Technical Contents

Engineering Guide: Car Door Weatherstrip

Engineering Insight: Material Selection in Car Door Weatherstrip Design

The performance and longevity of a car door weatherstrip are fundamentally determined by material selection. While off-the-shelf rubber profiles may appear cost-effective, they frequently fail to meet the dynamic sealing requirements of modern automotive applications. This failure stems from an oversimplification of the operational environment, which includes exposure to extreme temperatures, UV radiation, ozone, mechanical compression, and chemical contaminants such as road salts and cleaning agents. A standardized rubber compound cannot simultaneously optimize all critical properties—compression set resistance, tensile strength, low-temperature flexibility, and weathering resistance—across diverse vehicle platforms and climatic zones.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered elastomer solutions tailored to specific OEM performance criteria. For instance, EPDM (ethylene propylene diene monomer) remains the dominant polymer for exterior weatherstrips due to its superior resistance to heat, UV, and ozone degradation. However, not all EPDM formulations are equivalent. The ratio of ethylene to propylene, the type and quantity of curing system (sulfur vs. peroxide), and the inclusion of specialty fillers and stabilizers directly influence the compound’s service life and sealing integrity. A poorly formulated EPDM may exhibit premature cracking at -30°C or excessive compression set after 5,000 door cycles, leading to water ingress and customer dissatisfaction.

Moreover, the integration of co-extruded materials—such as low-friction TPE (thermoplastic elastomer) skins over a rigid EPDM core—requires precise compatibility in rheology and adhesion characteristics. Off-the-shelf profiles often lack this co-extrusion engineering, resulting in delamination under thermal cycling. Additionally, paint code compatibility is critical; certain plasticizers in generic rubber can migrate and cause discoloration on painted door surfaces, a defect unacceptable in premium automotive segments.

Another overlooked factor is dynamic sealing performance. A static compression test does not replicate the real-world scenario where the weatherstrip undergoes repeated deformation during door closure, often at variable speeds and angles. Materials with high resilience and low compression set, such as peroxide-cured EPDM or specialty silicone blends, maintain sealing force over time, whereas conventional compounds may relax and create gaps.

Below is a comparative analysis of key elastomer properties relevant to car door weatherstrip applications.

| Material | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Compression Set (22h, 100°C) | Low-Temp Flexibility (°C) | Weather Resistance |

|---|---|---|---|---|---|---|

| Standard EPDM | 60–70 | 10–12 | 300–400 | 25–35% | -40 | Excellent |

| Premium Peroxide-Cured EPDM | 65–75 | 14–16 | 350–450 | 15–20% | -50 | Excellent |

| SBR (General Purpose) | 60–70 | 12–15 | 300–500 | 40–60% | -20 | Poor |

| Silicone | 50–80 | 6–9 | 200–400 | 10–20% | -60 | Good |

| TPE (Styrenic) | 70–90 | 8–12 | 200–300 | 30–50% | -30 | Moderate |

The data illustrates why generic materials fall short. While SBR offers high elongation, its poor compression set and weather resistance make it unsuitable for long-term exterior use. Silicone excels in temperature range but lacks the mechanical durability required for door sealing. Only a precisely engineered EPDM formulation meets the balanced demands of durability, sealing force, and environmental resistance.

In conclusion, successful weatherstrip performance is not achieved through commoditized rubber but through material science rigor. At Baoshida, we collaborate with OEMs to develop application-specific compounds that ensure reliability, customer satisfaction, and compliance with automotive longevity standards.

Material Specifications

Material Specifications for Automotive Door Weatherstrip Applications

Suzhou Baoshida Trading Co., Ltd. provides engineered rubber solutions meeting stringent automotive OEM requirements for door weatherstrip systems. Material selection directly impacts sealing integrity, durability, and lifecycle performance under dynamic environmental stressors. This section details critical specifications for Viton (FKM), Nitrile (NBR), and Silicone (VMQ) compounds, validated per ASTM D2000 and ISO 37 standards. Each material addresses distinct operational profiles, balancing chemical resistance, thermal stability, and mechanical resilience.

Viton fluorocarbon elastomers excel in high-temperature and aggressive chemical environments, withstanding continuous exposure to -20°C to +230°C. Its molecular structure provides exceptional resistance to automotive fluids including gasoline, diesel, and transmission oils, with volume swell typically below 15% after 70 hours immersion per ASTM D471. Compression set remains below 25% at 200°C (70 hrs), ensuring long-term seal force retention. Viton is optimal for premium or performance vehicles where under-hood proximity or extreme climate operation necessitates superior fluid compatibility.

Nitrile rubber remains the industry standard for mainstream door weatherstripping due to its cost efficiency and balanced properties. Standard high-acrylonitrile (ACN) grades operate effectively from -30°C to +120°C, with specialized low-temperature formulations extending functionality to -50°C. NBR demonstrates robust resistance to water, alcohols, and non-polar solvents but exhibits moderate swelling (30–40%) in hydrocarbon fuels. Hardness ranges from 55 to 85 Shore A, allowing precise tuning for door closure force and acoustic sealing. Its compression set at 100°C (70 hrs) is typically 20–35%, making it ideal for mass-production applications where thermal exposure remains moderate.

Silicone elastomers deliver unmatched flexibility across extreme temperatures (-60°C to +200°C), with minimal compression set (<20% at 150°C/70 hrs). While inherently resistant to ozone and UV degradation, standard VMQ shows poor hydrocarbon resistance (swell >100% in fuels). Modified phenyl-silicone variants improve fuel tolerance but increase cost. Silicone’s consistent modulus across temperature ranges ensures reliable sealing in arctic or desert climates, though tensile strength (4–8 MPa) is lower than NBR or Viton. Its primary automotive use cases include EV battery compartment seals or regions requiring extreme cold flexibility.

Material selection must align with vehicle architecture, regional climate demands, and fluid exposure risks. Suzhou Baoshida validates all compounds through OEM-specific dynamic compression testing (SAE J1488) and 5,000-cycle door slam validation. The following comparative table summarizes key technical parameters for engineering evaluation.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to +230°C | -50°C to +120°C | -60°C to +200°C |

| Hardness Range (Shore A) | 60–90 | 55–85 | 40–70 |

| Tensile Strength (MPa) | 10–18 | 15–25 | 4–8 |

| Compression Set (ASTM D395B) | <25% @ 200°C/70h | 20–35% @ 100°C/70h | <20% @ 150°C/70h |

| Volume Swell in ASTM No. 3 Oil (70h) | <15% | 30–40% | >100% |

| Fluid Resistance | Excellent (fuels, oils) | Good (water, alcohols); Moderate (fuels) | Poor (hydrocarbons); Excellent (water, steam) |

| OEM Validation Focus | High-temp fuel exposure | Cost-driven mass production | Extreme cold/hot climates |

Suzhou Baoshida collaborates with global OEMs to customize formulations within these material families, ensuring compliance with GMW, Ford, and VW material standards. Final selection requires prototyping under actual door assembly tolerances and climatic chamber validation.

Manufacturing Capabilities

Engineering Excellence in Rubber Formulation and Mold Design for Automotive Weatherstrips

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the precision manufacturing of car door weatherstrips. Our dedicated team comprises five experienced mold engineers and two specialized rubber formula engineers, enabling us to deliver OEM-grade performance with consistent material integrity and dimensional accuracy. This integrated technical team ensures that every weatherstrip is engineered to meet the exact sealing, durability, and environmental resistance demands of modern automotive applications.

Our mold engineers bring over 60 combined years of experience in designing and optimizing rubber compression and transfer molds. They utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to develop high-tolerance tooling that ensures repeatable part geometry and minimal flash. Each mold is subjected to thermal and stress simulation to predict deformation under curing conditions, significantly reducing trial iterations and accelerating time-to-market. This rigorous design approach supports complex profiles required for multi-channel sealing, acoustic insulation, and water intrusion prevention in car door systems.

Complementing our mold expertise, our two in-house rubber formula engineers specialize in elastomer chemistry tailored to automotive sealing requirements. They formulate custom EPDM, silicone, and thermoplastic vulcanizate (TPV) compounds that balance compression set resistance, UV stability, low-temperature flexibility, and surface finish. All formulations are developed in alignment with OEM specifications such as GMW, Ford WSS, and VW TL standards. Our lab conducts accelerated aging, ozone resistance, and tensile testing to validate performance under real-world conditions, ensuring long-term sealing integrity across diverse climates.

We operate as a full-service OEM partner, capable of managing projects from initial concept to mass production. Our engineering team collaborates directly with automotive Tier 1 suppliers and OEMs to interpret 3D CAD data, conduct Design for Manufacturing (DFM) reviews, and deliver prototype samples within 15–20 days. With in-house mixing, molding, and testing facilities, we maintain full control over quality and traceability, supporting IATF 16949-compliant production runs.

The synergy between our mold design and rubber formulation capabilities allows us to solve complex sealing challenges, such as minimizing insertion force while maximizing air and water tightness. This technical integration is critical in meeting the evolving demands of electric vehicles, where noise reduction and environmental sealing are paramount.

Below is a summary of our core technical specifications and capabilities:

| Parameter | Specification |

|---|---|

| Material Types | EPDM, Silicone, TPV, NBR |

| Hardness Range (Shore A) | 40–90 |

| Temperature Resistance | -50°C to +150°C (depending on compound) |

| Tensile Strength | Up to 18 MPa (EPDM) |

| Elongation at Break | Up to 500% |

| Compression Set (22 hrs, 70°C) | ≤25% |

| Mold Accuracy Tolerance | ±0.1 mm |

| Lead Time (Prototype) | 15–20 days |

| OEM Standards Supported | GMW14125, WSS-M2G238, VW TL52415, JIS D4311 |

Our engineering framework ensures that every car door weatherstrip we produce meets the highest benchmarks in performance, reliability, and manufacturability.

Customization Process

Car Door Weatherstrip Customization Process

At Suzhou Baoshida Trading Co., Ltd., our customization process for automotive door weatherstrips integrates material science with precision manufacturing to meet stringent OEM performance and durability requirements. This four-stage workflow ensures seamless transition from design intent to high-volume production while mitigating engineering risks.

Drawing Analysis

We initiate with rigorous dimensional and functional validation of customer CAD drawings against ISO 1101 geometric tolerancing standards. Critical parameters include sealing surface curvature, compression zone geometry, and mounting clip interfaces. Our engineers identify potential stress concentrations, material flow constraints during extrusion, and compatibility with adjacent components like glass run channels. This phase confirms feasibility while flagging design modifications to prevent assembly interference or premature wear under dynamic door cycling.

Formulation Development

Based on thermal, chemical, and mechanical demands, our rubber chemists formulate proprietary EPDM compounds. Key considerations include operating temperature range (-40°C to +120°C), resistance to ozone/UV degradation, and adhesion to co-extruded TPE elements. We optimize filler ratios (e.g., silica vs. carbon black) to balance hardness, elongation, and compression set. All formulations undergo accelerated aging per ASTM D2240 and ASTM D395 to validate 10-year service life under automotive environmental exposure.

Prototyping & Validation

Precision aluminum tooling produces functional prototypes for dimensional verification and system-level testing. Samples undergo SAE J1887 cyclic durability trials (10,000+ door closures), water ingress testing at 150mm H₂O pressure, and wind noise validation in anechoic chambers. Critical performance metrics are cross-referenced against OEM specifications in the table below before tooling sign-off.

| Parameter | Target Value | Test Standard |

|---|---|---|

| Hardness (Shore A) | 65 ± 5 | ASTM D2240 |

| Compression Set | ≤ 25% (70°C/24h) | ASTM D395 Method B |

| Tensile Strength | ≥ 10 MPa | ASTM D412 |

| Elongation at Break | ≥ 300% | ASTM D412 |

| Tear Resistance | ≥ 25 kN/m | ISO 34-1 |

Mass Production Implementation

Approved prototypes transition to automated production lines featuring in-line laser micrometry for real-time dimensional control and 100% visual inspection via AI-powered cameras. We implement SPC monitoring of critical-to-quality characteristics (e.g., durometer consistency ±3 Shore A) with traceability to batch-level material certificates. Production lots undergo first-article inspection per PPAP Level 3 requirements, with ongoing reliability testing including thermal cycling (-40°C ↔ +85°C) and chemical resistance validation against common automotive fluids.

This structured methodology ensures weatherstrips achieve optimal sealing performance, noise/vibration/harshness (NVH) reduction, and longevity while adhering to automotive industry cost and timeline constraints. Suzhou Baoshida maintains IATF 16949-certified processes to guarantee repeatability across global supply chains.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Car Door Weatherstrip Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance industrial rubber solutions tailored to the rigorous demands of automotive manufacturing. As a trusted partner in the supply of precision-engineered car door weatherstrips, our expertise spans material formulation, extrusion technology, and OEM customization. Our products are designed to deliver superior sealing performance, durability, and noise reduction across a wide range of vehicle platforms and environmental conditions.

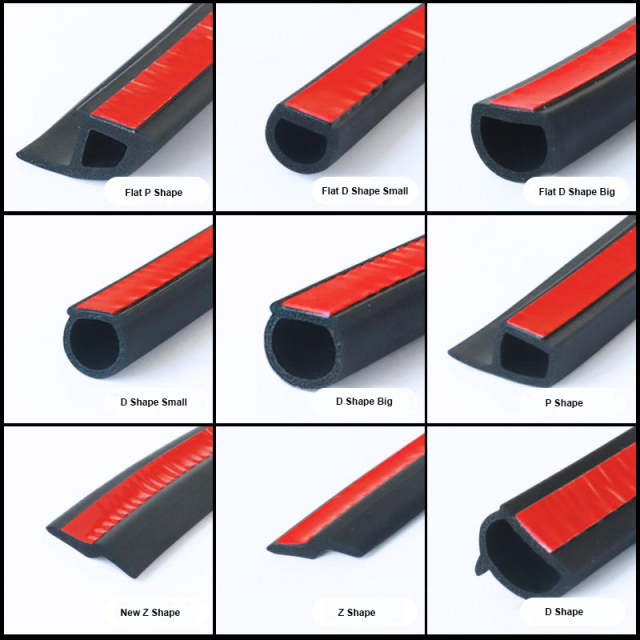

Our car door weatherstrips are manufactured using advanced EPDM and TPE compounds, ensuring resistance to UV radiation, ozone, extreme temperatures (-40°C to +150°C), and long-term compression set. Each profile is engineered to meet exact dimensional tolerances and surface finish requirements, supporting seamless integration into automated assembly lines. Whether you require sponge rubber seals for soft compression, dense rubber for structural support, or co-extruded multi-material profiles, Suzhou Baoshida delivers consistent quality under IATF 16949-certified processes.

We understand that performance specifications are critical in automotive sealing applications. Below is a representative technical specification table for our standard car door weatherstrip profiles:

| Property | Test Method | Value |

|---|---|---|

| Material Type | ASTM D1418 | EPDM / TPE |

| Hardness (Shore A) | ASTM D2240 | 55 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 8.0 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22h, 100°C) | ASTM D395 | ≤ 25% |

| Temperature Range | Internal | -40°C to +150°C |

| Density | ASTM D297 | 1.25 ± 0.05 g/cm³ |

| Color Options | Custom | Black, Grey, Beige, OEM Match |

| Flame Resistance | FMVSS 302 | Meets Standard |

All profiles can be customized in cross-section, length, and splicing method, with options for adhesive backing, 3D shaping, and automated packaging for JIT delivery. Our R&D team collaborates directly with OEMs to validate sealing force, insertion force, and durability through dynamic door cycle testing and environmental aging.

For technical consultation, sample requests, or to discuss volume production partnerships, contact Mr. Boyce, our dedicated OEM Manager. With over 15 years of experience in automotive rubber systems, Mr. Boyce leads client engagement with a focus on engineering alignment, cost optimization, and on-time delivery.

To initiate a project or request a detailed quotation, please reach out directly via email at [email protected]. We respond to all inquiries within 12 business hours and offer virtual technical meetings for global clients. Suzhou Baoshida is committed to being an extension of your engineering team—delivering precision rubber solutions that meet the evolving standards of modern vehicle design.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).