional range from -60°C to 200°C. It demonstrates outstanding resistance to UV light, ozone, and weathering, making it ideal for exterior architectural and transit window seals. Silicone also offers high purity and low toxicity, suitable for applications requiring compliance with health and safety standards. However, it has lower tensile strength and abrasion resistance compared to Viton and NBR, and is not recommended for dynamic sealing under high mechanical stress.

The following table summarizes key physical and chemical properties of these elastomers for comparative evaluation.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Fuel and Oil Resistance | Excellent | Good to Excellent | Poor |

| Ozone and UV Resistance | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Tensile Strength (MPa) | 15–20 | 10–20 | 5–8 |

| Hardness (Shore A, typical) | 70–90 | 60–80 | 40–80 |

| Fluid Compatibility – Water | Good | Good | Excellent |

| Fluid Compatibility – Acids | Good to Excellent | Fair | Fair |

Material selection for window seals must balance performance requirements with cost and manufacturability. Suzhou Baoshida Trading Co., Ltd. supports OEM partners with technical data, sample testing, and custom compounding to ensure optimal material fit for application-specific demands.

Manufacturing Capabilities

Engineering Excellence in Window Seal Manufacturing

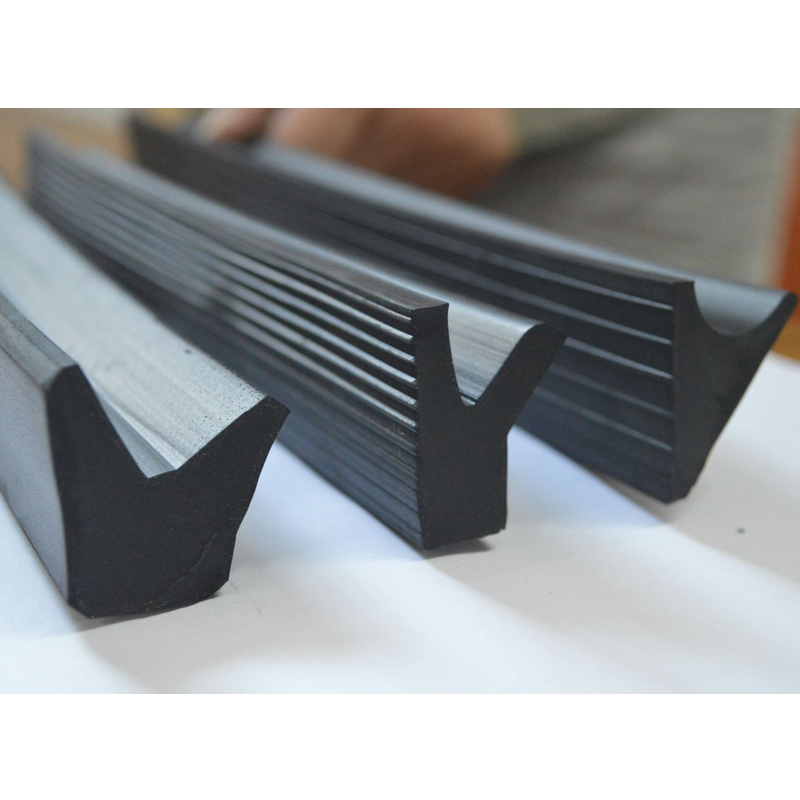

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered rubber window seals through integrated material science and mold design expertise. Our dedicated team of five mold engineers and two rubber formula specialists ensures every component meets stringent automotive and architectural performance standards. This dual-engineering approach eliminates siloed development, enabling seamless translation of client specifications into production-ready solutions with zero compromise on durability or sealing integrity.

Our formula engineers optimize compound formulations for EPDM, NBR, and silicone elastomers, targeting critical performance parameters such as compression set resistance, ozone stability, and low-temperature flexibility. Each formulation undergoes rigorous laboratory validation for crosslink density, filler dispersion, and curing kinetics, ensuring consistent extrusion and vulcanization behavior. We tailor compounds to withstand extreme conditions—from -50°C Arctic climates to 150°C engine bay exposures—while maintaining Shore A hardness tolerances within ±2 points. This granular control over polymer chemistry directly translates to extended service life and reduced field failures for end-users.

The mold engineering team leverages advanced CAD/CAM systems to design precision tooling with micron-level accuracy. Finite element analysis (FEA) simulates material flow and cavity pressure distribution, preempting defects like flash or incomplete curing. With five specialized engineers managing concurrent projects, we achieve rapid prototyping cycles—typically 15–20 days from CAD to functional samples—and maintain strict geometric tolerances per ISO 3302-1 M2 standards. Our in-house tooling facility supports complex geometries, including multi-cavity molds for high-volume OEM production and custom profiles with integrated foam cores or dual-durometer sections.

As a certified OEM partner, we provide end-to-end ownership of the manufacturing ecosystem. Clients retain full intellectual property rights while benefiting from our vertical integration: from raw material sourcing (with traceable batch records) to automated inspection using laser contour scanners. Our production lines incorporate real-time process monitoring, with SPC data logged for every batch to ensure lot-to-lot consistency. This infrastructure enables scalable production from pilot batches to 5 million units annually, all compliant with IATF 16949 and ISO 9001 frameworks.

Material performance is quantified through standardized testing, as demonstrated in our core window seal compound specifications:

| Property | Test Method | EPDM Standard | EPDM High-Performance | NBR Fuel-Resistant |

|---|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 65 ± 2 | 70 ± 2 | 75 ± 2 |

| Tensile Strength (MPa) | ASTM D412 | ≥10.0 | ≥12.5 | ≥14.0 |

| Elongation at Break (%) | ASTM D412 | ≥300 | ≥250 | ≥200 |

| Compression Set (70°C, 22h) | ASTM D395 | ≤25% | ≤18% | ≤30% |

| Temperature Range (°C) | ISO 188 | -50 to 135 | -55 to 150 | -30 to 120 |

This engineering synergy—where formula innovation and mold precision converge—positions Suzhou Baoshida as a strategic partner for global OEMs demanding window seals that exceed functional and regulatory requirements. We transform material science into measurable performance, ensuring every seal installed becomes a testament to engineered reliability.

Customization Process

Customization Process for Industrial Window Seals at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading, precision and performance define our approach to industrial rubber solutions. When manufacturing custom window seals, we follow a structured, four-phase engineering process that ensures dimensional accuracy, material compatibility, and long-term durability under real-world operating conditions.

The process begins with Drawing Analysis, where our technical team evaluates customer-supplied CAD files or technical blueprints. We assess critical dimensions, tolerance requirements, installation method, and environmental exposure parameters such as temperature range, UV resistance, and chemical contact. This phase includes cross-referencing design features with our in-house manufacturing capabilities, including extrusion, splicing, and molding techniques. Any design inconsistencies or potential sealing gaps are flagged and discussed with the client to ensure optimal functionality.

Following drawing validation, we proceed to Formulation Development. Our rubber formula engineers select the base polymer—commonly EPDM, silicone, or NBR—based on performance criteria. Additives such as reinforcing fillers, antioxidants, flame retardants, and processing aids are precisely calibrated to achieve the required Shore A hardness, compression set resistance, and weatherability. Each formulation is documented and archived for full traceability, ensuring consistency across production batches.

Once the compound is finalized, we move into Prototyping. Using short-run extrusion or injection molding, we produce sample seals for customer evaluation. These prototypes undergo preliminary testing in our lab for dimensional conformity, tensile strength, and flexibility across temperature extremes. We provide detailed test reports and coordinate with the client for fit, form, and function validation. Adjustments to the compound or profile geometry are implemented at this stage if necessary.

After prototype approval, the project transitions to Mass Production. We deploy automated extrusion lines with laser-guided dimensional control, ensuring uniform cross-sections and tight tolerances. Seals are cut to length, joined using heat or vulcanization splicing, and subjected to 100% visual inspection and batch sampling per ISO 3302 and ISO 2859-1 standards. Final packaging is customized to client logistics requirements, with labeling options for traceability.

Throughout the process, Suzhou Baoshida maintains strict adherence to ISO 9001 quality protocols and supports OEMs with full documentation, including material certifications and process capability (Cp/Cpk) data.

Typical Material Properties for Custom Window Seals

| Property | EPDM | Silicone | NBR |

|---|---|---|---|

| Temperature Range (°C) | -50 to +150 | -60 to +200 | -30 to +120 |

| Shore A Hardness Range | 50–80 | 40–70 | 55–90 |

| Compression Set (22h, 70°C) | ≤25% | ≤20% | ≤30% |

| Weather Resistance | Excellent | Excellent | Moderate |

| Fluid Resistance (oil/fuel) | Poor | Poor | Excellent |

| Typical Applications | Automotive glazing, construction | High-temp enclosures, medical | Industrial machinery, hydraulic systems |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Window Seal Solutions

Achieving optimal performance in window sealing applications demands exacting material science and manufacturing precision. Standard off-the-shelf elastomers often fail under the combined stresses of UV exposure, thermal cycling, and mechanical compression inherent in modern architectural and automotive glazing systems. At Suzhou Baoshida Trading Co., Ltd., we engineer custom EPDM and silicone compounds specifically formulated to maintain dimensional stability, elastic recovery, and adhesion integrity across 20,000+ compression cycles. Our ISO 9001-certified production lines utilize closed-mixing systems and laser-guided extrusion to ensure batch-to-batch consistency within ±0.3 Shore A hardness tolerance—critical for preventing air/water infiltration in high-performance fenestration.

Material selection directly impacts lifecycle costs and regulatory compliance. Generic seals may initially meet basic specifications but frequently exhibit premature compression set or surface degradation when exposed to ozone or temperature extremes. Our proprietary formulations undergo rigorous validation per ASTM D2000 and ISO 3302 standards, with accelerated aging protocols simulating 15+ years of field exposure. The table below summarizes key performance metrics achievable through our tailored compounding process for critical window seal applications.

| Material Property | Test Standard | Performance Value | Industrial Relevance |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 3 | Ensures consistent compression load distribution |

| Tensile Strength | ASTM D412 | ≥ 12.0 MPa | Resists tearing during installation and use |

| Elongation at Break | ASTM D412 | ≥ 350% | Accommodates structural movement without fracture |

| Compression Set (22h/70°C) | ASTM D395 | ≤ 22% | Maintains sealing force after prolonged compression |

| Low-Temperature Flexibility | ASTM D1329 | -50°C (Pass) | Prevents brittle failure in arctic climates |

| Heat Aging (70h/150°C) | ASTM D573 | ΔTensile ≤ 15% | Retains mechanical properties in hot climates |

These specifications represent baseline capabilities; actual formulations are optimized for your substrate adhesion requirements, color stability needs, and regulatory frameworks (e.g., LEED, EN 14351-1). Our engineering team collaborates directly with OEM design groups to resolve interface challenges—such as coefficient of thermal expansion mismatches between rubber and aluminum frames—through finite element analysis and prototype validation. This integrated approach reduces validation cycles by 30-45% compared to conventional supplier engagement models.

Initiate your technical consultation with Mr. Boyce, our dedicated OEM Relationship Manager, to advance your window seal development program. With 18 years of specialized experience in architectural elastomer systems, Mr. Boyce will coordinate material selection, DFM analysis, and accelerated qualification testing within your project timeline. Provide your target performance envelope and volume requirements to receive a formal technical proposal within 72 hours—including Durometer transition zone mapping and compression stress relaxation curves specific to your application geometry.

Contact Mr. Boyce directly at [email protected] to schedule a confidential technical review. Include your current material specification sheet and sealing interface drawings to expedite compound optimization. Suzhou Baoshida operates under strict ITAR-compliant data protocols, ensuring your intellectual property remains protected throughout the development cycle. For urgent RFQs, reference Project Code WND-SEAL-2024 to activate our priority engineering response channel. Partner with us to transform sealing performance from a cost factor into a competitive differentiator.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).