Technical Contents

Engineering Guide: Belt Furnace

Engineering Insight: Material Selection in Belt Furnace Applications

In high-temperature industrial environments, the belt furnace stands as a critical processing unit for vulcanization, sintering, and heat treatment of rubber and elastomeric components. While operational parameters such as temperature uniformity, residence time, and conveyor speed are frequently optimized, the material selection for furnace belts and seals is often underestimated. This oversight leads to premature failure, unplanned downtime, and compromised product quality—issues that off-the-shelf rubber components are ill-equipped to resolve.

Standard rubber formulations, typically based on EPDM, Nitrile, or Silicone, are designed for general-purpose use. They lack the tailored resistance required in belt furnace environments where continuous exposure to temperatures exceeding 300°C, oxidative atmospheres, and mechanical stress are routine. Off-the-shelf belts degrade rapidly under these conditions, exhibiting surface cracking, hardening, or softening due to polymer chain breakdown. Additionally, volatile emissions from low-grade materials can contaminate the furnace atmosphere, affecting downstream product integrity—particularly in precision applications such as automotive or aerospace rubber parts.

The failure of generic solutions underscores the necessity for engineered rubber compounds. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science in developing custom formulations that align with specific thermal, chemical, and mechanical demands. Fluorocarbon (FKM), Hydrogenated Nitrile (HNBR), and Perfluoroelastomers (FFKM) are selected based on application severity. Reinforcement with high-tensile fibers such as aramid or fiberglass ensures dimensional stability under prolonged thermal cycling. Surface treatments and anti-adhesive coatings further enhance release properties, minimizing residue buildup on furnace belts.

Equally critical is the compatibility between the rubber belt and the furnace atmosphere. Inert, oxidizing, or reducing environments demand different stabilizers and cross-linking systems. For example, peroxide-cured HNBR offers superior thermal-oxidative resistance compared to sulfur-cured variants, making it ideal for continuous air-circulating furnaces. Similarly, FKM compounds with high fluorine content resist decomposition in halogen-rich atmospheres often found in specialty sintering processes.

Material selection is not a one-size-fits-all proposition. It requires a deep understanding of polymer chemistry, processing dynamics, and failure mechanisms. The cost premium of engineered rubber is offset by extended service life, reduced maintenance, and improved throughput consistency.

Below is a comparison of common elastomers used in belt furnace applications:

| Material | Continuous Use Temp (°C) | Key Advantages | Limitations |

|---|---|---|---|

| EPDM | 150 | Good ozone resistance, low cost | Poor high-temp stability |

| Silicone | 230 | Flexibility at low and high temps | Low tensile strength, prone to tearing |

| Nitrile (NBR) | 120 | Excellent oil resistance | Limited thermal resistance |

| HNBR | 180–200 | High mechanical strength, good ozone resistance | Moderate high-temp performance |

| FKM | 250–300 | Exceptional chemical and heat resistance | Higher cost, harder processing |

| FFKM | 300–327 | Ultimate chemical and thermal resistance | Very high cost, limited availability |

At Suzhou Baoshida, we collaborate with OEMs to transition from reactive replacements to proactive material engineering—ensuring belt furnace systems operate at peak efficiency, reliability, and longevity.

Material Specifications

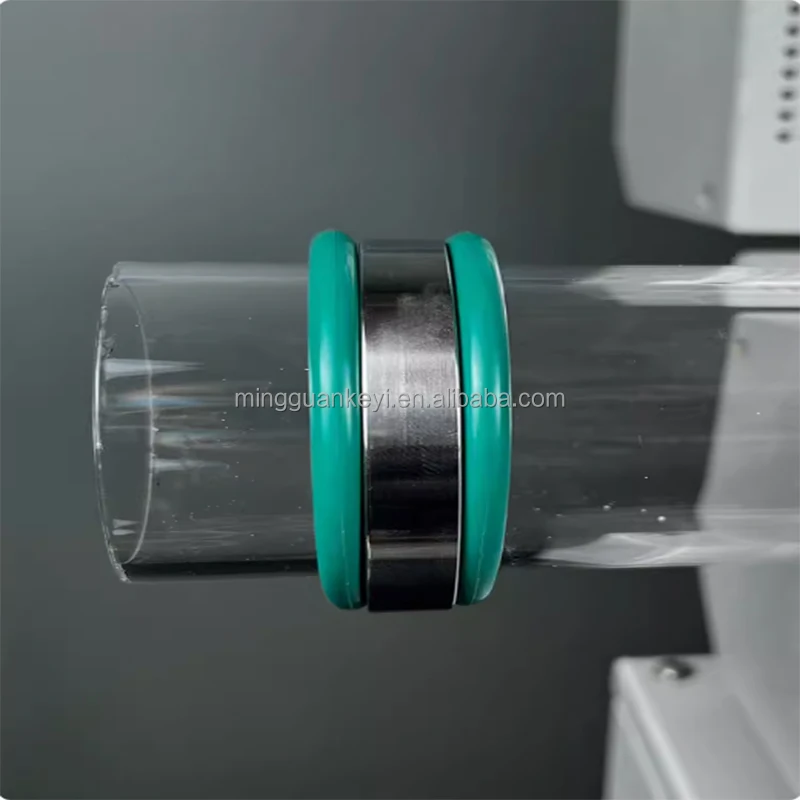

Belt Furnace Sealing Material Specifications: Viton, Nitrile, and Silicone

Selection of elastomeric sealing materials for belt furnace applications demands rigorous evaluation of thermal stability, chemical resistance, and mechanical integrity under continuous operational stress. Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber compounds specifically formulated to withstand the extreme conditions inherent in high-temperature industrial processing. The thermal cycling, exposure to aggressive media, and dynamic sealing requirements of belt furnaces necessitate materials exceeding standard industrial grades. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent the primary polymer families meeting these demands, each with distinct performance boundaries critical to furnace uptime and product yield.

Viton fluorocarbon rubber delivers unparalleled resistance to temperatures up to 230°C continuous service and short-term excursions to 300°C. Its molecular structure provides exceptional stability against oxygen, ozone, and a broad spectrum of chemicals including acids, bases, and hydrocarbon solvents prevalent in sintering and brazing atmospheres. This makes Viton the definitive choice for furnaces processing metal powders or ceramics requiring inert or reducing atmospheres. Nitrile rubber, while limited to 120°C continuous service, offers superior cost-effectiveness and resistance to oils, greases, and aliphatic hydrocarbons. High-acrylonitrile variants (e.g., 48% ACN) enhance fuel and lubricant resistance, positioning NBR as the optimal solution for lower-temperature conveyor sealing where petroleum-based contaminants are present. Silicone rubber provides the widest operational temperature range (-60°C to 200°C continuous), excellent flexibility at cryogenic extremes, and resistance to water vapor and ozone. However, its lower tensile strength and susceptibility to撕裂 under mechanical stress require careful design consideration for high-wear sealing points.

Critical performance parameters for belt furnace elastomers are summarized below. Compression set resistance directly correlates with long-term seal integrity, while tensile strength and elongation indicate resilience against dynamic movement and thermal shock.

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Continuous Temp Range | -20°C to +230°C | -30°C to +120°C | -60°C to +200°C |

| Peak Short-Term Temp | 300°C | 140°C | 230°C |

| Compression Set (22h/150°C) | ≤25% | ≤35% | ≤20% |

| Tensile Strength (MPa) | 12-18 | 15-20 | 6-10 |

| Elongation at Break (%) | 150-300 | 200-400 | 200-600 |

| Key Chemical Resistance | Acids, fuels, solvents | Oils, greases, water | Water vapor, ozone |

| Primary Limitation | Cost, low-temp flexibility | Poor heat/ozone resistance | Low tear strength |

Material degradation in belt furnaces manifests as hardening, cracking, or permanent set, leading to atmosphere leakage and process contamination. Suzhou Baoshida’s OEM engineering team validates all compounds against ASTM D2000 standards, with custom formulations available to address specific furnace atmospheres or temperature profiles. For applications exceeding 200°C or involving halogenated solvents, Viton remains the uncompromised solution. Nitrile is recommended for cost-sensitive, oil-exposed environments below 120°C, while Silicone serves specialized roles requiring extreme low-temperature flexibility or high-purity steam resistance. Partnering with our technical team ensures material selection aligns precisely with your furnace’s operational envelope, maximizing seal life and minimizing unplanned downtime.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the design and manufacturing of high-performance components for advanced thermal processing equipment such as belt furnaces. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, all of whom bring extensive experience in material science, precision tooling, and thermal system integration. This multidisciplinary expertise enables us to deliver OEM solutions that meet the exacting demands of high-temperature, continuous-operation environments.

The mould engineering team focuses on the precision design and optimization of rubber-based sealing and conveying components critical to belt furnace performance. Utilizing advanced CAD/CAM software and finite element analysis (FEA), our engineers ensure dimensional accuracy, thermal stability, and long-term durability under repeated thermal cycling. Each design undergoes rigorous simulation and real-world validation to confirm compatibility with furnace operating parameters, including temperature gradients, belt tension, and chemical exposure.

Complementing this is our rubber formulation expertise. Our two formula engineers specialize in developing custom elastomer compounds tailored to the operational conditions of belt furnaces. By adjusting polymer base selection, filler content, cross-linking systems, and additives, we create materials that resist thermal degradation, maintain elasticity at elevated temperatures, and exhibit low outgassing properties—essential for maintaining clean processing environments in semiconductor, ceramic, and powder metallurgy applications.

Our OEM capabilities are built on a foundation of technical agility and deep customer collaboration. We work directly with equipment manufacturers to co-engineer solutions that integrate seamlessly into existing furnace architectures. Whether modifying existing profiles or developing entirely new components—such as high-temperature belt splices, edge seals, or support pads—our team ensures full compliance with performance, regulatory, and production volume requirements.

This integrated approach—combining precision mould engineering with advanced material science—allows us to deliver rubber components that enhance furnace efficiency, reduce downtime, and extend service life. As a trusted partner in industrial thermal systems, Suzhou Baoshida Trading Co., Ltd. provides not just parts, but engineered performance.

| Specification | Detail |

|---|---|

| Mould Engineers | 5 in-house specialists |

| Formula Engineers | 2 dedicated rubber chemists |

| Design Tools | SolidWorks, AutoCAD, FEA simulation |

| Material Development | Custom EPDM, FKM, silicone, and HNBR formulations |

| OEM Services | Full design-to-production support, prototyping, validation testing |

| Application Focus | Belt furnace seals, conveyor components, high-temp gaskets |

| Temperature Range (Material Tested) | -60°C to +350°C (depending on compound) |

| Lead Time (Prototypes) | 15–25 days from design approval |

| Production Capacity | Scalable for low to high-volume OEM contracts |

Customization Process

Customization Process for Belt Furnace Rubber Components

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber customization for belt furnace applications follows a rigorously defined sequence to ensure thermal resilience, dimensional accuracy, and operational longevity. This process begins with Drawing Analysis, where engineering teams dissect client-provided technical schematics to extract critical parameters. We prioritize thermal exposure zones, mechanical stress points, and chemical resistance requirements inherent to high-temperature sintering or annealing environments. Cross-referencing ISO 1307 and ASTM D2000 standards, we identify tolerances for elongation, compression set, and surface finish that directly impact furnace efficiency. Any ambiguities in material callouts or geometric constraints are resolved through direct OEM consultation to prevent downstream deviations.

The Formulation phase leverages our proprietary compound database and accelerated aging simulations. Based on the drawing analysis, we engineer custom elastomer blends—typically silicone (VMQ), fluorosilicone (FVMQ), or perfluoroelastomer (FFKM)—tailored to the furnace’s peak operational temperature and atmospheric conditions. Key considerations include optimizing filler dispersion for thermal conductivity, selecting peroxide curing systems for low compression set at 250°C+, and incorporating anti-oxidants to mitigate thermo-oxidative degradation. Each formulation undergoes finite element analysis (FEA) to predict deformation under cyclic thermal loads, ensuring the rubber maintains seal integrity across 10,000+ operational hours.

Critical material properties are validated against industry benchmarks as shown below.

| Property | Target Range | Test Standard |

|---|---|---|

| Continuous Use Temperature | -40°C to +250°C | ASTM D2240 |

| Tensile Strength | ≥8.5 MPa | ASTM D412 |

| Elongation at Break | ≥200% | ASTM D412 |

| Compression Set (22h/250°C) | ≤25% | ASTM D395 |

| Volume Resistivity | ≥1.0 × 10¹² Ω·cm | ASTM D257 |

Prototyping transforms validated formulations into functional samples. Using precision CNC-molded tooling, we produce pilot batches subjected to client-specified thermal cycling protocols in controlled atmosphere chambers. Performance metrics include leakage rates under vacuum conditions, adhesion to metal substrates, and resistance to flux residues. Iterative adjustments to durometer or cure kinetics occur here, with full material traceability maintained via batch-coded RFID tags. Client feedback on prototype durability under actual furnace conditions dictates final sign-off.

Mass Production initiates only after prototype approval, with in-line statistical process control (SPC) monitoring every batch. Automated mixing systems ensure ±0.5% compound consistency, while laser micrometers verify cross-sectional tolerances to ±0.1 mm. Each shipment includes a full ASTM-certified material test report and dimensional inspection certificate. Our integrated ERP system tracks raw material lot numbers to the furnace production line, enabling rapid root-cause analysis if field issues arise. This closed-loop methodology guarantees that every rubber component—from conveyor belts to sealing gaskets—delivers uncompromised performance in demanding thermal processing environments.

Suzhou Baoshida’s process eliminates guesswork through data-driven material science, reducing OEM time-to-market by 30% while meeting stringent semiconductor, photovoltaic, and metallurgy industry demands.

Contact Engineering Team

For manufacturers operating belt furnaces in high-temperature industrial environments, selecting the right rubber components is critical to ensuring consistent performance, minimizing downtime, and extending equipment life. At Suzhou Baoshida Trading Co., Ltd., we specialize in precision-engineered rubber solutions tailored to the rigorous demands of thermal processing systems, including belt furnaces used in sintering, brazing, and continuous annealing applications. Our expertise lies in delivering high-performance elastomers capable of withstanding extreme thermal cycling, mechanical stress, and chemical exposure—common challenges in continuous conveyor-based furnace operations.

Our engineered rubber components are designed to interface seamlessly with belt furnace systems, particularly in sealing, insulation support, and drive mechanisms where thermal stability and dimensional accuracy are paramount. We supply custom-formulated silicone, fluoroelastomer (FKM), and perfluoroelastomer (FFKM) materials, each selected for optimal resistance to temperatures up to 300°C and beyond, depending on formulation. These materials maintain elasticity and structural integrity under prolonged exposure to oxidative atmospheres, halogen gases, and other aggressive media frequently encountered in vacuum and controlled-atmosphere furnaces.

We understand that every belt furnace application presents unique operational parameters. Whether your system operates under nitrogen-hydrogen atmospheres, requires low outgassing materials, or demands compliance with industry-specific standards such as ASTM D2000 or ISO 1817, our technical team works directly with OEMs and end-users to develop application-specific rubber solutions. From gaskets and O-rings to custom-molded insulating profiles, our products are manufactured under strict quality controls to ensure repeatability and long-term reliability.

To support your manufacturing objectives, we provide comprehensive technical documentation, material traceability, and on-site consultation for integration and failure analysis. Our goal is to enhance the efficiency and uptime of your thermal processing lines through advanced material science and responsive engineering support.

For immediate technical consultation or to request material samples compatible with your belt furnace environment, contact Mr. Boyce, OEM Manager at Suzhou Baoshida Trading Co., Ltd. He is available to discuss your specific application requirements, recommend suitable elastomer formulations, and provide customized quotations with rapid turnaround.

| Property | Silicone Rubber | FKM (Viton®) | FFKM (Kalrez®) |

|---|---|---|---|

| Temperature Range | -60°C to 260°C | -20°C to 250°C | -15°C to 327°C |

| Tensile Strength | 8–10 MPa | 12–15 MPa | 10–13 MPa |

| Elongation at Break | 300–500% | 200–300% | 150–250% |

| Compression Set (22h, 200°C) | 20–30% | 15–25% | 10–20% |

| Resistance to Oxidation | Excellent | Very Good | Excellent |

| Chemical Resistance | Good | Excellent | Exceptional |

Contact Mr. Boyce directly at [email protected] to initiate a technical dialogue and optimize your belt furnace’s performance with engineered rubber solutions from Suzhou Baoshida.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).