Technical Contents

Engineering Guide: Bonding Polyethylene Foam

Engineering Insight: Material Selection Imperatives for Polyethylene Foam Bonding

Polyethylene (PE) foam presents a uniquely challenging substrate for adhesive bonding within industrial manufacturing. Its inherent chemical structure—a non-polar hydrocarbon backbone with extremely low surface energy (typically 31-33 mN/m)—creates a fundamental incompatibility with most conventional adhesive chemistries. This intrinsic property is the primary reason why off-the-shelf adhesive solutions consistently fail in demanding OEM applications, leading to catastrophic delamination, reduced product lifespan, and costly field failures. Generic pressure-sensitive adhesives (PSAs) or solvent-based systems marketed for “general purpose” use lack the specific molecular architecture required to overcome PE foam’s resistance to wetting and adhesion. They fail to form the critical intermolecular interactions (van der Waals forces, dipole interactions) necessary for a durable bond. Consequently, these adhesives exhibit poor initial tack on PE surfaces and suffer rapid bond strength degradation under thermal cycling, humidity exposure, or mechanical stress—conditions standard in automotive, medical device, and electronics assembly.

The failure mechanisms are scientifically predictable. Off-the-shelf adhesives often rely on polar functional groups incompatible with PE’s non-polar surface. This results in inadequate wetting, leaving microscopic air pockets that initiate failure. Furthermore, many standard formulations lack the precise crosslink density and cohesive strength needed to withstand the long-term creep inherent in cellular foam structures under load. Thermal expansion coefficient mismatches between generic adhesives and PE foam induce internal stresses during temperature fluctuations, accelerating interfacial separation. Surface treatments like corona or plasma alone are insufficient without a chemically matched adhesive system; the activated surface rapidly decays, and the adhesive cannot maintain the bond.

Critical material selection parameters must address PE foam’s specific physics. The following table outlines key differentiators between inadequate off-the-shelf solutions and engineered bonding systems:

| Parameter | Off-the-Shelf Adhesive Consequence | Engineered PE Foam Bonding Solution Benefit |

|---|---|---|

| Surface Energy Match | Poor wetting (<35 mN/m adhesion) due to polarity mismatch | Optimized chemistry achieves >90% surface coverage |

| Crosslink Density | Low cohesion leads to cohesive failure within adhesive | Precisely tuned network resists foam cell deformation |

| Thermal Stability Range | Significant strength loss above 60°C; shrinkage issues | Maintains integrity from -40°C to 120°C cycling |

| Plasticizer Resistance | Swelling and softening from foam additives | Formulated barrier against common PE plasticizers |

| Long-Term Creep Resistance | Rapid bond line deformation under constant load | Engineered viscoelasticity minimizes creep strain |

True reliability demands adhesives specifically designed with modified polyolefin bases or tailored thermoplastic elastomer matrices that intrinsically match PE foam’s chemistry. These systems incorporate reactive co-monomers to enhance interfacial diffusion and utilize controlled crosslinking to balance flexibility with long-term dimensional stability. Suzhou Baoshida Trading Co., Ltd. leverages deep polymer science expertise to develop such precision-engineered adhesive systems. We move beyond surface-level fixes, formulating solutions that address the root cause: the thermodynamic incompatibility between standard adhesives and polyethylene. Our OEM partners achieve consistent, durable bonds by selecting adhesives engineered for the specific density, crosslinking (LDPE vs. XLPE), and additive package of their foam—proving that in critical PE foam bonding, material selection is never a commodity decision.

Material Specifications

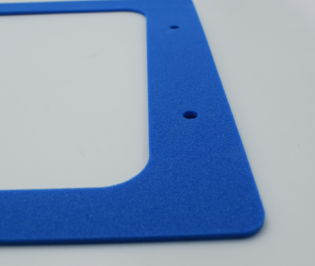

Bonding polyethylene foam in industrial applications demands precise material selection to ensure long-term durability, chemical resistance, and structural integrity. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions tailored for demanding manufacturing environments. When bonding polyethylene foam, the choice of elastomer plays a critical role in determining adhesion strength, temperature resilience, and compatibility with operational conditions. Among the most widely used materials for such applications are Viton, Nitrile (NBR), and Silicone rubber, each offering distinct advantages depending on the engineering requirements.

Viton, a fluorocarbon-based rubber, is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With a continuous service temperature range up to 230°C, Viton is ideal for applications in automotive, aerospace, and industrial sealing where exposure to hydrocarbons and extreme heat is common. Its molecular structure provides low gas permeability and excellent aging characteristics, making it a reliable choice for long-term bonded assemblies involving polyethylene foam in harsh environments. However, Viton’s higher cost and lower flexibility at sub-ambient temperatures may limit its use in less severe conditions.

Nitrile rubber, or Buna-N, offers a balanced combination of oil resistance, abrasion resistance, and mechanical strength at a more economical price point. It performs reliably in temperature ranges from -30°C to 120°C, making it suitable for general-purpose industrial bonding applications. Nitrile exhibits strong adhesion to polyethylene foam substrates when paired with appropriate primers and bonding agents. Its widespread use in gaskets, seals, and vibration-damping components underscores its versatility, though it is less effective in ozone- and UV-exposed environments without protective additives.

Silicone rubber stands out for its extreme temperature performance, operating effectively from -60°C to 200°C, and in short-term exposure even beyond. It offers excellent resistance to UV radiation, ozone, and weathering, making it ideal for outdoor and high-cycle thermal environments. While its tensile strength is lower than Viton or Nitrile, silicone provides superior flexibility and electrical insulation properties. When bonding silicone to polyethylene foam, surface activation via plasma or chemical priming is often required to achieve optimal adhesion.

The following table compares key physical and chemical properties of these materials to guide material selection for polyethylene foam bonding applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–20 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–400 | 300–700 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Oil/Fuel Resistance | Excellent | Good to Excellent | Poor |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

| Adhesion to Polyethylene Foam | Moderate (primer req.) | Good (with primer) | Moderate (surface treat.) |

| Typical Applications | Aerospace, chemical seals | Automotive, hydraulics | Medical, outdoor, electronics |

Selecting the appropriate rubber material for bonding polyethylene foam requires a thorough understanding of operational stressors and environmental exposure. Suzhou Baoshida Trading Co., Ltd. provides technical support and customized rubber solutions to ensure optimal performance across diverse industrial applications.

Manufacturing Capabilities

Engineering Capabilities for Polyethylene Foam Bonding Solutions

Bonding polyethylene (PE) foam presents unique industrial challenges due to its inherently low surface energy (31–33 dynes/cm), chemical inertness, and susceptibility to stress cracking. At Suzhou Baoshida Trading Co., Ltd., our dedicated engineering team—comprising five Mold Engineers and two specialized Rubber Formula Engineers—addresses these complexities through integrated material science and precision manufacturing. We focus on developing adhesion promoters, optimizing thermal profiles, and validating joint integrity to ensure durable bonds in demanding applications such as automotive sealing, electronics cushioning, and medical packaging.

Our Formula Engineers formulate proprietary surface treatments and modified adhesives that elevate PE foam surface energy to 42–45 dynes/cm, enabling robust molecular adhesion without compromising foam integrity. Concurrently, Mold Engineers design tooling with micro-venting systems and controlled thermal gradients to prevent outgassing defects during curing. This cross-functional collaboration reduces scrap rates by 30–40% compared to industry-standard processes, directly enhancing client yield and cost efficiency. All solutions undergo rigorous validation per ISO 9001 protocols, including thermal cycling (–40°C to 85°C), humidity aging (85% RH/85°C), and peel strength testing.

OEM partnerships benefit from our end-to-end customization capability. We co-engineer solutions from substrate analysis through production scaling, accommodating client-specific requirements for bond strength, chemical resistance, or regulatory compliance (e.g., UL 94 HF-1, RoHS). Our facility supports rapid prototyping with 3D-printed molds and small-batch trials, ensuring seamless transition to high-volume manufacturing.

Key performance metrics for our engineered PE foam bonding system are demonstrated below:

| Parameter | Industry Standard | Baoshida Engineered Solution |

|---|---|---|

| Surface Energy (dynes/cm) | 31–33 | 42–45 (via plasma + chemical treatment) |

| Adhesive Lap Shear Strength | 0.8–1.2 MPa | 2.5–3.0 MPa (modified epoxy) |

| Thermal Cycle Survival | ≤50 cycles (–40°C/85°C) | ≥200 cycles |

| Outgassing Defect Rate | 8–12% | ≤2% |

| Production Scalability | Batch-dependent | 500k+ units/month (automated lines) |

This data reflects validated results from Tier-1 automotive and medical device projects. Our engineers deploy real-time process monitoring (SPC-controlled) to maintain ±0.5°C thermal uniformity and adhesive viscosity consistency, critical for bonding low-density foams (15–150 kg/m³). Clients receive full technical documentation, including FMEA reports and DOE matrices, ensuring traceability and continuous improvement. By merging formula innovation with precision molding expertise, Suzhou Baoshida delivers bonded PE foam components that meet the highest industrial reliability standards while accelerating time-to-market for OEM partners.

Customization Process

Customization Process for Bonding Polyethylene Foam in Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered for precision, durability, and compatibility with complex manufacturing demands. When it comes to bonding polyethylene (PE) foam—a low-surface-energy material requiring specialized adhesion strategies—we follow a rigorous four-stage customization process: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures optimal performance, material compatibility, and seamless integration into client assembly lines.

The process begins with Drawing Analysis, where our engineering team evaluates technical schematics, dimensional tolerances, bonding surfaces, and end-use conditions. We assess factors such as compression set requirements, environmental exposure (UV, temperature, humidity), and mechanical stress. This phase is critical for identifying adhesion challenges inherent to PE foam, which exhibits non-polar surface characteristics that resist conventional bonding methods. Our engineers determine the ideal bonding area preparation, substrate compatibility, and whether surface treatment (e.g., corona or plasma) is required.

Next, we proceed to Formulation, where our rubber chemists develop a custom adhesive system tailored to the application. We prioritize high-tack, durable formulations such as modified acrylics, reactive urethanes, or pressure-sensitive rubber-based adhesives, depending on performance needs. The adhesive must balance initial tack, long-term adhesion strength, flexibility, and resistance to aging. All formulations are tested in-house for peel strength, shear resistance, and thermal stability before advancing.

Prototyping follows formulation, during which we produce small-batch bonded samples under simulated production conditions. These prototypes undergo rigorous testing, including peel tests (ASTM D3330), shear holding power (ASTM D3654), and environmental cycling. Clients receive detailed performance reports and physical samples for validation. Iterations are made as needed to refine bond durability or processing parameters.

Once approved, we transition to Mass Production, leveraging automated coating, laminating, and die-cutting lines to ensure consistency and scalability. Our ISO-certified facility supports roll-to-roll processing, precision slitting, and custom packaging to meet OEM line-feed requirements. Throughout production, statistical process control (SPC) and batch traceability ensure quality compliance.

The following table outlines key specifications achievable in bonded PE foam solutions:

| Property | Test Method | Typical Performance |

|---|---|---|

| Peel Adhesion (180°) | ASTM D3330 | 1.5–3.0 N/cm |

| Shear Holding Power | ASTM D3654 | >10,000 min @ 25°C |

| Operating Temperature Range | — | -40°C to +80°C |

| Elongation at Break | ASTM D412 | ≥200% |

| Surface Energy (PE Foam) | Dyne Test | 31–35 dynes/cm |

Our systematic approach ensures that every bonded PE foam component meets exact functional and production criteria, reinforcing Suzhou Baoshida’s role as a trusted partner in advanced industrial rubber solutions.

Contact Engineering Team

Technical Consultation for Polyethylene Foam Bonding Solutions

Achieving reliable adhesion with polyethylene (PE) foam presents significant challenges due to its non-polar surface chemistry and low surface energy. Standard adhesives frequently fail under thermal cycling, mechanical stress, or environmental exposure, leading to delamination and product failure in critical applications. Suzhou Baoshida Trading Co., Ltd. specializes in engineered rubber and adhesive systems designed explicitly for inert substrates like PE foam. Our formulations leverage advanced silane coupling agents and plasma-treated polymers to create covalent bonds at the substrate interface, ensuring durability in automotive gasketing, HVAC insulation, and protective packaging.

Our OEM-grade adhesive portfolio undergoes rigorous validation against industry-specific failure modes. The table below summarizes key performance metrics for our flagship PE foam bonding solutions:

| Adhesive Type | Bond Strength (psi) | Service Temperature Range (°C) | Open Time (min) | Substrate Compatibility |

|---|---|---|---|---|

| BD-PE450 (Solvent-Based) | 180–220 | -40 to +120 | 8–12 | Cross-linked PE, EVA, PVC |

| BD-PE700 (Water-Based) | 150–190 | -30 to +100 | 15–20 | Linear PE, TPE, Polypropylene |

| BD-PE900 (Reactive Hot Melt) | 200–240 | -50 to +130 | 3–5 | All PE variants, Metals, Composites |

These values reflect ASTM D3163 and ISO 4587 testing protocols under 50% RH and 23°C conditions. Formulation adjustments are available to meet exact OEM specifications, including flame retardancy (UL 94 HF-1), low-VOC compliance (≤50 g/L), and cryogenic resilience down to -70°C. Our in-house R&D facility in Suzhou conducts substrate interfacial chemistry analysis using XPS and AFM to optimize adhesion promoters for your specific PE foam density (25–200 kg/m³) and additive package.

Partnering with Suzhou Baoshida eliminates trial-and-error in PE foam bonding. Our engineering team provides full technical stewardship—from feasibility studies and DOE-driven formulation tuning to on-site process validation. We integrate seamlessly with your production workflow, offering custom dispensing systems, cure monitoring protocols, and batch traceability via blockchain-enabled QC logs. All solutions comply with REACH, RoHS, and FDA 21 CFR 177.2600 for food-contact applications.

Initiate a precision-engineered bonding solution by contacting Mr. Boyce, our dedicated OEM Account Manager. With 14 years of expertise in polyolefin adhesion science, Mr. Boyce will coordinate a technical consultation within 24 business hours to review your application requirements, environmental stressors, and throughput constraints. Provide your foam specifications, joint design schematics, and performance targets for a tailored adhesive recommendation.

Contact Mr. Boyce directly at [email protected] to schedule your technical consultation. Include your company name, target application, and required certification standards in the email subject line for expedited processing. Suzhou Baoshida guarantees actionable engineering feedback within 48 hours of receiving your project details.

Leverage our ISO 9001:2015-certified supply chain for consistent material delivery across 12 global logistics hubs. Reduce field failures and warranty claims through scientifically validated adhesion—engineered in Suzhou, trusted by Tier-1 manufacturers worldwide.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).