Technical Contents

Engineering Guide: Cushioned Stair Treads

Engineering Insight: The Critical Role of Material Selection in Cushioned Stair Treads

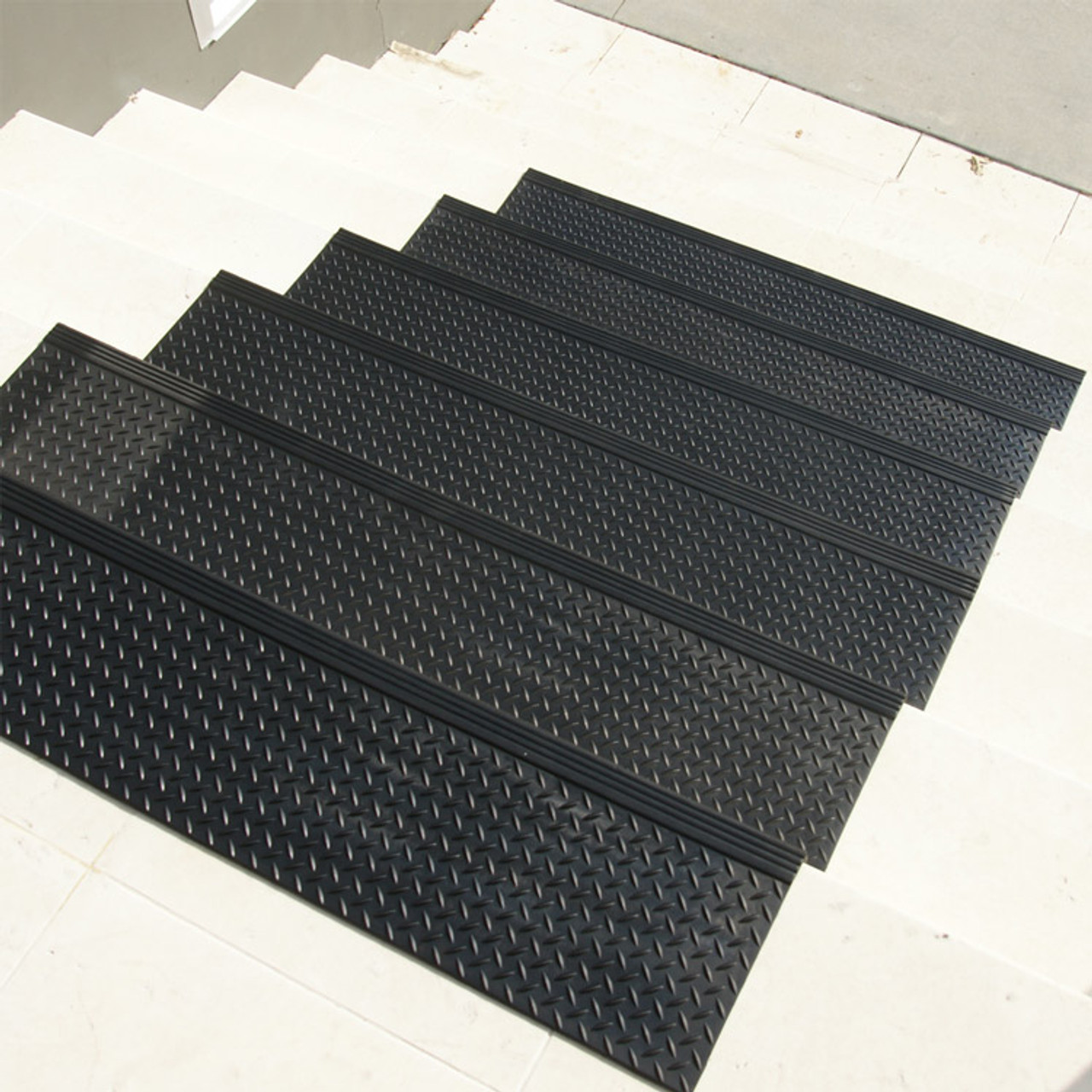

In industrial and commercial environments, cushioned stair treads are more than a comfort feature—they are engineered safety components designed to mitigate slip hazards, reduce impact fatigue, and withstand continuous mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is the foundational determinant of performance, longevity, and compliance. Off-the-shelf solutions often fail because they utilize generic elastomers optimized for cost, not for the complex interplay of mechanical, thermal, and chemical demands present in real-world applications.

Standard stair tread materials such as recycled rubber or basic EVA foams may appear adequate in controlled showroom conditions but degrade rapidly under industrial loads. These materials lack the molecular stability required to resist compression set, UV exposure, and hydrocarbon contamination. As a result, they harden, crack, or delaminate within months, compromising both safety and functionality. In high-traffic zones—such as manufacturing plants, offshore platforms, or public transit hubs—this premature failure increases liability and maintenance costs.

The optimal material for cushioned stair treads must balance durometer, resilience, and adhesion. We specify high-density EPDM (ethylene propylene diene monomer) rubber for its superior weathering resistance and thermal stability across -40°C to +120°C. For applications requiring enhanced abrasion resistance, we integrate a cured NBR (nitrile butadiene rubber) top layer, which provides excellent oil and grease resistance without sacrificing slip performance. These materials are compounded with controlled cross-link density to minimize permanent deformation under repeated loading.

Additionally, the bonding interface between cushioning layer and anti-slip surface must be engineered with chemical primers and vulcanization techniques to prevent delamination. Many commercial products use pressure-sensitive adhesives or mechanical fasteners, which fail under thermal cycling and dynamic shear forces. Our bonded systems undergo peel strength testing exceeding 12 kN/m, ensuring structural integrity over 10+ years of service.

Below is a comparative specification of standard versus engineered rubber compounds used in cushioned stair treads:

| Property | Off-the-Shelf Recycled Rubber | Engineered EPDM/NBR Composite (Baoshida Standard) |

|---|---|---|

| Shore A Hardness | 55–65 | 60–70 (adjustable) |

| Tensile Strength | 7–9 MPa | 14–18 MPa |

| Elongation at Break | 200–250% | 350–450% |

| Compression Set (22 hrs, 70°C) | 35–45% | ≤18% |

| Abrasion Loss (DIN 53516) | 180 mm³ | ≤90 mm³ |

| Operating Temperature Range | -20°C to +80°C | -40°C to +120°C |

| Slip Resistance (DIN 51130 R10) | Marginal (R9) | Confirmed (R11–R12) |

| Adhesion Strength (peel test) | 4–6 kN/m | ≥12 kN/m |

Material selection is not a commodity decision—it is an engineering imperative. Suzhou Baoshida Trading Co., Ltd. applies industrial rubber science to develop stair treads that perform reliably under real operational stress, ensuring safety, durability, and total cost efficiency. Off-the-shelf alternatives may offer short-term savings, but they invariably lead to higher lifecycle costs and compromised safety outcomes.

Material Specifications

Material Specifications for Industrial Cushioned Stair Treads

Selecting the optimal elastomer is critical for cushioned stair tread performance, directly influencing safety, durability, and lifecycle cost in commercial and industrial environments. At Suzhou Baoshida Trading Co., Ltd., we engineer solutions using Viton (FKM), Nitrile (NBR), and Silicone (VMQ) compounds, each rigorously formulated to meet ASTM D2000 and ISO 37 standards. Precise material properties dictate suitability for specific operational demands, including thermal exposure, chemical contact, and mechanical stress.

Viton (FKM) excels in extreme environments requiring resistance to high temperatures, aggressive chemicals, and ozone. Our FKM formulations for stair treads maintain integrity from -20°C to +230°C continuous service, with short-term peaks to 300°C. They demonstrate exceptional stability against hydraulic fluids, acids, and hydrocarbons, making them ideal for aerospace facilities, chemical processing plants, and high-heat industrial kitchens. Standard durometer ranges from 60 to 80 Shore A, providing firm yet resilient cushioning. However, FKM’s higher raw material cost necessitates justified application in severe-service scenarios.

Nitrile (NBR) remains the industry benchmark for oil and fuel resistance at cost-effective pricing. Baoshida’s NBR compounds operate reliably between -30°C and +120°C, with specialized grades extending to +150°C. They offer outstanding abrasion resistance and tensile strength (15–25 MPa), crucial for high-traffic zones like automotive workshops, marine decks, and food processing facilities where exposure to greases and animal fats occurs. Standard hardness spans 50–90 Shore A, allowing customization for softer cushioning or rigid support. Limitations include poor ozone resistance and reduced flexibility below -40°C.

Silicone (VMQ) provides unparalleled flexibility across extreme temperatures (-60°C to +200°C) and superior resistance to UV degradation and biological growth. Its inherent non-toxicity and compliance with FDA 21 CFR 177.2600 make it mandatory for pharmaceutical cleanrooms and food handling areas. VMQ’s low compression set (<20% at 150°C) ensures long-term shape retention under constant load. Typical durometers range from 30 to 80 Shore A, enabling ultra-soft tread surfaces. However, silicone exhibits lower tensile strength (6–12 MPa) and higher susceptibility to tearing versus NBR or FKM, restricting use in high-abrasion mechanical environments.

The following table summarizes critical performance parameters for informed material selection:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Durometer Range (Shore A) | 60–80 | 50–90 | 30–80 |

| Tensile Strength (MPa) | 12–20 | 15–25 | 6–12 |

| Key Resistance | Acids, fuels, ozone | Oils, fuels, abrasion | UV, ozone, steam |

| Primary Limitation | Cost, low-temp flexibility | Poor ozone/weathering | Low tear strength |

| Optimal Application | Chemical plants, high-heat kitchens | Automotive, marine, food processing | Cleanrooms, medical facilities |

Material choice must align with environmental stressors and safety compliance (e.g., ASTM F1637 for slip resistance). Baoshida’s OEM partnerships ensure compound customization—such as adding anti-slip silica or flame retardants—to meet exact project specifications while optimizing cost efficiency. Consult our engineering team for application-specific validation testing protocols.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber engineering, delivering precision-engineered cushioned stair treads tailored to exact OEM specifications. Our engineering capability is anchored by a dedicated team of five mould engineers and two specialized rubber formulation scientists, enabling us to control every phase of product development—from concept to mass production. This integrated technical team ensures that both the physical geometry and material performance of our stair treads meet rigorous industrial, safety, and durability standards.

Our mould engineers utilize advanced CAD/CAM systems and finite element analysis (FEA) to design injection and compression moulds optimized for dimensional stability, cycle efficiency, and long service life. Each design undergoes rigorous simulation to predict flow behavior, shrinkage, and part ejection, minimizing defects and tooling revisions. This precision in mould engineering translates into consistent part quality, critical for applications where slip resistance, load distribution, and long-term resilience are non-negotiable.

Complementing our mould expertise, our two in-house rubber formula engineers specialize in elastomer compounding for performance-critical applications. They develop proprietary rubber formulations using SBR, EPDM, and NBR base polymers, tailored to balance hardness, compression set, abrasion resistance, and coefficient of friction. Additives such as reinforcing fillers, anti-aging agents, and flame retardants are precisely dosed to meet regional safety codes and environmental conditions. These formulations are validated through accelerated aging, dynamic mechanical analysis (DMA), and slip resistance testing under wet and dry conditions.

We offer full OEM support, including private labeling, custom tread profiles, color matching (Pantone or RAL), and integration of anti-slip elements such as grit inserts or molded patterns. Our clients benefit from rapid prototyping, with sample delivery typically within 15–20 working days. Tooling is developed in-house, allowing tight control over lead times and modification cycles.

All cushioned stair treads are engineered to comply with international safety standards, including ISO 14122-3 for industrial access and ASTM F1637 for walkway safety. Our manufacturing facility is equipped with automated rubber injection lines and real-time quality monitoring systems to ensure batch-to-batch consistency.

Below is a representative technical specification for a standard cushioned stair tread formulation:

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 10 MPa |

| Elongation at Break | ASTM D412 | ≥ 250% |

| Compression Set (22 hrs, 70°C) | ASTM D395B | ≤ 25% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤ 80 mg |

| Coefficient of Friction (wet) | ASTM F2913 | ≥ 0.45 |

| Operating Temperature Range | — | -40°C to +100°C |

Suzhou Baoshida Trading Co., Ltd. combines deep materials science insight with precision engineering to deliver OEM stair tread solutions that perform reliably in demanding environments such as factories, marine vessels, and public infrastructure.

Customization Process

Customization Process for Industrial Cushioned Stair Treads

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for cushioned stair treads integrates rigorous rubber science with precision manufacturing. This structured workflow ensures optimal performance, safety compliance, and longevity for high-traffic industrial environments. Each phase undergoes stringent validation before progression.

Drawing Analysis and Requirement Translation

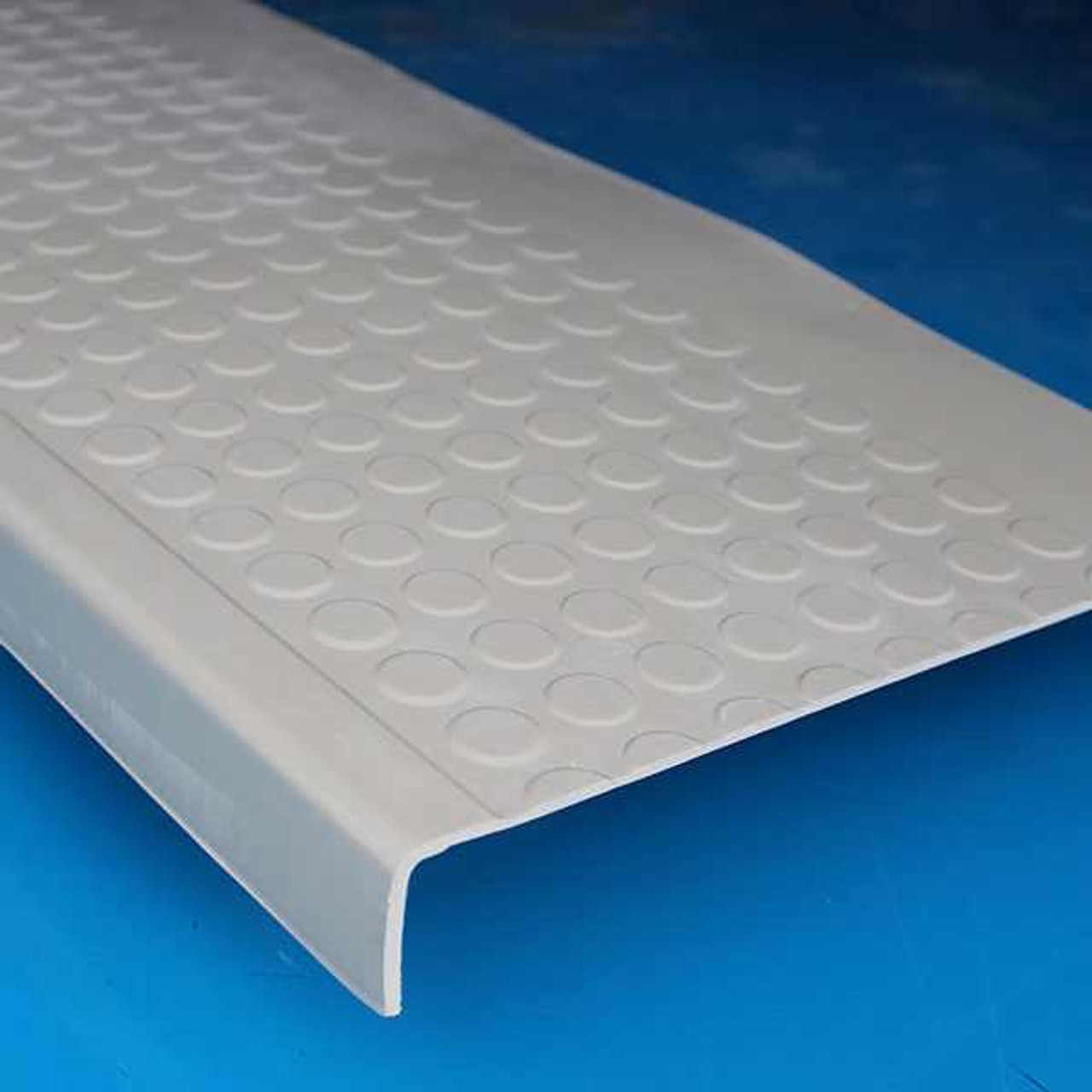

Client-provided technical drawings and performance specifications undergo detailed engineering review. We analyze critical dimensions, load-bearing requirements, surface texture profiles, and environmental exposure conditions. This phase identifies key material properties needed, such as impact absorption thresholds, slip resistance coefficients under wet/dry conditions, and fire retardancy classifications per regional standards (e.g., ASTM F1637, EN 14041). Any ambiguities or potential manufacturability conflicts are resolved collaboratively with the client to establish a definitive technical baseline.

Precision Rubber Formulation Development

Based on the validated requirements, our rubber formula engineering team designs a bespoke compound. This involves selecting the optimal base polymer (typically high-rebound SBR or EPDM for durability and cushioning), reinforcing fillers, plasticizers, vulcanizing agents, and specialty additives. Critical focus areas include achieving the target Shore A hardness for comfort versus stability, optimizing tear strength to resist edge damage, and incorporating anti-slip particulates without compromising wear life. Formulation parameters are meticulously calculated and initial small-batch mixes are prepared for laboratory testing.

Prototyping and Performance Validation

Physical prototypes are manufactured using client-specified tooling or our precision CNC-machined molds. These samples undergo comprehensive in-house testing against the agreed specifications. Key evaluations include durometer measurement, tensile and tear strength verification, coefficient of friction testing under simulated conditions, accelerated aging for UV/ozone resistance, and real-world slip resistance trials. Client feedback on prototype fit, finish, and functional performance is incorporated. Only after successful validation and client sign-off does the process advance.

Controlled Mass Production Implementation

Approved formulations and processes transition to our ISO-certified production lines. Strict batch control ensures raw material traceability and consistent mixing parameters. Continuous inline monitoring checks critical dimensions (thickness, width, profile accuracy) and surface integrity. Final products undergo 100% visual inspection and random sampling for physical property verification against the master specification. Rigorous packaging protocols prevent deformation during transit. Full production documentation, including material certifications and test reports, is provided for client quality assurance.

Critical Material Specifications for Industrial Stair Treads

| Property | Typical Target Range | Test Standard | Significance for Application |

|---|---|---|---|

| Shore A Hardness | 55 – 70 | ASTM D2240 | Balances foot comfort with structural stability |

| Density (g/cm³) | 1.15 – 1.30 | ASTM D297 | Influences weight, cushioning, and material cost |

| Tensile Strength (MPa) | ≥ 10.0 | ASTM D412 | Resists tearing under foot traffic and cleaning |

| Tear Strength (kN/m) | ≥ 30.0 | ASTM D624 (Die B) | Critical for edge durability on stair nosings |

| Abrasion Loss (mm³) | ≤ 120 | ASTM D5963 (Akron) | Determines long-term wear resistance in high-use |

| Static CoF (Wet Ceramic) | ≥ 0.6 | ASTM F2913 | Essential slip resistance for safety compliance |

This systematic approach, grounded in material science and industrial manufacturing discipline, guarantees that every cushioned stair tread solution from Suzhou Baoshida meets the exacting demands of commercial and industrial infrastructure projects.

Contact Engineering Team

For manufacturers and industrial suppliers seeking high-performance cushioned stair treads engineered for durability, safety, and long-term structural integrity, Suzhou Baoshida Trading Co., Ltd. delivers precision rubber solutions tailored to rigorous operational environments. As a trusted OEM partner in the industrial rubber sector, we specialize in custom-formulated elastomeric compounds that meet exact mechanical, thermal, and wear-resistance requirements. Our cushioned stair treads are designed to minimize impact stress, reduce noise transmission, and enhance slip resistance—critical attributes for industrial walkways, commercial staircases, and heavy-traffic architectural installations.

Each product is developed using advanced vulcanization techniques and reinforced with high-tensile backing layers to ensure dimensional stability and fatigue resistance under repeated loading. We utilize EPDM, SBR, and specialty nitrile rubber compounds, selected based on environmental exposure, load cycles, and surface adhesion needs. Our in-house R&D team collaborates directly with clients to optimize tread profile geometry, durometer rating, and bonding methodology, ensuring seamless integration with existing substrates such as steel, aluminum, or concrete.

Below are key technical specifications representative of our standard cushioned stair tread offerings. Custom configurations are available upon request.

| Property | Value | Test Method |

|---|---|---|

| Hardness (Shore A) | 60–75 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22 hrs, 70°C) | ≤20% | ASTM D395 |

| Abrasion Resistance (loss, mm³) | ≤120 | ASTM D5963 |

| Slip Resistance (DIN 51130, R-value) | R10–R13 | DIN 51130 |

| Operating Temperature Range | -40°C to +100°C | Internal |

| Bond Strength to Metal Substrate | ≥4.5 kN/m | ASTM D903 |

All products undergo stringent quality control per ISO 9001 protocols, with full traceability from raw material sourcing to final shipment. We support low-volume prototyping and high-volume production runs, with lead times optimized for global logistics networks. Our technical documentation packages include material compliance reports (REACH, RoHS), aging studies, and adhesion performance data.

To initiate a project or request a customized formulation for your specific application, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over 12 years of experience in industrial rubber applications and serves as the primary technical liaison between engineering teams and international clients. He will coordinate sample submissions, review design specifications, and provide feasibility assessments within 48 hours of initial inquiry.

Reach Mr. Boyce directly at [email protected]. Include detailed requirements such as load parameters, environmental conditions, substrate type, and dimensional drawings for expedited processing. For urgent technical consultations, our engineering desk is available Monday through Friday, 8:00 AM to 5:00 PM China Standard Time. At Suzhou Baoshida, we do not supply rubber products—we engineer long-term performance solutions. Partner with us to elevate your stair safety systems with scientifically validated, industrially hardened cushioned treads.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).