Technical Contents

Engineering Guide: Pinch Weld Adapter

Engineering Insight: The Critical Role of Material Selection in Pinch Weld Adapter Performance

In industrial manufacturing environments, the pinch weld adapter serves as a vital interface between sealing systems and structural components, particularly in automotive assembly, heavy equipment, and hydraulic applications. While often perceived as a simple mechanical connector, the performance and longevity of a pinch weld adapter are fundamentally determined by the precision of material selection. Off-the-shelf solutions frequently fail to meet operational demands due to a one-size-fits-all approach that neglects the complex interplay between chemical exposure, thermal cycling, mechanical stress, and environmental degradation.

Standard adapters are typically manufactured using generic rubber compounds such as natural rubber (NR) or low-grade EPDM, which may offer adequate elasticity but lack resistance to ozone, UV radiation, or industrial oils. In high-stress environments, these materials degrade rapidly, leading to cracking, compression set, and eventual seal failure. Furthermore, the bonding integrity between the rubber element and the metal substrate in pinch weld adapters is highly dependent on the compatibility of the rubber compound with the priming and vulcanization processes. Generic formulations often fail to achieve optimal adhesion, resulting in delamination under cyclic loading.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber solutions tailored to the specific operational parameters of the application. Our pinch weld adapters utilize high-purity, peroxide-cured EPDM or specialty FKM (fluoroelastomer) compounds where extreme temperature stability and chemical resistance are required. These materials maintain elasticity across a broad temperature range (–50°C to +200°C for FKM) and exhibit minimal swelling when exposed to hydraulic fluids, brake oils, or industrial solvents. The reinforcement of the metal core with phosphate conversion coating ensures superior rubber-to-metal adhesion, critical for maintaining structural integrity during repeated compression and vibration.

Custom formulation also allows for precise control over hardness (Shore A), tensile strength, and elongation at break—properties that directly influence sealing performance and service life. For example, in dynamic suspension systems, an overly hard compound may transmit vibration and reduce comfort, while an overly soft material may extrude under pressure. Only through targeted material engineering can these trade-offs be optimized.

Below is a comparison of typical material properties used in pinch weld adapters:

| Material | Temperature Range (°C) | Hardness (Shore A) | Tensile Strength (MPa) | Fluid Resistance | Typical Use Case |

|---|---|---|---|---|---|

| NR (Natural Rubber) | –30 to +70 | 50–70 | 18–25 | Poor | Low-stress, indoor applications |

| Standard EPDM | –40 to +135 | 55–75 | 10–15 | Moderate (water, steam) | General industrial seals |

| Peroxide-Cured EPDM | –50 to +150 | 60–80 | 16–20 | Good (ozone, UV) | Automotive underhood |

| FKM (Fluoroelastomer) | –20 to +200 | 70–90 | 12–18 | Excellent (oils, acids) | High-performance hydraulic systems |

In conclusion, the failure of off-the-shelf pinch weld adapters is not inherent to the design, but to the inadequacy of material selection for real-world conditions. Precision-engineered rubber compounds, matched to environmental and mechanical demands, are essential for achieving reliability, safety, and cost efficiency in industrial applications.

Material Specifications

Material Specifications for Pinch Weld Adapters

Pinch weld adapters demand precision-engineered elastomers capable of maintaining seal integrity under dynamic mechanical stress, fluid exposure, and thermal cycling. At Suzhou Baoshida Trading Co., Ltd., our rubber formulations undergo rigorous OEM validation to ensure compatibility with automotive and industrial fluid systems. Material selection directly impacts service life, leak prevention, and resistance to compression set. We prioritize compounds meeting or exceeding ASTM D2000 and ISO 3601 standards, with Shore A hardness calibrated between 70–85 for optimal flange sealing without extrusion. Below is a technical analysis of our primary elastomer solutions, each compounded for specific operational envelopes.

Viton Fluoroelastomer (FKM)

Viton remains the benchmark for high-severity applications requiring resistance to aggressive fluids and elevated temperatures. Our FKM formulations withstand continuous exposure to engine oils, transmission fluids, biofuels, and hydraulic media up to 250°C. Critical for turbocharger and EGR systems, Viton exhibits minimal swell in aromatic hydrocarbons and retains >85% tensile strength after 1,000 hours at 200°C. Standard compounds achieve 75±5 Shore A hardness with low compression set (<15% per ASTM D395). Limitations include higher cost and reduced flexibility below -20°C, necessitating careful application vetting.

Nitrile Butadiene Rubber (NBR)

NBR delivers exceptional value for fuel and oil-handling systems operating below 120°C. Our high-acrylonitrile (45–50%) grades provide superior resistance to petroleum derivatives, glycols, and aliphatic hydrocarbons while maintaining resilience at -40°C. Optimized for transmission lines and hydraulic couplings, these compounds achieve 70–80 Shore A hardness with compression set values under 20%. NBR is susceptible to ozone degradation and swelling in phosphate esters, requiring protective additives in demanding environments. Cost efficiency makes it ideal for high-volume OEM production where thermal demands are moderate.

Silicone Rubber (VMQ)

Silicone excels in extreme-temperature scenarios requiring flexibility from -60°C to 230°C. Our platinum-cured VMQ formulations resist brake fluids, coolants, and steam without significant hardening or cracking. Preferred for EV battery cooling circuits and under-hood sensors, silicone maintains seal force across thermal cycles with hardness stability (65–80 Shore A). However, its lower tensile strength and permeability to hydrocarbons necessitate design adjustments for high-pressure fuel systems. Compression set resistance is critical; our compounds achieve <25% per ISO 3384.

Material Performance Comparison

| Material | Temperature Range (°C) | Key Fluid Resistances | Typical Hardness (Shore A) | Primary Applications |

|---|---|---|---|---|

| Viton (FKM) | -20 to 250 | Engine oils, biofuels, acids, aromatics | 75 ± 5 | Turbochargers, EGR valves, fuel rails |

| Nitrile (NBR) | -40 to 120 | Petroleum oils, aliphatic hydrocarbons | 70–80 | Transmissions, hydraulic lines |

| Silicone (VMQ) | -60 to 230 | Coolants, brake fluids, steam | 65–80 | EV thermal management, sensors |

Suzhou Baoshida’s OEM engineering team validates all compounds through dynamic seal testing per SAE J2208 and fluid immersion protocols. Material recommendations are application-specific—Viton for high-temperature fuel exposure, NBR for cost-driven oil systems, and Silicone for wide-temperature coolant circuits. Consult our technical dossier for compound-specific ASTM test reports and processing guidelines.

Manufacturing Capabilities

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber solutions, delivering precision-engineered components tailored to the exacting demands of global OEMs. Within our Engineering Capability division, we maintain a dedicated team of five certified mould engineers and two specialized rubber formulation engineers. This integrated technical team enables us to control every phase of product development—from concept and material selection to tooling design and final production validation—ensuring optimal performance, durability, and cost-efficiency for each component we manufacture.

Our mould engineers bring over 60 combined years of experience in precision rubber and elastomer tooling, with expertise in multi-cavity, cold runner, and transfer mould systems. They utilize advanced CAD/CAM software, including SolidWorks and AutoCAD, to develop high-tolerance steel and aluminum tooling suited for both prototyping and high-volume production. Each mould design undergoes rigorous simulation for flow dynamics, thermal distribution, and part ejection to minimize defects and maximize tool life. This proactive engineering approach reduces time-to-market and ensures consistent dimensional accuracy, especially critical for safety-sensitive applications such as pinch weld adapters used in automotive sealing systems.

Complementing our tooling expertise, our two in-house rubber formula engineers specialize in custom elastomer development. They formulate compounds based on NBR, EPDM, silicone, and FKM to meet specific requirements for temperature resistance, compression set, chemical exposure, and mechanical strength. For pinch weld adapters, which must endure dynamic stress, environmental aging, and sealing integrity under compression, our formula team tailors material properties to balance elasticity, resilience, and long-term durability. All formulations are tested in-house using ASTM and ISO-compliant procedures, including tensile strength, hardness (Shore A), and accelerated aging cycles.

Our OEM capabilities are built on a foundation of technical agility and confidentiality. We support co-engineering projects, where our team collaborates directly with client R&D departments to refine designs, optimize manufacturability, and qualify materials per OEM specifications. From initial prototype to full-scale production, we maintain full traceability, process validation (PPAP), and dimensional inspection (GD&T) to meet Tier 1 automotive and industrial equipment standards.

The following table outlines the technical specifications commonly achieved for our pinch weld adapter solutions:

| Parameter | Typical Range / Value | Test Standard |

|---|---|---|

| Hardness (Shore A) | 50–80 | ASTM D2240 |

| Tensile Strength | 8–18 MPa | ASTM D412 |

| Elongation at Break | 200–500% | ASTM D412 |

| Compression Set (70°C, 22h) | ≤25% | ASTM D395 |

| Operating Temperature | -40°C to +150°C (varies by compound) | — |

| Material Types | EPDM, NBR, FKM, Silicone | — |

| Mould Tolerance | ±0.05 mm | ISO 2768 |

Through the synergy of advanced tooling design and scientific rubber formulation, Suzhou Baoshida delivers engineered reliability in every component, reinforcing our role as a trusted OEM partner in the global industrial supply chain.

Customization Process

Customization Process for Pinch Weld Adapters: Precision Engineering from Concept to Volume

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization pathway for industrial rubber pinch weld adapters, ensuring seamless integration into demanding automotive assembly lines. This process transcends standard manufacturing, embedding material science and dimensional precision at every phase to meet exacting OEM specifications and operational requirements. Our methodology guarantees adapters deliver critical sealing, alignment, and structural support during vehicle body-in-white construction.

The process initiates with comprehensive Drawing Analysis. Our engineering team conducts a meticulous dimensional and geometric review of the client-provided CAD model or technical drawing against the target vehicle platform’s pinch weld flange specifications. We validate critical parameters including flange width tolerance, curvature radius, chamfer angles, and positional datums. Simultaneously, we assess the operational environment – exposure to welding spatter, hydraulic pressure during clamping, ambient temperature fluctuations, and required service life. This phase identifies potential stress concentrations and defines the precise material performance envelope necessary for the application, forming the non-negotiable foundation for subsequent development.

Leveraging the insights from drawing analysis, our Rubber Formula Engineering team advances to Formulation Development. This stage involves the strategic design of a custom elastomeric compound. We select the optimal base polymer (typically EPDM or specialty nitrile variants for heat and oil resistance) and meticulously engineer the additive package. Key considerations include achieving the exact Shore A hardness for controlled deformation under clamping force, optimizing tensile strength and elongation to withstand repeated flexing without fracture, and minimizing compression set to ensure long-term sealing integrity. Cure kinetics are precisely tuned to match production cycle times, while fillers and stabilizers are dosed to enhance abrasion resistance against metal flanges and thermal stability near welding operations. Every formulation is computationally modeled before lab-scale mixing.

Prototyping transforms the validated formula into physical reality. Using precision CNC-machined molds reflecting the final geometry, we produce initial adapter batches under controlled vulcanization conditions. These prototypes undergo stringent in-house testing: dimensional verification via CMM against the original drawing, compression stress relaxation (CSR) testing at elevated temperatures simulating production line dwell times, and dynamic fatigue testing replicating thousands of clamping cycles. Performance data is rigorously compared against the target specifications. Any deviations trigger immediate compound or process refinement, ensuring only adapters meeting all functional criteria proceed to validation with the client on actual production equipment.

Upon successful prototype validation, Mass Production commences under Suzhou Baoshida’s certified quality management system. Production utilizes dedicated, temperature-controlled molding cells with real-time monitoring of critical parameters (temperature, pressure, cure time). Statistical Process Control (SPC) is implemented for every batch, with routine sampling for hardness, tensile properties, and dimensional checks per AQL standards. Full traceability from raw material batch to finished adapter is maintained. Our OEM management team ensures seamless coordination, providing clients with detailed material certifications, production reports, and proactive communication, guaranteeing consistent delivery of pinch weld adapters that uphold the highest standards of automotive manufacturing reliability.

Key Material Performance Specifications for Pinch Weld Adapters

| Property | Typical Target Range | Test Standard | Critical Function |

|---|---|---|---|

| Hardness (Shore A) | 65 ± 5 | ASTM D2240 | Controlled deformation under clamping force |

| Tensile Strength | ≥ 12 MPa | ASTM D412 | Resistance to tearing during installation |

| Elongation at Break | ≥ 300% | ASTM D412 | Accommodates flange irregularities |

| Compression Set (22h, 100°C) | ≤ 25% | ASTM D395 | Long-term sealing force retention |

| Temperature Range | -40°C to +150°C (continuous) | Material Specific | Stability near welding operations |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Tooling Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering high-performance industrial rubber solutions tailored to the exacting demands of modern manufacturing. As a trusted partner in the rubber processing and automotive tooling sectors, we provide engineered components that ensure reliability, durability, and precision in every application. Our expertise extends to the design and supply of specialized tooling systems, including the advanced pinch weld adapter – a critical component in tire bead seating, rim protection, and safe tire mounting operations.

The pinch weld adapter is engineered to interface seamlessly with tire changers and mounting systems, protecting the pinch weld area of modern vehicle rims during servicing. This prevents costly damage to structural welds on multi-piece wheels and ensures compliance with OEM safety standards. Our adapters are manufactured using high-grade reinforced rubber compounds, optimized for resistance to abrasion, compression set, and environmental degradation. Each unit undergoes rigorous quality control to meet dimensional tolerances and performance benchmarks required by automotive service centers, OEMs, and industrial maintenance facilities.

We understand that every client has unique operational requirements. Whether you are integrating pinch weld adapters into an automated tire handling line or sourcing replacement tooling for service bays, our engineering team collaborates closely with clients to deliver customized solutions. From material selection and durometer profiling to geometric adaptation for non-standard rim configurations, Suzhou Baoshida provides end-to-end technical support.

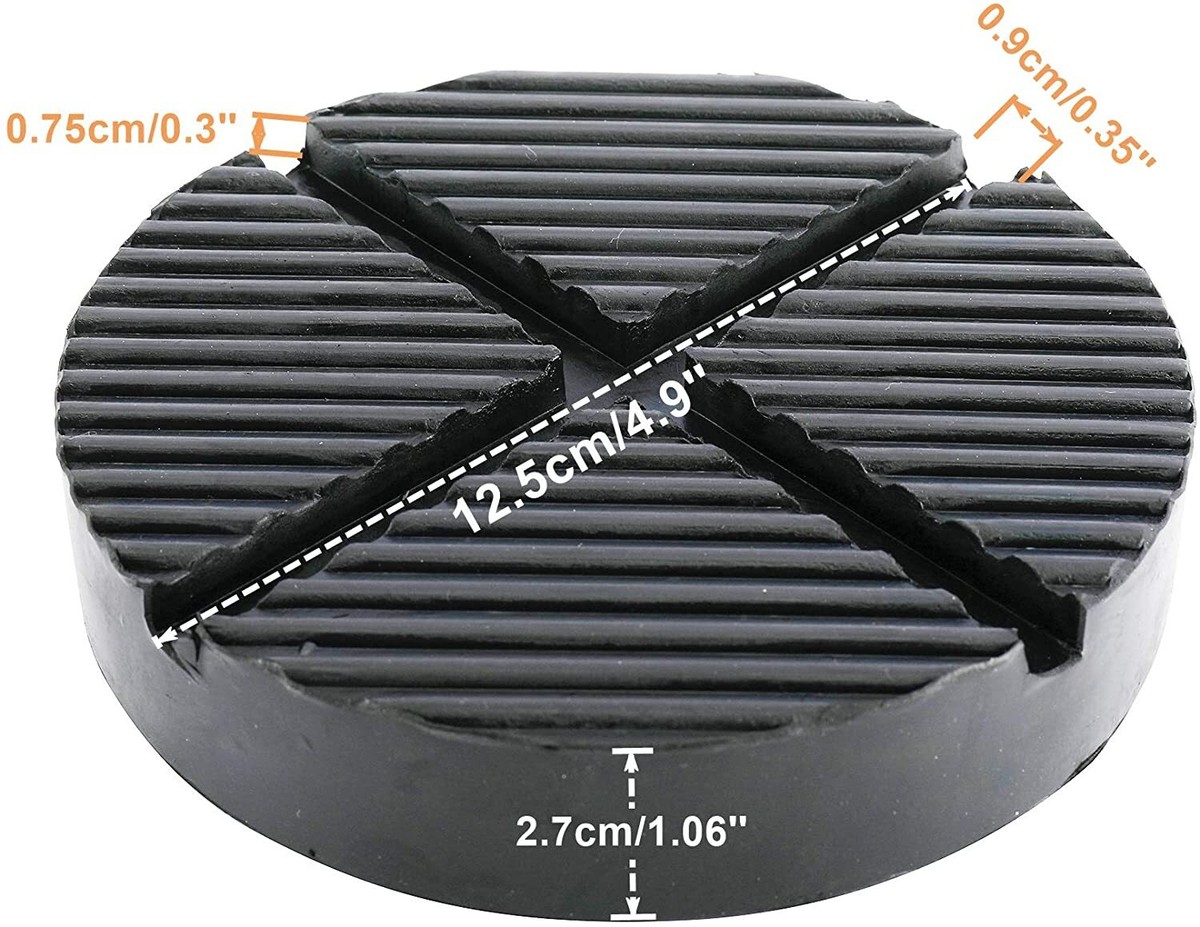

Below are the standard technical specifications for our most widely deployed pinch weld adapter model:

| Parameter | Specification |

|---|---|

| Material | High-strength NBR/EPDM composite |

| Hardness (Shore A) | 70 ± 5 |

| Operating Temperature Range | -30°C to +120°C |

| Tensile Strength | ≥15 MPa |

| Elongation at Break | ≥300% |

| Compression Set (24h @ 70°C) | ≤20% |

| Outer Diameter | 45 mm (customizable: 38–60 mm) |

| Inner Bore Diameter | 12 mm (adaptable for standard tool shafts) |

| Height | 22 mm (tolerance: ±0.5 mm) |

| Color | Black with red identification ring |

For volume procurement, technical integration, or custom formulation requests, we invite you to contact Mr. Boyce, our dedicated OEM and technical sales manager. With over 15 years of experience in rubber tooling systems, Mr. Boyce provides consultative support to manufacturers and distributors worldwide. He is available to discuss application-specific challenges, product testing protocols, and scalable supply chain solutions.

Reach out today via email at [email protected] to request samples, technical data sheets, or a personalized quotation. At Suzhou Baoshida Trading Co., Ltd., we are committed to advancing industrial efficiency through precision rubber engineering – let us be your strategic partner in tooling innovation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).