Technical Contents

Engineering Guide: Global O Ring Houston

Engineering Insight: Global O Ring Houston Applications

Generic O-rings represent a critical vulnerability in demanding industrial environments like Houston’s oil and gas infrastructure. Standard off-the-shelf solutions frequently fail due to insufficient material-property alignment with operational extremes. These failures manifest as extrusion under high pressure, chemical degradation from sour gas exposure, or thermal hardening in downhole conditions, leading to catastrophic seal breaches, unplanned downtime, and safety hazards. Material selection is not a commodity decision; it is a precision engineering requirement dictated by fluid compatibility, temperature cycling, pressure dynamics, and regulatory standards specific to Gulf Coast sour gas environments.

The core issue lies in the oversimplification of elastomer capabilities. Many suppliers offer generic NBR or FKM compounds marketed as “universal,” ignoring nuanced formulation differences. For instance, standard NBR degrades rapidly in H₂S-rich environments common in Houston reservoirs, while basic FKM may lack low-temperature flexibility for offshore platform startups. True performance requires engineered compounds with tailored polymer backbones, filler systems, and cure chemistries. A 70-durometer NBR suitable for hydraulic fluid fails catastrophically when exposed to amine-based corrosion inhibitors at 150°C. Material science dictates that seal longevity depends on matching the elastomer’s glass transition temperature (Tg), compression set resistance, and permeation rates to the exact service profile—not nominal industry categories.

Suzhou Baoshida Trading Co., Ltd. addresses this through OEM-driven material qualification. We do not sell catalog parts; we co-engineer solutions using accelerated aging protocols per ASTM D2000 and ISO 2230. Below is a comparative analysis of critical elastomer properties for Houston-relevant applications:

| Elastomer Type | Continuous Temp Range (°C) | Key Chemical Resistance | Critical Limitation in Houston Context |

|---|---|---|---|

| Standard NBR | -30 to +100 | Mineral oils, water | Rapid H₂S degradation; poor heat aging above 100°C |

| Specialty HNBR | -40 to +150 | Sour gas, amines, steam | Limited aromatic hydrocarbon resistance |

| FKM (Standard) | -20 to +200 | Crude oil, acids | Poor low-temp flexibility; swells in ketones |

| Perfluoroelastomer (FFKM) | -15 to +325 | All hydrocarbons, H₂S | Extreme cost; over-engineered for non-critical zones |

| Aflas (TFE/P) | -15 to +200 | H₂S, amines, steam | Poor fuel resistance; requires specialized tooling |

OEM partnership is non-negotiable for mission-critical seals. At Suzhou Baoshida, we mandate fluid immersion testing at actual wellhead pressures and temperatures, not just standard bench tests. Our engineers collaborate with Houston-based clients to analyze failure modes from field returns, then reformulate compounds—adjusting fluorine content in FKMs or incorporating specialty co-agents in HNBR—to eliminate specific degradation pathways. This precision approach reduces seal replacement frequency by 60–80% compared to off-the-shelf alternatives, directly enhancing operational safety and reducing total cost of ownership in high-stakes energy applications. Material selection is the foundation of reliability; generic solutions compromise it at your peril.

Material Specifications

Precision rubber seals are critical components in industrial sealing applications, where performance under extreme conditions determines system reliability and safety. At Suzhou Baoshida Trading Co., Ltd., we specialize in manufacturing high-integrity O-rings using advanced elastomeric compounds tailored to meet the demanding requirements of global industries, including oil and gas, chemical processing, automotive, and aerospace. Our core materials—Viton, Nitrile (NBR), and Silicone—are selected for their distinct chemical resistance, thermal stability, and mechanical properties, ensuring optimal performance across diverse operating environments.

Viton, a fluorocarbon-based rubber (FKM), is engineered for high-performance applications involving aggressive chemicals and elevated temperatures. It exhibits exceptional resistance to oils, fuels, acids, and many halogenated solvents, making it ideal for use in downhole drilling equipment, refinery systems, and aerospace hydraulics. Viton O-rings maintain functional integrity from -20°C to +200°C, with short-term exposure tolerance up to 250°C. Its low gas permeability and excellent aging characteristics further enhance long-term sealing reliability in critical systems.

Nitrile rubber, or Buna-N, is one of the most widely used elastomers in industrial sealing due to its excellent resistance to petroleum-based oils and fuels. It offers good abrasion resistance and mechanical strength, making it suitable for hydraulic systems, fuel delivery components, and general-purpose pneumatic applications. Nitrile O-rings perform reliably within a temperature range of -30°C to +100°C, with some formulations extending to +125°C. While less resistant to ozone and UV exposure than other materials, Nitrile remains a cost-effective solution for dynamic and static seals in non-extreme environments.

Silicone rubber (VMQ) excels in applications requiring extreme temperature resilience and biocompatibility. It operates effectively from -60°C to +200°C, offering unmatched low-temperature flexibility and thermal stability. Silicone demonstrates good resistance to ozone, UV radiation, and water, making it suitable for outdoor, medical, and food-grade applications. However, it has lower tensile strength and abrasion resistance compared to Viton and Nitrile, and is not recommended for dynamic seals under high mechanical stress. Its inert nature and compliance with FDA and USP Class VI standards make it ideal for pharmaceutical and semiconductor processing equipment.

The selection of the appropriate elastomer depends on a comprehensive evaluation of temperature, chemical exposure, mechanical load, and regulatory requirements. Below is a comparative summary of key material properties to guide engineering decisions.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +200 | -30 to +100 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 10–20 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–400 | 400–600 |

| Hardness (Shore A) | 70–90 | 60–90 | 40–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Chemical Resistance | Excellent | Good | Fair |

| Compression Set Resistance | Excellent | Good | Good |

| FDA Compliance | Limited grades | No | Yes (specific grades) |

Understanding these material characteristics enables precise matching of O-ring composition to application demands, ensuring longevity, safety, and regulatory compliance in global industrial systems.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Seal Development at Suzhou Baoshida

Suzhou Baoshida Trading Co., Ltd. delivers advanced engineering solutions for critical sealing applications through a dedicated team of specialized professionals. Our core strength in precision rubber seal manufacturing is anchored by a robust engineering department comprising five certified Mould Engineers and two expert Rubber Formula Engineers. This integrated team operates under stringent ISO 9001 protocols, ensuring every seal design and compound formulation meets exacting global performance standards for the most demanding industrial environments, including those specified by global o ring houston requirements.

Our Rubber Formula Engineers possess deep expertise in polymer science and material compounding. They systematically develop and optimize custom elastomer formulations to address specific challenges such as extreme temperature exposure, aggressive chemical resistance, low compression set, or stringent biocompatibility needs. Utilizing advanced laboratory testing including rheometry, DSC, TGA, and accelerated aging protocols per ASTM D2000 standards, they precisely tailor compounds for longevity and reliability. This scientific approach ensures material properties align perfectly with the operational lifecycle demands of aerospace, oil & gas, semiconductor, and pharmaceutical applications, directly mitigating field failure risks associated with suboptimal material selection.

Complementing this material science capability, our five Mould Engineers focus on precision tooling design and manufacturing process optimization. They employ advanced CAD/CAM software (SolidWorks, AutoCAD Moldflow) to engineer complex multi-cavity molds with micron-level tolerances, critical for consistent part geometry and sealing performance. Their expertise spans intricate geometries, tight tolerance control (±0.05mm achievable), and efficient production methodologies. This team rigorously analyzes flow dynamics, cooling systems, and ejection mechanisms to eliminate defects like flash, knit lines, or incomplete cures, guaranteeing dimensional stability and functional integrity batch after batch.

Our OEM capabilities are engineered for seamless integration with client workflows. We manage the entire process from initial RFQ review and technical feasibility assessment through prototype development, rigorous validation testing, and full-scale production. Clients benefit from direct engineering collaboration, strict IP confidentiality agreements, and adherence to customer-specific PPAP documentation requirements. This turnkey approach, backed by our in-house engineering depth, significantly reduces time-to-market while ensuring absolute compliance with global o ring houston specifications and end-use performance criteria.

Material performance is foundational. The table below summarizes key properties of standard and advanced compounds we routinely formulate and manufacture:

| Material Type | Key Properties | Typical Applications |

|---|---|---|

| NBR (Nitrile) | -40°C to +125°C; Excellent oil/fuel resistance; Good abrasion resistance | Hydraulic systems, fuel handling, general industrial |

| FKM (Viton®) | -20°C to +230°C; Exceptional chemical/heat resistance; Low gas permeability | Aerospace fuel systems, chemical processing, semiconductor |

| EPDM | -50°C to +150°C; Outstanding ozone/weather resistance; Steam resistant | Automotive cooling, HVAC, potable water systems |

| VMQ (Silicone) | -60°C to +200°C; High biocompatibility; Excellent electrical insulation | Medical devices, food processing, high-temp electrical |

| FFKM (Perfluoroelastomer) | -15°C to +327°C; Ultimate chemical resistance; Ultra-low outgassing | Semiconductor plasma etching, critical chemical seals |

This engineering synergy between material science and precision tooling design positions Suzhou Baoshida as a strategic partner for solving complex sealing challenges, ensuring operational safety and efficiency for global industrial clients.

Customization Process

Customization Process for Precision Rubber Seals at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance, custom-engineered rubber seals tailored to the rigorous demands of industrial applications, particularly within the energy, petrochemical, and oil & gas sectors served by global o ring houston markets. Our systematic customization process ensures dimensional accuracy, material compatibility, and long-term sealing reliability under extreme operational conditions.

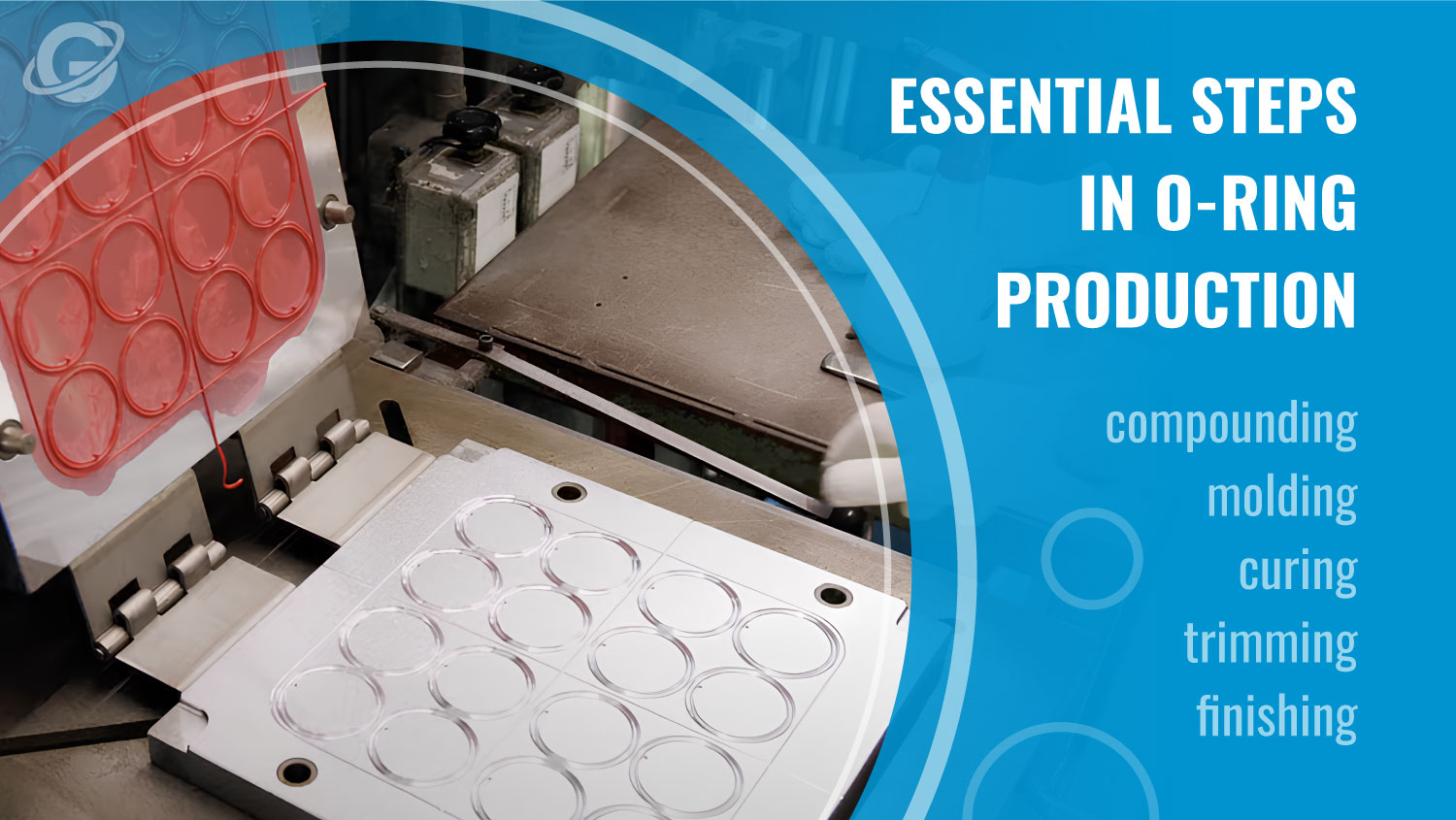

The process begins with Drawing Analysis, where our engineering team conducts a detailed review of customer-supplied technical drawings, 3D models, or physical samples. We assess critical dimensions, tolerance requirements (per ISO 3601 or AS568 standards), groove design, and application parameters such as pressure, temperature, and media exposure. This stage ensures design-for-manufacturability and identifies any potential sealing challenges early in the development cycle.

Following drawing validation, we proceed to Formulation Development. Our in-house rubber chemists select the optimal elastomer compound based on chemical resistance, thermal stability, compression set, and mechanical strength. Common base polymers include Nitrile (NBR), Fluorocarbon (FKM/Viton®), Ethylene Propylene (EPDM), and Hydrogenated Nitrile (HNBR), with custom compounding for specific fluid compatibility—such as sour gas (H₂S), crude oil, or hydraulic fluids. Additives are precisely balanced to enhance wear resistance, low-temperature flexibility, or non-contamination properties as required.

Once the material formulation is finalized, we enter the Prototyping Phase. Utilizing precision molding techniques—such as compression, transfer, or injection molding—we produce small-batch prototypes for functional testing. These samples undergo rigorous evaluation, including hardness testing (Shore A), tensile strength, volume swell in target media, and dynamic or static sealing performance in simulated service environments. Customer feedback is incorporated at this stage to refine geometry or material before full-scale release.

Upon prototype approval, the project transitions to Mass Production. Our automated production lines, supported by statistical process control (SPC) and 100% visual inspection, ensure batch-to-batch consistency. All finished seals are packaged per international cleanroom standards to prevent contamination during transit.

Below is a representative specification table for a custom FKM O-ring developed for high-temperature sour service:

| Parameter | Specification |

|---|---|

| Material | FKM 70 (Custom Formulation) |

| Hardness (Shore A) | 70 ± 5 |

| Tensile Strength | ≥15 MPa |

| Elongation at Break | ≥150% |

| Compression Set (70h/150°C) | ≤25% |

| Volume Swell (ASTM Oil No. 3, 70h/100°C) | ≤15% |

| Operating Temperature | -20°C to +200°C (intermittent to +230°C) |

| Fluid Compatibility | Crude oil, H₂S, CO₂, amine solutions |

| Compliance | ISO 3601, API 6A, NACE MR0175 |

This structured, science-driven approach enables Suzhou Baoshida to deliver mission-critical sealing solutions that meet the exacting standards of global o ring houston clients, ensuring safety, efficiency, and operational longevity in demanding environments.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Seal Solutions

As a globally recognized manufacturer of engineered elastomeric components, Suzhou Baoshida Trading Co., Ltd. delivers uncompromising precision for critical sealing applications in demanding industrial environments. Our technical team, comprising specialized rubber formulation engineers and OEM management professionals, operates at the intersection of material science and industrial pragmatism. We understand that in sectors like oil and gas—particularly within Houston’s high-pressure, high-temperature wellhead and pipeline infrastructure—a single point of seal failure carries catastrophic operational and safety implications. Our value proposition is rooted in rigorous ASTM D2000 classification adherence, ISO 9001-certified production protocols, and proprietary compound development tailored to resist sour gas exposure, thermal degradation, and chemical permeation.

Our engineering approach begins with molecular-level compound optimization. Unlike generic seal suppliers, we deploy advanced polymer blending techniques to enhance resilience under extreme conditions. For instance, our hydrogenated nitrile (HNBR) formulations achieve sustained performance at 150°C while maintaining low compression set values critical for dynamic sealing in rotating equipment. Every compound undergoes accelerated life testing per ISO 1817 and ASTM D471 standards, ensuring predictable service longevity in Houston’s corrosive downhole environments. This scientific methodology translates to reduced downtime, minimized fugitive emissions, and compliance with API 6A and NORSOK M-710 specifications.

The following table summarizes key material capabilities relevant to Gulf Coast industrial applications:

| Material Type | Temperature Range (°C) | Hardness (Shore A) | Key Resistance Properties | Common Standards Met |

|---|---|---|---|---|

| Perfluoroelastomer (FFKM) | -20 to 325 | 70–90 | H₂S, amines, steam, acids | ASTM D2000 EE, API 6A |

| Hydrogenated Nitrile (HNBR) | -40 to 150 | 60–90 | Oil, ozone, sour gas | NORSOK M-710, ISO 23936-2 |

| Fluorosilicone (FVMQ) | -60 to 200 | 50–80 | Jet fuels, hydraulic fluids | AMS 3303, SAE AS5585 |

| EPDM | -55 to 150 | 50–90 | Steam, water, alkalis | ISO 3601, ASTM D1418 |

For Houston-based operations confronting aggressive H₂S environments or deepwater thermal cycling, generic O-rings represent an unacceptable risk. Suzhou Baoshida’s OEM partnership model integrates directly with your engineering workflows. We provide full material traceability, batch-specific certificates of conformance, and on-demand formulation adjustments to address field-specific challenges—such as mitigating rapid gas decompression (RGD) in subsea trees. Our technical team collaborates with your design engineers to validate seal geometry via finite element analysis (FEA), ensuring optimal stress distribution under operational loads.

Initiate a precision-engineered solution pathway by contacting Mr. Boyce, our dedicated OEM Account Manager. With 18 years of experience supporting North American energy clients, he will coordinate immediate material sampling, technical documentation review, or application-specific compound development. Direct all engineering inquiries and procurement requests to [email protected]. Specify your operational parameters—including media exposure, pressure cycles, and temperature profiles—to receive a validated compound recommendation within 24 business hours. Suzhou Baoshida does not sell commodities; we deliver certified engineering assurance for the world’s most unforgiving sealing interfaces. Your next-specification O-ring begins with precise technical dialogue.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).