Technical Contents

Engineering Guide: Ptfe Plate

Engineering Insight: Material Selection in PTFE Plate Applications

In industrial environments where chemical exposure, thermal cycling, and mechanical stress are routine, the selection of polymer materials is not a matter of convenience—it is a determinant of system integrity and operational continuity. Polytetrafluoroethylene (PTFE) plates are frequently specified for their exceptional chemical inertness, low coefficient of friction, and thermal stability. However, the assumption that all PTFE plates are functionally equivalent leads to premature failure, unplanned downtime, and safety risks. Off-the-shelf solutions, while cost-attractive, often fail because they are manufactured to generic specifications without accounting for application-specific variables such as load distribution, creep resistance, or thermal expansion differentials.

PTFE, in its virgin form, exhibits near-universal chemical resistance and operates continuously from -200°C to +260°C. These properties make it ideal for sealing, insulating, and bearing applications in chemical processing, semiconductor manufacturing, and aerospace systems. Yet, virgin PTFE is prone to cold flow and has limited wear resistance under dynamic loads. Industrial applications demanding dimensional stability under sustained pressure require filled PTFE compounds—reinforced with materials such as glass fiber, carbon, graphite, or bronze. Each filler modifies the base polymer’s behavior: glass enhances compressive strength, carbon improves thermal conductivity and wear resistance, while bronze increases thermal conductivity and reduces permeation in high-vacuum environments.

The failure of standard PTFE plates often originates in mismatched material formulation. For example, a gasket in a high-pressure reactor may perform adequately in lab-scale trials using virgin PTFE but fail in field deployment due to creep relaxation under prolonged stress. Similarly, a bearing plate in a continuous-motion machine may exhibit rapid wear if the PTFE lacks appropriate fillers to resist abrasive particulates or oscillating loads.

At Suzhou Baoshida Trading Co., Ltd., we emphasize application-driven material engineering. Our PTFE plate solutions are formulated based on operational parameters: temperature profile, media compatibility, mechanical loading, and service life expectations. This approach ensures that the selected material not only resists chemical attack but also maintains structural fidelity over time.

Below are key mechanical and thermal properties of common PTFE plate variants used in industrial applications:

| Property | Virgin PTFE | 25% Glass-Filled PTFE | 15% Carbon + 5% Graphite PTFE | 10% Bronze-Filled PTFE |

|---|---|---|---|---|

| Continuous Use Temperature | -200°C to +260°C | -200°C to +260°C | -200°C to +280°C | -200°C to +280°C |

| Tensile Strength (MPa) | 20–35 | 25–40 | 30–45 | 28–42 |

| Compressive Strength (MPa) | 10–15 | 15–25 | 20–30 | 18–28 |

| Coefficient of Friction | 0.05–0.10 | 0.10–0.15 | 0.12–0.18 | 0.15–0.20 |

| Linear Thermal Expansion (10⁻⁵/K) | 10–12 | 5–7 | 6–8 | 7–9 |

| Creep Resistance | Low | Moderate | High | High |

Material selection must transcend catalog numbers. It requires a partnership between manufacturer and end user—one grounded in engineering data, environmental simulation, and lifecycle analysis. At Baoshida, we provide not just PTFE plates, but engineered solutions calibrated to the rigors of real-world operation.

Material Specifications

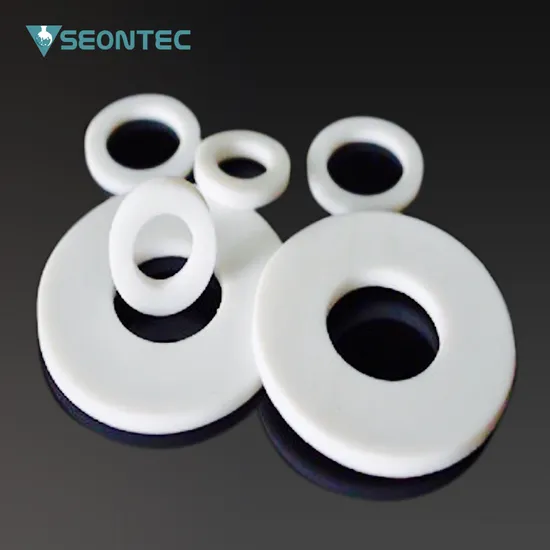

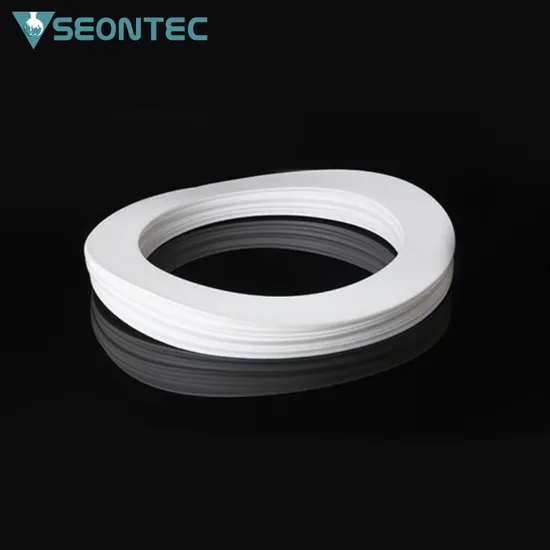

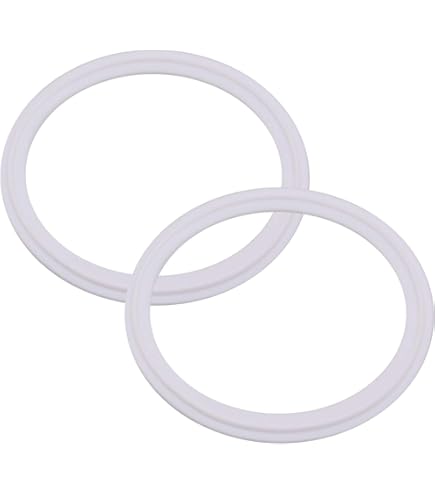

Material Specifications for Elastomeric Components Complementing PTFE Plate Systems

PTFE (Polytetrafluoroethylene) plates serve as critical inert barriers in demanding industrial applications, yet their performance is often dependent on compatible elastomeric sealing elements. At Suzhou Baoshida Trading Co., Ltd., we engineer precision rubber solutions specifically designed to interface with PTFE plates under extreme conditions. While PTFE itself offers unmatched chemical inertness and thermal stability (continuous use up to 260°C), the dynamic sealing requirements in flanges, valves, and gaskets necessitate complementary elastomers. Viton (FKM), Nitrile (NBR), and Silicone (VMQ) represent our core material families for such applications, each selected based on rigorous analysis of operational parameters including chemical exposure, temperature cycling, and mechanical stress. Misalignment in elastomer-PTFE system compatibility directly compromises integrity, leading to permeation, extrusion, or premature failure. Our OEM protocols mandate precise material validation against the specific service environment, ensuring the rubber component maintains resilience without degrading the PTFE interface.

The following table details critical specifications for these elastomers when deployed alongside PTFE plates. Key metrics include operational temperature limits, resistance to common industrial fluids, and inherent mechanical limitations. Data reflects standardized testing per ASTM D2000 and ISO 37, validated through our in-house R&D facility in Suzhou.

| Material | Temperature Range (°C) | Key Chemical Resistance | Typical Applications with PTFE Plates | Critical Limitations |

|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Excellent against oils, acids, fuels, halogenated solvents | Chemical processing seals, semiconductor wafer handling, high-temp fluid systems | Poor resistance to ketones, esters; higher cost; limited low-temp flexibility |

| Nitrile (NBR) | -30 to +120 | Good for petroleum oils, water, aliphatic hydrocarbons | Hydraulic systems, general-purpose gaskets, food-grade PTFE-lined equipment | Swells in strong acids, ozone, polar solvents; degrades above 120°C |

| Silicone (VMQ) | -60 to +200 | Resists water, ozone, mild chemicals, steam | Pharmaceutical diaphragms, cryogenic seals, medical device components with PTFE | Poor tensile strength; incompatible with concentrated acids, fuels, hydrocarbons |

Material selection transcends basic compatibility charts. For instance, in sulfuric acid handling systems using PTFE-lined reactors, Viton’s superior acid resistance justifies its cost despite NBR’s lower price point. Conversely, NBR remains optimal for hydraulic manifolds with PTFE wear strips where cost efficiency and petroleum fluid resistance dominate. Silicone’s extreme low-temperature flexibility suits cryogenic PTFE valve seats but fails in fuel-exposed environments. Our engineering team conducts application-specific permeation testing and compression set analysis to prevent elastomer swelling or hardening that could distort PTFE plate alignment.

Suzhou Baoshida integrates material science with OEM manufacturing rigor. We provide certified test reports for every batch, including Shore A hardness consistency (±2 points) and volume swell data in client-specified media. This precision ensures rubber components maintain dimensional stability against PTFE plates throughout the product lifecycle. For complex multi-fluid exposures, our formula engineers develop custom FKM or perfluoroelastomer (FFKM) blends, extending service life beyond standard compounds. Partner with us to transform PTFE plate system reliability through scientifically validated elastomer integration.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability is anchored in deep technical expertise and precision-driven processes, enabling us to deliver high-performance PTFE plate solutions tailored to demanding industrial applications. Our team comprises five dedicated mould engineers and two specialized rubber formula engineers, ensuring that both the physical design and material composition of each PTFE plate are optimized for performance, durability, and consistency. This integrated approach allows us to support full-cycle development from concept to mass production, particularly for OEM partners requiring custom-engineered components.

Our mould engineers utilize advanced CAD/CAM software and CNC machining protocols to develop precision tooling that ensures dimensional accuracy and surface integrity in every PTFE plate produced. With extensive experience in compression and isostatic moulding techniques, our team can accommodate complex geometries, tight tolerances, and application-specific surface finishes. Each mould design undergoes rigorous simulation and validation to minimize defects and maximize production efficiency, particularly for high-volume OEM contracts.

Complementing our mould engineering strength is our in-house rubber formulation capability. Our two certified formula engineers specialize in polymer science with a focus on enhancing the performance characteristics of PTFE and PTFE-composite materials. By modifying fillers such as glass fiber, carbon, graphite, or bronze, we can tailor the thermal stability, wear resistance, electrical insulation, and friction coefficient of PTFE plates to meet exact customer requirements. This level of material customization is critical for clients in aerospace, semiconductor manufacturing, chemical processing, and high-vacuum environments where standard-grade PTFE may not suffice.

We operate under strict quality control protocols aligned with ISO standards, ensuring batch-to-batch consistency and full traceability. Our facility supports small-batch prototyping as well as large-scale manufacturing, making us a flexible partner for global OEMs. All formulations and mould designs are documented and protected under confidentiality agreements, safeguarding our clients’ intellectual property.

The following table outlines the standard technical specifications we achieve for PTFE plates, with custom parameters available upon request.

| Property | Standard Value | Test Method |

|---|---|---|

| Density | 2.1–2.3 g/cm³ | ASTM D792 |

| Tensile Strength | ≥20 MPa | ASTM D638 |

| Elongation at Break | ≥200% | ASTM D638 |

| Operating Temperature Range | -200°C to +260°C | ASTM D696 / D1711 |

| Dielectric Strength | ≥15 kV/mm | ASTM D149 |

| Coefficient of Friction | ≤0.15 (dynamic) | ASTM D3702 |

| Water Absorption (24h) | 0.01% | ASTM D570 |

Our engineering team works in close collaboration with clients to analyze application conditions, environmental stressors, and mechanical loads, ensuring that every PTFE plate solution is scientifically validated before release. This systematic, data-driven approach underscores our commitment to excellence in industrial rubber solutions.

Customization Process

PTFE Plate Customization Process: Precision Engineering for Industrial Applications

At Suzhou Baoshida Trading Co., Ltd., our PTFE plate customization process integrates rigorous engineering protocols to transform client specifications into high-performance industrial components. This structured workflow ensures dimensional accuracy, material integrity, and compliance with sector-specific standards, from initial concept to volume delivery.

Drawing Analysis initiates the process, where our engineering team conducts a granular review of technical schematics. Critical parameters—including dimensional tolerances (±0.05 mm achievable), surface finish requirements (Ra ≤ 0.8 μm), and geometric complexities—are cross-referenced against PTFE’s inherent material behavior. We identify potential manufacturing constraints such as isotropic shrinkage during sintering or stress concentration points, providing actionable feedback to optimize design feasibility without compromising functional intent. This phase aligns client expectations with material science realities, preventing downstream rework.

Formulation Development follows, leveraging our proprietary compound library to tailor PTFE’s properties. Pure PTFE offers exceptional chemical resistance but limited mechanical stability; thus, we strategically incorporate fillers like glass fiber, carbon, or bronze to enhance creep resistance, thermal conductivity, or wear performance. Each formulation is modeled using rheological simulations to predict flow behavior during compression molding, ensuring optimal density distribution. Critical variables—such as filler concentration (5–25% by weight), particle size distribution, and sintering temperature profiles—are precisely calibrated to meet application-specific demands, whether for semiconductor seals or chemical processing gaskets.

Prototyping validates the engineered solution through controlled small-batch production. Plates are manufactured under ISO 9001-certified processes, with real-time monitoring of pressure cycles (20–40 MPa) and sintering profiles (360–380°C ramp rates). Each prototype undergoes destructive and non-destructive testing: tensile strength verification per ASTM D1457, dielectric strength assessment, and chemical immersion trials. Dimensional conformity is confirmed via CMM inspection, with deviations triggering iterative refinement. This phase mitigates risk by exposing material or process gaps before tooling commitment.

Mass Production commences only after prototype approval, deploying optimized parameters across our automated production lines. Continuous in-line monitoring tracks sintering oven gradients, press tonnage, and cooling rates to maintain ±2°C thermal uniformity. Every batch undergoes statistical process control (SPC), with certificates of conformance detailing traceable material lots and test results. Final plates are vacuum-sealed to prevent moisture absorption, ensuring shelf stability until deployment.

Key PTFE Plate Specifications and Customization Ranges

| Property | Standard Unfilled PTFE | Customizable Range (Filled Grades) | Test Standard |

|---|---|---|---|

| Density (g/cm³) | 2.15–2.20 | 2.25–2.45 | ASTM D792 |

| Tensile Strength (MPa) | 20–35 | 30–65 | ASTM D638 |

| Continuous Service Temp (°C) | -200 to +260 | -200 to +300 (special grades) | ASTM D149 |

| Dielectric Strength (kV/mm) | 60 | 40–80 | ASTM D149 |

| Coefficient of Friction | 0.05–0.10 | 0.08–0.30 (filler-dependent) | ASTM D3702 |

This end-to-end methodology guarantees that Suzhou Baoshida’s PTFE plates exceed OEM performance thresholds while minimizing time-to-market. Our commitment to material science rigor and process transparency establishes a foundation for long-term industrial partnerships.

Contact Engineering Team

Contact Suzhou Baoshida for High-Performance PTFE Plate Solutions

At Suzhou Baoshida Trading Co., Ltd., we specialize in delivering precision-engineered industrial rubber and polymer solutions tailored to the exacting demands of modern manufacturing. As a trusted OEM partner in the field of high-performance materials, we provide PTFE (polytetrafluoroethylene) plates engineered for superior chemical resistance, thermal stability, and low friction across a wide range of industrial applications. Whether your operation requires non-stick surfaces, electrical insulation, or corrosion-resistant components, our PTFE plates are manufactured to meet international quality standards and customized to your dimensional and performance requirements.

Our technical team, led by Mr. Boyce, brings over a decade of experience in polymer material science and industrial component supply. We understand that in high-stakes environments—such as semiconductor processing, chemical processing, food machinery, or aerospace systems—material integrity is non-negotiable. That’s why we implement strict quality control protocols from raw material sourcing through final inspection, ensuring each PTFE plate batch meets precise mechanical and thermal specifications.

We invite engineering managers, procurement officers, and R&D teams to contact us directly to discuss your PTFE plate needs. Whether you require standard sizes or custom-machined components, we offer rapid prototyping, volume production, and just-in-time delivery solutions to support your operational efficiency.

Below are the key technical specifications of our standard PTFE plate offerings:

| Property | Value | Test Standard |

|---|---|---|

| Density | 2.10–2.20 g/cm³ | ASTM D792 |

| Tensile Strength | ≥20 MPa | ASTM D638 |

| Elongation at Break | ≥250% | ASTM D638 |

| Melting Point | 327°C | ASTM D4565 |

| Continuous Use Temperature | -200°C to +260°C | ASTM D618 |

| Dielectric Strength | ≥60 kV/mm | ASTM D149 |

| Coefficient of Friction | 0.05–0.10 (dynamic) | ASTM D3702 |

| Water Absorption (24h) | <0.01% | ASTM D570 |

All PTFE plates are available in virgin and filled grades (including glass-filled, carbon-filled, and bronze-filled variants) to enhance wear resistance, dimensional stability, or thermal conductivity based on application demands. We also offer machining services to produce precise geometries, hole patterns, and surface finishes.

To initiate a technical consultation or request a material data sheet, contact Mr. Boyce directly at [email protected]. Include your application details, required dimensions, and performance criteria to receive a tailored proposal within 24 business hours. Our team supports English and Chinese communication and provides logistics solutions to North America, Europe, Southeast Asia, and beyond.

Partner with Suzhou Baoshida Trading Co., Ltd. for reliable, high-precision PTFE plate supply backed by technical expertise and responsive service. Your next-generation industrial solution starts with a single email.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).