Technical Contents

Engineering Guide: Central Sales Company

Engineering Insight: The Critical Role of Material Selection in Industrial Rubber Applications

In the domain of industrial rubber solutions, material selection is not merely a technical consideration—it is the foundation of performance, longevity, and system reliability. At Suzhou Baoshida Trading Co., Ltd., we operate as a central sales company with deep engineering integration, enabling us to bridge the gap between OEM requirements and material science. This positioning allows us to move beyond off-the-shelf rubber components, which frequently fail under real-world operational stresses due to mismatched material properties.

Generic rubber parts, often sourced for cost efficiency, are typically formulated for broad compatibility rather than specific environmental conditions. They lack the precision engineering required to withstand variables such as extreme temperatures, aggressive chemical exposure, dynamic mechanical loads, or prolonged compression. As a result, premature degradation—manifesting as cracking, swelling, hardening, or loss of sealing integrity—becomes inevitable. These failures lead to unplanned downtime, increased maintenance costs, and potential safety hazards.

The root cause lies in the absence of application-specific formulation. Industrial environments demand elastomers engineered at the molecular level. For example, a seal operating in an oil refinery must resist non-polar hydrocarbons, while a component in a wastewater treatment facility requires resilience against ozone, UV radiation, and biological agents. Each scenario calls for a tailored polymer matrix, optimized cure system, and reinforcing filler package.

At Baoshida, our engineering team collaborates directly with OEMs to analyze operational parameters, including temperature range, media exposure, pressure cycles, and mechanical stress profiles. This data informs the selection of base polymers such as NBR, EPDM, FKM, Silicone, or specialty compounds like HNBR or ACM. We then validate material performance through accelerated aging tests, compression set analysis, and fluid immersion studies—ensuring that the final product meets or exceeds field requirements.

Below is a comparison of common industrial elastomers and their key performance characteristics:

| Material | Temperature Range (°C) | Fluid Resistance | Compression Set | Typical Applications |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 (+120 short-term) | Excellent for oils, fuels | Good | Hydraulic seals, O-rings, gaskets |

| EPDM | -50 to +150 | Resistant to water, steam, ozone | Very Good | Cooling systems, outdoor seals |

| FKM (Viton®) | -20 to +200 (+250 short-term) | Outstanding for hydrocarbons, acids | Excellent | Aerospace, chemical processing |

| Silicone | -60 to +200 | Limited fluid resistance | Good | High-temp insulation, medical devices |

| HNBR | -40 to +150 | Superior to NBR in oils and heat | Excellent | Automotive timing belts, oilfield equipment |

The data underscores why a one-size-fits-all approach fails. Selecting the correct elastomer requires not only understanding chemical compatibility but also evaluating long-term mechanical behavior under cyclic loads.

As a central sales company with engineering authority, Suzhou Baoshida ensures that every rubber solution is validated for its intended service environment. We do not supply commodities—we deliver engineered performance. This commitment to material precision is what differentiates reliable industrial systems from those prone to failure.

Material Specifications

Material Specifications: Critical Selection Criteria for Industrial Sealing Applications

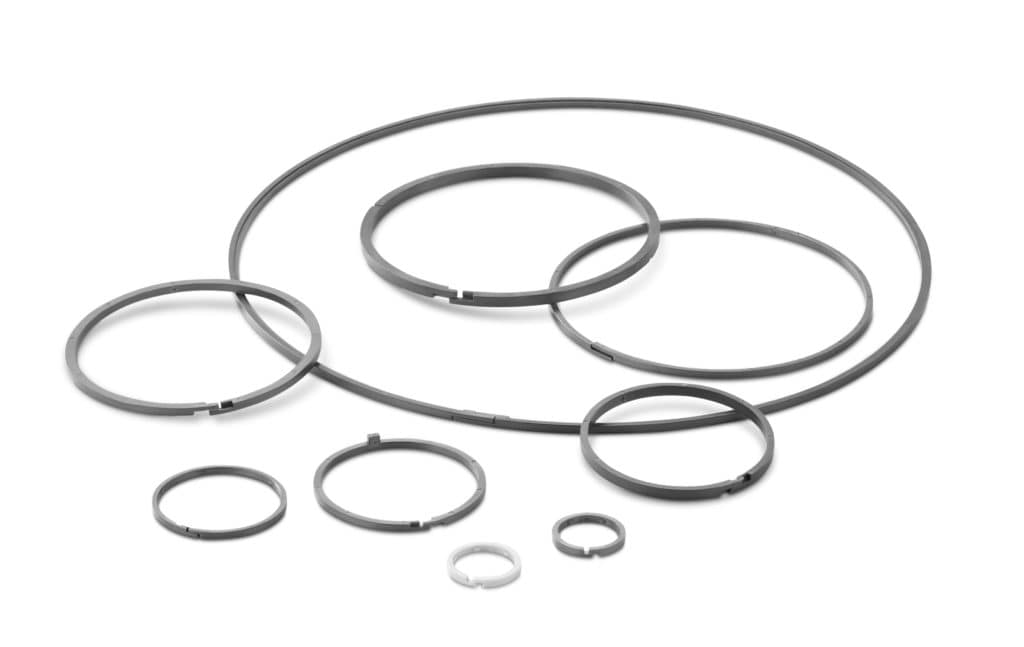

Precise elastomer selection directly impacts operational reliability in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., we prioritize material compatibility with fluid exposure, temperature extremes, and mechanical stress to prevent premature seal failure. Misalignment between application parameters and polymer properties remains a leading cause of system downtime. Our technical team rigorously validates each compound against OEM specifications, ensuring compliance with ASTM D2000 and ISO 3601 standards. Below we detail three foundational materials for hydraulic, pneumatic, and fluid handling systems.

Viton fluoroelastomers (FKM) deliver superior performance in aggressive chemical environments. With continuous service capability from -20°C to 230°C and short-term excursions to 300°C, Viton resists degradation from aromatic hydrocarbons, acids, and jet fuels. Its molecular structure provides exceptional resistance to oxygen and ozone, making it ideal for aerospace fuel systems and chemical processing seals. However, Viton exhibits limited flexibility at sub-zero temperatures and higher material costs compared to alternatives. Our custom formulations optimize compression set resistance for dynamic applications requiring long-term sealing integrity under thermal cycling.

Nitrile rubber (NBR) remains the industry standard for petroleum-based fluid exposure due to its cost-effectiveness and robust mechanical properties. Standard grades operate effectively between -40°C and 120°C, with hydrogenated variants (HNBR) extending upper limits to 150°C. NBR demonstrates excellent resistance to aliphatic hydrocarbons, lubricants, and water, commonly used in automotive fuel injectors and hydraulic O-rings. Key limitations include vulnerability to ozone cracking and reduced performance with polar solvents like acetone. Our precision-compounded NBR formulations achieve Shore A hardness from 50 to 90 to balance extrusion resistance with sealing force requirements.

Silicone rubber (VMQ) excels in extreme temperature applications requiring consistent flexibility. Its operational range spans -60°C to 200°C, with specialized grades functioning at 230°C. Silicone maintains elasticity in cryogenic conditions and resists UV degradation, making it suitable for medical device seals and food-grade gaskets. However, it possesses lower tensile strength and poor resistance to hydrocarbons and steam. Our platinum-cured silicone compounds meet USP Class VI and FDA 21 CFR 177.2600 requirements for biocompatibility while minimizing extractables.

The following table provides critical comparative specifications for informed material selection:

| Material | Temperature Range (°C) | Tensile Strength (MPa) | Elongation at Break (%) | Key Chemical Resistances | Primary Industrial Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 230 | 10–18 | 150–300 | Aromatic hydrocarbons, acids, jet fuels, ozone | Aerospace fuel systems, chemical pump seals, semiconductor manufacturing |

| Nitrile (NBR) | -40 to 120 | 15–25 | 200–500 | Petroleum oils, aliphatic hydrocarbons, water | Automotive fuel systems, hydraulic accumulators, industrial hoses |

| Silicone (VMQ) | -60 to 200 | 5–10 | 300–700 | Water, alcohols, oxidizing agents, UV | Medical tubing, food processing gaskets, electronic encapsulation |

Material selection requires holistic analysis of chemical exposure profiles, thermal cycles, and mechanical loads. Suzhou Baoshida Trading Co., Ltd. provides application-specific compound recommendations backed by accelerated aging tests and OEM validation protocols. Contact our engineering team for custom formulation support to optimize seal lifecycle performance in your critical systems.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, enabling us to deliver precision, reliability, and innovation tailored to the complex demands of global OEMs. Our in-house engineering team comprises five dedicated mould engineers and two specialized rubber formulation engineers, all operating within a tightly integrated development workflow. This multidisciplinary structure allows us to control every phase of product realization—from concept and material design to tooling and final validation—ensuring alignment with both technical specifications and production scalability.

Our mould engineers bring extensive experience in designing precision rubber compression, transfer, and injection moulds. Utilizing advanced CAD/CAM software such as AutoCAD, SolidWorks, and UG NX, they develop robust tooling solutions optimized for cycle efficiency, part consistency, and longevity. Each mould design undergoes rigorous simulation analysis for flow, shrinkage, and ejection dynamics, minimizing trial iterations and accelerating time-to-market. We specialize in multi-cavity and family moulds for high-volume production, with tight tolerances maintained to ±0.05 mm, meeting the exacting standards of automotive, industrial machinery, and fluid handling sectors.

Complementing our tooling expertise, our two rubber formula engineers focus on material science innovation, formulating custom elastomer compounds to meet specific performance criteria. With access to a fully equipped laboratory for rheological, mechanical, and environmental testing, they develop formulations in NBR, EPDM, FKM, silicone, and specialty blends. Each compound is engineered for targeted properties such as oil resistance, high-temperature stability, compression set resistance, or low-temperature flexibility. All formulations are validated against international standards including ASTM D2000, ISO 3302, and ISO 2230, ensuring repeatability and compliance across production batches.

Our OEM capabilities are built on a foundation of technical collaboration. We work directly with client engineering teams to co-develop solutions, offering Design for Manufacturability (DFM) feedback, rapid prototyping, and full documentation packages including material certifications, PPAP files, and 3D tooling drawings. This collaborative model ensures seamless integration into client supply chains and supports long-term product lifecycle management.

The synergy between our mould and formula engineering teams enables a holistic approach to rubber part development—where material behavior informs tool design, and tooling constraints guide compound optimization. This integrated methodology reduces development risk, enhances product performance, and supports scalable manufacturing for global OEMs requiring consistent, high-integrity rubber components.

Material and Moulding Specifications

| Parameter | Capability Range |

|---|---|

| Mould Tolerance | ±0.05 mm |

| Compound Types | NBR, EPDM, FKM, Silicone, CR, NR, ACM, AEM |

| Hardness Range (Shore A) | 30–90 |

| Temperature Resistance | -60°C to +300°C (depending on compound) |

| Moulding Processes | Compression, Transfer, Injection |

| Standard Compliance | ASTM D2000, ISO 3302, ISO 2230, ROHS, REACH |

| Sample Lead Time | 15–25 days (including compound development) |

| Production Cycle Time | Optimized for high-volume runs (as low as 30s) |

Customization Process

Industrial Rubber Customization Process: Precision Engineering from Concept to Volume Production

At Suzhou Baoshida Trading Co., Ltd., our customization process for industrial rubber components integrates rigorous scientific methodology with OEM manufacturing excellence. This structured workflow ensures dimensional accuracy, material resilience, and seamless scalability for mission-critical applications across automotive, aerospace, and heavy machinery sectors.

Drawing Analysis initiates the engagement, where our engineering team conducts a comprehensive review of client-provided technical schematics. We validate geometric tolerances per ISO 2768-mK standards, assess sealing surface integrity, and identify potential stress concentration zones. Critical attention is given to material compatibility with operational environments—including temperature extremes, chemical exposure, and dynamic loading conditions. Any discrepancies in design feasibility or specification ambiguity are resolved collaboratively with the client prior to formulation development, preventing downstream rework.

Formulation Engineering leverages Suzhou Baoshida’s proprietary material database and accelerated aging protocols. Our rubber chemists select base polymers, curatives, fillers, and additives to achieve target performance metrics. Key parameters are optimized through iterative lab-scale compounding, with real-time adjustments based on Mooney viscosity, scorch time, and cure kinetics data. The table below illustrates typical specification ranges for common elastomer systems:

| Material Type | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Temperature Range (°C) |

|---|---|---|---|---|

| NBR | 50–90 | 15–25 | 200–400 | -30 to +120 |

| EPDM | 40–80 | 10–20 | 250–450 | -50 to +150 |

| FKM | 60–85 | 12–18 | 150–250 | -20 to +250 |

Prototyping employs precision molding techniques—compression, transfer, or injection—using client-approved tooling. Each prototype undergoes stringent validation: dimensional verification via CMM (Coordinate Measuring Machine), compression set testing per ASTM D395, and fluid resistance evaluation in simulated service conditions. Performance data is benchmarked against the initial technical requirements, with formal sign-off required before progression to volume manufacturing.

Mass Production commences only after prototype validation, utilizing fully documented process control plans. All batches are traceable to raw material lot numbers, with in-process checks at 30-minute intervals for cure state (via rheometry) and surface defects. Final inspection includes 100% visual screening and statistical sampling for physical properties. Suzhou Baoshida maintains ISO 9001-certified production lines with integrated SPC (Statistical Process Control) to ensure batch-to-batch consistency, delivering OEM-grade reliability at scale.

This end-to-end methodology minimizes time-to-market while guaranteeing that every component meets the uncompromising performance standards demanded by industrial applications. Our commitment to scientific rigor at each phase transforms conceptual requirements into durable, high-precision rubber solutions.

Contact Engineering Team

Contact Suzhou Baoshida for Advanced Industrial Rubber Solutions

Suzhou Baoshida Trading Co., Ltd. stands at the forefront of industrial rubber formulation and OEM manufacturing, delivering precision-engineered elastomeric components tailored to the stringent demands of global industrial sectors. As a central sales company representing advanced rubber technologies, we specialize in custom compound development, high-performance sealing solutions, and durable rubber-to-metal bonded systems. Our engineering team applies scientific rigor to every formulation, ensuring compliance with international standards including ASTM, ISO, and OEM-specific material specifications.

For technical collaboration, product inquiries, or sourcing support, Mr. Boyce serves as the primary technical liaison between our manufacturing partners and international clients. With over 15 years of experience in rubber chemistry and industrial supply chain management, Mr. Boyce provides expert guidance on material selection, performance optimization, and scalable production strategies. Whether you require low-volume specialty compounds or high-volume molded components, our team ensures seamless integration of technical requirements with cost-efficient manufacturing.

To initiate a technical consultation or request a material data sheet, contact Mr. Boyce directly at [email protected]. Include detailed application parameters such as operating temperature range, media exposure, mechanical loading, and environmental conditions to facilitate rapid compound evaluation and proposal development. Our responsive engineering support enables clients to accelerate prototyping cycles and reduce time-to-market for critical sealing and damping applications.

Suzhou Baoshida maintains strict quality control protocols across our partner production facilities, with full traceability, batch testing, and third-party certification capabilities. We support industries including automotive powertrain systems, rail transit damping components, semiconductor manufacturing equipment, and heavy industrial hydraulics. All formulations are developed using controlled polymer bases such as NBR, EPDM, FKM, VMQ, and specialty hydrogenated nitrile (HNBR), with reinforcement via carbon black, silica, or PTFE encapsulation where required.

The following table outlines key technical capabilities and material performance ranges available through our manufacturing network:

| Property | Range / Specification |

|---|---|

| Hardness (Shore A) | 30–90 ±5 |

| Operating Temperature | -60°C to +300°C (depending on compound) |

| Tensile Strength | Up to 30 MPa |

| Elongation at Break | 200% – 600% |

| Compression Set (24h, 70°C) | ≤20% (ASTM D395) |

| Fluid Resistance | Customizable for oils, fuels, water, steam, acids |

| Certifications | ISO 9001, IATF 16949, RoHS, REACH |

Partner with Suzhou Baoshida to leverage data-driven rubber formulation and precision manufacturing. Initiate your project with a technical discussion by contacting Mr. Boyce at [email protected].

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).