Technical Contents

Engineering Guide: Rubber Floor Tiles For Home

Engineering Insight: Material Selection in Rubber Floor Tiles for Home Applications

In residential environments, rubber floor tiles are increasingly specified not only for their durability but also for their acoustic damping, slip resistance, and thermal insulation properties. However, the performance of these tiles in real-world home settings is heavily dependent on precise material selection—a factor often overlooked in off-the-shelf consumer products. At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber formulations that meet defined performance thresholds, as generic compounds fail to address the nuanced demands of domestic use.

Standard rubber tiles available in mass retail channels are typically formulated using recycled rubber content exceeding 70%, often sourced from post-industrial or post-consumer tire stock. While cost-effective, such materials introduce inconsistencies in crosslink density, plasticizer retention, and polymer chain integrity. These inconsistencies manifest as premature surface cracking, delamination under thermal cycling, and accelerated oxidation due to residual unsaturation in styrene-butadiene rubber (SBR) matrices. Moreover, high filler loading—common in economy-grade tiles—reduces elasticity and increases compression set, leading to permanent indentation around high-traffic zones such as kitchen islands or home gym equipment.

A scientifically formulated rubber compound for residential flooring must balance hardness, resilience, and long-term stability. Virgin ethylene propylene diene monomer (EPDM) rubber, when compounded with controlled carbon black dispersion and antioxidant packages, offers superior UV resistance and ozone stability—critical for sunroom or patio installations. Additionally, the inclusion of reactive plasticizers such as polyesters or polyethers enhances low-temperature flexibility, preventing embrittlement in unheated basements or seasonal homes.

Another critical failure point in consumer-grade tiles is inadequate vulcanization control. Off-the-shelf products frequently exhibit under-cured or over-cured states due to inconsistent press times and temperatures during manufacturing. This results in either poor tensile strength or reduced elongation at break, compromising impact absorption—a key requirement in homes with children or elderly occupants.

To ensure reliability, Suzhou Baoshida implements ASTM D2000-compliant material grading, with each batch subjected to Shore A hardness testing, compression set analysis (ASTM D395), and accelerated aging per ASTM G154. Our proprietary blends maintain a hardness range of 55–65 Shore A, optimal for residential comfort and wear resistance.

Below is a comparison of key performance indicators between standard retail rubber tiles and our engineered solution:

| Property | Standard Retail Tile | Baoshida Engineered Tile |

|---|---|---|

| Base Polymer | Recycled SBR (≥70%) | Virgin EPDM (≥85%) |

| Hardness (Shore A) | 70–80 | 55–65 |

| Tensile Strength (MPa) | 4.5 | 9.2 |

| Elongation at Break (%) | 120 | 280 |

| Compression Set (22 hrs, 70°C) | 28% | 12% |

| UV Resistance (QUV, 500 hrs) | Severe chalking, cracking | Minimal color fade, no cracks |

| Temperature Range | -10°C to 60°C | -40°C to 100°C |

In summary, material selection is not a cost variable but a performance determinant. Off-the-shelf rubber tiles fail because they prioritize economy over engineering integrity. At Suzhou Baoshida, we design rubber floor tiles as engineered systems—ensuring longevity, safety, and consistent performance across diverse home environments.

Material Specifications

Material Specifications for Residential Rubber Floor Tiles

Suzhou Baoshida Trading Co., Ltd. engineers industrial-grade rubber floor tiles for residential applications where exceptional durability, chemical resistance, and safety are non-negotiable. Unlike standard PVC or foam alternatives, our formulations leverage high-performance elastomers to withstand household challenges including oil spills, cleaning agents, temperature fluctuations, and heavy foot traffic. Each compound is precision-tailored to balance performance with residential practicality, ensuring longevity without compromising aesthetic flexibility. Below we detail the core materials deployed in our OEM tile production, emphasizing properties critical to home environments such as slip resistance, compression recovery, and non-toxic compliance.

The comparative analysis below outlines key technical parameters for Viton, Nitrile, and Silicone formulations. These values represent standard production grades; Baoshida offers custom tuning of hardness, color, and additive packages to meet specific project requirements. All materials comply with ISO 17025 testing protocols and EU REACH regulations for indoor use.

| Material | Temperature Range | Key Chemical Resistances | Typical Hardness (Shore A) | Primary Home Applications | Cost Factor |

|---|---|---|---|---|---|

| Viton | -20°C to +230°C | Oils, acids, solvents, ozone | 60–80 | Garages, workshops, utility rooms | Premium |

| Nitrile | -30°C to +120°C | Grease, hydraulic fluids, water | 50–70 | Kitchens, laundry rooms, basements | Moderate |

| Silicone | -55°C to +200°C | Steam, cleaning detergents, UV | 40–65 | Bathrooms, poolsides, aging-in-place zones | High |

Viton (FKM) delivers unparalleled resistance to automotive fluids and extreme heat, making it ideal for attached garages where tire chemicals or workshop spills occur. Its high thermal stability prevents deformation near radiators or in sun-drenched spaces. Nitrile (NBR) provides optimal cost-performance for high-moisture zones like kitchens, resisting common degreasers while maintaining flexibility at low temperatures. Silicone (VMQ) excels in wet environments due to hydrophobic properties and superior slip resistance when wet, critical for bathroom safety. All three materials achieve Shore A hardness levels that absorb impact without excessive softness that traps debris.

Critical to residential adoption is our compression set optimization. Baoshida tiles retain ≤15% permanent deformation after 24 hours at 70°C, ensuring consistent underfoot comfort and seam integrity even under furniture loads. Non-slip textured surfaces are integrated during vulcanization, achieving DIN 51130 R10 ratings without topical coatings that degrade. For home installations, we prioritize low-VOC formulations with odor suppression additives—essential for indoor air quality compliance under LEED and WELL Building standards. OEM partners benefit from our rapid prototyping capabilities, enabling hardness adjustments within ±5 Shore A units and custom color matching to residential design palettes. This precision engineering transforms industrial elastomer science into residential flooring solutions that outperform conventional alternatives by 3–5× in lifecycle testing.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering precision-engineered rubber floor tiles tailored for residential applications without compromising on industrial-grade performance. Our engineering capability is anchored in a dedicated team of highly trained professionals, including five specialized mould engineers and two advanced rubber formulation scientists. This technical backbone enables us to design, develop, and produce custom rubber flooring systems that meet exacting performance, aesthetic, and durability standards for home environments.

Our mould engineering team leverages CAD/CAM software and CNC prototyping technologies to design high-tolerance moulds that ensure dimensional accuracy, surface consistency, and long production cycles. Each mould is stress-analyzed and optimized for thermal distribution, minimizing warpage and ensuring uniform curing. These capabilities are critical in producing rubber floor tiles with precise interlocking patterns, clean edge definition, and repeatable quality across large production runs.

Complementing our mould expertise, our two in-house rubber formula engineers specialize in elastomer compounding for residential performance requirements. They formulate custom rubber blends using SBR, EPDM, and recycled rubber feedstocks, adjusting hardness, density, abrasion resistance, and slip resistance to suit home environments. Additives such as UV stabilizers, anti-aging agents, and non-yellowing antioxidants are precisely dosed to ensure long-term color retention and material integrity, even under variable indoor lighting and humidity conditions. All formulations are developed in accordance with REACH and RoHS compliance standards, ensuring environmental and user safety.

Our OEM service model is built on technical collaboration. We work directly with partners to translate design concepts into manufacturable products, offering full support from concept sketch to mass production. This includes 3D modelling, material selection, tooling development, prototype validation, and batch testing. With in-house rheometry, tensile testing, and aging chambers, we conduct rigorous quality control to validate performance before shipment.

The following table outlines the standard technical specifications achievable for our rubber floor tiles under OEM production:

| Property | Standard Value | Test Method |

|---|---|---|

| Hardness (Shore A) | 65–85 | ASTM D2240 |

| Tensile Strength | ≥7.5 MPa | ASTM D412 |

| Elongation at Break | ≥200% | ASTM D412 |

| Abrasion Resistance (loss) | ≤120 mm³ | ASTM D5963 |

| Density | 1.15–1.30 g/cm³ | ASTM D297 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395 |

| Slip Resistance (DIN 51130) | R9–R11 | DIN 51130 |

| Operating Temperature Range | -40°C to +80°C | Internal Protocol |

With integrated engineering disciplines and a disciplined approach to material science and manufacturing, Suzhou Baoshida ensures that every rubber floor tile meets the dual demands of domestic application aesthetics and industrial resilience. Our OEM framework is designed for scalability, precision, and compliance, making us a trusted partner in advanced rubber flooring solutions.

Customization Process

Customization Process for Residential Rubber Floor Tiles

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for rubber floor tiles prioritizes precision engineering and client-specific requirements. This four-phase workflow ensures seamless translation from concept to mass production while meeting stringent residential performance standards.

Drawing Analysis Phase

Initial technical drawings undergo rigorous dimensional and functional validation. We assess substrate compatibility, load-bearing requirements per ASTM F3293, and aesthetic specifications including color gradients and surface textures. Critical attention is given to residential-specific factors such as moisture resistance for basements, thermal expansion tolerances in temperature-variable environments, and slip coefficients compliant with ADA 302.1. Any geometric inconsistencies or material feasibility gaps are resolved through collaborative engineering reviews within 72 hours of submission.

Formulation Development Phase

Based on validated drawings, our rubber compounding team designs proprietary formulations using SBR, EPDM, or recycled rubber matrices. Key parameters include Shore A hardness (65–85 range for residential comfort), VOC emissions below 0.5 mg/m³ (meeting EN 14041), and acoustic damping properties targeting 15–20 dB reduction. We optimize cure kinetics for energy-efficient press cycles while ensuring UV stability for sun-exposed areas. All formulations undergo computational simulation for wear life prediction before physical prototyping.

Prototyping and Validation Phase

Three functional prototypes are produced using client-approved molds. Each unit undergoes accelerated aging tests (72-hour ASTM D573 exposure), flammability validation per UL 94 HF-1, and real-world slip resistance trials on wet/dry surfaces. Color accuracy is verified against Pantone® standards under D65 lighting. Clients receive comprehensive test reports with actionable feedback; typical iteration cycles require ≤48 hours for formulation adjustments.

Mass Production Execution Phase

Upon prototype sign-off, we initiate production with embedded quality checkpoints. Every 500th tile undergoes destructive testing for tensile strength (min. 7.5 MPa) and elongation (min. 250%). Automated vision systems inspect surface defects at 0.1mm resolution. Batch traceability is maintained via laser-etched QR codes linking to raw material certificates and process parameters. Standard lead time from order confirmation to shipment is 25–35 days for 20ft container quantities.

Critical material properties for residential applications are standardized in our compound selection matrix:

| Compound Type | Shore A Hardness | Tensile Strength (MPa) | Recycled Content | Key Residential Advantage |

|---|---|---|---|---|

| Virgin EPDM | 70–80 | 9.0–11.0 | 0% | Superior UV/weather resistance for sunrooms |

| SBR Blend | 65–75 | 7.5–9.0 | 30–40% | Optimal cost/performance for basements |

| TPE Composite | 60–70 | 6.0–8.0 | 50–60% | Enhanced acoustic damping for multi-story homes |

This structured methodology guarantees tiles that balance safety, durability, and aesthetic flexibility. Suzhou Baoshida maintains ISO 9001-certified process controls throughout, ensuring every residential project meets global building code requirements without compromising customization agility.

Contact Engineering Team

For manufacturers, distributors, and industrial partners seeking high-performance rubber floor tiles designed specifically for residential applications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in industrial rubber solutions. Our engineered rubber flooring products combine durability, safety, and aesthetic versatility, meeting the rigorous demands of modern home environments—from basements and garages to home gyms and playrooms. As a professional OEM manager and rubber formula engineer, we specialize in custom compounding and precision manufacturing to ensure every tile meets exact performance criteria, including slip resistance, impact absorption, and long-term resilience under variable conditions.

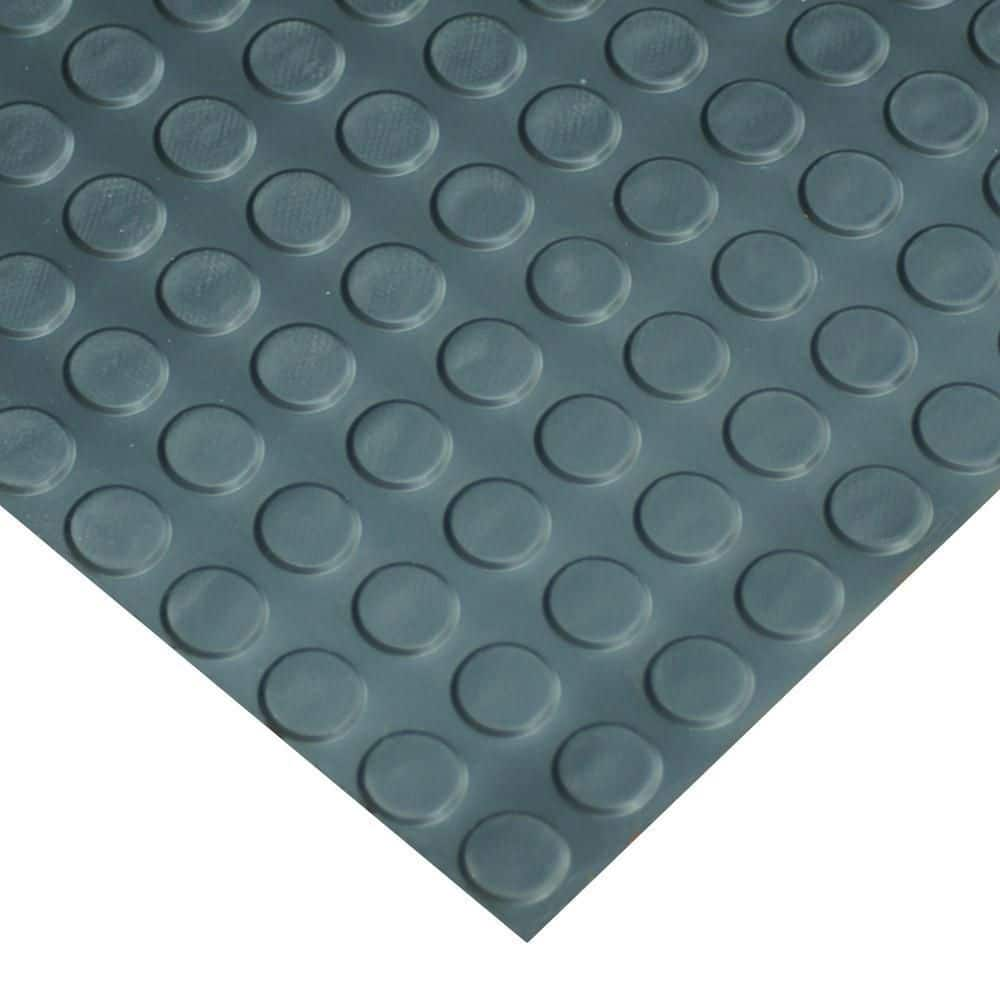

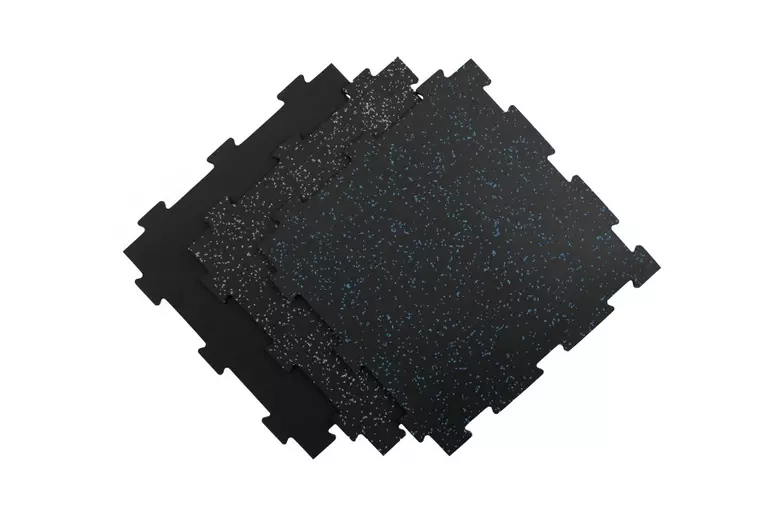

Our rubber floor tiles are produced using advanced vulcanization techniques and premium-grade recycled and virgin rubber compounds. This ensures consistent density, dimensional stability, and resistance to compression set, UV exposure, and common household chemicals. Each batch undergoes stringent quality control, including hardness testing (Shore A), tensile strength evaluation, and abrasion resistance checks, to guarantee compliance with international safety and environmental standards. Whether you require interlocking puzzle tiles, rolled sheet formats, or custom die-cut designs, we offer scalable production runs tailored to your market’s specifications.

We invite global partners—importers, building material suppliers, and private-label brands—to engage directly with our technical team for product development, sample validation, and volume manufacturing support. Mr. Boyce, our dedicated OEM and technical liaison, brings over 12 years of experience in rubber formulation and industrial flooring applications. He leads client collaboration from initial inquiry through to final production, ensuring seamless communication, technical accuracy, and on-time delivery.

To initiate a partnership or request technical documentation, material safety data sheets (MSDS), or physical samples, please contact Mr. Boyce at [email protected]. We respond to all inquiries within 12 business hours and offer virtual consultations for in-depth project discussions. Our facility in Suzhou operates under ISO 9001 standards, with export experience across North America, Europe, and Southeast Asia. We support MOQs tailored to startup brands as well as large-scale distribution networks.

Below are key technical specifications for our standard residential rubber floor tile series:

| Property | Specification | Test Standard |

|---|---|---|

| Material Composition | 70% recycled rubber, 30% virgin SBR/EPDM | ASTM D2000 |

| Thickness | 8 mm, 10 mm, 12 mm | ISO 175 |

| Density | 1.25 ± 0.05 g/cm³ | ISO 2781 |

| Hardness (Shore A) | 65–75 | ASTM D2240 |

| Tensile Strength | ≥ 7.5 MPa | ASTM D412 |

| Elongation at Break | ≥ 150% | ASTM D412 |

| Abrasion Loss | ≤ 120 mm³ | ISO 4649 |

| Slip Resistance (DSR) | ≥ 0.65 (wet) | DIN 51130 |

| Fire Rating | Class Bfl-s1 (EN 13501-1) | EN 13823 |

| Temperature Range | -30°C to +80°C | IEC 60068 |

Partner with Suzhou Baoshida to deliver scientifically optimized, industrially produced rubber flooring solutions to the residential market. Contact Mr. Boyce today at [email protected] to begin technical evaluation and product customization.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).