Technical Contents

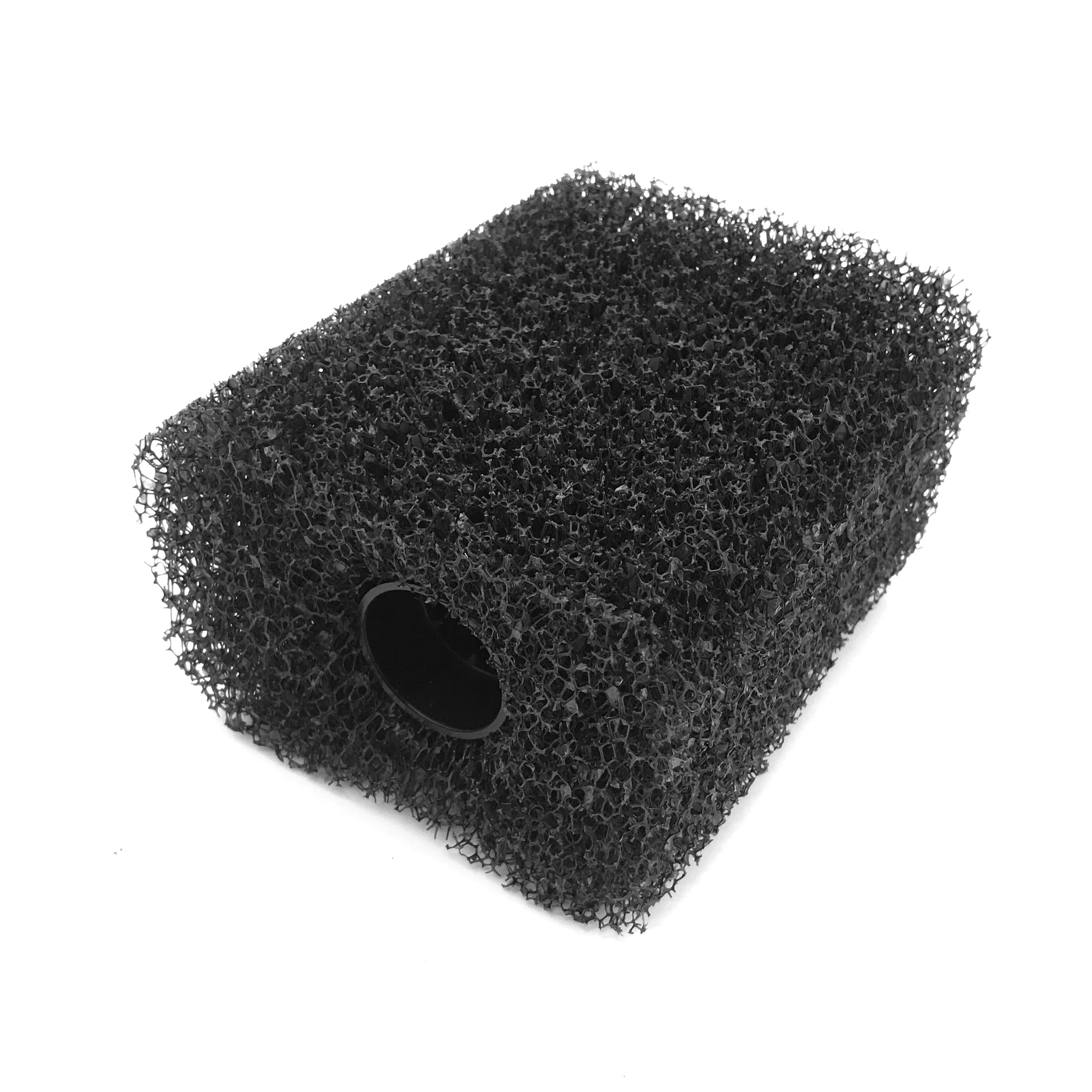

Engineering Guide: Filter Foam For Ponds

Engineering Insight: Material Selection in Filter Foam for Ponds

In industrial and commercial pond filtration systems, the performance and longevity of filter foam are directly tied to precise material engineering. While off-the-shelf foam solutions may appear cost-effective initially, they frequently fail under sustained hydraulic load, biological stress, and environmental exposure. These failures stem from inadequate polymer formulation, inconsistent cell structure, and poor resistance to microbial degradation—factors that compromise filtration efficiency and increase lifecycle costs.

At Suzhou Baoshida Trading Co., Ltd., we approach filter foam as a functional component within a dynamic ecosystem, not merely as a disposable medium. Standard polyether or polyester-based foams commonly available in general markets degrade rapidly due to hydrolysis and oxidation, especially in warm, nutrient-rich water environments. This breakdown leads to particulate shedding, channeling within the filter bed, and reduced surface area for beneficial bacterial colonization—critical for biological filtration.

The core challenge lies in balancing porosity, mechanical resilience, and chemical stability. Open-cell structure is essential for maximizing surface-to-volume ratio and enabling efficient particulate entrapment. However, excessive openness without structural reinforcement results in compression set and collapse under continuous water flow. Conversely, overly dense foams restrict flow rates and increase backpressure, reducing system efficiency.

Our engineered rubber-based filter foams utilize modified polyurethane matrices with enhanced cross-linking density. This molecular architecture provides superior resistance to hydrolytic degradation while maintaining an optimal pore size distribution (ranging from 10 to 45 pores per inch). The result is a durable, high-surface-area medium that supports long-term biofilm formation and withstands frequent backwashing without structural fatigue.

Additionally, we incorporate stabilizing additives that resist UV degradation and microbial attack—common failure points in outdoor installations. Unlike commodity foams that rely on short-term physical properties, our formulations are validated through accelerated aging tests simulating 5+ years of continuous operation.

Below is a comparative specification table highlighting key performance parameters between standard off-the-shelf foams and our engineered solution:

| Parameter | Standard Polyether Foam | Engineered Rubber-Based Foam (Baoshida) |

|---|---|---|

| Pore Density (PPI) | 20–30 | 10–45 (customizable) |

| Tensile Strength (ISO 1798) | 80–120 kPa | 180–250 kPa |

| Elongation at Break | 120–180% | 200–300% |

| Compression Set (50%, 22h) | 15–25% | <8% |

| Water Absorption (24h) | 8–12% | 3–5% |

| Hydrolysis Resistance (90d) | Poor (visible cracking) | Excellent (no structural change) |

| Microbial Resistance | Low | High (additive-protected) |

| Service Life (est. outdoor) | 12–18 months | 5+ years |

Material selection is not a commodity decision—it is a systems engineering imperative. Off-the-shelf foams fail because they are not designed for the sustained mechanical and biochemical demands of pond filtration. Our engineered solutions ensure reliability, reduce maintenance cycles, and optimize total cost of ownership in industrial and municipal applications.

Material Specifications

Material Specifications for Pond Filter Foam Applications

Selecting optimal elastomeric materials for pond filter foam requires rigorous evaluation of chemical resistance, thermal stability, and mechanical performance under continuous aquatic exposure. At Suzhou Baoshida Trading Co., Ltd., we engineer custom rubber formulations to withstand biological contaminants, organic debris, and variable pH conditions inherent in pond ecosystems. Our technical analysis prioritizes long-term compression set resistance, hydrolytic stability, and non-toxicity to aquatic life. Below we detail three critical polymers for this application: Viton (FKM), Nitrile (NBR), and Silicone (VMQ).

Viton fluorocarbon rubber offers superior resistance to oils, fuels, and aggressive chemicals that may enter pond systems via runoff or maintenance products. Its thermal stability spans -20°C to +230°C, making it ideal for regions with extreme seasonal fluctuations. Viton maintains integrity when exposed to chlorine-based sanitizers or algaecides, though its high cost necessitates strategic deployment in high-risk zones. Compression set values remain below 25% after 70 hours at 150°C, ensuring consistent sealing performance over extended service life.

Nitrile rubber provides an economical balance for general pond filtration, with exceptional resistance to aliphatic hydrocarbons and moderate ozone exposure. Operating effectively between -30°C and +120°C, NBR formulations achieve Shore A hardness of 50–90, allowing tunable density for optimal water flow dynamics. While susceptible to degradation from aromatic solvents, standard NBR grades resist common pond contaminants like fish waste enzymes and decaying organic matter. Cost efficiency and rapid manufacturability make NBR the preferred choice for OEMs targeting mid-tier filtration systems.

Silicone rubber excels in biocompatibility and extreme temperature resilience (-60°C to +200°C), critical for ponds housing sensitive species or subjected to sterilization cycles. Its inert surface inhibits biofilm adhesion, reducing maintenance frequency. Silicone demonstrates unmatched UV resistance compared to hydrocarbon rubbers, preventing embrittlement in sun-exposed installations. However, lower tensile strength (5–8 MPa) requires structural reinforcement in high-pressure filter housings.

The comparative specifications below guide material selection based on operational priorities:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Density (g/cm³) | 1.82–1.98 | 0.95–1.05 | 1.10–1.30 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Temp Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 10–15 | 15–25 | 5–8 |

| Key Resistances | Oils, acids, ozone | Hydrocarbons, water | UV, steam, microbes |

| Pond-Specific Advantage | Chemical spill resilience | Cost-effective organic waste resistance | Non-toxic biofilm resistance |

Material selection directly impacts filter longevity and ecosystem health. Viton suits premium systems requiring chemical aggression resistance, NBR delivers value-driven performance for standard applications, and Silicone is optimal for biologically sensitive or UV-intensive environments. Suzhou Baoshida Trading Co., Ltd. provides OEMs with ISO 9001-certified compound validation, including ASTM D2000 compliance testing for compression set, fluid immersion, and accelerated aging. Our engineering team collaborates with manufacturers to optimize durometer, cell structure, and additive packages for site-specific pond parameters. This precision ensures minimal maintenance cycles and compliance with global aquatic safety standards.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Development for Filter Foam Applications

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance filter foam for pond filtration systems. With a dedicated team of five mould engineers and two specialized rubber formula engineers, we maintain full in-house control over material science, design optimization, and manufacturing precision. This integrated technical structure enables us to deliver engineered solutions that meet exacting OEM requirements while ensuring long-term reliability in aquatic environments.

Our formula engineers focus on polymer chemistry tailored to aquatic applications, developing closed-cell and open-cell foam compounds with optimized porosity, resilience, and resistance to biological degradation. Using EPDM, neoprene, and blended synthetic rubbers, we formulate materials that withstand prolonged exposure to water, UV radiation, and fluctuating temperatures without compromising filtration efficiency or structural integrity. Each formulation is tested for compression set, tensile strength, and water absorption under controlled laboratory conditions, ensuring consistency across production batches.

Complementing material development, our five mould engineers specialize in precision tooling design for continuous and batch foam production. They utilize CAD/CAM systems and finite element analysis (FEA) to simulate flow dynamics and curing behavior, minimizing defects and maximizing cell uniformity. Custom moulds are fabricated to support complex geometries, including multi-layer configurations and graded pore density profiles, allowing for multi-stage mechanical and biological filtration within a single unit. This level of design sophistication is essential for OEM partners seeking to differentiate their pond filtration products in competitive markets.

We operate under a robust OEM framework, providing end-to-end support from concept validation to mass production. Our engineering team collaborates directly with client R&D departments to interpret performance specifications, conduct prototyping iterations, and validate final designs through accelerated life testing. This collaborative model ensures seamless integration of our filter foam components into complete filtration units, whether for residential, commercial, or ecological water management systems.

The following table outlines key technical specifications achievable through our engineering and manufacturing platform:

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Pore Density (PPI) | 10–45 pores per inch | ASTM D6468 |

| Compression Set (22h, 70°C) | ≤ 20% | ASTM D395 |

| Tensile Strength | 0.8–2.5 MPa | ASTM D412 |

| Elongation at Break | 150–300% | ASTM D412 |

| Water Absorption (24h) | ≤ 5% | ISO 175 |

| Temperature Resistance | -40°C to +120°C (continuous) | DIN 53508 |

| Cell Structure | Open-cell, semi-open, or closed | Microscopic Analysis |

Through the convergence of advanced rubber formulation and precision mould engineering, Suzhou Baoshida delivers technically superior filter foam solutions that meet the functional demands of modern pond filtration. Our OEM capabilities are built on engineering rigor, material expertise, and a commitment to performance-driven innovation.

Customization Process

Customization Process for Industrial Pond Filter Foam Solutions

At Suzhou Baoshida Trading Co., Ltd., our customization process for pond filter foam integrates rigorous engineering protocols to ensure optimal performance in aquatic filtration systems. This structured methodology transforms client specifications into durable, high-efficiency rubber components through four critical phases.

Drawing Analysis initiates the workflow, where our engineering team conducts dimensional conformance verification against ISO 2768-mK tolerances. We assess pore geometry, wall thickness uniformity, and fluid dynamics compatibility using CAD cross-referencing. Critical parameters such as open-cell density distribution and edge integrity are validated to prevent channeling defects under continuous water pressure. Non-compliant geometries trigger immediate collaborative redesign with the client to align with manufacturable constraints.

Formulation Development follows, leveraging our proprietary EPDM and silicone compound libraries. Material selection prioritizes hydrolysis resistance against common pond algaecides (e.g., copper sulfate, hydrogen peroxide) and UV stability per ASTM D4329. Key variables include:

Accelerator systems for controlled vulcanization at 150–180°C

Filler ratios (e.g., 30–50 phr silica) to balance compressive strength and permeability

Antioxidant packages targeting 5,000+ hours of accelerated weathering

This phase culminates in a traceable formula sheet with batch-specific rheology curves and cure kinetics data.

Prototyping employs precision compression molding with tooling certified to ISO 8062 Class 2. Each prototype undergoes:

Flow rate testing at 0.5–2.0 m³/h per DIN 51562

Compression set analysis after 72h immersion in pH 6.5–8.5 synthetic pond water

Microbial resistance screening per ASTM G22

Client validation occurs within 15 business days, with iterative refinements until all performance thresholds are met.

Mass Production activates upon prototype sign-off, utilizing automated SPC monitoring across 12 critical control points. Every production run adheres to ISO 9001:2015 protocols, with real-time tracking of:

Shore A hardness (±2 units)

Tensile strength (min. 6.5 MPa)

Pore size distribution (verified via mercury intrusion porosimetry)

Final inspection includes 100% visual grading for surface defects and batch traceability to raw material lot codes.

Critical Performance Specifications

| Parameter | Standard Range | Test Method | Customization Limit |

|——————–|———————-|——————-|———————|

| Pore Size (ppi) | 10–45 | ASTM F316 | ±2 ppi |

| Density (kg/m³) | 25–120 | ISO 845 | ±5% |

| Tensile Strength | 5.0–9.0 MPa | ISO 37 | Min. 4.5 MPa |

| Compression Set | ≤25% (22h, 70°C) | ISO 815 | ≤30% |

| Water Absorption | ≤0.8% (24h, 23°C) | ISO 2818 | ≤1.2% |

This end-to-end process guarantees pond filter foams that maintain structural integrity across 5+ years of operational exposure while optimizing biological filtration efficiency. Suzhou Baoshida’s engineering discipline ensures seamless scalability from prototype to 50,000+ unit production runs without performance deviation.

Contact Engineering Team

For industrial partners seeking high-performance filter foam solutions tailored specifically for pond filtration systems, Suzhou Baoshida Trading Co., Ltd. stands at the forefront of precision-engineered rubber materials. As a trusted OEM manager and rubber formula engineer, we specialize in developing customized porous elastomeric media that meet exact hydrodynamic, biological, and mechanical requirements for sustainable water treatment applications. Our expertise lies in formulating closed-cell and open-cell foam structures with controlled pore distribution, tensile resilience, and long-term resistance to UV degradation, microbial attack, and chemical exposure—critical factors in outdoor pond environments.

Filter foam for ponds is not a one-size-fits-all product. It must balance water flow rate, particulate retention, ease of cleaning, and biofilm support for beneficial nitrifying bacteria. At Suzhou Baoshida, we leverage proprietary rubber compounding techniques using EPDM, neoprene, and specialized synthetic blends to produce filtration media that outperforms standard polyurethane foams in durability and functional lifespan. Each batch is engineered under ISO-compliant processes, ensuring dimensional accuracy, consistent porosity, and compliance with environmental safety standards.

We invite technical procurement teams, OEM system integrators, and industrial designers to engage directly with Mr. Boyce, our lead Rubber Formula Engineer and OEM Manager. With over 15 years of experience in elastomer application development, Mr. Boyce leads client-driven formulation projects from concept to mass production. Whether you require custom density gradients, antimicrobial additives, or flame-retardant variants for specialized pond ecosystems, our R&D pipeline supports rapid prototyping and performance validation under real-world conditions.

To initiate collaboration or request sample batches for testing, contact Mr. Boyce via email at [email protected]. Include your technical specifications, target application parameters, and production volume estimates to receive a tailored material proposal within 48 hours. Our team supports multilingual communication and provides full documentation, including material safety data sheets (MSDS), compression set reports, and permeability test results.

Below are key technical specifications representative of our standard pond filter foam offerings. All properties can be adjusted based on client requirements.

| Property | Test Method | Typical Value |

|---|---|---|

| Density | ASTM D3574 | 0.28–0.45 g/cm³ |

| Tensile Strength | ASTM D412 | 1.8–3.2 MPa |

| Elongation at Break | ASTM D412 | 150–280% |

| Compression Deflection (ILD) | ASTM D3574 | 0.8–2.1 kPa @ 25% |

| Pore Size (PPI) | Optical Microscopy | 10–45 Pores Per Inch |

| Water Absorption | ASTM D395 | < 5% after 72 hrs |

| Operating Temperature | — | -40°C to +120°C |

| Aging Resistance | ASTM D573 | < 15% property loss after 7 days @ 100°C |

Partner with Suzhou Baoshida to transform your pond filtration performance through scientifically optimized rubber foam technology. Reach out to Mr. Boyce today at [email protected] and elevate your next-generation aquatic system design with industrial-grade precision.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).