Technical Contents

Engineering Guide: Automotive Rubber Seal Suppliers

Material Selection in Automotive Rubber Seals: A Precision Engineering Imperative

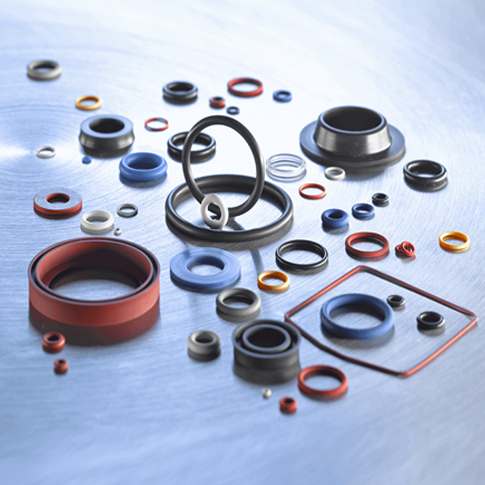

In the domain of automotive sealing systems, material selection is not a secondary consideration—it is the foundational determinant of performance, durability, and system integrity. Off-the-shelf rubber seals, while economically appealing in the short term, frequently fail to meet the rigorous demands of modern automotive environments. These failures stem from an inadequate match between elastomer properties and operational conditions, including temperature extremes, chemical exposure, dynamic loading, and long-term compression set resistance. Precision rubber seals must be engineered at the molecular level to align with specific application requirements, a task that generic solutions are structurally incapable of fulfilling.

Automotive sealing applications span a wide spectrum—from engine gaskets exposed to hot oil and combustion byproducts, to door seals subjected to UV radiation and ozone, to fuel system components in contact with aggressive biofuels. Each environment imposes unique chemical and mechanical stresses. For instance, nitrile rubber (NBR) offers excellent resistance to oils and fuels but degrades rapidly under high-temperature conditions exceeding 120°C. Conversely, fluorocarbon rubber (FKM) maintains stability up to 200°C and resists a broad range of chemicals, making it ideal for under-hood applications, yet it is significantly more expensive and less flexible at low temperatures.

The failure of standard seals often manifests as premature hardening, cracking, extrusion, or loss of sealing force due to compression set. These issues lead to fluid leaks, reduced engine efficiency, increased emissions, and in severe cases, component failure. Such outcomes are not merely operational setbacks—they compromise safety and regulatory compliance.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-specific elastomer formulation. Our engineering process begins with a comprehensive analysis of the operating environment, including temperature range, media exposure, pressure cycles, and mating surface dynamics. This data informs the selection of base polymer, filler systems, plasticizers, and cure chemistry, enabling the production of seals with tailored performance characteristics.

The following table outlines key elastomer options and their suitability across critical performance parameters:

| Material | Temperature Range (°C) | Oil/Fuel Resistance | Compression Set | Cost Index | Typical Automotive Use |

|---|---|---|---|---|---|

| NBR (Nitrile) | -30 to +120 | Excellent | Moderate | 1.0 | Transmission seals, O-rings |

| EPDM | -50 to +150 | Poor | Good | 1.2 | Weatherstripping, coolant hoses |

| FKM (Viton®) | -20 to +200 | Outstanding | Excellent | 3.5 | Turbocharger hoses, fuel injectors |

| ACM (Acrylic) | -10 to +170 | Very Good | Good | 2.0 | Valve stem seals, oil pans |

| Silicone (VMQ) | -60 to +180 | Poor | Fair | 2.8 | Electrical connectors, sensors |

Material selection is not a compromise between cost and performance—it is a science-driven alignment of polymer physics with real-world engineering demands. Off-the-shelf solutions ignore this principle, leading to systemic vulnerabilities. True reliability emerges only when the seal is designed as an integrated component of the system, not as an afterthought.

Material Specifications

Material Specifications for Automotive Rubber Seals

Selecting the optimal elastomer for automotive sealing applications demands rigorous evaluation of operational parameters including temperature extremes, chemical exposure, and mechanical stress. At Suzhou Baoshida Trading Co., Ltd., we prioritize material science precision to ensure seals maintain integrity across dynamic automotive environments. This section details critical specifications for three industry-standard compounds: Viton (FKM), Nitrile (NBR), and Silicone (VMQ). Each material exhibits distinct performance characteristics that directly influence longevity and reliability in targeted applications.

Viton fluorocarbon rubber delivers exceptional resistance to high temperatures up to 250°C and aggressive fluids such as engine oils, fuels, and transmission fluids. Its molecular structure provides superior stability against oxidation and ozone degradation, making it ideal for under-hood components like turbocharger hoses and fuel injector seals. However, Viton exhibits higher compression set at elevated temperatures compared to alternatives and carries a premium cost, necessitating judicious application in high-value systems where failure is unacceptable.

Nitrile butadiene rubber remains the industry benchmark for cost-effective hydrocarbon resistance, operating effectively between -40°C and 120°C. Its acrylonitrile content directly correlates with oil and fuel resistance, with high-ACN grades (45-50%) preferred for transmission seals and fuel system O-rings. Nitrile offers excellent abrasion resistance and tensile strength but suffers from poor ozone resistance and limited low-temperature flexibility below -40°C, requiring protective additives for extended service life in harsh climates.

Silicone rubber excels in extreme temperature resilience from -60°C to 230°C and demonstrates outstanding ozone and UV stability. Its inert composition suits coolant hoses, sensor gaskets, and EV battery thermal interface seals where electrical insulation is critical. Silicone maintains flexibility at cryogenic temperatures but exhibits lower tensile strength and tear resistance than hydrocarbon-based elastomers, often requiring reinforcement for dynamic sealing applications involving significant mechanical stress.

Material selection must align with OEM engineering requirements and lifecycle cost analysis. The following table summarizes key comparative specifications for precision seal design validation.

| Material | Temperature Range (°C) | Key Fluid Resistance | Tensile Strength (MPa) | Compression Set (22h/150°C) | Primary Automotive Applications |

|---|---|---|---|---|---|

| Viton (FKM) | -20 to 250 | Excellent: Fuels, oils, acids, brake fluid | 10-18 | 15-25% | Turbocharger seals, fuel injector O-rings, transmission shaft seals |

| Nitrile (NBR) | -40 to 120 | Excellent: Hydrocarbons, water-based fluids | 15-30 | 20-40% | Fuel hose covers, transmission seals, CV joint boots |

| Silicone (VMQ) | -60 to 230 | Good: Water, glycols, brake fluid (limited oil) | 5-10 | 10-20% | Coolant hose gaskets, EV battery thermal pads, sensor housings |

Suzhou Baoshida Trading Co., Ltd. leverages this technical framework to guide OEM partners through material qualification. We emphasize that no universal elastomer exists; optimal performance arises from matching compound attributes to specific operational demands. Our engineering team conducts application-specific validation testing per ISO 3601 and SAE J2236 standards to mitigate field failure risks. Partner with us to transform material specifications into engineered sealing solutions that meet stringent automotive durability and safety mandates.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering infrastructure is built to meet the exacting demands of global automotive OEMs and Tier-1 suppliers. With a dedicated team of five certified mould engineers and two advanced rubber formulation engineers, we maintain full control over both the physical tooling and material science aspects of precision rubber seal manufacturing. This dual expertise enables us to deliver technically optimized sealing solutions that perform reliably under dynamic thermal, mechanical, and chemical conditions typical in automotive applications.

Our mould engineering team specializes in the design, simulation, and validation of high-precision rubber compression, transfer, and injection moulds. Utilizing advanced CAD/CAM software including SolidWorks, UG NX, and AutoCAD, our engineers develop moulds with tight tolerances (±0.05 mm) and optimized flow channels to ensure consistent part quality and minimal flash. Finite Element Analysis (FEA) is routinely applied to predict deformation, wear, and cycle performance, reducing time-to-prototype and improving tool longevity. All mould designs comply with ISO 1302 surface finish standards and are validated through first-article inspection reports (FAIR) and dimensional layout reports (DLR).

Complementing our tooling strength is our in-house rubber formulation capability. Our two senior formula engineers hold over 15 years of combined experience in elastomer chemistry, specializing in NBR, EPDM, FKM, ACM, and custom blended compounds. We develop proprietary formulations tailored to specific customer requirements such as low-temperature flexibility (down to -50°C), oil resistance, ozone stability, and low compression set. Each compound is rigorously tested for tensile strength, elongation, hardness (Shore A), and volume swell in accordance with ASTM D2000 and ISO 3302 standards. Our lab is equipped with rheometers, aging ovens, tensile testers, and Shore A/D durometers to ensure batch-to-batch consistency and long-term performance predictability.

We operate as a certified OEM partner, supporting customers from concept to mass production. Our engineering team collaborates directly with client R&D departments to co-develop seals that integrate seamlessly into complex assemblies such as engine gaskets, transmission shafts, door systems, and HVAC units. With full traceability, PPAP documentation, and APQP alignment, we meet IATF 16949 quality system requirements and support just-in-time (JIT) delivery models.

The integration of advanced mould design and deep materials science positions Suzhou Baoshida as a technically differentiated supplier in the competitive automotive rubber seal market.

Material and Performance Specifications

| Property | NBR | EPDM | FKM | ACM |

|---|---|---|---|---|

| Temperature Range (°C) | -30 to +120 | -50 to +150 | -20 to +200 | -30 to +150 |

| Oil Resistance | Excellent | Poor | Excellent | Good |

| Ozone Resistance | Fair | Excellent | Excellent | Good |

| Compression Set (22 hrs, 100°C) | ≤25% | ≤20% | ≤15% | ≤22% |

| Hardness Range (Shore A) | 50–90 | 55–85 | 60–90 | 65–80 |

| Typical Applications | Fuel systems, O-rings | Weather seals, coolant hoses | Turbocharger hoses, valve seals | Transmission seals, clutch components |

Customization Process

Customization Process for Precision Automotive Rubber Seals

At Suzhou Baoshida Trading Co., Ltd., our customization process for automotive rubber seals integrates engineering rigor with industrial scalability. This four-phase methodology ensures compliance with OEM specifications while optimizing performance, cost, and delivery timelines. Each stage undergoes stringent validation to mitigate risks inherent in dynamic sealing applications.

Drawing Analysis

We commence with comprehensive technical drawing assessment, focusing on GD&T callouts, material specifications, and functional requirements. Critical parameters include sealing surface tolerances (±0.05mm typical), interference fits, and environmental exposure conditions. Finite element analysis (FEA) validates stress distribution under compression, preventing extrusion or permanent set in service. Non-conformities trigger immediate engineering feedback loops with the client, resolving ambiguities before formulation begins.

Formulation Development

Material selection is driven by operational demands. Our laboratory synthesizes compounds using proprietary polymer blends, fillers, and curatives to achieve target properties. Key considerations include fluid resistance (e.g., brake fluid, transmission oil), thermal stability (-55°C to +150°C), and compression set (<25% per ASTM D395). Each formula undergoes accelerated aging tests per SAE J2236 and ISO 1817, with iterative adjustments to crosslink density and filler dispersion. Traceable batch records document all raw material lots (e.g., polymer grade, sulfur content) for full supply chain accountability.

Prototyping and Validation

Prototypes are manufactured using production-intent tooling to eliminate process variables. We conduct:

Dimensional inspection via CMM (accuracy ±0.01mm)

Dynamic seal performance testing on custom rigs simulating 500,000 cycles

Fluid immersion resistance at 150°C for 72 hours

Leak rate validation at 0.5 bar differential pressure

Data is compiled into a PPAP-compliant dossier. Failure modes trigger root-cause analysis using Ishikawa diagrams, with reformulation completed within 72 hours.

Mass Production

Approved designs transition to automated production lines with real-time SPC monitoring. Key controls include:

In-line Shore A hardness checks (±2 points tolerance)

Continuous cure monitoring via dielectric sensors

100% visual inspection via AI-powered cameras

Batch retention sampling for compression set retest

All seals carry laser-etched batch codes linking to material certificates and process logs. Production yields exceed 99.2% through poka-yoke tooling and Six Sigma-driven process optimization.

Critical Material Properties for Automotive Seals

| Material Type | Shore A Hardness Range | Temperature Range (°C) | Compression Set (70h/100°C) | Typical Automotive Application |

|---|---|---|---|---|

| EPDM | 50–80 | -55 to +150 | ≤22% | Weatherstripping, coolant hoses |

| NBR | 60–90 | -30 to +120 | ≤18% | Fuel systems, gaskets |

| FKM | 65–85 | -20 to +230 | ≤15% | Turbocharger hoses, engine seals |

This structured workflow ensures every seal meets OEM durability and safety standards while maintaining cost efficiency. Suzhou Baoshida’s closed-loop system—from drawing validation to traceable mass production—delivers zero-defect components for critical automotive systems. All processes adhere to IATF 16949 protocols, with documentation available for full audit transparency.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Automotive Rubber Seal Solutions

When sourcing high-performance rubber seals for automotive applications, precision, material integrity, and consistent manufacturing standards are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in the development and supply of engineered rubber seals designed to meet the rigorous demands of modern automotive systems. From dynamic shaft seals to static gaskets and custom-profiled extrusions, our products are built to deliver long-term reliability under extreme temperature, pressure, and chemical exposure conditions.

Our technical team works closely with OEMs and Tier-1 suppliers to ensure that every seal component conforms to international quality benchmarks, including ISO 9001, IATF 16949, and ASTM D2000 specifications. We leverage advanced compounding techniques, precision molding, and stringent QC protocols to produce seals in NBR, EPDM, FKM (Viton), silicone, and specialty fluoroelastomers tailored to your operational requirements.

To initiate a technical consultation or request a custom quote, contact Mr. Boyce, our dedicated OEM Manager and Rubber Formula Engineer. With over 12 years of experience in elastomer formulation and industrial rubber processing, Mr. Boyce leads client engagements with a focus on material optimization, cost-efficiency, and rapid prototyping. Whether you require low-volume validation samples or high-volume production runs, our facility in Suzhou is equipped with automated molding lines, CNC trimming systems, and in-house testing labs to support fast turnaround and full traceability.

We understand that every automotive sealing application presents unique challenges—be it resistance to engine oil at 150°C, low-temperature flexibility in sub-zero climates, or compression set performance in safety-critical joints. Our consultative approach begins with a detailed analysis of your operating environment, followed by material selection, finite element analysis (FEA) when required, and iterative testing to validate performance.

Partnering with Suzhou Baoshida means gaining access to a vertically integrated supply chain, real-time production monitoring, and technical documentation including material certifications, PPAP files, and 3D dimensional reports. We support global logistics with DDP and EXW shipping terms and maintain inventory hubs in Shanghai and Rotterdam for just-in-time delivery.

For immediate assistance, reach out to Mr. Boyce via email at [email protected]. Include your technical specifications, annual volume requirements, and any applicable drawings or reference parts to accelerate the evaluation process. We respond to all inquiries within 4 business hours and offer virtual factory audits upon request.

Below are key technical capabilities and material specifications routinely utilized in our automotive seal production:

| Property | NBR | EPDM | FKM (Viton) | Silicone |

|---|---|---|---|---|

| Temperature Range (°C) | -30 to +120 | -50 to +150 | -20 to +200 | -60 to +200 |

| Fluid Resistance | Oil, fuel, hydraulic fluid | Water, steam, brake fluid | Aggressive fuels, acids, oils | Low surface tension fluids |

| Hardness Range (Shore A) | 50–90 | 55–85 | 60–90 | 40–80 |

| Compression Set (22 hrs, 100°C) | ≤25% | ≤20% | ≤20% | ≤25% |

| Common Applications | Transmission seals, O-rings | Radiator hoses, weatherstripping | Turbocharger hoses, valve stem seals | Electrical insulation, gaskets |

Contact Mr. Boyce today to discuss your next-generation sealing solution.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).