Technical Contents

Engineering Guide: Doormat Holiday

Engineering Insight: Material Selection in doormat holiday Applications

In the industrial domain, the term doormat holiday refers to a critical failure mode where rubber components—typically seals, gaskets, or protective mats—degrade prematurely under operational stress, leading to unexpected downtime and safety risks. This phenomenon is not a function of usage intensity alone but stems directly from improper material selection during the design phase. Off-the-shelf rubber solutions are frequently deployed as cost-saving measures, yet they lack the tailored formulation required for specific environmental and mechanical demands. As a result, these generic materials often fail to maintain structural integrity under thermal cycling, chemical exposure, or dynamic loading, culminating in what engineers classify as a doormat holiday—a sudden and avoidable system interruption.

The root cause lies in the inherent variability of rubber as a polymer matrix. Natural rubber, EPDM, NBR, and silicone each exhibit distinct responses to temperature, UV radiation, ozone, and fluid immersion. A material that performs adequately in a controlled warehouse environment may rapidly deteriorate in an outdoor industrial setting with fluctuating humidity and temperature gradients. For instance, standard NBR compounds degrade when exposed to polar solvents, while EPDM exhibits poor oil resistance despite excellent weatherability. Deploying such mismatched materials without rigorous environmental profiling leads to accelerated aging, surface cracking, and loss of compressive recovery—hallmarks of impending failure.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber solutions calibrated to application-specific parameters. Our approach begins with a failure mode and effects analysis (FMEA) of the operational environment, followed by material screening using accelerated aging tests per ASTM D573 and ISO 188 standards. This ensures that the selected compound maintains its durometer, tensile strength, and elongation at break over the intended service life.

The table below outlines key performance characteristics of common industrial rubbers under standardized test conditions:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Resistance to Oils | Resistance to UV/Ozone |

|---|---|---|---|---|---|

| Natural Rubber | -40 to +80 | 18–25 | 400–600 | Low | Low |

| NBR (Nitrile) | -30 to +100 | 15–20 | 300–500 | High | Moderate |

| EPDM | -50 to +150 | 10–18 | 250–450 | Low | Excellent |

| Silicone | -60 to +200 | 6–10 | 200–400 | Low | Excellent |

Selecting the correct material is not merely a technical decision—it is an economic imperative. The cost of unplanned maintenance, equipment damage, and production loss during a doormat holiday far exceeds the incremental investment in a purpose-formulated rubber compound. Suzhou Baoshida Trading Co., Ltd. provides OEM-level material engineering support, ensuring that every rubber component is optimized for durability, compliance, and long-term reliability in its intended application.

Material Specifications

Material Specifications for Industrial Holiday Door Mat Manufacturing

Material selection critically determines performance longevity in seasonal door mat applications subjected to variable weather exposure and high foot traffic. Suzhou Baoshida Trading Co., Ltd. formulates compounds using Viton fluorocarbon rubber, Nitrile butadiene rubber (NBR), and silicone to address specific environmental stressors. Each material offers distinct advantages in thermal stability, chemical resistance, and mechanical resilience. Precise compound engineering ensures optimal grip, wear resistance, and dimensional stability under cyclic compression from pedestrian use.

Viton fluorocarbon rubber provides exceptional resistance to extreme temperatures and aggressive chemicals, making it suitable for commercial entrances in industrial zones or regions with severe winter conditions. Its molecular structure maintains integrity between -20°C and 230°C, resisting degradation from road salts, oils, and UV exposure. However, Viton’s higher cost necessitates strategic application where standard elastomers would fail prematurely.

Nitrile butadiene rubber (NBR) delivers superior resistance to petroleum-based fluids and moderate temperature ranges, ideal for automotive dealership or garage entrances during holiday seasons. Formulated with acrylonitrile content between 34%–45%, NBR compounds achieve tensile strengths of 15–25 MPa and elongation at break exceeding 300%. This balance ensures durability against oil spills while maintaining flexibility down to -30°C, preventing brittle fracture in cold climates.

Silicone rubber excels in applications requiring extreme temperature resilience and non-toxic compliance, such as indoor hospitality or healthcare facility holiday mats. Its inorganic backbone sustains performance from -60°C to 200°C with minimal compression set (typically <20% at 150°C/24h). Platinum-cured silicone formulations meet FDA and EU food-contact standards, offering hypoallergenic properties essential for sensitive environments.

The following table details comparative technical specifications for OEM formulation guidance:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness Range (Shore A) | Key Applications |

|---|---|---|---|---|---|

| Viton | -20 to 230 | 8–15 | 150–250 | 60–85 | Industrial entrances, chemical zones |

| Nitrile (NBR) | -30 to 100 | 15–25 | 300–500 | 50–90 | Automotive, oil-prone areas |

| Silicone | -60 to 200 | 6–12 | 400–700 | 30–80 | Indoor hospitality, healthcare |

Selection must align with site-specific factors: Viton for extreme chemical exposure, NBR for cost-effective oil resistance, and silicone for ultra-low-temperature flexibility or regulatory compliance. Suzhou Baoshida’s OEM team validates all compounds per ASTM D2000 standards, ensuring Shore A hardness tolerances within ±3 points and compression set values below 25% after 70 hours at maximum service temperature. This precision engineering guarantees holiday door mats maintain structural integrity and safety performance across 5,000+ foot traffic cycles. Partner with our technical team to specify the optimal elastomer matrix for your seasonal product line.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber manufacturing, delivering precision-engineered solutions tailored to the demanding requirements of global OEMs. Our Engineering Capability division is anchored by a specialized team of five dedicated mould engineers and two advanced formula development specialists, enabling us to offer fully integrated product development from concept to mass production. This dual expertise in physical tooling and material science ensures that every rubber component we produce meets exact performance, durability, and environmental specifications.

Our mould engineers bring extensive experience in designing and optimizing rubber compression, transfer, and injection moulds. Utilizing advanced CAD/CAM software and precision CNC machining, they create robust, high-tolerance tooling systems that support efficient cycle times, minimal flash, and consistent part quality. Each design undergoes rigorous simulation and validation processes to anticipate material flow, shrinkage behavior, and ejection dynamics, reducing time-to-market and minimizing costly iterations. With in-house tooling fabrication and modification capabilities, we maintain full control over lead times and design confidentiality.

Complementing our mould engineering strength is our proprietary rubber formulation expertise. Our two formula engineers specialize in developing custom elastomer compounds tailored to specific mechanical, thermal, and chemical resistance requirements. Leveraging a deep understanding of polymer chemistry, filler systems, vulcanization kinetics, and aging behavior, they formulate materials based on NBR, EPDM, silicone, neoprene, and other specialty rubbers. This scientific approach allows us to meet industry-specific standards such as ASTM D2000, ISO 3302, and FDA/USP Class VI where applicable.

Our OEM capabilities are structured to support long-term partnerships with manufacturers requiring high-reliability rubber components. We engage early in the design phase, offering Design for Manufacturability (DFM) feedback, material selection guidance, and prototyping services using production-intent tooling. From low-volume pilot runs to high-volume automated production, our systems are scalable and ISO 9001-certified, ensuring consistent quality across batches.

The integration of mould design and compound development within a single technical team enables rapid problem-solving and innovation. Whether addressing sealing performance under dynamic loads, resistance to extreme temperatures, or compliance with environmental regulations, our engineers deliver optimized solutions that balance performance, cost, and manufacturability.

The following table outlines key engineering specifications and capabilities:

| Parameter | Specification |

|---|---|

| Mould Design Capacity | 50+ moulds/month |

| CAD Systems | SolidWorks, AutoCAD, UG NX |

| Mould Tolerance | ±0.02 mm |

| Compound Development Range | Hardness: 30–90 Shore A; Temperature Range: -60°C to +250°C |

| Standard Materials | NBR, EPDM, Silicone, CR, SBR, FKM |

| Testing Capabilities | Tensile, Compression Set, Hardness, Aging, Fluid Resistance |

| OEM Support | Full DFM, IP Protection, Rapid Prototyping, Batch Traceability |

Suzhou Baoshida Trading Co., Ltd. stands as a technically advanced partner for OEMs requiring precision rubber components backed by deep engineering insight and scalable manufacturing excellence.

Customization Process

Customization Process for Industrial Rubber Doormats

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for industrial rubber doormats integrates material science with precision manufacturing to deliver solutions meeting exact client specifications. This structured workflow ensures optimal performance, durability, and cost efficiency from concept to bulk production.

Drawing Analysis

Initial engagement begins with rigorous technical drawing review. Our engineering team scrutinizes dimensional tolerances, surface textures, drainage patterns, and structural reinforcements. Critical parameters such as edge thickness, cleat geometry, and anti-slip profiles are validated against ISO 9001 standards. We identify potential manufacturability risks early, including undercuts or draft angles incompatible with rubber molding, and collaborate with clients to refine designs without compromising functional intent. This phase reduces prototyping iterations by up to 40% through preemptive geometric optimization.

Formulation Engineering

Based on the finalized design and application requirements, our rubber chemists develop tailored polymer compounds. We select base polymers (SBR, EPDM, or recycled rubber blends) and adjust filler ratios, plasticizers, and vulcanizing agents to achieve target properties. For exterior doormats, formulations prioritize UV stability, ozone resistance, and Shore A hardness between 55–75 to balance flexibility and abrasion resistance. Each compound undergoes computational modeling to predict flow behavior during injection molding, ensuring uniform cavity filling and minimizing voids.

Prototyping and Validation

A physical prototype is produced within 72 hours using CNC-machined aluminum molds. We conduct accelerated lifecycle testing per ASTM D2240 and ISO 48 standards, measuring tensile strength, elongation at break, and compression set. Critical performance metrics include slip resistance (ASTM F2913), colorfastness to UV exposure, and chemical resistance against common contaminants like oil or de-icing salts. Client feedback on ergonomics and aesthetics is incorporated before final sign-off, with material certifications provided for traceability.

Mass Production Execution

Upon prototype approval, we transition to high-volume manufacturing in our ISO 14001-certified facility. Automated injection molding presses with ±0.1mm positional accuracy ensure batch consistency, while real-time rheometer monitoring controls cure kinetics. Every 500 units undergo inline quality checks for dimensional conformity and surface defects. Finished mats are palletized with moisture-resistant wrapping, accompanied by CoA documentation detailing compound batch numbers, hardness variance (<±3 Shore A), and compliance with REACH/ROHS regulations.

Key Rubber Compound Specifications

| Property | Standard Compound | Custom Compound (Example) | Test Method |

|---|---|---|---|

| Shore A Hardness | 65 ± 5 | 72 ± 3 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ≥18 MPa | ISO 37 |

| Elongation at Break | ≥250% | ≥320% | ISO 37 |

| Ozone Resistance | 50 ppm, 40°C, 20h | 100 ppm, 40°C, 100h | ASTM D1149 |

| Compression Set (22h) | ≤25% | ≤15% | ISO 815 |

This end-to-end process guarantees that Suzhou Baoshida’s rubber doormats exceed industrial durability benchmarks while adhering to stringent OEM timelines. Our technical team remains engaged through production to ensure zero deviation from validated specifications.

Contact Engineering Team

Contact Suzhou Baoshida Trading Co., Ltd. for Premium Industrial Rubber Solutions

When sourcing high-performance rubber components for industrial applications, precision, material integrity, and supply chain reliability are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions tailored to meet the rigorous demands of global OEMs and manufacturing partners. Our expertise spans custom formulations, compression and injection molding, and advanced testing protocols that ensure every part exceeds industry standards. As your dedicated rubber formula engineer and OEM manager, Mr. Boyce leads a technical team committed to delivering materials and components optimized for durability, chemical resistance, temperature stability, and mechanical performance.

Whether you are developing seals, gaskets, dampers, or specialized rubber mats—including seasonal or promotional variants such as doormat holiday products—our R&D-driven approach ensures material compatibility and long-term functionality under real-world conditions. We utilize a range of elastomers including NBR, EPDM, silicone, neoprene, and FKM, each compounded to meet specific hardness, tensile strength, and environmental resistance requirements. Our facility in Suzhou is equipped with state-of-the-art mixing, molding, and QC equipment, enabling rapid prototyping and scalable production runs with consistent batch-to-batch repeatability.

To initiate a technical consultation or request a customized rubber formulation, contact Mr. Boyce directly at [email protected]. He will guide you through material selection, design validation, and compliance documentation, ensuring your project aligns with both performance goals and regulatory frameworks such as RoHS, REACH, and FDA (where applicable). We support clients across automotive, electronics, construction, and consumer goods industries with end-to-end engineering collaboration—from initial concept to mass production.

Below are representative specifications for a standard rubber doormat compound commonly adapted for holiday or seasonal applications. This formulation balances wear resistance, slip prevention, and aesthetic versatility while maintaining industrial-grade resilience.

| Property | Test Method | Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 65 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 8.0 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤ 20% |

| Temperature Range | — | -40°C to +100°C |

| Specific Gravity | ASTM D297 | 1.15 ± 0.03 |

| Color Options | — | Custom (Pantone matched) |

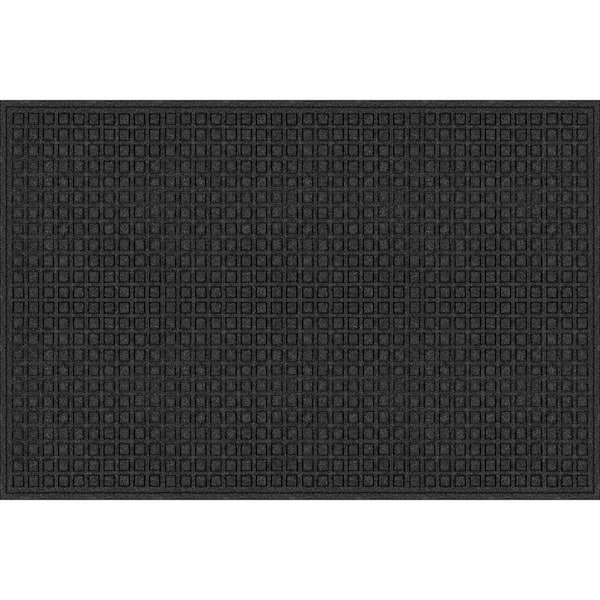

| Surface Finish | — | Textured, Molded Logo, Anti-Slip Pattern |

All formulations are subject to modification based on client specifications. We offer full technical data sheets (TDS), material safety data sheets (MSDS), and sample submissions upon request.

Partner with Suzhou Baoshida Trading Co., Ltd. to leverage advanced rubber science in your next product development cycle. For immediate technical support and quoting, reach out to Mr. Boyce at [email protected]. Let us engineer reliability, one compound at a time.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).