Technical Contents

Engineering Guide: Latex Rubber Sheeting

Engineering Insight: The Critical Role of Material Selection in Latex Rubber Sheeting

In industrial applications, the performance and longevity of latex rubber sheeting are directly tied to precise material selection. While off-the-shelf rubber sheets may appear cost-effective and readily available, they frequently fail to meet the rigorous demands of specialized environments. This failure stems from a fundamental mismatch between generic formulations and application-specific requirements such as chemical exposure, temperature fluctuations, mechanical stress, and regulatory compliance.

Latex rubber, derived from natural rubber latex ( NRL ), offers exceptional elasticity, tensile strength, and resilience. However, its inherent properties can vary significantly based on the source of raw latex, compounding additives, and vulcanization processes. Standard commercial-grade sheets often utilize high filler content and lower-grade polymers to reduce production costs, compromising mechanical integrity and durability under operational stress. In contrast, engineered latex formulations are tailored to balance elongation, tear resistance, and compression set for targeted use cases—ranging from gasketing in automotive systems to liner materials in chemical containment.

One of the primary reasons off-the-shelf solutions fail is their inadequate resistance to environmental degradation. For example, exposure to ozone, UV radiation, or specific industrial solvents can accelerate surface cracking and embrittlement in non-formulated latex. Additionally, many generic sheets lack consistent thickness tolerances or fail to meet flammability, FDA, or REACH standards required in regulated industries.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-driven engineering. Our technical team collaborates with OEMs to analyze operating conditions, stress profiles, and lifecycle expectations before recommending or developing a custom latex compound. This approach ensures optimal performance, reduces downtime, and extends service life—delivering measurable ROI despite higher initial material costs.

The following table outlines key performance parameters between standard commercial latex sheeting and engineered formulations:

| Property | Standard Commercial Grade | Engineered Latex (Baoshida OEM Grade) |

|---|---|---|

| Tensile Strength (MPa) | 18–22 | 28–32 |

| Elongation at Break (%) | 600–700 | 800–950 |

| Hardness (Shore A) | 50 ± 5 | 45–70 (customizable) |

| Compression Set (22h, 70°C) | ≤ 35% | ≤ 20% |

| Ozone Resistance (100 pphm) | Poor (cracking at 24h) | Excellent (no cracking at 96h) |

| Temperature Range (°C) | -10 to +60 | -30 to +80 |

| Regulatory Compliance | None specified | FDA, ROHS, REACH available |

Material selection is not a commodity decision—it is an engineering imperative. By moving beyond off-the-shelf alternatives and adopting a specification-first approach, industrial manufacturers can prevent premature failure, ensure compliance, and optimize total cost of ownership. Suzhou Baoshida Trading Co., Ltd. stands at the intersection of rubber science and industrial demand, delivering latex rubber sheeting solutions engineered for real-world performance.

Material Specifications

Material Specifications for Industrial Rubber Sheeting

Suzhou Baoshida Trading Co., Ltd. provides precision-engineered rubber sheeting solutions for critical industrial applications. While natural latex rubber sheeting serves specific low-demand sectors, high-performance industrial environments require advanced synthetic elastomers. This section details the technical specifications of three industry-standard materials: Viton® (FKM), Nitrile (NBR), and Silicone (VMQ). These synthetics deliver superior resistance to thermal degradation, chemical exposure, and mechanical stress compared to natural latex, ensuring reliability in aerospace, automotive, and chemical processing systems. Material selection must align with operational parameters including temperature extremes, fluid compatibility, and mechanical loading to prevent premature failure.

Viton® fluoroelastomer excels in extreme chemical and thermal environments. It maintains integrity from -20°C to +230°C continuous service, with brief excursions up to 300°C. Its molecular structure provides exceptional resistance to jet fuels, hydraulic fluids, acids, and aromatic hydrocarbons. Standard hardness ranges from 60 to 90 Shore A, with tensile strength typically 10–15 MPa. Viton® is indispensable for aerospace seals, semiconductor manufacturing gaskets, and chemical reactor linings where failure is not an option.

Nitrile rubber (NBR) offers optimal balance for oil and fuel resistance at moderate temperatures. Operating effectively between -30°C and +120°C, it withstands prolonged exposure to petroleum derivatives, aliphatic hydrocarbons, and water-based fluids. Hardness spans 40–90 Shore A, with tensile strength of 10–20 MPa. Its cost-effectiveness and abrasion resistance make it ideal for automotive fuel hoses, O-rings in hydraulic systems, and industrial printing rollers. Limitations include poor ozone resistance and vulnerability to polar solvents like ketones.

Silicone rubber (VMQ) dominates applications requiring extreme temperature flexibility and biocompatibility. It functions reliably from -60°C to +230°C, with specialized grades enduring 300°C. While resistant to water, oxygen, and UV radiation, it exhibits poor resistance to concentrated acids and non-polar solvents. Hardness typically falls between 30–80 Shore A, with tensile strength of 5–10 MPa. Key uses include medical device components, food-grade conveyor belts, and high-temperature electrical insulation where material purity is critical.

The comparative analysis below summarizes essential properties for informed material selection. All values represent typical commercial compound ranges per ASTM D2000 standards.

| Property | Viton® (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to +230 | -30 to +120 | -60 to +230 |

| Key Fluid Resistance | Fuels, acids, oils | Petroleum oils, water | Water, ozone, steam |

| Hardness Range (Shore A) | 60–90 | 40–90 | 30–80 |

| Tensile Strength (MPa) | 10–15 | 10–20 | 5–10 |

| Primary Limitations | Cost, low-temp flexibility | Poor ozone/solvent resistance | Low tear strength, solvent vulnerability |

Suzhou Baoshida Trading Co., Ltd. emphasizes rigorous material validation against OEM specifications. Our engineering team collaborates with clients to match elastomer properties to application-specific stressors, ensuring optimal service life and regulatory compliance. Contact our technical department for compound customization or accelerated aging test data.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance latex rubber sheeting. With a dedicated team of five specialized mould engineers and two certified rubber formula engineers, we maintain full in-house control over the product development cycle—from concept and material formulation to tooling design and final production validation. This integrated approach ensures precision, consistency, and rapid turnaround for both standard and custom OEM requirements.

Our formula engineers possess advanced expertise in polymer chemistry, with a focused specialization in natural and synthetic latex systems. They are responsible for tailoring compound formulations to meet specific performance criteria such as tensile strength, elongation at break, compression set resistance, and environmental durability. By adjusting vulcanization systems, filler content, and accelerator packages, we achieve optimal balance between elasticity, resilience, and service life. All formulations undergo rigorous laboratory testing, including aging, ozone resistance, and dynamic mechanical analysis (DMA), to ensure compliance with international standards and customer-specific performance benchmarks.

Complementing our formulation expertise, the five-member mould engineering team specializes in precision tool design for calendering, compression molding, and dip molding processes—key manufacturing methods for latex rubber sheeting. Utilizing CAD/CAM software and finite element analysis (FEA), our engineers optimize mould geometry to ensure uniform thickness distribution, minimal flash, and dimensional accuracy across large-format sheets. We support both steel and composite mould systems, with surface finishes ranging from mirror-polished to textured, depending on application needs.

Our OEM capabilities are built on a foundation of technical agility and scalability. We work closely with clients to co-develop proprietary formulations and custom sheet profiles, including variable thicknesses, embedded reinforcements, and functional additives such as anti-static or UV-stabilized compounds. From prototype sampling to full-scale production, we maintain strict process controls under ISO 9001-certified procedures, ensuring batch-to-batch repeatability and traceability.

The synergy between our formula and mould engineering teams enables rapid iteration and problem-solving, reducing time-to-market for new products. Whether serving the automotive, construction, or industrial sealing sectors, our engineering framework is designed to deliver technically superior latex rubber sheeting solutions that meet the most demanding operational environments.

Typical Latex Rubber Sheeting Specifications

| Property | Test Method | Typical Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 40 – 70 |

| Tensile Strength | ASTM D412 | ≥12 MPa |

| Elongation at Break | ASTM D412 | ≥400% |

| Compression Set (22 hrs, 70°C) | ASTM D395 | ≤25% |

| Tear Resistance | ASTM D624 | ≥30 kN/m |

| Operating Temperature Range | — | -20°C to +80°C |

| Specific Gravity | ASTM D297 | 0.95 – 1.10 |

Customization Process

Latex Rubber Sheeting Customization Process: Precision Engineering from Concept to Volume Production

At Suzhou Baoshida Trading Co., Ltd., our OEM customization process for industrial latex rubber sheeting integrates material science rigor with scalable manufacturing. This systematic approach ensures dimensional accuracy, performance consistency, and compliance with client-specific functional requirements. The workflow progresses through four critical phases, each governed by ISO 9001 protocols and ASTM test methodologies.

Step 1: Engineering Drawing Analysis

Client technical drawings undergo dimensional tolerance validation and material compatibility assessment. Our engineering team scrutinizes critical parameters including thickness uniformity (±0.1 mm tolerance), surface texture (Ra 0.8–3.2 μm), and edge definition. Finite element analysis (FEA) identifies potential stress concentrations or compression set risks under operational loads. Non-conformance flags trigger immediate cross-functional review with the client to resolve ambiguities before formulation begins.

Step 2: Compound Formulation Development

Based on validated drawings and performance targets, our rubber chemists design bespoke latex formulations. Natural rubber (NR) or nitrile-butadiene rubber (NBR) bases are modified with accelerators, antioxidants, and fillers to achieve target properties. Each formulation is optimized for cure kinetics (140–160°C range), aging resistance (per ASTM D573), and chemical exposure per client specifications. Material Safety Data Sheets (MSDS) and RoHS/REACH compliance documentation are generated concurrently.

Step 3: Prototype Validation

Three prototype batches undergo accelerated life testing and dimensional re-measurement. Physical properties are verified against client benchmarks using ASTM D2000 standards. Key metrics include tensile strength, elongation at break, and compression set after 24 hours at 70°C. Clients receive test reports with statistical process control (SPC) charts showing ±3σ variance limits. Prototype approval requires ≤5% deviation from target specifications across all critical-to-quality (CTQ) parameters.

Step 4: Mass Production Scaling

Approved formulations transition to automated calendaring lines with in-line laser micrometers ensuring thickness consistency. Each production lot includes:

Real-time cure monitoring via dielectric sensors

Batch-specific traceability codes

Final inspection per AQL 1.0 (MIL-STD-1916)

Volume production maintains ±2% property consistency through closed-loop feedback from rheometer and tensile test data.

Critical Performance Specifications for Latex Rubber Sheeting

| Property | Test Standard | Typical Range | Customization Flexibility |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 30–90 | ±3 points |

| Tensile Strength (MPa) | ASTM D412 | 10–30 | ±15% of target |

| Elongation at Break (%) | ASTM D412 | 200–700 | ±20% of target |

| Compression Set (%) | ASTM D395 | 10–40 (70°C/24h) | ±5% absolute |

This structured workflow eliminates guesswork in rubber component manufacturing. Suzhou Baoshida guarantees seamless transition from prototype to high-volume output through embedded quality gates and material science expertise, reducing time-to-market by 30% versus industry averages. All production batches include full traceability from raw material certificates to final test reports, ensuring compliance with automotive, aerospace, and industrial sealing standards.

Contact Engineering Team

For industrial manufacturers and procurement specialists seeking high-performance latex rubber sheeting solutions, Suzhou Baoshida Trading Co., Ltd. stands as a trusted partner in the global rubber supply chain. With years of engineering expertise and a deep understanding of industrial material requirements, we deliver precision-formulated latex rubber sheets tailored to demanding applications across automotive, construction, healthcare, and manufacturing sectors. Our commitment to quality, consistency, and technical support ensures that every product meets rigorous international standards.

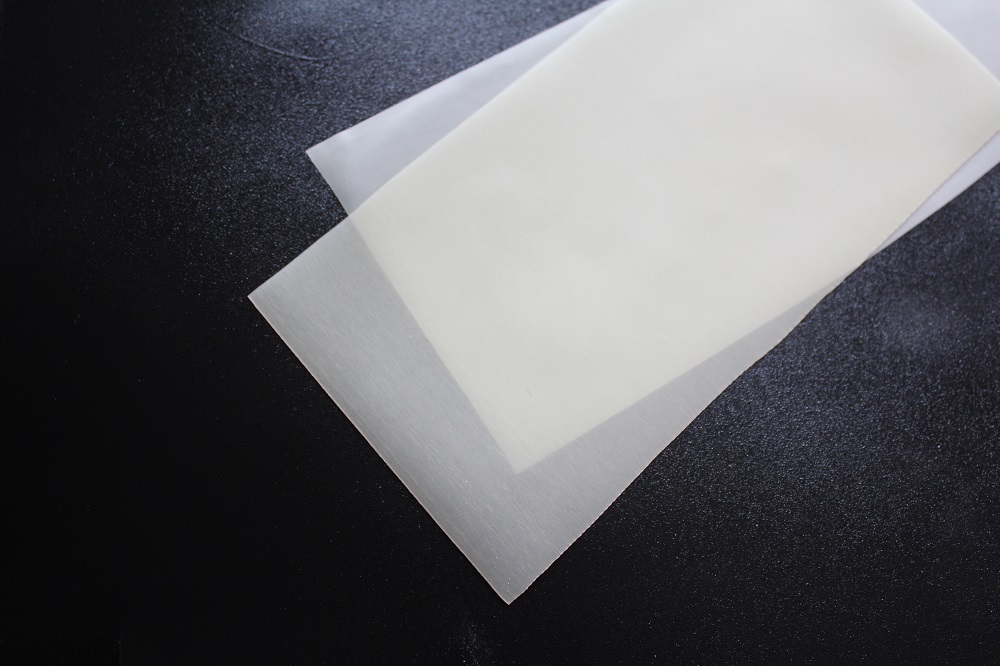

Latex rubber sheeting produced and supplied by Suzhou Baoshida is engineered for superior elasticity, tensile strength, and resistance to abrasion and environmental degradation. We utilize natural and synthetic latex compounds, optimized through controlled vulcanization processes, to achieve consistent physical properties across all thicknesses and grades. Whether your application requires thin, flexible membranes for sealing or thick, impact-resistant sheets for protective linings, our formulations are designed to perform under real-world conditions.

We understand that industrial buyers require more than just raw materials—they demand technical collaboration, reliable logistics, and responsive customer service. That’s why we assign dedicated engineering support to every client, ensuring material compatibility, regulatory compliance, and performance validation prior to delivery. Our production facilities adhere to ISO 9001 quality management protocols, and all batches undergo comprehensive testing for thickness uniformity, elongation, tear resistance, and hardness.

Below are representative technical specifications for our standard latex rubber sheeting products:

| Property | Test Method | Value (Typical) |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 45 – 65 |

| Tensile Strength | ASTM D412 | ≥18 MPa |

| Elongation at Break | ASTM D412 | ≥600% |

| Tear Resistance | ASTM D624 (Type B) | ≥45 kN/m |

| Thickness Range | — | 0.5 mm – 10 mm |

| Color Options | — | Natural, Black, Custom |

| Temperature Resistance | — | -20°C to +80°C |

| Specific Gravity | ASTM D297 | 0.95 – 1.15 |

All specifications can be customized based on application requirements, including oil resistance, anti-static properties, or FDA compliance for food-grade environments. We also offer calendered, dipped, and molded fabrication methods to achieve precise dimensional tolerances and surface finishes.

To initiate a technical consultation or request a sample batch for evaluation, contact Mr. Boyce, OEM Manager and Rubber Formula Engineer at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce leads our industrial solutions team and specializes in custom compound development, cost-optimized material substitution, and long-term supply planning. He is available to discuss your project specifications, volume requirements, and performance targets in detail.

Reach out directly via email at [email protected] to schedule a technical review. Include your application context, required dimensions, environmental exposures, and any regulatory standards your product must meet. We respond to all inquiries within 24 hours during business days and provide material data sheets, test reports, and sample shipments upon request. Partner with Suzhou Baoshida for engineered latex rubber sheeting that delivers durability, precision, and value—backed by expert support from concept to delivery.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).