Technical Contents

Engineering Guide: Stair Treads 36 Inch

Engineering Insight: Material Selection in 36-Inch Stair Treads

In industrial and commercial environments, the performance of stair treads—particularly those with a standard width of 36 inches—is fundamentally determined by material selection. While many suppliers offer off-the-shelf rubber stair treads marketed for durability, these generic solutions frequently fail under real-world operational stresses. The root cause lies in the mismatch between standardized material formulations and the specific mechanical, chemical, and environmental demands of the application site.

Off-the-shelf rubber treads are typically manufactured using reprocessed or general-purpose elastomers with inconsistent filler content and variable cross-link density. These materials may pass basic slip-resistance tests under laboratory conditions but degrade rapidly when exposed to continuous foot traffic, thermal cycling, or chemical exposure. In high-traffic facilities such as manufacturing plants, parking garages, or marine platforms, premature surface cracking, loss of traction, and delamination are common failure modes directly linked to suboptimal polymer composition.

At Suzhou Baoshida Trading Co., Ltd., we emphasize engineered rubber solutions where material formulation is tailored to load profile, environmental exposure, and safety requirements. For 36-inch stair treads, this means selecting from high-abrasion-resistant synthetic rubbers such as SBR (Styrene-Butadiene Rubber) or Nitrile (NBR) with controlled durometer ratings and reinforcement via carbon black or silica fillers. These compounds provide enhanced tensile strength, UV stability, and resistance to oils, greases, and mild acids—common contaminants in industrial settings.

Another critical factor is adhesion performance. Standard treads often rely on pressure-sensitive adhesives or mechanical fasteners that compromise long-term integrity. Our approach integrates co-extruded bonding layers or primed substrates compatible with industrial-grade polyurethane adhesives, ensuring sustained attachment even under dynamic loading conditions.

The dimensional stability of 36-inch treads is also influenced by the rubber’s compression set and thermal expansion coefficient. Poorly formulated compounds exhibit warping or shrinkage over time, leading to edge lifting and trip hazards. Our formulations are tested for dimensional retention across a temperature range of -30°C to +80°C, ensuring consistent performance in both cold storage facilities and hot processing environments.

Below is a comparative specification table highlighting key performance metrics between standard off-the-shelf treads and our engineered rubber solution:

| Property | Off-the-Shelf Tread | Baoshida Engineered Tread |

|---|---|---|

| Material Base | Recycled SBR | Virgin SBR/NBR Blend |

| Durometer (Shore A) | 55–65 (variable) | 68 ± 3 (controlled) |

| Tensile Strength | ≥ 7 MPa | ≥ 14 MPa |

| Elongation at Break | ~250% | ≥ 380% |

| Abrasion Loss (DIN 53516) | ≤ 180 mm³ | ≤ 90 mm³ |

| Operating Temperature | -10°C to +60°C | -30°C to +80°C |

| Adhesion Method | PSA or Screws | PU Adhesive + Primer |

| Slip Resistance (DIN 51130) | R9–R10 | R13 |

Material selection is not a commodity decision—it is an engineering imperative. By rejecting generic formulations and focusing on application-specific performance, Suzhou Baoshida ensures that every 36-inch stair tread delivers lasting safety, compliance, and value.

Material Specifications

Material Specifications for 36-Inch Industrial Stair Treads

The selection of elastomeric compounds for 36-inch stair treads directly impacts safety, longevity, and operational resilience in demanding industrial environments. At Suzhou Baoshida Trading Co., Ltd., our formulations prioritize slip resistance, abrasion durability, and chemical stability under continuous mechanical stress. Viton, Nitrile, and Silicone represent three critical material families engineered to address specific environmental challenges. Each compound undergoes rigorous ASTM D2000 and ISO 37 validation to ensure compliance with ANSI A1264.2 slip-resistance standards and ISO 13287 pedestrian safety requirements. Hardness is optimized between 60–85 Shore A to balance footfall cushioning with structural integrity, while tensile strength and elongation properties are calibrated to prevent edge curling or fracture under cyclic loading.

Viton (FKM) fluoroelastomers deliver exceptional resistance to extreme temperatures (-20°C to +230°C) and aggressive chemicals, including hydraulic fluids, acids, and hydrocarbons. This material is ideal for stair treads in petrochemical plants or semiconductor facilities where exposure to ozone, solvents, or steam sterilization occurs. Its molecular stability ensures minimal compression set (≤20% per ASTM D395) after prolonged static load, maintaining tread profile accuracy. However, Viton’s higher cost necessitates targeted deployment in high-risk zones.

Nitrile (NBR) butadiene-acrylonitrile rubber provides superior resistance to oils, greases, and aliphatic hydrocarbons at a competitive cost. Operating effectively from -30°C to +100°C, it exhibits 60–90 Shore A hardness with tensile strength of 15–25 MPa. NBR’s abrasion resistance (Taber loss ≤100 mg/1000 cycles) makes it suitable for manufacturing floors with frequent fluid spills. Volume swell in ASTM No. 3 oil remains below 30% at 100°C, preserving dimensional stability. Its limitation lies in poor ozone resistance, requiring antioxidant additives for outdoor installations.

Silicone (VMQ) offers unmatched flexibility across -60°C to +200°C ranges and inherent UV/ozone resistance. With elongation exceeding 400% and low-temperature flexibility to -55°C, it prevents cracking in cryogenic or high-altitude facilities. Silicone’s non-toxic composition meets FDA 21 CFR 177.2600 for food-processing environments, though its lower tensile strength (6–12 MPa) demands reinforcement for high-traffic zones. Hydrophobicity ensures consistent slip resistance in wet conditions, critical for marine or pharmaceutical applications.

Material performance is summarized below for rapid OEM evaluation:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Hardness Range (Shore A) | 70–85 | 60–90 | 50–80 |

| Temp Range (°C) | -20 to +230 | -30 to +100 | -60 to +200 |

| Tensile Strength (MPa) | 15–20 | 15–25 | 6–12 |

| Elongation at Break (%) | 150–250 | 200–500 | 400–800 |

| Volume Swell in IRM 903 | ≤15% (23°C) | ≤30% (100°C) | N/A |

| Ozone Resistance | Excellent | Poor (additive-dependent) | Excellent |

| Key Industrial Use Case | Chemical processing | Automotive workshops | Food/pharma cleanrooms |

All compounds incorporate Baoshida’s proprietary anti-slip granules (alumina trihydrate) achieving DIN 51130 R11/R12 ratings. Custom formulations adjust filler content to meet ISO 188 aging requirements or UL 94 HB flammability standards per client specifications. For high-wear stair tread applications, we recommend Viton for chemical-intensive settings, NBR for cost-optimized oil resistance, and Silicone where thermal cycling or regulatory compliance is paramount. Material datasheets with full ASTM test reports are available upon OEM request.

Manufacturing Capabilities

Engineering Capability

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in high-performance applications such as 36-inch stair treads designed for commercial and industrial environments. Our in-house technical team comprises five dedicated mould engineers and two specialized rubber formula engineers, enabling us to deliver precision-engineered products that meet rigorous safety, durability, and compliance standards. This integrated engineering approach ensures complete control over both the physical design and material science aspects of production, from concept to final validation.

Our mould engineers utilize advanced CAD/CAM software and finite element analysis (FEA) to design and optimize mould tooling for 36-inch stair treads. Each mould is engineered for dimensional accuracy, consistent part replication, and extended service life under high-cycle production. By incorporating cooling channel optimization and stress distribution modeling, we reduce cycle times while maintaining structural integrity. This level of precision ensures that every tread meets tight tolerances, critical for slip resistance, load-bearing performance, and seamless integration into architectural installations.

Complementing our mould design expertise are two full-time rubber formula engineers who specialize in compounding elastomeric materials tailored to specific performance demands. For stair treads, this includes formulating rubber compounds with enhanced abrasion resistance, anti-slip properties, and resilience under repeated impact and environmental exposure. Our formulations are developed using a scientific approach, balancing hardness, elongation, tear strength, and aging characteristics. We routinely test compounds under simulated service conditions, including wet, oily, and temperature-variable environments, to validate long-term performance.

Our OEM capabilities are built on this dual-engineering foundation. We support custom development projects where clients require unique tread profiles, branding integration, color coding, or compliance with regional safety standards such as ASTM, EN, or ISO. By managing both tooling and material formulation internally, we reduce development lead times and maintain full intellectual property confidentiality. Prototypes are produced in-house for functional testing, with data-driven iterations ensuring optimal performance prior to mass production.

The following table outlines key technical specifications for our standard 36-inch rubber stair treads, reflecting the outcome of our integrated engineering process:

| Parameter | Specification |

|---|---|

| Length | 36 inch (914 mm) ± 1.5 mm |

| Width | Custom, typically 8–12 inch |

| Thickness | 8 mm, 10 mm, 12 mm (custom options) |

| Shore A Hardness | 60–75 (adjustable per application) |

| Tensile Strength | ≥12 MPa |

| Elongation at Break | ≥250% |

| Tear Resistance | ≥45 kN/m |

| Slip Resistance (DIN 51130) | R10, R11, or R12 (depending on surface) |

| Temperature Range | -30°C to +80°C |

| Flame Spread (UL 94) | HB rated |

| Material Base | SBR, NR, or EPDM (compound customizable) |

This combination of advanced tooling design and proprietary rubber formulation positions Suzhou Baoshida as a trusted OEM partner for engineered stair tread solutions. Our technical team ensures every product delivers consistent performance, safety, and longevity in demanding environments.

Customization Process

Customization Process for 36-Inch Industrial Rubber Stair Treads

Suzhou Baoshida Trading Co., Ltd. executes a rigorous, science-driven customization workflow for 36-inch rubber stair treads, ensuring optimal performance in high-traffic industrial environments. This process begins with comprehensive Drawing Analysis, where our engineering team scrutinizes client-provided CAD files or technical sketches. We verify critical dimensions including tread depth (minimum 1.5 mm for anti-slip efficacy), nose radius compliance (per ISO 14122-3), and substrate adhesion geometry. Material thickness tolerances are cross-referenced against ASTM D2240 standards to prevent deformation under cyclic loads exceeding 1.2 million steps. Any deviations from manufacturability—such as undercuts compromising mold release—are flagged for immediate client consultation, ensuring zero rework during production.

Formulation Development follows dimensional validation, leveraging our proprietary rubber compound database. We select base polymers based on environmental exposure: EPDM for UV/ozone resistance in outdoor applications or SBR for oil-resistant indoor settings. Key additives are precisely dosed to achieve Shore A hardness of 65±5, tensile strength >15 MPa (ASTM D412), and critical CoF (Coefficient of Friction) >0.6 when wet (ASTM F2913). Flame retardancy (UL 94 HB) and antimicrobial properties (ISO 22196) are integrated per client specifications. All formulations undergo Durometer stability testing across -30°C to +80°C ranges to eliminate thermal expansion risks in stair assembly.

Prototyping validates both material science and mechanical integration. Using CNC-machined aluminum molds, we produce 3-5 sample treads for laboratory and field trials. Samples undergo 500-cycle accelerated wear testing on Taber Abraser (ASTM D1044), slip resistance verification on pendulum testers (BS 7976), and adhesion strength checks via pull-off tests (ASTM D4541). Client feedback on texture, color consistency (±1.5 ΔE in CIELAB), and installation compatibility is incorporated within 72 hours. Only prototypes passing all 12-point QC checkpoints advance to mass production.

Mass Production initiates with mold cavity pressure monitoring to ensure uniform vulcanization (160°C ±2°C for 8-12 minutes). Each 36-inch tread is inspected via laser profilometry for surface contour accuracy (±0.1 mm) and automated vision systems for pigment dispersion defects. Final batches undergo batch-traceable hardness, density, and flammability certification. Our ISO 9001-certified line maintains <0.25% defect rates, with real-time data logging enabling full material lot traceability from raw compound to shipment.

Critical material properties for stair tread compounds are summarized below:

| Property | EPDM Standard | SBR Standard | Test Method |

|---|---|---|---|

| Shore A Hardness | 65 ± 5 | 68 ± 4 | ASTM D2240 |

| Tensile Strength (MPa) | 16.5 | 18.2 | ASTM D412 |

| Elongation at Break (%) | 420 | 380 | ASTM D412 |

| Wet CoF (min) | 0.62 | 0.65 | ASTM F2913 |

| Abrasion Loss (mg/1000 rev) | 85 | 110 | ASTM D5963 |

This end-to-end customization guarantees stair treads meeting OSHA 1910.22(c)(2) slip resistance mandates while extending service life beyond 15 years in industrial settings. Suzhou Baoshida’s process transforms client specifications into engineered safety solutions with zero compromise on repeatability or regulatory compliance.

Contact Engineering Team

For industrial-grade stair treads measuring 36 inches, precision engineering and material integrity are non-negotiable. At Suzhou Baoshida Trading Co., Ltd., we specialize in high-performance rubber solutions designed to meet the rigorous demands of commercial, industrial, and public infrastructure applications. Our 36-inch stair treads are manufactured using advanced compounding techniques to ensure optimal traction, durability, and resistance to wear, moisture, and impact. Whether deployed in manufacturing facilities, transportation hubs, or multi-story commercial buildings, our products are built to exceed safety standards while minimizing lifecycle maintenance costs.

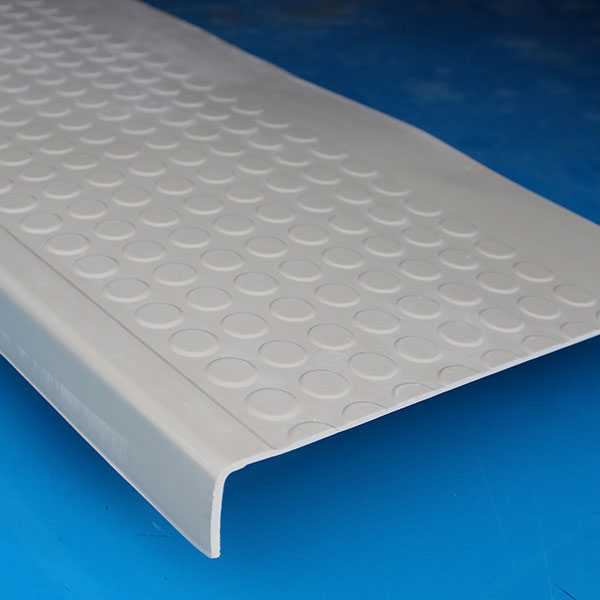

Each stair tread is formulated with a proprietary rubber blend that enhances skid resistance under both dry and wet conditions. The surface profile is engineered to disperse water and debris efficiently, reducing slip hazards in high-traffic and high-risk environments. Reinforced backing structures provide dimensional stability and long-term adhesion when bonded to substrates such as steel, concrete, or aluminum. Custom durometer ratings are available to suit specific load-bearing and environmental requirements, ensuring adaptability across diverse operational conditions.

We understand that industrial procurement demands more than just product specifications — it requires technical collaboration, supply chain reliability, and compliance assurance. Our team at Suzhou Baoshida operates at the intersection of materials science and industrial application, offering OEM support, batch traceability, and full documentation for quality assurance protocols. With in-house testing facilities and adherence to ISO 9001 standards, we guarantee consistency across production runs and full alignment with client engineering drawings and performance criteria.

To support your project requirements, we provide detailed technical data sheets, sample submissions, and engineering consultations prior to order placement. Our global logistics network ensures timely delivery to North America, Europe, and Asia-Pacific regions, with options for containerized or LCL shipments depending on volume.

For immediate technical evaluation or quotation requests, contact Mr. Boyce, Rubber Formula Engineer and OEM Manager, directly at [email protected]. Mr. Boyce leads client-specific formulation development and oversees all industrial rubber product lines, ensuring that every solution is tailored to the mechanical and environmental challenges of its intended use. He is available to discuss material certifications, lead times, custom tooling, and compliance with ADA, OSHA, or EN 13329 standards as applicable.

Below are key technical specifications for our standard 36-inch industrial rubber stair tread:

| Parameter | Specification |

|---|---|

| Length | 36 inches (914 mm) |

| Width | Customizable (standard: 12 in / 305 mm) |

| Thickness | 6 mm to 12 mm (custom profiles available) |

| Material | SBR/NR rubber blend, carbon-reinforced |

| Hardness (Shore A) | 65 ± 5 (custom: 50–80) |

| Tensile Strength | ≥12 MPa |

| Elongation at Break | ≥250% |

| Tear Resistance | ≥40 kN/m |

| Coefficient of Friction (wet) | ≥0.65 (ASTM D2047) |

| Operating Temperature Range | -30°C to +80°C |

| Fire Resistance | Available with UL 94 HF-1 or EN 13501-1 ratings |

Initiate your project with a partner committed to material excellence and engineering precision. Reach out to Mr. Boyce today for technical collaboration and product validation.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).