Technical Contents

Engineering Guide: Jar Gasket Sizes

Engineering Insight: The Critical Role of Material Selection in Jar Gasket Sizing

In precision rubber sealing applications, jar gasket sizes are not merely dimensional references—they represent a complex interplay between geometry, compression behavior, and material properties. At Suzhou Baoshida Trading Co., Ltd., we emphasize that off-the-shelf gasket solutions frequently fail not due to incorrect sizing per se, but due to inappropriate material selection for the operational environment. Standard gaskets, often manufactured from generic elastomers like low-grade NBR or unmodified silicone, lack the chemical resistance, thermal stability, or compression set performance required in industrial, food-grade, or pharmaceutical applications.

Material selection directly influences sealing integrity under dynamic conditions such as thermal cycling, pressure fluctuations, and exposure to aggressive media. For instance, a gasket sized correctly for a 70 mm jar opening may still leak if fabricated from a rubber compound that swells upon contact with organic solvents or degrades under repeated autoclaving. This mismatch leads to premature failure, contamination risks, and costly downtime—issues commonly misattributed to dimensional inaccuracies.

The compression set value of a rubber compound is particularly critical in jar gasket performance. A low compression set ensures the gasket regains its shape after sealing pressure is released, maintaining long-term resilience. Materials such as fluorocarbon (FKM), EPDM, or high-purity platinum-cured silicone exhibit superior recovery characteristics compared to standard rubber blends. Furthermore, FDA-compliant formulations are essential in food and pharmaceutical packaging, where extractables and leachables must be minimized.

Another overlooked factor is durometer (hardness). While a softer rubber (50–60 Shore A) may provide excellent initial sealing force, it can deform excessively under sustained load, leading to extrusion or stress relaxation. Conversely, harder compounds (70–80 Shore A) offer better structural support but may require higher closure torque, increasing the risk of jar damage. The optimal durometer depends on the closure mechanism, internal pressure, and service temperature.

Custom-engineered gaskets account for these variables through material-specific design adjustments. For example, a gasket intended for high-temperature retort processing will require a different cross-sectional profile than one used in ambient storage, even if both serve the same jar size. Off-the-shelf gaskets, constrained by mass production, cannot accommodate such nuances.

The following table outlines key material properties for common jar gasket elastomers:

| Material | Temperature Range (°C) | Durometer Range (Shore A) | Compression Set (%), 22 hrs @ 150°C | Key Applications |

|---|---|---|---|---|

| NBR (Nitrile) | -30 to +100 | 60–75 | 25–35 | Oil-resistant closures, industrial jars |

| EPDM | -50 to +150 | 55–70 | 15–25 | Steam sterilization, hot-fill containers |

| FKM (Viton®) | -20 to +200 | 70–80 | 10–20 | High-temperature, chemical-resistant sealing |

| Silicone (VMQ) | -60 to +200 | 40–80 | 15–30 | Food, pharmaceutical, biocompatible packaging |

At Suzhou Baoshida, we advocate for application-specific gasket engineering—where size, material, and performance are co-optimized. Standard gaskets may fit, but only a scientifically selected compound ensures lasting, leak-free performance.

Material Specifications

Material Specifications for Precision Jar Gasket Applications

Material selection is a critical engineering decision directly impacting the functional integrity, service life, and regulatory compliance of jar gaskets in industrial sealing applications. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber seals utilizing advanced polymer formulations meeting stringent OEM performance requirements. The three primary elastomers employed for jar gaskets—Viton (FKM), Nitrile (NBR), and Silicone (VMQ)—exhibit distinct chemical, thermal, and mechanical properties necessitating careful evaluation against the specific media, temperature profile, and operational demands of the end-use environment. Selecting the optimal material prevents seal failure, contamination, and costly production downtime.

Viton fluoroelastomers represent the premium solution for applications involving aggressive chemicals, high temperatures, and stringent purity requirements. Formulated with high fluorine content, Viton gaskets demonstrate exceptional resistance to oils, fuels, acids, bases, and ozone across an extended continuous service range. This material maintains seal integrity in demanding food, beverage, and pharmaceutical processing where exposure to cleaning agents like sodium hydroxide or steam sterilization cycles is routine. Its inherent low gas permeability and high thermal stability make it indispensable for critical sealing tasks, though it commands a higher cost basis compared to standard elastomers.

Nitrile rubber, specifically hydrogenated nitrile (HNBR) for enhanced performance, offers an optimal balance of oil resistance, mechanical strength, and cost-effectiveness for general-purpose jar gasket applications. Standard NBR formulations provide robust resistance to aliphatic hydrocarbons, vegetable oils, and water, performing reliably within moderate temperature constraints. HNBR variants significantly improve heat resistance, ozone stability, and mechanical durability over standard NBR, extending service life in applications encountering intermittent higher temperatures or more aggressive organic media. Nitrile remains the most economically viable solution for non-extreme sealing environments common in food packaging and industrial liquid containment.

Silicone rubber excels in applications demanding extreme temperature flexibility and biocompatibility. Its unique polymer structure enables continuous operation from cryogenic temperatures up to +230°C, with short-term excursions beyond +300°C possible in specific grades. Silicone exhibits excellent resistance to water, steam, ozone, and UV radiation, coupled with very low toxicity and compliance with FDA 21 CFR 177.2600 and EU 10/2011 for direct food contact. While possessing lower tensile strength and abrasion resistance than Viton or NBR, silicone is the unequivocal choice for aseptic processing, high-temperature canning, and applications requiring wide thermal cycling without permanent set.

The following comparative table details essential material specifications per relevant ASTM and ISO test standards for precision engineering evaluation:

| Material | Temperature Range (°C) | Key Properties | Typical Jar Gasket Applications |

|---|---|---|---|

| Viton (FKM) | -20 to +230 | Exceptional chemical resistance (acids, bases, fuels, oils), low gas permeability, high thermal stability, excellent ozone resistance | High-purity food processing, chemical reagent containers, pharmaceutical packaging, aggressive media storage |

| Nitrile (NBR/HNBR) | -40 to +120 (NBR) / -40 to +150 (HNBR) | Excellent oil/fuel resistance, good abrasion resistance, moderate cost, good mechanical strength | Vegetable oil containers, beverage jars, general industrial liquid storage, cost-sensitive food packaging |

| Silicone (VMQ) | -60 to +230 | Outstanding high/low temperature flexibility, excellent biocompatibility (FDA/EU compliant), high gas permeability, good ozone/UV resistance | Baby food jars, medical/pharmaceutical containers, high-temperature canning, aseptic packaging, cryogenic storage |

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering division is built on a foundation of precision, material science, and deep manufacturing expertise. With a dedicated team of five certified mould engineers and two specialized rubber formulation engineers, we ensure every jar gasket produced meets exacting industrial standards for performance, durability, and dimensional accuracy. Our engineers work in close collaboration across disciplines to optimize both the physical design of sealing components and the chemical composition of rubber compounds, enabling us to deliver fully integrated OEM solutions tailored to client specifications.

Our mould engineering team leverages advanced CAD/CAM software and finite element analysis (FEA) to design and validate gasket tooling before production. This ensures optimal flow dynamics, minimal flash, and consistent part geometry across high-volume runs. Each design undergoes rigorous simulation for compression set, sealing pressure, and thermal stability, particularly critical in food, pharmaceutical, and chemical packaging applications where jar gaskets must maintain integrity under varying environmental conditions.

Complementing our tooling expertise is our proprietary rubber formulation capability. Our two in-house formula engineers specialize in developing custom elastomer compounds based on NBR, EPDM, silicone, and FDA-compliant materials. These formulations are engineered to deliver targeted performance attributes such as oil resistance, ozone stability, low-temperature flexibility, and long-term compression recovery. Every compound is batch-tested for hardness, tensile strength, elongation, and aging characteristics to ensure consistency and compliance with international standards including ISO 3302 and ASTM D2000.

We operate a fully integrated development cycle from concept to mass production, enabling fast turnaround for OEM clients. Our facility supports rapid prototyping, DFM analysis, and first-article inspection reports (FAIR), ensuring seamless scale-up from pilot runs to full automation. With ISO 9001-certified processes and in-line QC monitoring, we maintain tight tolerances and traceability across every production batch.

The following table outlines standard technical specifications for our precision jar gasket offerings:

| Parameter | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 40–80 ±5 | ASTM D2240 |

| Tensile Strength | ≥7 MPa | ASTM D412 |

| Elongation at Break | ≥200% | ASTM D412 |

| Compression Set (24h, 70°C) | ≤20% | ASTM D395 |

| Operating Temperature | -40°C to +150°C (varies by compound) | Material Specific |

| Dimensional Tolerance | ±0.1 mm to ±0.3 mm (based on size) | ISO 3302 |

| FDA Compliance Available | Yes (for silicone and specific EPDM) | FDA 21 CFR 177.2600 |

Our engineering-driven approach ensures that every jar gasket is not only dimensionally precise but also chemically and mechanically optimized for its intended application. This capability positions Suzhou Baoshida as a trusted OEM partner in the global packaging and sealing industry.

Customization Process

Customization Process for Precision Jar Gasket Manufacturing

Suzhou Baoshida Trading Co., Ltd. implements a rigorous four-phase customization protocol for jar gasket production, ensuring dimensional accuracy, material integrity, and regulatory compliance for global OEM clients. This methodology mitigates sealing failure risks inherent in food preservation, pharmaceutical, and chemical packaging applications where gasket performance directly impacts product shelf life and safety.

Drawing Analysis Protocol

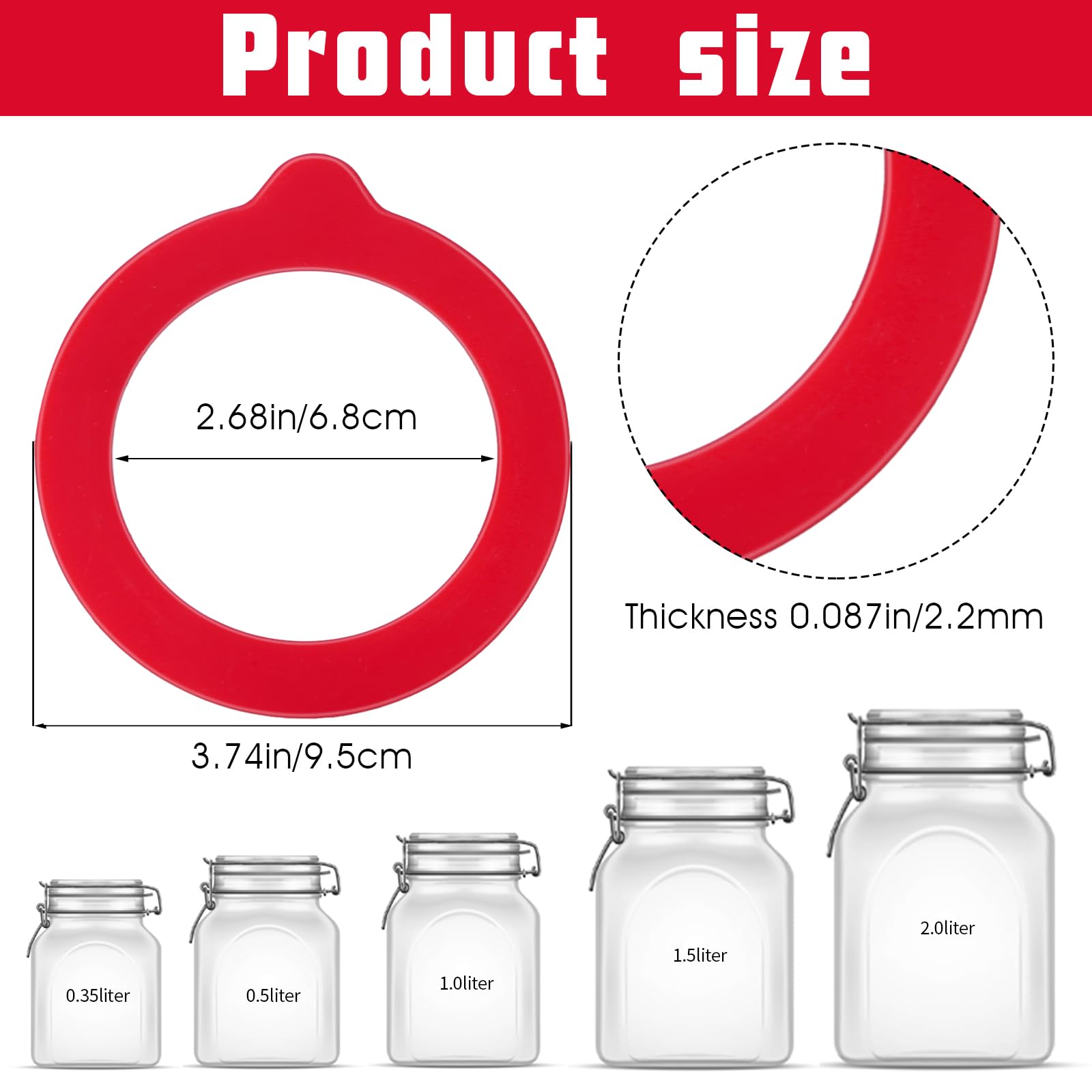

Initial engagement requires client-provided technical drawings conforming to ISO 10609-2 standards. Our engineering team conducts comprehensive geometric dimensioning and tolerancing (GD&T) validation, focusing on critical features: inner/outer diameter tolerances (±0.05 mm), cross-section consistency (±0.03 mm), and sealing surface flatness (Ra ≤ 0.8 µm). Finite element analysis (FEA) simulates compression set behavior under lid torque specifications (typically 0.8–1.2 N·m for 70mm jars). Deviations from ASME Y14.5 standards trigger collaborative redesign sessions to optimize cavity fill and prevent flash formation during molding.

Material Formulation Engineering

Based on application requirements, we select base polymers and compound formulations meeting FDA 21 CFR 177.2600 or EU 10/2011 for food contact. Key variables include temperature exposure, chemical resistance, and compression set targets. Our proprietary rubber blends undergo iterative optimization in controlled laboratory environments, adjusting filler ratios (e.g., silica for tensile strength), plasticizers (low-migration types), and curing systems to achieve target Shore A hardness within ±3 points. Accelerated aging tests per ASTM D573 validate long-term performance before prototyping.

Prototyping and Validation

Precision-machined aluminum molds produce 50–100 prototype gaskets for functional testing. Each batch undergoes:

Compression set measurement (ASTM D395 Method B, 22h @ 70°C) targeting <25%

Leak testing under 0.5 bar differential pressure for 72 hours

Torque-to-seal verification using calibrated lid applicators

Dimensional re-inspection via coordinate measuring machine (CMM)

Client approval requires documented evidence of zero leakage and dimensional conformance across three consecutive prototype batches.

Controlled Mass Production

Approved formulations transition to automated production lines with real-time statistical process control (SPC). Key parameters monitored include:

Mold temperature stability (±1.5°C)

Cure time consistency (±0.5s)

Post-cure oven profiles (160°C ±5°C for 4h)

Every production lot undergoes 100% visual inspection and random sampling for hardness, dimensions, and odor (per ISO 16000-6). Traceability is maintained via laser-etched lot codes linking raw material certificates (including peroxide cure agents) to final test reports. Typical lead time from approved prototype to shipment is 14–21 days.

Critical Material Specifications for Jar Gaskets

| Material Type | Hardness Range (Shore A) | Temp Range (°C) | Compression Set (22h @ 70°C) | Key Applications |

|---|---|---|---|---|

| NBR | 45–70 | -30 to +120 | ≤22% | Vegetable oil, sauces |

| EPDM | 50–75 | -50 to +150 | ≤18% | Acidic foods, dairy |

| FKM | 60–80 | -20 to +200 | ≤15% | High-temperature canning |

This structured approach ensures Suzhou Baoshida delivers jar gaskets with ≤0.1% field failure rates while accommodating client-specific regulatory frameworks and performance thresholds. All processes adhere to IATF 16949 quality management standards for automotive-grade precision adapted to sealing applications.

Contact Engineering Team

For industrial manufacturers and OEMs requiring precision rubber seals, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the development and supply of high-performance jar gasket solutions. Our engineering team specializes in custom formulation and dimensional accuracy, ensuring that every gasket meets rigorous application demands across food packaging, pharmaceuticals, cosmetics, and chemical containment systems. With advanced material testing protocols and strict ISO-compliant manufacturing controls, we deliver consistent sealing performance under variable temperature, pressure, and chemical exposure conditions.

Our expertise extends beyond standard off-the-shelf sizes. We understand that sealing efficiency is directly influenced by compound selection, durometer, compression set resistance, and geometric precision. Whether you are working with glass jars, metal closures, or automated capping lines, Suzhou Baoshida provides tailored gasket solutions engineered for leak-free integrity and long-term durability. We utilize EPDM, silicone, butyl, and FDA-compliant compounds to meet regulatory standards and operational requirements.

To ensure seamless integration into your production process, we maintain a comprehensive reference database of industry-standard jar gasket dimensions and closure types. Below is a representative table of common gasket specifications we support:

| Inner Diameter (mm) | Outer Diameter (mm) | Height (mm) | Material | Hardness (Shore A) | Application Type |

|---|---|---|---|---|---|

| 38.0 | 58.0 | 3.5 | EPDM | 55 | Food Jars |

| 43.0 | 63.0 | 4.0 | Silicone | 60 | Cosmetic Lids |

| 58.0 | 78.0 | 4.5 | Butyl | 50 | Pharmaceutical |

| 63.0 | 83.0 | 5.0 | EPDM | 60 | Industrial |

| 70.0 | 90.0 | 5.5 | Silicone | 55 | High-Temp Use |

All dimensions are tolerance-controlled to ±0.1 mm, with custom profiles available upon request. We support low-volume prototyping and high-volume production runs with rapid tooling turnaround and batch traceability.

For technical collaboration, material data sheets, or custom gasket design support, contact Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd. Direct correspondence ensures prompt engineering feedback, sample fulfillment, and scalable supply chain integration. We respond to all inquiries within 12 business hours and offer virtual technical consultations for global partners.

To initiate a project or request a quote, email Mr. Boyce at [email protected]. Include your application parameters, volume requirements, and preferred material specifications for accelerated processing. Our team is equipped to assist in English, Mandarin, and technical German, facilitating clear communication across international manufacturing teams.

Partner with Suzhou Baoshida for precision rubber seals engineered to perform—where material science meets industrial reliability.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).