Technical Contents

Engineering Guide: 3Mm Rubber O Rings

Engineering Insight: 3mm Rubber O Rings – The Critical Role of Material Selection

In precision sealing applications, the 3mm rubber o ring is one of the most commonly specified cross-sectional sizes across industries ranging from automotive and medical devices to industrial hydraulics and semiconductor manufacturing. While its dimensions may appear standardized, the performance of a 3mm o ring is profoundly influenced by material selection—a factor often underestimated in procurement decisions. Off-the-shelf o rings may meet dimensional tolerances, but they frequently fail under real-world operational conditions due to inadequate material compatibility.

Material selection governs critical performance metrics such as compression set resistance, thermal stability, chemical resistance, and tensile strength. For instance, a 3mm o ring made from Nitrile Butadiene Rubber (NBR) performs well in oil and fuel environments but degrades rapidly when exposed to ozone or chlorinated solvents. Conversely, Fluorocarbon (FKM) o rings offer superior resistance to high temperatures and aggressive chemicals but come at a higher cost and reduced flexibility at low temperatures. Selecting the wrong elastomer—even with precise 3mm dimensions—can lead to premature seal failure, system contamination, and costly downtime.

Another often-overlooked factor is the operating environment. A 3mm o ring used in a high-pressure hydraulic system must withstand not only mechanical stress but also dynamic movement and temperature cycling. Ethylene Propylene Diene Monomer (EPDM) may perform adequately in static water applications but fails under high-pressure dynamic conditions due to extrusion and wear. Similarly, Silicone (VMQ) offers excellent thermal range but poor tensile strength and abrasion resistance, making it unsuitable for dynamic sealing despite its dimensional conformity.

Suzhou Baoshida Trading Co., Ltd. emphasizes engineered material solutions over generic replacements. We analyze fluid media, temperature profiles, pressure cycles, and mating surface finishes to recommend or formulate the optimal elastomer for each application. Our in-house testing ensures that every 3mm o ring meets ASTM D2000 and ISO 3601 standards, with traceable material certifications.

Below is a comparison of common elastomers used in 3mm o rings, highlighting key performance characteristics.

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Hardness (Shore A) | Key Resistance Properties |

|---|---|---|---|---|

| NBR | -30 to +100 | 15–20 | 60–90 | Oil, fuel, water |

| FKM | -20 to +200 | 12–18 | 65–90 | High heat, chemicals, oils |

| EPDM | -50 to +150 | 10–16 | 50–80 | Steam, water, ozone |

| VMQ | -60 to +200 | 5–8 | 40–80 | Extreme temperatures |

| FFKM | -15 to +300 | 10–15 | 70–90 | Ultra-aggressive chemicals |

Material selection is not a secondary consideration—it is the foundation of reliable sealing performance. At Suzhou Baoshida, we prioritize application-specific engineering to ensure that every 3mm rubber o ring delivers long-term integrity, even in the most demanding environments.

Material Specifications

Material Specifications for 3mm Rubber O-Rings

Suzhou Baoshida Trading Co., Ltd. delivers precision-engineered 3mm cross-section O-rings meeting stringent industrial sealing requirements. Material selection is critical for performance, longevity, and compatibility with operational environments. Our formulations adhere to ASTM D2000 and ISO 3601 standards, ensuring dimensional accuracy within ±0.05mm tolerance and consistent durometer control across production batches. Below we detail the core elastomer options for 3mm O-rings, emphasizing technical parameters essential for OEM integration.

Viton (FKM)

Viton dominates applications requiring extreme chemical and thermal resilience. Our FKM compounds withstand continuous exposure from -20°C to +230°C, with brief excursions to 300°C. They exhibit exceptional resistance to aviation fuels, hydraulic fluids, acids, and aromatic hydrocarbons, making them ideal for aerospace, semiconductor, and chemical processing systems. Standard durometer ranges from 70 to 90 Shore A, with low compression set (<20% per ASTM D395) ensuring long-term seal integrity. Viton O-rings comply with AMS 7257 and ISO 2230 specifications, though higher cost necessitates justification by operational demands.

Nitrile (NBR)

Nitrile remains the industry standard for cost-effective petroleum-based fluid sealing. Our NBR formulations operate reliably between -30°C and +120°C, offering superior resistance to mineral oils, greases, and aliphatic hydrocarbons. With tensile strength exceeding 15 MPa (ASTM D412) and abrasion resistance 20% higher than standard silicone, NBR excels in automotive fuel systems, hydraulics, and general industrial machinery. Durometer options span 50–90 Shore A, with low-temperature grades (e.g., -40°C) available. Compression set remains below 25% after 70 hours at 100°C, though ozone and ketone exposure requires protective additives.

Silicone (VMQ)

Silicone provides unmatched thermal stability for extreme temperature applications. Our VMQ compounds function continuously from -60°C to +200°C, with special grades rated to -110°C or +230°C. They maintain flexibility in cryogenic environments while resisting oxidation at elevated temperatures. Silicone exhibits excellent biocompatibility (USP Class VI, FDA 21 CFR 177.2600) for medical and food-grade seals but has limited resistance to petroleum derivatives. Tensile strength typically ranges 5–8 MPa, with compression set under 20% after aging. Ideal for pharmaceutical, aerospace, and consumer electronics where purity and temperature extremes coexist.

Comparative Material Performance

| Parameter | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +200 |

| Tensile Strength (MPa) | 12–18 | 15–25 | 5–8 |

| Compression Set (%)* | <20 | <25 | <20 |

| Key Chemical Resistance | Fuels, Acids, Ozone | Oils, Greases | Water, Steam |

| Standard Compliance | AMS 7257, ISO 2230 | SAE J200, ISO 3601 | USP Class VI, FDA |

*Per ASTM D395, 70h @ 100°C for NBR/Viton; 22h @ 150°C for Silicone

Material choice must align with fluid media, temperature profiles, and regulatory constraints. Suzhou Baoshida provides custom formulation services—including fluorosilicone blends for ketone resistance or peroxide-cured NBR for low-temperature flexibility—to optimize 3mm O-ring performance for your specific assembly. All compounds undergo rigorous batch testing per ISO 9001 protocols, with full traceability from raw material to finished product. Consult our engineering team to validate material suitability against your operational parameters before integration.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and a systematic approach to precision rubber seal manufacturing. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, working in tandem to deliver high-performance 3mm rubber O-rings tailored to exacting industrial standards. This integrated team structure enables us to control every phase of development—from material formulation to mould design and final production—ensuring consistency, reliability, and performance in every component we produce.

Our formula engineers possess advanced knowledge in polymer chemistry and material behavior under dynamic conditions. They are responsible for developing custom rubber compounds optimized for specific applications, including resistance to temperature extremes, chemical exposure, compression set, and mechanical stress. Whether the requirement calls for NBR, EPDM, FKM, or silicone, our team formulates materials that meet or exceed international standards such as ASTM D2000 and ISO 3601. This in-house formulation capability allows us to address unique customer challenges, such as prolonged service life in aggressive media or low-temperature flexibility in cryogenic environments.

Complementing our material science expertise, our five mould engineers specialize in precision tooling for small-section O-rings, with particular mastery in 3mm cross-section geometries. Utilizing CAD/CAM software and CNC machining, they design and produce high-tolerance steel moulds that ensure dimensional accuracy, consistent parting lines, and minimal flash. Their experience in shrinkage control, gating optimization, and cavity layout directly translates into stable production runs and high first-pass yield rates. All moulds undergo rigorous validation through first-article inspection and process capability (Cp/Cpk) analysis before full-scale manufacturing.

As an OEM manufacturing partner, we prioritize customization, scalability, and technical collaboration. Our engineering team works directly with clients to interpret drawings, validate seal designs, and conduct DFM (Design for Manufacturability) reviews. We support low-volume prototyping as well as high-volume production, with full traceability and batch documentation. Our facility is equipped for overmoulding, secondary curing, and precision packaging, enabling turnkey solutions for demanding industries such as automotive, medical devices, and industrial automation.

The following table outlines the key technical specifications we achieve for 3mm rubber O-rings under controlled manufacturing conditions:

| Parameter | Specification |

|---|---|

| Cross Section Diameter | 3.00 ± 0.05 mm (per ISO 3601) |

| Inner Diameter Range | 5 mm to 200 mm |

| Material Hardness Range | 50 to 90 Shore A (±5) |

| Temperature Resistance | -40°C to +230°C (depending on compound) |

| Tensile Strength | ≥10 MPa (ASTM D412) |

| Elongation at Break | ≥200% |

| Compression Set (70 hrs, 100°C) | ≤25% (FKM), ≤30% (NBR) |

| Tolerance Class | Class M (Standard), Class H (High Precision) |

| Moulding Process | Compression, Transfer, or Injection Moulding |

Our engineering-led approach ensures that every 3mm O-ring we produce is not just a component, but a precision-engineered solution designed for reliability and long-term performance.

Customization Process

Customization Process for 3mm Rubber O-Rings: Precision Engineering Pathway

At Suzhou Baoshida Trading Co., Ltd., our customization process for 3mm rubber O-rings begins with rigorous Drawing Analysis. Every client-supplied technical drawing undergoes dimensional conformity verification against ISO 3601 standards, with particular focus on cross-section tolerance (±0.03mm typical for 3mm ID rings), groove compatibility, and surface finish requirements. Our engineering team utilizes GD&T analysis to identify potential sealing interface risks, such as excessive compression set or extrusion gaps, ensuring the design aligns with the intended pressure and temperature profile. Critical parameters like radial clearance and gland fill percentage are recalculated to prevent premature failure in dynamic applications.

Formulation Development follows dimensional validation, where material science dictates performance. For 3mm O-rings, compound selection balances resilience against compression set with low-temperature flexibility. Standard NBR formulations suit general hydraulic systems (-30°C to +100°C), while fluorocarbon (FKM) variants are engineered for aerospace or chemical exposure (-20°C to +230°C). Each batch incorporates precision-dosed additives: peroxide curing systems for minimal outgassing in vacuum applications, or specialty fillers to achieve Shore A 70±5 hardness for optimal seal force in compact glands. All formulations undergo ASTM D2000 classification verification prior to molding.

Prototyping employs micro-injection molding with cavity-specific tooling to address 3mm-scale challenges. Initial samples undergo three-phase validation: First, dimensional metrology via optical comparators confirms cross-section consistency (critical for seal integrity at this size). Second, accelerated life testing simulates 500+ compression cycles under 25% squeeze. Third, fluid compatibility checks per ASTM D471 ensure <15% volume swell in target media. Client feedback integrates within 72 hours for iterative adjustments, with material certificates and traceability logs provided for every prototype batch.

Mass Production transitions validated designs into ISO 13485-certified manufacturing. For 3mm O-rings, we implement 100% automated visual inspection coupled with SPC-controlled hardness and dimensional checks (sample rate: 1 unit/500). Vulcanization parameters are monitored via real-time cavity pressure sensors to maintain durometer uniformity. Final lots undergo helium leak testing at 1.5x operating pressure, with failure rates held below 50 PPM. All shipments include material traceability codes linking to original formulation logs and third-party compliance certificates (FDA 21 CFR 177.2600, RoHS).

Critical Tolerance Specifications for 3mm O-Rings

| Parameter | Standard Industry Tolerance | Baoshida Precision Tolerance | Measurement Method |

|————————–|—————————–|——————————|————————–|

| Inner Diameter (ID) | ±0.10 mm | ±0.05 mm | Optical Comparator (ISO 3601) |

| Cross-Section (CS) | ±0.05 mm | ±0.02 mm | Laser Micrometer |

| CS Variation (per ring) | 0.08 mm | 0.03 mm | Roundness Tester |

| Hardness (Shore A) | ±8 points | ±3 points | ASTM D2240 Durometer |

This end-to-end engineering protocol ensures Suzhou Baoshida delivers 3mm O-rings with leak-tight integrity across automotive, medical, and semiconductor applications, where micron-level precision directly impacts system reliability. Collaborative validation at each phase eliminates costly field failures while meeting OEM volume demands.

Contact Engineering Team

For industrial manufacturers and engineering teams seeking high-performance 3mm rubber O-rings tailored to exacting specifications, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in precision rubber sealing solutions. With years of expertise in material science, compound formulation, and OEM manufacturing, we deliver consistent quality, technical reliability, and rapid response times to meet the demands of global supply chains. Our 3mm O-rings are engineered for critical sealing applications across automotive, aerospace, medical devices, hydraulics, and industrial automation sectors.

Each 3mm rubber O-ring produced under our supervision undergoes rigorous quality control, from raw material selection to final inspection. We specialize in custom formulations using Nitrile (NBR), Ethylene Propylene Diene Monomer (EPDM), Silicone (VMQ), Fluorocarbon (FKM/Viton®), and other high-grade elastomers. This allows us to match material properties precisely to operational conditions such as temperature extremes, chemical exposure, pressure differentials, and dynamic movement.

Our manufacturing process integrates advanced molding techniques, precise curing cycles, and post-production validation using metrology-grade measurement systems. Dimensional tolerances adhere strictly to ISO 3601 and AS568 standards, ensuring interchangeability and sealing integrity in demanding environments. Whether you require standard durometers or custom Shore A hardness levels, we offer full flexibility in compound design and batch production scalability.

Below is a representative specification table for our standard 3mm inner diameter rubber O-rings, commonly requested by clients. All parameters are adjustable based on application requirements.

| Parameter | Standard Value |

|---|---|

| Inner Diameter (ID) | 3.0 mm ± 0.05 mm |

| Cross Section (CS) | 1.5 mm ± 0.04 mm |

| Material Options | NBR, EPDM, FKM, VMQ, NR, CR |

| Hardness Range | 50 to 90 Shore A (customizable) |

| Temperature Range | -30°C to +250°C (depends on material) |

| Standard Compliance | ISO 3601, AS568, ROHS, REACH |

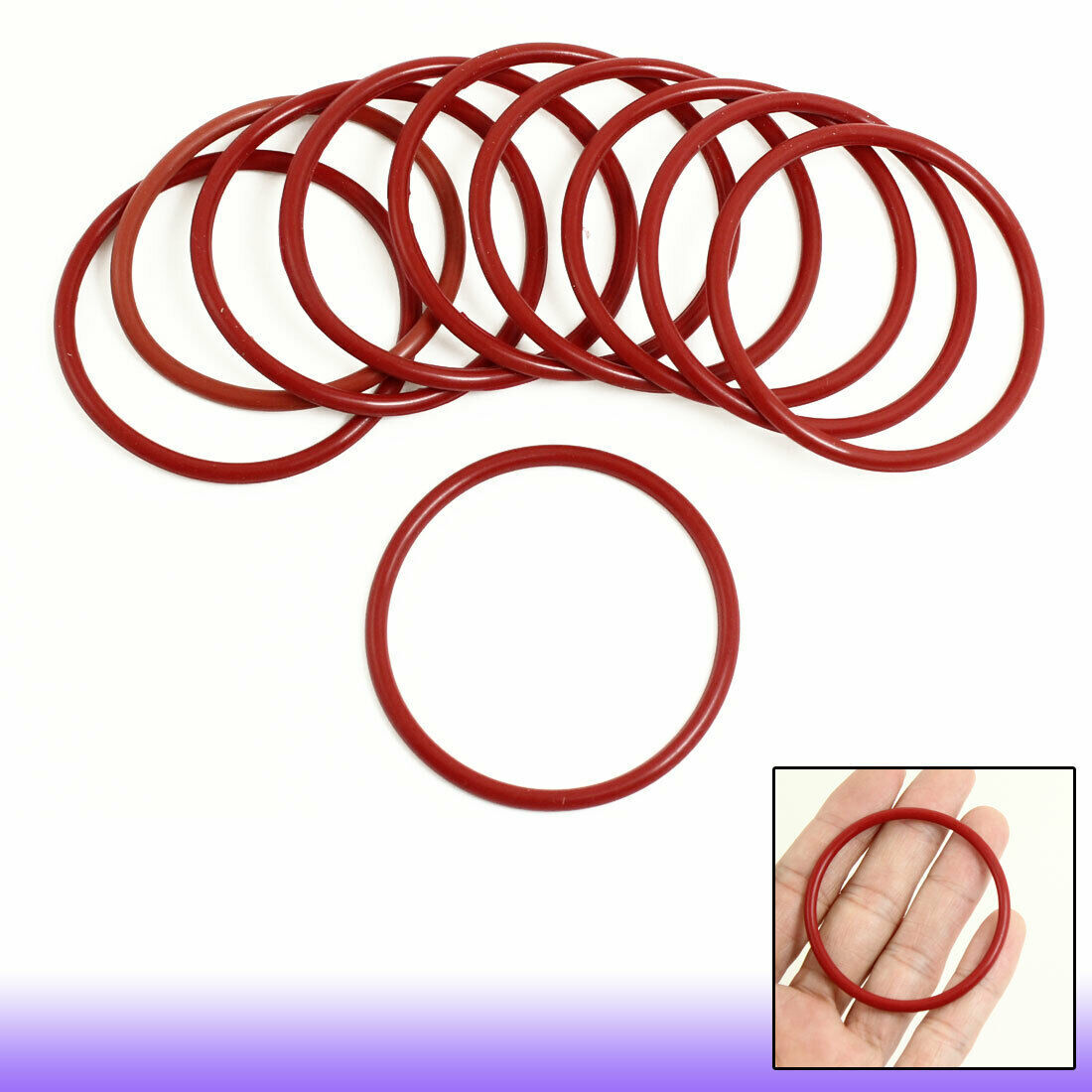

| Color Options | Black, red, green, blue, custom |

| Packaging | Bulk, blister packs, vacuum sealed |

| Lead Time | 7–15 days (sample), 15–30 (mass) |

To ensure optimal performance, we recommend engaging our engineering team early in the design or sourcing phase. Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer, leads technical consultations and material selection support. With direct oversight of formulation development and production coordination, Mr. Boyce ensures that every O-ring meets not just dimensional specs, but functional reliability under real-world conditions.

For quotes, samples, technical data sheets (TDS), or material compatibility analysis, contact Mr. Boyce directly at [email protected]. We respond to all inquiries within 12 business hours and offer rapid prototyping for qualified projects. Suzhou Baoshida Trading Co., Ltd. is committed to delivering engineered sealing solutions that enhance system efficiency, reduce downtime, and exceed industry expectations. Reach out today to integrate precision, durability, and expertise into your next O-ring application.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).