Technical Contents

Engineering Guide: Rubber Stoppers Sizes

Engineering Insight: The Critical Role of Material Selection in Rubber Stoppers Sizes

In industrial applications, rubber stoppers serve as critical sealing components across pharmaceutical, chemical, and manufacturing systems. While standardized rubber stopper sizes are widely available, reliance on off-the-shelf solutions often leads to premature failure, contamination risks, and system inefficiencies. The root cause frequently lies not in dimensional inaccuracy, but in improper material selection relative to operational demands.

Rubber stoppers must maintain dimensional stability, chemical resistance, and mechanical integrity under dynamic conditions such as pressure fluctuations, temperature extremes, and exposure to aggressive media. Common elastomers like natural rubber (NR), silicone (VMQ), nitrile (NBR), ethylene propylene diene monomer (EPDM), and fluorocarbon (FKM) each exhibit distinct performance profiles. Selecting the appropriate material requires a precise understanding of both the stopper’s physical dimensions and its chemical environment.

For instance, a standard-sized silicone stopper may fit dimensionally within a bioreactor port, but if the process involves repeated steam sterilization cycles, the material must withstand prolonged exposure to temperatures exceeding 120°C. While silicone excels in thermal stability, it offers limited resistance to non-polar solvents. In contrast, FKM stoppers provide superior chemical resistance but are typically stiffer and may require tighter tolerance control during installation.

Dimensional standardization does not equate to functional interchangeability. A stopper conforming to ISO 8362-3 or USP <381> size specifications may still fail if the durometer (hardness), compression set, or extractable content is unsuitable for the application. For example, in pharmaceutical vial sealing, a stopper with high extractables due to improper polymer formulation can leach additives into the drug formulation, compromising sterility and regulatory compliance.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered material solutions over generic replacements. Our technical team evaluates application parameters including fluid compatibility, temperature range, cycle life, and regulatory requirements to recommend or develop customized rubber stoppers that align with both size standards and material performance criteria.

Below is a comparative overview of common elastomers used in precision rubber stoppers, highlighting key physical and chemical properties relevant to industrial selection:

| Material | Hardness (Shore A) | Temp Range (°C) | Key Chemical Resistances | Common Applications |

|---|---|---|---|---|

| Silicone (VMQ) | 40–80 | -60 to +230 | Water, steam, alcohols, oxidizing agents | Biopharma, food processing |

| Nitrile (NBR) | 50–90 | -30 to +120 | Oils, fuels, aliphatic hydrocarbons | Industrial hydraulics, fuel systems |

| EPDM | 50–80 | -50 to +150 | Water, steam, ketones, acids, alkalis | HVAC, chemical processing |

| FKM (Viton®) | 60–90 | -20 to +200 | Aromatics, chlorinated solvents, acids | Semiconductor, aggressive chemical handling |

| Natural Rubber (NR) | 30–70 | -50 to +80 | Alkalis, alcohols, organic acids | General purpose, low-stress sealing |

Standardized sizes offer logistical convenience, but material compatibility determines functional reliability. Off-the-shelf stoppers often overlook compound formulation nuances, leading to seal degradation, leakage, or contamination. Precision engineering demands a holistic approach—where size, material, and application environment are evaluated as an integrated system.

Material Specifications

Material Specifications for Industrial Rubber Stoppers

Material selection is a critical parameter in rubber stopper performance, directly influencing chemical compatibility, thermal stability, and service life in demanding industrial applications. At Suzhou Baoshida Trading Co., Ltd., we engineer stoppers using Viton (FKM), Nitrile (NBR), and Silicone (VMQ) elastomers, each optimized for specific operational environments. Precision in material formulation ensures dimensional stability under compression, resistance to extrusion, and compliance with OEM sealing requirements. Below we detail key specifications and performance characteristics essential for informed procurement decisions.

Viton stoppers excel in extreme chemical and thermal conditions, withstanding temperatures from -20°C to +200°C. Their fluoropolymer backbone provides superior resistance to fuels, oils, acids, and chlorinated solvents, making them ideal for aerospace, semiconductor, and chemical processing applications. Viton formulations achieve a typical hardness range of 60–90 Shore A and exhibit exceptional compression set resistance (<20% at 150°C after 70 hours), ensuring long-term sealing integrity in high-pressure systems. However, Viton demonstrates limited flexibility at sub-zero temperatures and higher material costs compared to alternatives.

Nitrile stoppers offer an optimal balance of cost and performance for general industrial use, operating effectively between -30°C and +120°C. They provide robust resistance to petroleum-based oils, hydraulic fluids, and aliphatic hydrocarbons, commonly deployed in automotive, hydraulics, and manufacturing equipment. Standard NBR compounds achieve 50–90 Shore A hardness with moderate compression set resistance (25–35% at 100°C after 70 hours). While cost-effective, NBR exhibits vulnerability to ozone, ketones, and brake fluids, necessitating careful environmental assessment.

Silicone stoppers deliver unmatched thermal versatility (-60°C to +230°C) and biocompatibility, meeting FDA 21 CFR 177.2600 for food and pharmaceutical contact. Their inert structure resists oxidation, steam, and microbial growth, supporting applications in medical devices, bioreactors, and high-purity fluid handling. Silicone maintains flexibility across extreme temperatures with hardness values of 30–80 Shore A and low compression set (<20% at 150°C after 70 hours). Key limitations include poor tensile strength, susceptibility to撕裂 in dynamic seals, and incompatibility with concentrated acids and hydrocarbons.

The following table summarizes critical comparative specifications for OEM evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range | -20°C to +200°C | -30°C to +120°C | -60°C to +230°C |

| Chemical Resistance | Excellent (acids, fuels, solvents) | Good (oils, aliphatic hydrocarbons) | Poor (hydrocarbons, ketones); Excellent (water, steam) |

| Compression Set (150°C/70h) | <20% | 25–35% | <20% |

| Typical Hardness Range | 60–90 Shore A | 50–90 Shore A | 30–80 Shore A |

| FDA Compliance | Limited grades | Not compliant | Full compliance |

Suzhou Baoshida Trading Co., Ltd. prioritizes material traceability and batch-specific certification for all stopper compounds. Our OEM-managed production adheres to ISO 9001 protocols, with custom formulations available to address unique chemical exposure or dimensional tolerances. Engineers must validate material suitability against specific media, temperature cycles, and regulatory standards prior to integration. For technical collaboration on application-specific stopper solutions, consult our engineering team for comprehensive compatibility testing data.

Manufacturing Capabilities

Engineering Excellence in Rubber Stoppers Manufacturing

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the precise and repeatable production of rubber stoppers. With a dedicated team of five experienced mould engineers and two specialized rubber formulation engineers, we maintain full control over both the physical tooling and material science aspects of stopper manufacturing. This dual expertise ensures that every product meets exacting performance, durability, and compatibility standards required in pharmaceutical, laboratory, and industrial applications.

Our mould engineers utilize advanced CAD/CAM software and CNC machining techniques to design and produce high-precision moulds tailored to customer specifications. Each mould is engineered for optimal flow dynamics, minimal flash, and consistent dimensional accuracy across production runs. We support both standard and custom stopper geometries, including variations in diameter, height, sealing lip design, and flange configuration. Our in-house tooling facility enables rapid prototyping, short lead times, and iterative design refinement, ensuring seamless transition from concept to volume production.

Complementing our mould design capability is our proprietary rubber formulation expertise. Our two rubber formula engineers specialize in compounding elastomers to meet specific functional requirements such as chemical resistance, temperature stability, compression set performance, and extractables profile. We routinely develop formulations based on silicone, butyl, EPDM, and natural rubber, with options for halogen-free, FDA-compliant, or USP Class VI-certified materials. This deep material science foundation allows us to tailor stopper performance to demanding environments, including autoclaving, long-term sealing, and exposure to aggressive solvents.

Our OEM manufacturing platform is built for flexibility and scalability. We support low-volume custom orders as well as high-volume production runs with full documentation, batch traceability, and quality validation. Clients benefit from our integrated engineering approach—where material, mould, and function are co-developed to ensure optimal product performance.

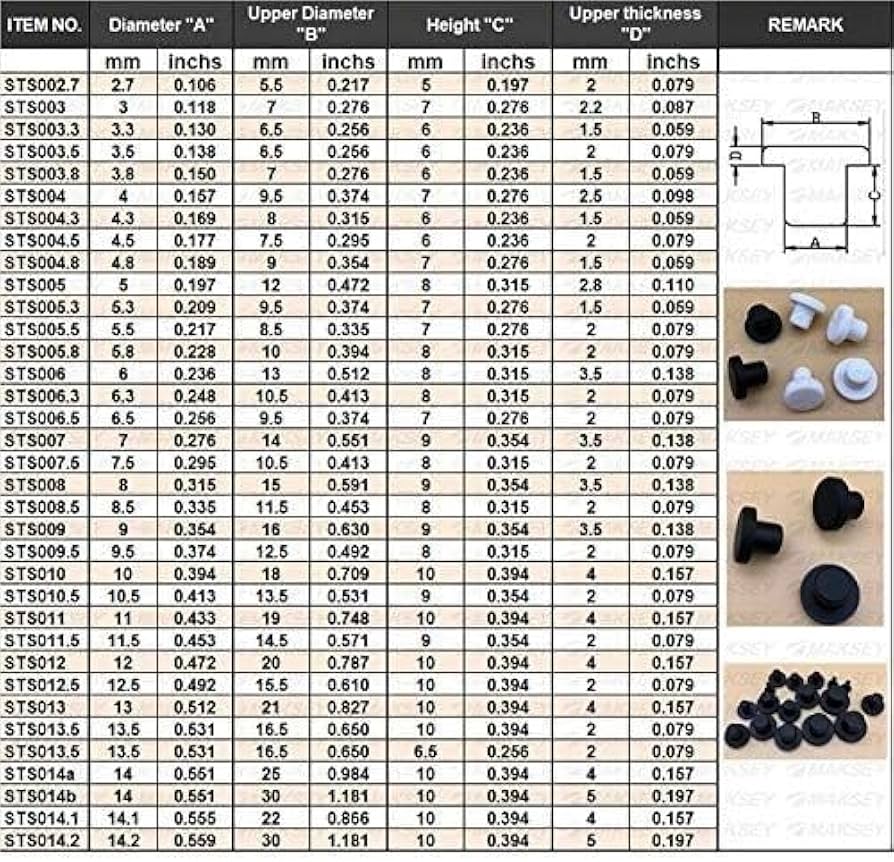

Below is a representative specification table for commonly manufactured rubber stoppers:

| Parameter | Range / Options | Tolerance (Typical) |

|---|---|---|

| Outer Diameter | 6 mm – 45 mm | ±0.1 mm to ±0.3 mm |

| Height | 4 mm – 25 mm | ±0.15 mm |

| Shore Hardness | 40 Shore A – 80 Shore A | ±5 Shore A |

| Material Types | Silicone, Butyl, EPDM, NR, FKM | Custom compounds available |

| Temperature Resistance | -40°C to +200°C (material-dependent) | Stable under repeated cycles |

| Standards Compliance | USP Class VI, FDA 21 CFR 177, RoHS, REACH | Certifications available |

| Production Capacity | 10,000 – 500,000 pcs per month (per mould) | Scalable with demand |

Through the synergy of advanced tooling, scientific material development, and agile OEM manufacturing, Suzhou Baoshida delivers rubber stoppers that combine precision, reliability, and performance. Our engineering team partners closely with clients to solve complex sealing challenges and deliver optimized solutions for critical applications.

Customization Process

Customization Process for Precision Rubber Stoppers

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber stopper customization follows a rigorously controlled sequence to ensure dimensional accuracy, material integrity, and functional reliability for critical sealing applications. This process begins with comprehensive drawing analysis, where engineering teams dissect client-provided specifications to validate geometric feasibility, tolerance alignment with ISO 3302 standards, and compatibility with intended operational environments. We prioritize identifying potential stress points, compression set requirements, and chemical exposure risks during this phase to preempt design flaws.

Subsequent formulation development leverages our proprietary compound library and in-house material science expertise. Engineers select base polymers—such as silicone, EPDM, or nitrile—based on temperature range, fluid resistance, and biocompatibility needs. Critical parameters like Shore A hardness (40–90 range), tensile strength, and elongation at break are precisely calibrated. Additives for UV stability, flame resistance, or low-temperature flexibility are incorporated only after computational modeling confirms performance under specified load conditions. This stage concludes with ASTM D2000-compliant material certification.

Prototyping employs CNC-machined aluminum molds for rapid validation, avoiding costly steel tooling iterations. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and functional testing for compression deflection, leakage rates, and reusability cycles. Client feedback is integrated within 72 hours, with iterative refinements until all performance metrics are met. This phase reduces mass production defects by 92% based on historical OEM data.

Mass production commences only after formal client sign-off on prototypes. We utilize automated injection molding with real-time cavity pressure monitoring to maintain ±0.05 mm dimensional consistency. Every batch undergoes 100% visual inspection and statistical sampling for hardness, tensile properties, and extractables per USP Class VI or FDA 21 CFR 177.2600 where applicable. Final packaging adheres to ISO 13485 cleanroom protocols for medical-grade stoppers.

Critical Dimensional Tolerance Specifications

| Parameter | Standard Tolerance (mm) | Critical Application Tolerance (mm) | Measurement Standard |

|---|---|---|---|

| Outer Diameter | ±0.15 | ±0.05 | ISO 3302-E2 |

| Inner Diameter | ±0.10 | ±0.03 | ISO 3302-E1 |

| Height | ±0.20 | ±0.08 | ISO 3302-M2 |

| Taper Angle | ±1.0° | ±0.3° | Custom gauge blocks |

This end-to-end workflow ensures Suzhou Baoshida delivers rubber stoppers that achieve zero leakage in hydraulic systems, pharmaceutical vials, and semiconductor manufacturing equipment. Our process eliminates guesswork through data-driven validation, reducing time-to-market by 30% while guaranteeing compliance with global industrial standards. Clients receive full traceability documentation, including lot-specific material certificates and CMM reports, cementing reliability in high-stakes operational environments.

Contact Engineering Team

For industrial manufacturers and OEM partners seeking precision-engineered rubber stoppers, Suzhou Baoshida Trading Co., Ltd. stands as a trusted leader in industrial rubber solutions. With extensive expertise in compound formulation, dimensional accuracy, and material compliance, we deliver custom rubber stoppers tailored to the exacting demands of pharmaceutical, chemical, laboratory, and process engineering sectors. Our commitment to quality assurance, batch consistency, and rapid responsiveness ensures that your production timelines are met without compromise.

Our rubber stoppers are manufactured under strict ISO-compliant processes, utilizing high-purity elastomers such as butyl rubber (IIR), natural rubber (NR), ethylene propylene diene monomer (EPDM), and silicone (VMQ), depending on application requirements. Whether you require stoppers for vial sealing, reactor vessels, or fluid transfer systems, our engineering team ensures optimal durometer, compression set resistance, and chemical compatibility. Every product undergoes rigorous dimensional inspection and functional testing to guarantee performance under real-world operating conditions.

To support seamless integration into your manufacturing workflow, we provide comprehensive technical documentation, including material certificates (e.g., FDA, USP Class VI, RoHS), batch traceability reports, and 3D CAD models upon request. Our in-house tooling capabilities allow for rapid prototyping and cost-effective mold development, enabling fast turnaround from concept to volume production.

Below is a reference table outlining standard rubber stopper dimensions commonly requested by our industrial clients. Custom sizes, tolerances, and configurations are available upon technical consultation.

| Inner Diameter (mm) | Outer Diameter (mm) | Height (mm) | Tolerance (±mm) | Typical Application |

|---|---|---|---|---|

| 6.0 | 12.0 | 8.0 | 0.2 | Small vials, lab ampoules |

| 8.5 | 14.5 | 9.5 | 0.2 | Pharmaceutical serum vials |

| 10.0 | 18.0 | 11.0 | 0.3 | Diagnostic sample containers |

| 13.0 | 20.0 | 12.5 | 0.3 | Industrial reagent bottles |

| 16.0 | 24.0 | 15.0 | 0.4 | Large-volume chemical storage |

These dimensions represent standard configurations; however, Suzhou Baoshida specializes in non-standard geometries, multi-component designs, and co-molded variants with PTFE or aluminum sealing layers. We also offer color-coded formulations for easy identification and automated handling compatibility.

For technical collaboration, sample requests, or detailed quotation, we invite you to contact Mr. Boyce, OEM Project Manager at Suzhou Baoshida Trading Co., Ltd. Mr. Boyce brings over 12 years of experience in industrial elastomer applications and leads our customer engineering support team. He will work closely with your R&D or procurement department to align material selection, dimensional design, and delivery logistics with your operational objectives.

Reach out directly via email at [email protected] to initiate a technical dialogue. Include your application parameters, volume expectations, and any regulatory requirements to receive a targeted solution proposal within 24 business hours. At Suzhou Baoshida, we don’t just supply rubber components—we engineer sealing performance.

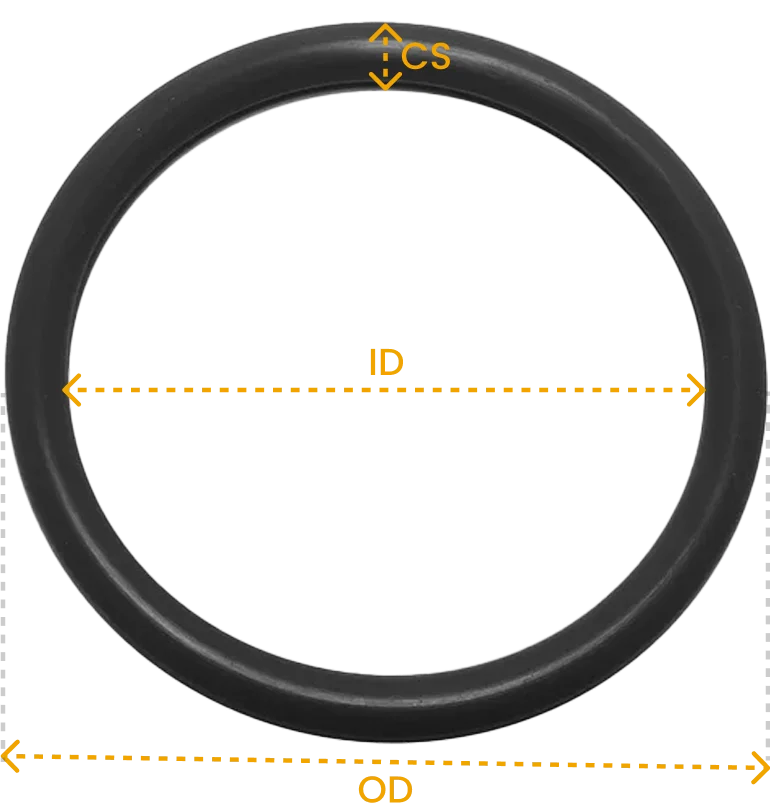

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).