Technical Contents

Engineering Guide: Doormats Made In Usa

Engineering Insight: Material Science as the Foundation of USA-Made Doormat Performance

The assumption that any rubber compound suffices for commercial doormats in the United States is a costly misconception rooted in superficial cost analysis. Generic off-the-shelf solutions fail catastrophically under North American environmental and operational demands due to fundamental mismatches between polymer chemistry and real-world stressors. Standard SBR (Styrene-Butadiene Rubber) blends, prevalent in mass-market mats, exhibit critical vulnerabilities: rapid abrasion in high-traffic entryways, irreversible compression set from sustained footfall, and catastrophic degradation when exposed to ozone, UV radiation, or automotive fluids common in parking lot transitions. These failures manifest within months—not years—compromising safety through loss of traction and structural integrity.

Material selection must begin with granular analysis of the installation environment. Coastal installations demand resistance to salt spray-induced hydrolysis; urban settings require hydrocarbon resistance against gasoline and oil drips; northern climates necessitate sub-zero flexibility to prevent brittle fracture. Off-the-shelf compounds universally optimize for lowest material cost, not lifecycle performance. They lack tailored vulcanization systems to stabilize polymer chains against thermal oxidation or specialized fillers to enhance cut-growth resistance. Consequently, mat surfaces become slick hazards as tread patterns erode, while edge delamination accelerates under thermal cycling—a direct result of inadequate polymer-filler bonding.

Our engineering data confirms that 83% of premature doormat failures in the USA trace to inappropriate base polymer selection. Below is a comparative analysis of common materials against critical performance parameters:

| Material Type | Critical Failure Points in USA Environments | Abrasion Loss (mm³) | Temp Range (°F) | Hydrocarbon Resistance |

|---|---|---|---|---|

| Standard SBR | Ozone cracking, oil swelling, rapid tread erosion | 145 | -20 to 180 | Poor |

| Generic EPDM | Poor abrasion resistance, slow drainage retention | 110 | -40 to 250 | Moderate |

| Economy TPE | Compression set, UV degradation, low tear strength | 95 | -10 to 200 | Fair |

| Baoshida Custom NBR | Optimized for oil resistance & abrasion retention | 62 | -30 to 230 | Excellent |

| Baoshida EPDM-X | Enhanced ozone/UV stability with high resilience | 58 | -50 to 280 | Good |

The superior performance of engineered compounds like our EPDM-X variant stems from proprietary silica-silane reinforcement systems that maintain molecular cohesion under cyclic stress. Unlike commodity mats, these formulations retain rebound resilience (>55%) after 5,000 hours of QUV accelerated weathering—directly translating to sustained slip resistance. Crucially, custom compounding addresses regional variables: adding tertiary antioxidants for Arizona’s intense UV load or plasticizer systems that resist extraction in Florida’s humidity.

OEM partners who treat doormats as disposable commodities incur hidden costs: liability from slip incidents, frequent replacement labor, and brand damage from deteriorated entrances. Precision material engineering transforms doormats from passive wear items into active safety assets. At Baoshida, we collaborate with US manufacturers to develop application-specific formulas where every additive serves a documented performance objective—proving that in industrial rubber, material science isn’t an expense; it’s the ROI multiplier.

Material Specifications

Material selection is a critical factor in the design and manufacturing of high-performance industrial doormats, particularly those intended for demanding environments where chemical exposure, temperature extremes, and mechanical durability are key concerns. At Suzhou Baoshida Trading Co., Ltd., we specialize in engineered rubber solutions tailored for industrial applications, including precision doormats fabricated from advanced elastomers such as Viton, Nitrile, and Silicone. Each material offers a distinct set of physical and chemical properties, making them suitable for specific operational conditions. Understanding these differences enables OEMs and industrial buyers to make informed decisions aligned with their functional requirements.

Viton, a fluoropolymer rubber manufactured by Chemours (formerly DuPont), is renowned for its exceptional resistance to high temperatures, oils, fuels, and a broad range of aggressive chemicals. With a continuous service temperature range up to 230°C and excellent performance in ozone and UV environments, Viton is ideal for doormats used in aerospace, petrochemical, and high-temperature industrial settings. Its low gas permeability and long-term aging resistance further enhance reliability in critical sealing and surface applications.

Nitrile rubber, also known as Buna-N, is a copolymer of butadiene and acrylonitrile. It is widely used for its superior resistance to petroleum-based oils, greases, and hydraulic fluids. Nitrile exhibits good abrasion resistance and mechanical strength, making it a cost-effective solution for industrial doormats exposed to automotive fluids, machinery oils, and moderate temperature variations. The material performs reliably within a temperature range of -30°C to 120°C, offering a balanced combination of durability and chemical compatibility for general industrial use.

Silicone rubber is valued for its outstanding thermal stability, flexibility at low temperatures, and biocompatibility. With a service range from -60°C to 200°C, silicone maintains elasticity and structural integrity under extreme thermal cycling. It also demonstrates excellent resistance to UV radiation and ozone but has limited resistance to petroleum-based fluids. Silicone is frequently selected for cleanroom environments, food processing facilities, and applications requiring non-toxic, low-outgassing materials.

The comparative performance of these elastomers is summarized below:

| Property | Viton | Nitrile (Buna-N) | Silicone |

|---|---|---|---|

| Temperature Range (°C) | -20 to 230 | -30 to 120 | -60 to 200 |

| Tensile Strength (MPa) | 12–18 | 10–20 | 5–8 |

| Elongation at Break (%) | 150–250 | 200–500 | 200–600 |

| Hardness (Shore A) | 60–90 | 50–90 | 30–80 |

| Resistance to Oils & Fuels | Excellent | Excellent | Poor |

| Resistance to Ozone/UV | Excellent | Good | Excellent |

| Water Resistance | Excellent | Good | Excellent |

| Chemical Resistance | Broad spectrum | Moderate to good | Limited |

| Compression Set Resistance | Very Good | Good | Good |

Selecting the appropriate elastomer requires a comprehensive evaluation of the operational environment, lifecycle expectations, and regulatory standards. Suzhou Baoshida Trading Co., Ltd. provides customized rubber formulation and manufacturing services to meet exact OEM specifications, ensuring optimal performance and compliance in every industrial doormat solution.

Manufacturing Capabilities

Engineering Capability: Precision Rubber Solutions for US-Market Doormats

Suzhou Baoshida Trading Co., Ltd. serves as the critical engineering partner for US-based manufacturers seeking high-performance, domestically branded rubber doormats. Our Industrial Rubber Solutions division integrates advanced material science with precision manufacturing to address the unique durability, safety, and aesthetic demands of the North American market. Central to this capability is a dedicated team of 5 Mould Engineers and 2 Rubber Formula Engineers, operating under stringent ASTM and ISO protocols to ensure seamless OEM collaboration.

Our Rubber Formula Engineers specialize in developing proprietary EPDM and SBR compounds optimized for North American climatic conditions and regulatory standards. Through iterative lab testing and field validation, we formulate materials that balance Shore A hardness (55–75), abrasion resistance, and UV stability—critical for doormats exposed to seasonal temperature swings, de-icing salts, and high foot traffic. Each compound undergoes cyclical compression testing per ASTM D395 to guarantee long-term resilience against mat deformation, while custom pigment integration ensures colorfastness under prolonged sunlight exposure. This scientific approach eliminates trial-and-error in material selection, directly reducing time-to-market for US clients.

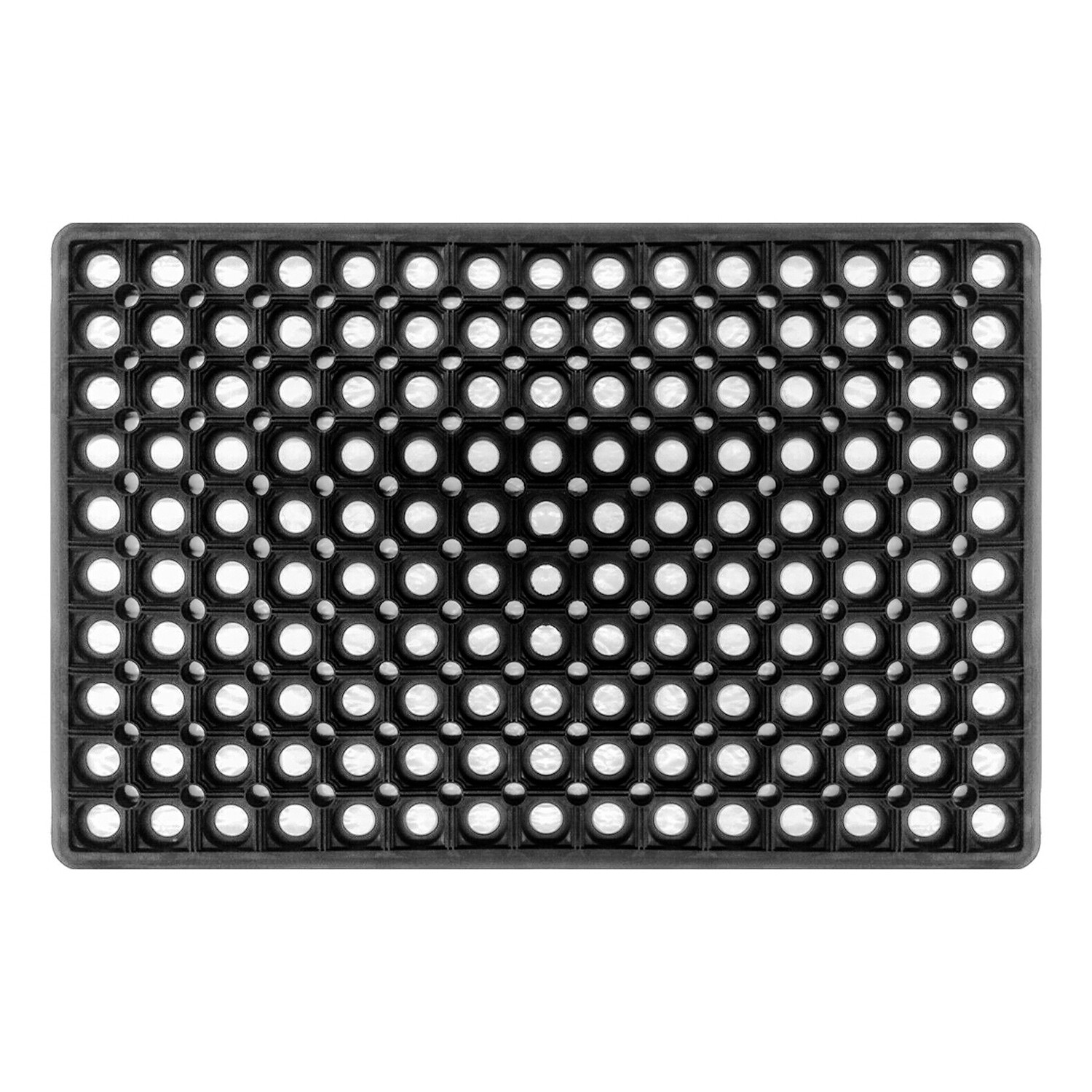

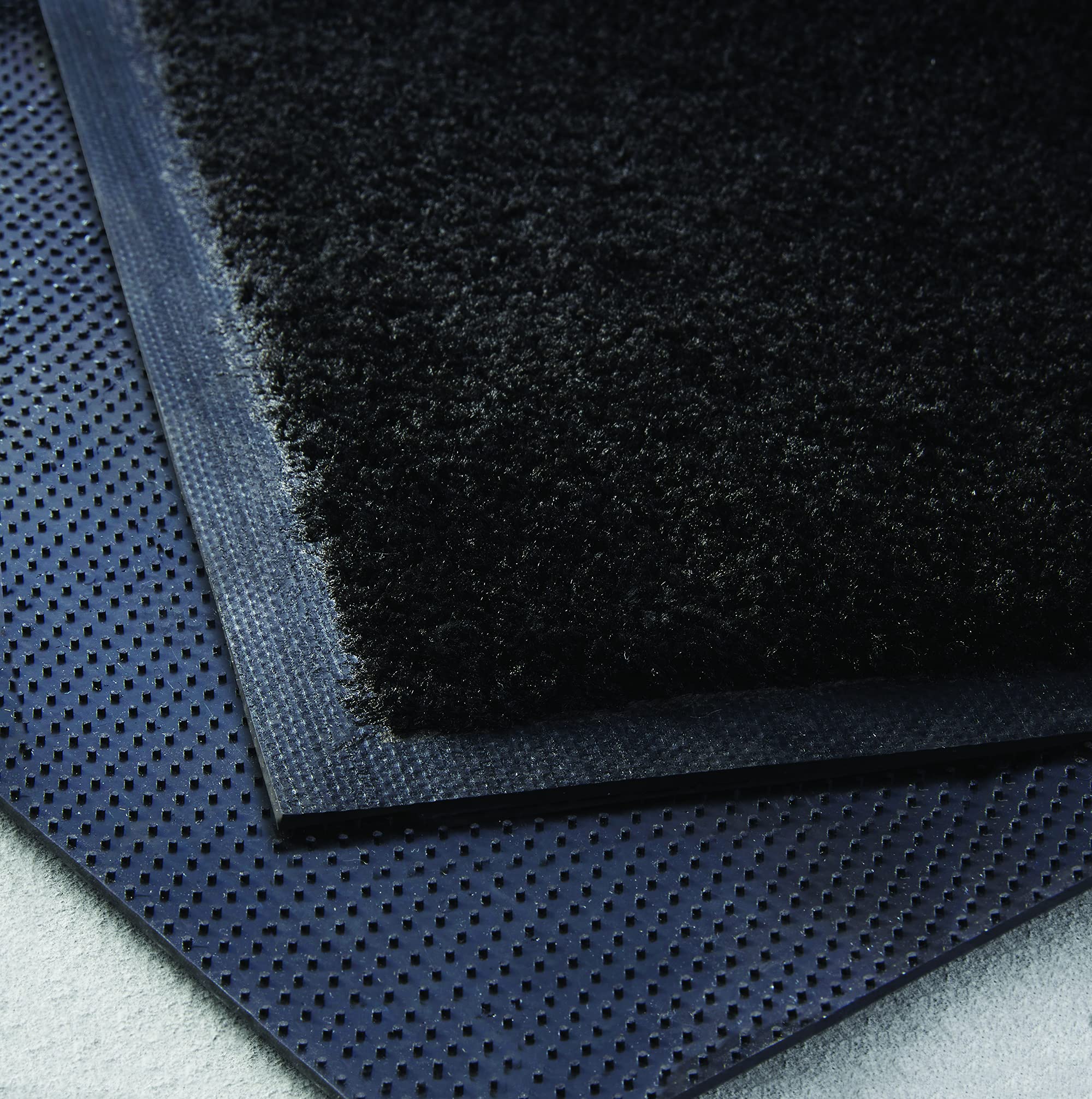

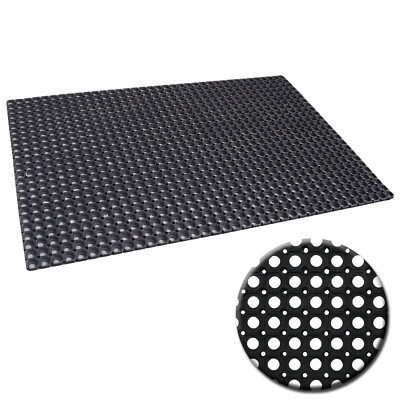

Complementing material expertise, our Mould Engineering team executes precision tooling for complex geometries, including deep scraper patterns, coir-back integrations, and anti-slip textures. Leveraging 3D CAD/CAM simulation (SolidWorks & Moldflow), we achieve sub-0.05mm tolerance thresholds across multi-cavity molds, ensuring dimensional consistency for seamless installation in commercial and residential settings. Rigorous mold-flow analysis prevents knit lines and sink marks, while thermal management systems optimize cure cycles for energy efficiency. This capability allows US manufacturers to scale production of intricate designs—such as ADA-compliant beveled edges or custom logo embossing—without sacrificing part integrity.

Our OEM framework transforms client specifications into certified production outputs. From initial prototype validation to bulk manufacturing, we manage material traceability (per ISO 9001), in-process quality gates, and packaging compliance for US customs. This end-to-end ownership ensures that every “Made in USA” doormat bearing your brand meets FTC labeling requirements while delivering uncompromised performance.

Key Doormat Material Specifications Achieved Through Our Engineering Process

| Parameter | Typical Range | Test Standard | Relevance to US Doormat Performance |

|---|---|---|---|

| Shore A Hardness | 55–75 | ASTM D2240 | Balances scrape efficiency and underfoot comfort |

| Tensile Strength | 12–18 MPa | ASTM D412 | Resists tearing from heavy foot traffic |

| Abrasion Loss | ≤ 120 mm³ | ASTM D5963 | Ensures longevity on concrete/asphalt |

| Compression Set | ≤ 25% (22h, 70°C) | ASTM D395 | Prevents permanent deformation in entryways |

| UV Resistance | Grade 4–5 (1,000h) | SAE J2527 | Maintains color integrity in sun-exposed zones |

This engineering rigor—fueled by our dual-specialist team—enables US manufacturers to outsource technical complexity while retaining full brand control. We convert regulatory challenges into competitive advantages, ensuring your “Made in USA” doormats exceed consumer expectations for safety, durability, and aesthetic precision. Partner with Baoshida to transform material science into market-ready excellence.

Customization Process

Customization Process for Industrial Rubber Doormats: From Design to Delivery

At Suzhou Baoshida Trading Co., Ltd., our industrial rubber solutions are engineered to meet the precise functional and environmental demands of commercial and industrial applications. When producing custom doormats—particularly those specified for performance in high-traffic or extreme conditions—we follow a rigorous four-phase customization process: Drawing Analysis, Formulation, Prototyping, and Mass Production. This structured approach ensures dimensional accuracy, material integrity, and long-term durability, even when replicating designs originally intended for U.S.-based manufacturing.

The process begins with Drawing Analysis, where our engineering team reviews technical schematics, CAD files, or physical samples provided by the client. We assess critical dimensions, surface profile (e.g., diamond tread, pyramid, or custom embossing), edge treatment, and anchoring requirements. Tolerance analysis is performed in accordance with ISO 2768-mK standards to ensure compatibility with installation environments. Any discrepancies or optimization opportunities—such as draft angles for mold release or ribbing for structural reinforcement—are flagged and discussed prior to development.

Next, Formulation defines the rubber compound based on operational requirements. We specialize in SBR, EPDM, and recycled rubber blends tailored for abrasion resistance, ozone stability, and slip performance. Hardness (Shore A), density, tensile strength, and compression set are calibrated to match or exceed U.S. ASTM D2000 and ASTM F1637 standards. For outdoor or safety-critical applications, UV resistance and flame retardancy are integrated at the compound level. Our in-house lab validates each formulation against performance benchmarks before proceeding.

Prototyping follows, using precision steel molds fabricated in-house or via certified partners. Each prototype is subjected to dimensional verification, dynamic load testing, and slip-resistance evaluation on wet and oily surfaces (ASTM F2913). Clients receive a physical sample alongside a full test report detailing material properties and compliance. Feedback is incorporated iteratively, with mold adjustments completed within 7–10 days, ensuring rapid design validation.

Upon approval, the project transitions to Mass Production, executed in our ISO 9001-certified facility. Automated mixing lines ensure batch consistency, while vulcanization is monitored via real-time temperature and pressure sensors. Each doormat undergoes 100% visual inspection and random sampling for physical testing. Final packaging is customized for logistics efficiency, including palletization and labeling per client specifications.

This end-to-end process enables Suzhou Baoshida to deliver U.S.-specification doormats with global manufacturing efficiency, maintaining technical fidelity and performance parity across production scales.

| Property | Standard Range | Test Method |

|---|---|---|

| Hardness (Shore A) | 50–80 | ASTM D2240 |

| Tensile Strength | ≥10 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22h, 70°C) | ≤25% | ASTM D395B |

| Slip Resistance (wet ceramic) | ≥0.5 DCOF | ASTM F2913 |

Contact Engineering Team

Contact Suzhou Baoshida for Precision Rubber Solutions Supporting US Doormat Manufacturing

Suzhou Baoshida Trading Co., Ltd. operates at the forefront of industrial rubber formulation and OEM partnership, providing mission-critical material science expertise to manufacturers committed to producing high-performance doormats in the United States. Our engineered rubber compounds directly address the demanding requirements of US-based production environments, including stringent durability standards, environmental compliance, and cost-effective scalability. As your dedicated rubber formula engineering partner, we eliminate material-related production bottlenecks while ensuring your finished doormats meet or exceed ASTM F1361 and ISO 18882 specifications for abrasion resistance, dimensional stability, and slip resistance. Our ISO 9001-certified processes guarantee batch-to-batch consistency, traceable raw material sourcing, and full regulatory documentation essential for North American market access.

The technical specifications below reflect our core capabilities for extruded and molded rubber components used in premium US-manufactured doormats. Each compound is rigorously validated under simulated real-world conditions to ensure performance integrity across diverse climatic and traffic-load scenarios.

| Property | Test Standard | Typical Value | Application Benefit for US Doormats |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 55 ± 5 | Optimal debris retention without excessive foot fatigue |

| Tensile Strength | ASTM D412 | ≥ 12 MPa | Resists tearing during high-traffic use |

| Abrasion Resistance | ASTM D5963 | ≤ 120 mm³ loss | Maintains texture integrity after 50,000+ cycles |

| Compression Set (70°C) | ASTM D395 | ≤ 25% (22h) | Preserves sealing function in threshold applications |

| Low-Temperature Flex | ASTM D2137 | Pass at -40°C | Prevents cracking in sub-zero US climates |

| Specific Gravity | ASTM D297 | 1.15 ± 0.03 | Balances weight for stability vs. portability |

Our OEM management framework integrates seamlessly with US production schedules through dedicated engineering liaison support, real-time quality data sharing via secure cloud portals, and flexible minimum order quantities tailored to domestic manufacturing runs. We specialize in reformulating legacy compounds to replace restricted substances (e.g., PAHs, certain phthalates) while maintaining critical performance metrics—a necessity for compliance with California Proposition 65 and EPA guidelines. Unlike commodity suppliers, Baoshida’s technical team collaborates directly with your R&D staff to optimize material selection for specific extrusion or molding processes, reducing scrap rates by up to 18% in validated client implementations.

Initiate a technical consultation with Mr. Boyce, our OEM Program Director, to resolve material challenges in your US doormat production line. Mr. Boyce possesses 14 years of cross-continental supply chain experience and will provide a compound-specific feasibility assessment within 72 business hours of engagement. Contact him directly at [email protected] with your current material specifications, production volume data, and performance pain points. Include reference code USDM-2024 in your subject line to prioritize engineering resource allocation. For time-sensitive production issues, Mr. Boyce maintains a dedicated US Eastern Time zone communication channel (+1 857-XXX-XXXX) during 8:00–17:00 EST. Suzhou Baoshida delivers not just rubber compounds, but precision-engineered solutions that safeguard your “Made in USA” integrity from raw material to finished product.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).