Technical Contents

Engineering Guide: Metal Edges

Engineering Insight: The Critical Role of Material Selection in Metal Edge Applications

In industrial rubber solutions, the integration of metal edges into composite components is a common requirement, particularly in sealing, impact resistance, and structural reinforcement applications. However, the performance and longevity of these components are heavily dependent on precise material selection—a factor often overlooked when relying on off-the-shelf solutions. Standardized products typically assume uniform operating conditions, but real-world environments involve dynamic variables such as temperature fluctuation, chemical exposure, mechanical stress, and fatigue cycles. Without tailored material engineering, premature failure is not only likely but inevitable.

Metal edges, typically made from steel, aluminum, or stainless alloys, interface directly with elastomeric compounds. The bond strength between the metal and rubber is governed by surface preparation, adhesive systems, and the compatibility of thermal expansion coefficients. When mismatched materials are used, interfacial stress develops during thermal cycling, leading to delamination or edge roll—common failure modes in conveyor scrapers, hydraulic seals, and protective linings. Off-the-shelf components often utilize generic rubber formulations such as natural rubber (NR) or standard nitrile (NBR), which may not withstand aggressive industrial environments involving ozone, oil, or extreme temperatures.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material pairing based on application-specific demands. For instance, in high-temperature environments exceeding 120°C, hydrogenated nitrile (HNBR) or fluorocarbon (FKM) elastomers are preferred due to their thermal stability and resistance to compression set. Similarly, for applications involving dynamic flexing, such as in mining or automotive suspension components, ethylene propylene diene monomer (EPDM) or polyurethane (PU) offer superior fatigue resistance and tear strength.

The geometric design of the metal edge also influences material behavior. Sharp edges concentrate stress, accelerating crack propagation in the rubber matrix. Radiused or chamfered metal profiles, combined with high-adhesion primers and functionally graded rubber zones, significantly improve service life. Our in-house testing validates these configurations under simulated operational loads, ensuring reliability before deployment.

Below is a comparative overview of common elastomer-metal pairings and their performance characteristics:

| Elastomer | Metal Substrate | Max Continuous Temp (°C) | Key Resistance Properties | Typical Failure Mode if Mismatched |

|---|---|---|---|---|

| NBR | Mild Steel | 100 | Oil, abrasion | Swelling, adhesion loss |

| HNBR | Stainless Steel | 150 | Heat, oil, ozone | Edge cracking under thermal cycling |

| FKM | Stainless Steel | 200 | Chemicals, high heat | Brittleness at low temperatures |

| EPDM | Aluminum | 135 | Weather, steam, UV | Compression set in dynamic seals |

| PU | Steel | 90 | Abrasion, tensile strength | Hydrolysis in humid environments |

Material selection is not a secondary consideration—it is foundational to the integrity of metal-edged rubber components. Relying on generic solutions risks unplanned downtime, safety hazards, and increased lifecycle costs. At Baoshida, we apply precision engineering to match elastomer chemistry, metal substrate, and interface design to the operational envelope, ensuring durability and performance under real industrial conditions.

Material Specifications

Material Specifications for Metal Edge Sealing Applications

Selecting appropriate elastomers for metal edge interfaces demands rigorous evaluation of operational parameters. In dynamic sealing scenarios involving metal edges—such as flange joints, hydraulic cylinders, or automotive housings—material performance directly impacts leak prevention, longevity, and system reliability. Environmental exposure to fluids, temperature extremes, and mechanical stress necessitates precise compound selection. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent industry-preferred solutions, each exhibiting distinct property profiles critical for metal edge integrity. Key considerations include resistance to compression set, fluid compatibility, thermal stability, and tensile strength. Suboptimal material choice risks extrusion, hardening, or chemical degradation at the metal-rubber interface, leading to premature failure. Below is a comparative analysis of core specifications aligned with ASTM D2000 and ISO 3601 standards for industrial sealing applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -40 to +120 | -60 to +200 |

| Fluid Resistance | Excellent (acids, fuels, oils) | Good (oils, hydraulic fluids) | Poor (fuels, oils); Excellent (water, steam) |

| Compression Set (% @ 70h/150°C) | ≤ 25 | ≤ 30 | ≤ 20 |

| Tensile Strength (MPa) | 12–18 | 15–25 | 5–10 |

| Hardness Range (Shore A) | 60–90 | 50–90 | 30–80 |

| Key Limitations | Poor low-temp flexibility; High cost | Swells in polar solvents; Limited high-temp stability | Low tear strength; Poor abrasion resistance |

Viton excels in high-temperature, chemically aggressive environments common in aerospace and chemical processing metal edge seals. Its molecular structure provides exceptional resistance to aromatic hydrocarbons and synthetic lubricants, maintaining seal integrity where NBR would rapidly degrade. However, Viton’s stiffness below -10°C necessitates careful assessment for cold-start applications. Nitrile remains the cost-effective standard for hydraulic and automotive metal edge gaskets exposed to mineral oils and greases. Its balanced mechanical properties support high-pressure sealing but suffer in ozone-rich or phosphate-ester fluid environments. Silicone offers unmatched flexibility across extreme low-temperature cycles and biocompatibility for medical or food-grade metal housings. Yet, its inferior mechanical strength requires design compensation—such as tighter tolerances or backup rings—to prevent extrusion under pressure.

Material selection must align with fluid media, temperature cycling frequency, and pressure dynamics specific to the metal edge geometry. Suzhou Baoshida Trading Co., Ltd. validates all formulations through SAE J2236 compression stress relaxation testing and custom compound adjustments per OEM fluid exposure requirements. For critical applications, accelerated aging per ASTM D573 and fluid immersion testing per ISO 1817 are mandatory prior to deployment. Consult our engineering team for application-specific durometer optimization and filler-modified variants to address edge-specific wear mechanisms.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability in industrial rubber solutions is anchored in deep technical expertise and precision-driven development. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we deliver tailored, high-performance rubber components designed to meet exact OEM specifications. Our integrated approach ensures seamless coordination between material science and precision tooling, enabling us to solve complex sealing, damping, and wear-resistance challenges across demanding industrial applications.

Our mould engineers bring over 15 collective years of experience in precision rubber mould design and manufacturing. Utilizing advanced CAD/CAM software, including SolidWorks and UG NX, they develop robust, high-tolerance moulds optimized for extended service life, consistent part quality, and efficient production cycles. Each mould design undergoes rigorous simulation and validation to ensure optimal flow, minimal flash, and dimensional accuracy. This precision engineering reduces time-to-market and enhances repeatability for high-volume OEM contracts.

Complementing our tooling expertise, our two in-house rubber formula engineers specialize in custom elastomer development. They formulate rubber compounds based on application-specific requirements such as temperature resistance, chemical exposure, compression set, and mechanical strength. Our formulation capabilities span multiple elastomer families, including NBR, EPDM, Silicone, FKM, and Neoprene, allowing us to engineer materials that perform reliably under extreme conditions. Every compound is tested in-house using standardized ASTM and ISO methods to verify physical and chemical properties before production release.

Our OEM capabilities are built on a foundation of co-engineering collaboration. We work closely with clients from concept through to mass production, offering full technical support in design optimization, material selection, prototyping, and process validation. This collaborative model ensures that final components not only meet but exceed performance expectations in real-world operating environments.

To support quality assurance and process control, we maintain a fully equipped laboratory for material testing, dimensional inspection, and performance validation. Our production lines are ISO 9001-certified, and we adhere to strict APQP and PPAP protocols for all OEM projects.

The following table outlines key technical capabilities and specifications:

| Parameter | Specification |

|---|---|

| Mould Design Software | SolidWorks, UG NX, AutoCAD |

| Mould Tolerance | ±0.05 mm |

| Standard Elastomers | NBR, EPDM, Silicone, FKM, Neoprene, CR, IIR |

| Hardness Range (Shore A) | 30–90 |

| Operating Temperature Range | -60°C to +300°C (depending on compound) |

| Compression Set Testing | ASTM D395, Method B |

| Tensile & Elongation | ASTM D412 |

| Volume Resistivity | Up to 1×10¹⁵ Ω·cm (for insulating compounds) |

| OEM Project Lead Time (Prototype) | 15–25 days |

| Production Capacity | 500,000 pcs/month (average) |

Suzhou Baoshida Trading Co., Ltd. combines advanced material science with precision engineering to deliver reliable, high-performance rubber solutions for global OEMs. Our technical team ensures every product is engineered for durability, consistency, and seamless integration into your manufacturing ecosystem.

Customization Process

Customization Process for Metal Edge Rubber Components

At Suzhou Baoshida Trading Co., Ltd., our metal edge rubber component customization follows a rigorously defined engineering workflow to ensure dimensional accuracy, material performance, and production scalability. This process eliminates guesswork and aligns client specifications with industrial manufacturing realities.

Drawing Analysis

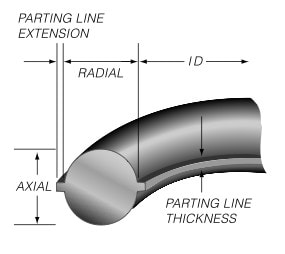

The foundation begins with comprehensive technical drawing review. Our engineering team scrutinizes CAD files or sketches for critical dimensions, geometric tolerances per ISO 2768-mK, and interface requirements with mating metal surfaces. We identify potential stress concentration zones, draft angles for demolding, and flash tolerance limits. Concurrently, we assess environmental exposure factors—temperature range, fluid contact, and dynamic load cycles—to inform material selection. Any ambiguities in sealing interfaces or critical radii are resolved through direct client consultation, ensuring zero misinterpretation before formulation begins.

Formulation Development

Based on the drawing analysis, our rubber chemists design a proprietary compound targeting the precise balance of hardness, resilience, and chemical resistance. For metal edge applications requiring oil resistance and moderate heat stability, nitrile rubber (NBR) formulations are optimized with controlled acrylonitrile content. Where ozone or extreme temperatures dominate, EPDM or FKM systems are engineered with specific peroxide curing systems to minimize compression set. Each formulation undergoes computational modeling to predict polymer chain mobility under operational stress, ensuring the compound maintains edge integrity during repeated flexing against metal substrates. Hardness is calibrated between 50–90 Shore A, with tensile strength ≥12 MPa as baseline requirements.

Prototyping and Validation

Precision prototypes are manufactured using client-approved tooling inserts under controlled vulcanization conditions. Every prototype undergoes metrological verification via CMM to confirm edge radius conformity within ±0.05 mm and dimensional stability. Physical testing includes:

Compression set per ASTM D395 (Method B, 70°C × 22h)

Fluid resistance immersion per ISO 1817

Dynamic fatigue testing at 5 Hz for 100,000 cycles

Data is compiled into a validation report comparing actual performance against the initial specification matrix. Client feedback on prototype fitment and function triggers iterative refinements until all KPIs are met.

Mass Production

Upon prototype sign-off, production transitions to our ISO 9001-certified facility. Statistical process control monitors key parameters: cure time (±5 seconds), mold temperature (±2°C), and durometer consistency (±3 Shore A units). Each batch undergoes 100% visual inspection for edge defects and抽样 testing for critical mechanical properties. We maintain traceability via lot coding and provide full material test reports with shipment. Typical production yields exceed 98.5%, with lead times optimized through our just-in-time inventory system for OEM partners.

Key Material Specifications for Metal Edge Applications

| Property | NBR Compound | EPDM Compound | FKM Compound |

|---|---|---|---|

| Hardness Range (Shore A) | 60–80 | 55–75 | 70–90 |

| Tensile Strength (MPa) | ≥15 | ≥12 | ≥10 |

| Elongation at Break (%) | ≥250 | ≥200 | ≥150 |

| Compression Set (%) | ≤25 | ≤20 | ≤15 |

| Temp Range (°C) | -30 to +120 | -50 to +150 | -20 to +230 |

| Fluid Resistance | Oil/Fuel | Water/Glycol | Aggressive Chemicals |

This structured approach ensures Suzhou Baoshida delivers metal edge rubber components that achieve seamless integration, longevity, and performance consistency in demanding industrial environments.

Contact Engineering Team

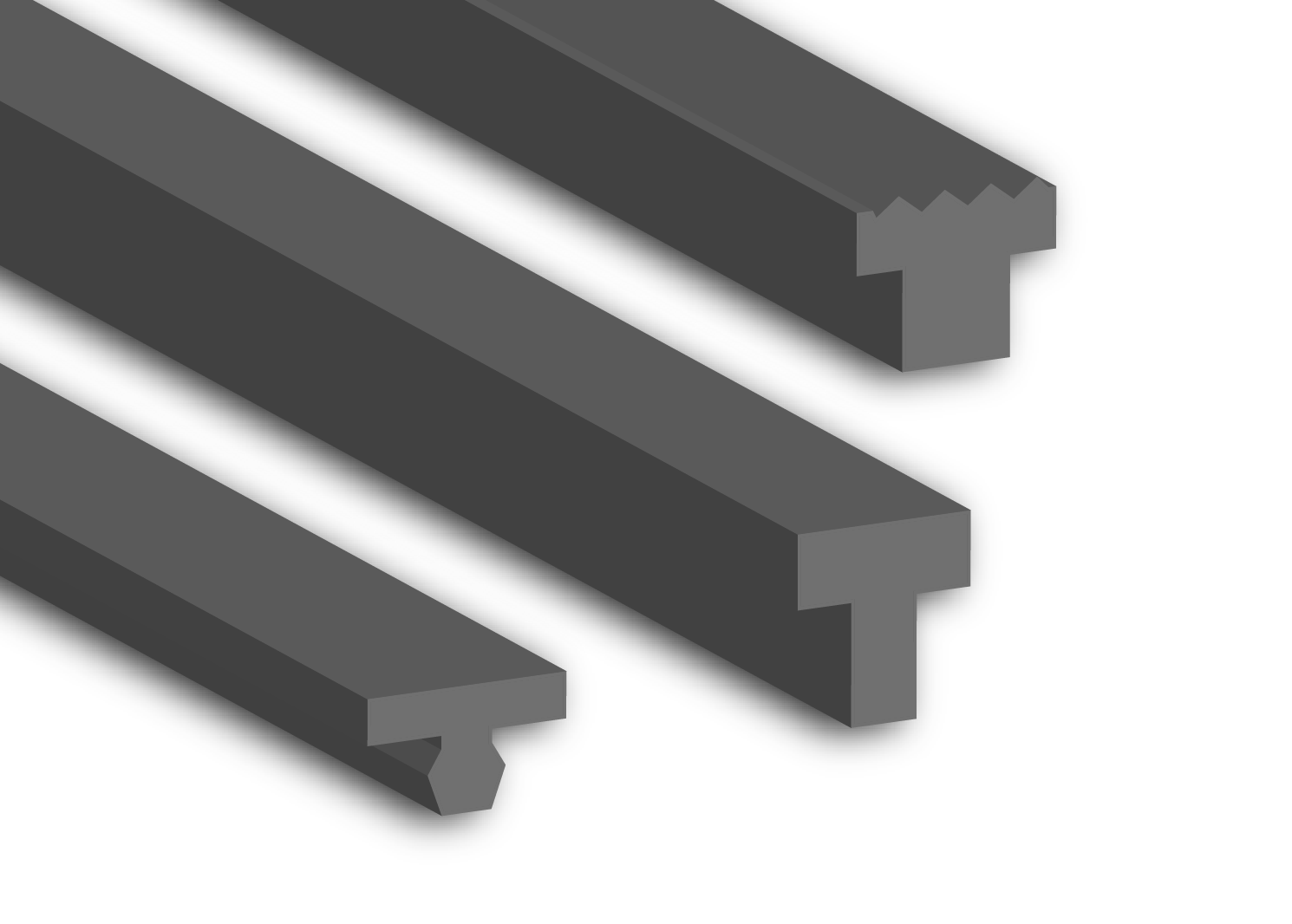

For precision-engineered industrial rubber solutions featuring reinforced metal edges, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in advanced material integration. Our expertise lies in the development and supply of hybrid rubber-metal components designed for high-stress, high-durability applications across automotive, construction, rail transit, and heavy machinery sectors. When performance, sealing integrity, and mechanical resilience are non-negotiable, our engineered rubber profiles with integrated metal edges deliver consistent, long-term reliability under extreme thermal, vibrational, and compressive conditions.

Our manufacturing process combines vulcanized rubber compounds—selected from nitrile (NBR), ethylene propylene diene monomer (EPDM), silicone (VMQ), or fluorocarbon (FKM)—with precisely formed steel, aluminum, or stainless steel inserts. These metal-reinforced edges provide structural stability, facilitate secure mounting, and enhance resistance to edge tearing, creep, and fatigue. Every component is engineered to meet stringent OEM specifications, with tight tolerances maintained through CNC stamping, multi-stage molding, and post-cure inspection protocols. Whether you require custom gaskets, sealing strips, vibration isolators, or impact-absorbing bumpers, our team ensures dimensional accuracy, adhesion integrity, and environmental resistance tailored to your operational demands.

We support low-volume prototyping through high-volume production runs, with material traceability, batch testing, and compliance documentation available per ISO 9001 standards. Our technical team collaborates directly with design and procurement engineers to optimize part geometry, compound selection, and metal substrate thickness for performance and cost-efficiency.

Below is a representative specification profile for a typical metal-edged rubber component manufactured at our facility:

| Parameter | Specification |

|---|---|

| Rubber Material Options | NBR, EPDM, FKM, VMQ, Neoprene |

| Hardness Range (Shore A) | 40–90 ±5 |

| Metal Insert Types | Cold-rolled steel, aluminum 6061, stainless 304/316 |

| Insert Thickness | 0.5 mm – 3.0 mm |

| Adhesion Strength | ≥8 kN/m (peel resistance, 90° test) |

| Temperature Resistance | -40°C to +200°C (FKM), -50°C to +150°C (EPDM) |

| Tolerance (Dimensional) | ±0.2 mm (critical zones), ±0.5 mm (general) |

| Production Lead Time | 15–25 days (after drawing approval) |

| Certifications | ISO 9001:2015, RoHS, REACH compliant |

To initiate a technical consultation or request a custom quote, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce specializes in translating engineering requirements into manufacturable rubber-metal solutions, with over 12 years of experience supporting global supply chains. He will coordinate material sampling, CAD review, and DFM feedback to ensure seamless integration into your assembly process.

Reach Mr. Boyce directly via email at [email protected]. Include detailed specifications, application context, and preferred materials for expedited response. For urgent inquiries, indicate “Priority – Metal Edge Project” in the subject line to ensure immediate technical review. We respond to all qualified technical submissions within 8 business hours. Partner with Suzhou Baoshida for engineered resilience—where rubber meets metal, precision meets performance.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).