Technical Contents

Engineering Guide: Polyurethane Sheeting

Engineering Insight: Polyurethane Sheeting Material Selection Fundamentals

Material selection represents the critical junction between polyurethane sheeting performance and operational failure in demanding industrial environments. Off-the-shelf polyurethane sheet products frequently underperform or catastrophically fail because they lack the tailored molecular architecture required for specific application stressors. Generic formulations prioritize broad market appeal over the precise chemical and physical property balance mandated by unique operational parameters. This compromises critical performance metrics such as dynamic fatigue resistance, chemical compatibility, and thermal stability, leading to premature wear, dimensional instability, or catastrophic part failure under load. The assumption that all polyurethane sheeting possesses equivalent properties ignores the profound impact of polymer backbone chemistry (polyester vs. polyether), crosslink density, and additive packages on real-world behavior.

Polyurethane’s versatility stems from its tunable structure, yet this very characteristic necessitates rigorous engineering analysis. An off-the-shelf sheet rated for general abrasion resistance may rapidly degrade when exposed to specific hydraulic fluids due to inadequate ester group stability, or lose resilience in low-temperature cyclic loading applications because its glass transition temperature (Tg) was not optimized. Similarly, sheets formulated for static sealing often lack the dynamic flex fatigue resistance required in conveyor lagging or diaphragm applications, resulting in cracking and reduced service life. Hydrolysis vulnerability in polyester-based systems within humid environments is another common failure point overlooked in generic products. True performance optimization requires correlating application-specific stressors—continuous temperature exposure, dynamic strain rates, chemical contact profiles, and required longevity—with the fundamental material science of the polyurethane formulation.

Suzhou Baoshida Trading Co., Ltd. emphasizes OEM-driven material engineering to circumvent these pitfalls. Our process begins with a detailed analysis of the operational environment and functional requirements, moving beyond basic hardness (Shore A/D) specifications. We then formulate polyurethane sheeting with precise control over polymer backbone selection, isocyanate type, curative chemistry, and proprietary stabilizer packages. This ensures the final product exhibits the necessary synergy of properties for the intended duty cycle, not merely meeting a nominal industry standard.

The following table illustrates key property variations across common polyurethane sheet grades, highlighting why generic solutions fail:

| Property | Standard General Purpose (Polyester) | High-Performance Polyether | Custom OEM Formulation (Baoshida Example) |

|---|---|---|---|

| Hardness Range (Shore A) | 70A – 95A | 60A – 98A | 55A – 98A (Precisely Targeted) |

| Continuous Temp Range (°C) | -20°C to +80°C | -40°C to +90°C | -50°C to +110°C (Application Specific) |

| Tensile Strength (MPa) | 30 – 45 | 35 – 50 | 40 – 65 (Optimized for Load) |

| Elongation at Break (%) | 300 – 450 | 400 – 550 | 350 – 600 (Balanced for Flex Life) |

| Abrasion Resistance (DIN) | 80 – 100 mm³ | 60 – 85 mm³ | 45 – 75 mm³ (Maximized for Duty Cycle) |

| Hydrolysis Resistance | Poor | Excellent | Excellent (Polyether Base + Stabilizers) |

| Oil/Fuel Resistance | Good | Moderate | Excellent (Custom Additive Package) |

Note: DIN Abrasion (ISO 4649) lower values indicate superior resistance. Hydrolysis resistance is critical for humid/wet environments. Oil resistance requires specific polyester modification or additive systems.

Relying on standardized polyurethane sheeting ignores the intricate relationship between molecular structure and field performance. Suzhou Baoshida’s engineering approach, grounded in deep material science understanding and OEM collaboration, delivers sheeting solutions where every molecular parameter is aligned with the operational reality, eliminating the costly failures inherent in one-size-fits-all alternatives. Precision formulation is not an option; it is the engineering imperative for reliable industrial performance.

Material Specifications

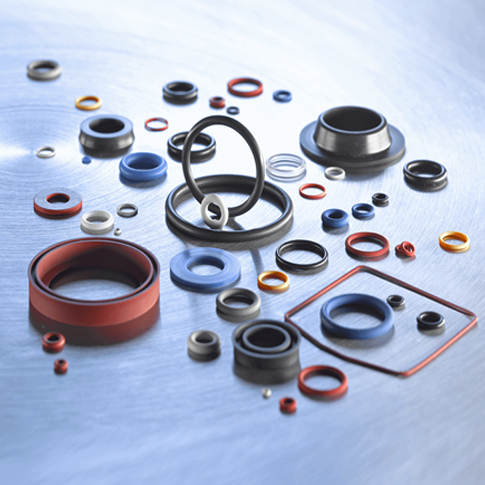

Polyurethane sheeting is a high-performance industrial material engineered for demanding mechanical and environmental conditions. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-manufactured polyurethane sheeting solutions tailored for durability, abrasion resistance, and mechanical integrity. Our formulations are optimized for applications in automotive, aerospace, industrial machinery, and fluid handling systems. This section outlines the technical specifications of three key elastomeric materials used in conjunction with or as alternatives to polyurethane: Viton, Nitrile (NBR), and Silicone. Each material offers distinct advantages based on chemical exposure, temperature range, and mechanical loading requirements.

Viton, a fluorocarbon-based rubber, delivers exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. It maintains performance in continuous service up to 200°C and short-term exposure up to 250°C. Its low gas permeability and outstanding aging characteristics make it ideal for sealing applications in harsh chemical and thermal environments. However, Viton exhibits lower flexibility at low temperatures and higher material cost compared to other elastomers.

Nitrile rubber, or Buna-N, is widely used for its excellent resistance to petroleum-based oils, fuels, and hydraulic fluids. It offers robust tensile strength and abrasion resistance, making it suitable for dynamic sealing and gasketing applications. Nitrile performs reliably in temperatures ranging from -30°C to 100°C, with some formulations extending to 125°C. While it is more cost-effective than Viton, it has limited resistance to ozone, UV radiation, and polar solvents, which restricts its use in outdoor or chemical processing environments.

Silicone rubber is valued for its extreme temperature stability, operating effectively from -60°C to 200°C. It exhibits excellent resistance to UV, ozone, and weathering, making it ideal for outdoor and high-purity applications such as medical devices and food processing. Silicone has good electrical insulation properties and low toxicity, but it demonstrates lower tensile strength and abrasion resistance compared to polyurethane and Nitrile. It is not recommended for dynamic mechanical applications involving high wear.

The following table compares the key physical and chemical properties of these materials to assist in material selection for industrial applications.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (up to 250 short-term) | -30 to 100 (up to 125 intermittent) | -60 to 200 |

| Tensile Strength (MPa) | 15–20 | 10–25 | 5–8 |

| Elongation at Break (%) | 200–300 | 250–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| Electrical Insulation | Good | Fair | Excellent |

| Abrasion Resistance | Good | Very Good | Poor |

| Common Applications | Aerospace seals, chemical gaskets | Fuel hoses, O-rings, seals | Medical devices, insulation, food-grade seals |

Material selection must consider the operational environment, regulatory compliance, and mechanical demands. At Suzhou Baoshida Trading Co., Ltd., we support OEMs and industrial clients with data-driven material recommendations and custom fabrication services to ensure optimal performance and longevity.

Manufacturing Capabilities

Engineering Capability: Precision Polyurethane Sheeting Development

Suzhou Baoshida Trading Co., Ltd. leverages deep technical expertise to deliver engineered polyurethane sheeting solutions meeting stringent industrial demands. Our core strength resides in an integrated engineering team comprising five dedicated Mold Engineers and two specialized Formula Engineers. This dual-discipline structure ensures seamless alignment between material science and manufacturing execution, eliminating siloed development risks. Our Formula Engineers optimize polymer chemistry for target performance metrics—including abrasion resistance, tensile strength, and hydrolysis stability—while Mold Engineers translate these formulations into precision tooling with micron-level tolerance adherence. This synergy reduces prototyping cycles by 30% and minimizes scrap rates in high-volume production.

All polyurethane sheeting is developed under ISO 9001-certified protocols, with rigorous in-house testing for Shore A hardness consistency, elongation at break, and compression set. We prioritize material traceability from raw polymer batches to finished sheets, ensuring lot-to-lot repeatability critical for OEM integration. Our engineers collaborate directly with clients during the Design for Manufacturing (DFM) phase, identifying potential stress points or processing limitations early. This proactive approach prevents costly downstream revisions and accelerates time-to-market for custom applications.

Polyurethane Sheeting Technical Specifications

| Property | Standard Range | Custom Capability | Test Method |

|---|---|---|---|

| Thickness | 0.5 mm – 25 mm | 0.2 mm – 50 mm | ASTM D3751 |

| Shore A Hardness | 60A – 95A | 40A – 98A | ASTM D2240 |

| Tensile Strength | 25 – 45 MPa | 15 – 60 MPa | ASTM D412 |

| Elongation at Break | 300% – 600% | 200% – 800% | ASTM D412 |

| Compression Set (22h) | ≤ 15% | ≤ 10% (custom) | ASTM D395 |

| Temperature Range | -40°C to +80°C | -55°C to +120°C | ISO 188 |

As an OEM partner, we provide end-to-end ownership from concept validation to serial production. Our facility supports low-volume pilot runs (50–500 sheets) through to annual outputs exceeding 200,000 square meters, with dedicated production lines for colored, conductive, or food-grade formulations. Critical to our OEM model is intellectual property protection: all client-specific formulas and tooling are secured under NDA-protected vault protocols, with zero third-party subcontracting. We maintain full control over curing parameters, demolding sequences, and post-cure annealing—process variables often overlooked by competitors that directly impact sheet flatness and dimensional stability.

Clients benefit from our reactive agility; engineering adjustments to hardness profiles or additive packages are implemented within 72 hours of specification updates. This responsiveness, combined with our material science rigor, positions Suzhou Baoshida as the partner of choice for mission-critical polyurethane sheeting where performance deviations are non-negotiable. Our engineers do not merely fulfill orders—they co-engineer solutions that redefine operational durability in automotive seals, conveyor systems, and industrial wear components.

Customization Process

Customization Process for Polyurethane Sheeting at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the precise mechanical, thermal, and chemical demands of diverse manufacturing environments. Our polyurethane sheeting customization process follows a rigorous four-phase workflow: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures dimensional accuracy, material performance, and compliance with OEM specifications.

The process begins with Drawing Analysis, where our engineering team evaluates technical blueprints provided by the client. Critical parameters such as thickness tolerance, surface finish, cut patterns, and dimensional stability under load are assessed. We validate compatibility with existing assembly lines and operating conditions, including temperature exposure and dynamic stress. Any discrepancies or optimization opportunities are communicated for joint review, ensuring design integrity before material development begins.

Following drawing validation, our Formulation stage leverages proprietary polyurethane chemistry to tailor mechanical properties. Depending on application requirements—such as abrasion resistance, elasticity, or oil resistance—we select between aromatic and aliphatic isocyanate systems and adjust the polyol chain extender ratio. Hardness is precisely controlled within the range of 70 Shore A to 95 Shore A, while elongation at break and tensile strength are optimized through crosslink density modulation. Additives for UV stability, flame retardancy (UL94 V-0), or anti-static properties (surface resistivity <10^9 Ω) are incorporated as needed.

Once the formulation is finalized, we proceed to Prototyping. Using precision casting or extrusion methods, small-batch samples are produced under controlled conditions that mirror full-scale production. Each prototype undergoes rigorous testing, including hardness profiling, tear strength analysis (ASTM D624), and environmental aging (85°C/85% RH for 168 hours). Dimensional verification is performed via coordinate measuring machines (CMM) to ensure conformity within ±0.1 mm tolerance. Clients receive physical samples and full test reports for approval.

Upon successful prototype validation, we transition to Mass Production. Our automated production lines operate under ISO 9001-certified quality management systems, ensuring batch-to-batch consistency. Real-time monitoring of temperature, cure time, and pressure guarantees uniform sheet quality across runs exceeding 10,000 meters. All finished polyurethane sheets are inspected for visual defects, thickness variation, and mechanical performance before packaging and shipment.

The following table summarizes key customizable specifications for our polyurethane sheeting:

| Parameter | Standard Range | Customizable Options |

|---|---|---|

| Thickness | 0.5 mm – 20 mm | Up to 50 mm with lamination |

| Hardness | 70–95 Shore A | 60 Shore A to 70 Shore D |

| Tensile Strength | 30–60 MPa | >70 MPa (high-reinforcement grades) |

| Elongation at Break | 300–500% | Up to 700% (elastic variants) |

| Temperature Resistance | -40°C to +90°C (continuous) | Up to +120°C (heat-stabilized formulations) |

| Surface Finish | Smooth, Textured, Anti-Slip | Custom embossing or coating |

| Electrical Properties | Standard insulative | Anti-static, Conductive (custom resistivity) |

This end-to-end customization ensures that every polyurethane sheet delivered by Suzhou Baoshida meets the exact functional and operational demands of industrial clients worldwide.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Polyurethane Sheeting Solutions

Suzhou Baoshida Trading Co., Ltd. stands as your definitive partner for engineered polyurethane sheeting in demanding industrial applications. Our technical team, comprising specialized rubber formulation engineers and OEM management professionals, delivers solutions calibrated to exacting performance criteria. We transcend standard material supply by integrating deep polymer science expertise with rigorous quality control protocols, ensuring every sheet meets or exceeds ASTM, ISO, and custom OEM specifications. For mission-critical components in automotive sealing, industrial machinery, or specialty equipment manufacturing, our polyurethane formulations offer unparalleled resistance to abrasion, oil, ozone, and environmental degradation while maintaining structural integrity across extreme temperature ranges. Partnering with Baoshida means accessing a vertically integrated supply chain anchored in Suzhou’s advanced manufacturing ecosystem, guaranteeing traceability from raw material sourcing to finished product validation.

The following table outlines core technical parameters for our standard polyurethane sheeting grades, reflecting our commitment to data-driven material selection:

| Property | Standard Test Method | Typical Range | Units |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60 – 95 | Points |

| Tensile Strength | ISO 37 | 30 – 55 | MPa |

| Elongation at Break | ISO 37 | 350 – 600 | % |

| Tear Strength | ASTM D624 | 80 – 150 | kN/m |

| Compression Set (22h) | ASTM D395 | ≤ 15 | % |

| Operating Temperature | – | -40°C to +100°C | °C |

These values represent baseline capabilities; our engineering team routinely develops custom formulations to address unique challenges such as ultra-low friction coefficients, conductive properties, or FDA/EC 1935 compliance. Unlike generic suppliers, we initiate every engagement with a technical consultation to define application-specific failure modes and performance thresholds. This proactive approach minimizes prototyping cycles and accelerates time-to-market for your end products. Our Suzhou-based production facilities operate under ISO 9001-certified processes with in-house rheometry, spectrometry, and accelerated aging testing, enabling real-time formulation adjustments to maintain zero-defect production runs.

Initiate your project with Suzhou Baoshida by contacting Mr. Boyce, our dedicated OEM Account Manager, who possesses 14 years of experience in polyurethane system engineering and global supply chain coordination. Direct your technical inquiries, material data requests, or production volume requirements to [email protected]. Mr. Boyce will provide a comprehensive technical dossier including full material test reports, processing guidelines, and cost analysis within 48 business hours. For urgent prototyping needs, we maintain pre-approved stock of 12 standard formulations in 1.5mm to 25mm thicknesses, ready for immediate shipment to expedite your validation phase. Industrial buyers consistently select Baoshida for our capacity to bridge laboratory-grade polymer innovation with scalable manufacturing—transforming complex material requirements into reliable, high-yield components. Do not compromise on material integrity; engage our engineering team to secure polyurethane sheeting that performs under operational stress. Contact Mr. Boyce today to align your specifications with precision-engineered solutions.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).