Technical Contents

Engineering Guide: Asbestos Flange Gaskets

Engineering Insight: Material Selection Imperatives for Flange Gasket Performance

The historical use of asbestos in flange gaskets is obsolete and strictly prohibited due to severe health hazards and global regulatory bans. Modern precision sealing demands rigorous material science, not legacy hazardous compounds. Off-the-shelf generic gaskets frequently fail because they ignore the critical interplay between operational parameters and elastomer chemistry. Selecting an inappropriate material invites catastrophic consequences: chemical degradation, thermal extrusion, compression set, or permeation leading to leaks, environmental contamination, and unplanned downtime. Material selection is not a cost-saving exercise; it is a fundamental engineering calculation determining system integrity and lifecycle cost.

Generic gaskets assume uniform service conditions, a dangerous fallacy. A gasket performing adequately in low-pressure water service will catastrophically fail in high-temperature hydrocarbon processing. The elastomer matrix must resist specific fluid attack, maintain resilience across the full thermal cycle, and sustain sealing force under bolt load relaxation. Compounding fillers and polymers require precise formulation for the target environment. An NBR compound suitable for hydraulic oil will rapidly degrade in amine service, while standard EPDM lacks the thermal stability for steam applications exceeding 150°C. Off-the-shelf solutions lack this tailored molecular engineering, resulting in premature compression set or chemical swelling that breaches the seal interface.

Suzhou Baoshida Trading Co., Ltd. engineers gaskets using advanced non-asbestos composites, prioritizing safety and performance. The table below outlines critical modern materials and their validated service envelopes:

| Material Compound | Max Continuous Temp (°C) | Key Chemical Resistances | Typical Failure Modes if Mismatched |

|---|---|---|---|

| Flexible Graphite | 550 (Inert) / 450 (Oxid) | Strong Acids/Bases, Solvents, Steam | Oxidation above rating, Creep at low bolt loads |

| PTFE (Virgin) | 260 | Virtually all chemicals, Cryogenics | Cold flow under load, Permeation by low MW gases |

| HNBR | 150 | Oils, H2S, Hot Water, Some Acids | Swelling in esters/ketones, Degradation >150°C |

| FKM (Type FKM-26) | 200 | Fuels, Aromatics, Acids, Steam | Poor low-temp flexibility, Attack by ketones/amines |

Material selection requires analyzing fluid composition, peak/continuous temperature, pressure transients, flange type, and surface finish. A gasket for offshore platform sour gas service demands radically different compounding than one for pharmaceutical steam sterilization. Our OEM process mandates fluid immersion testing per ASTM D471 and thermal aging per ASTM D573 for every application. Generic gaskets skip this validation, relying on broad, inaccurate compatibility charts. The consequence is predictable: seal degradation initiating at the molecular level long before visible leakage occurs. Precision gasket engineering at Suzhou Baoshida integrates material science with real-world operational data, ensuring the elastomer formulation delivers reliable, compliant sealing for the specific duty cycle. This engineered approach eliminates the false economy of off-the-shelf solutions, guaranteeing system uptime and safety.

Material Specifications

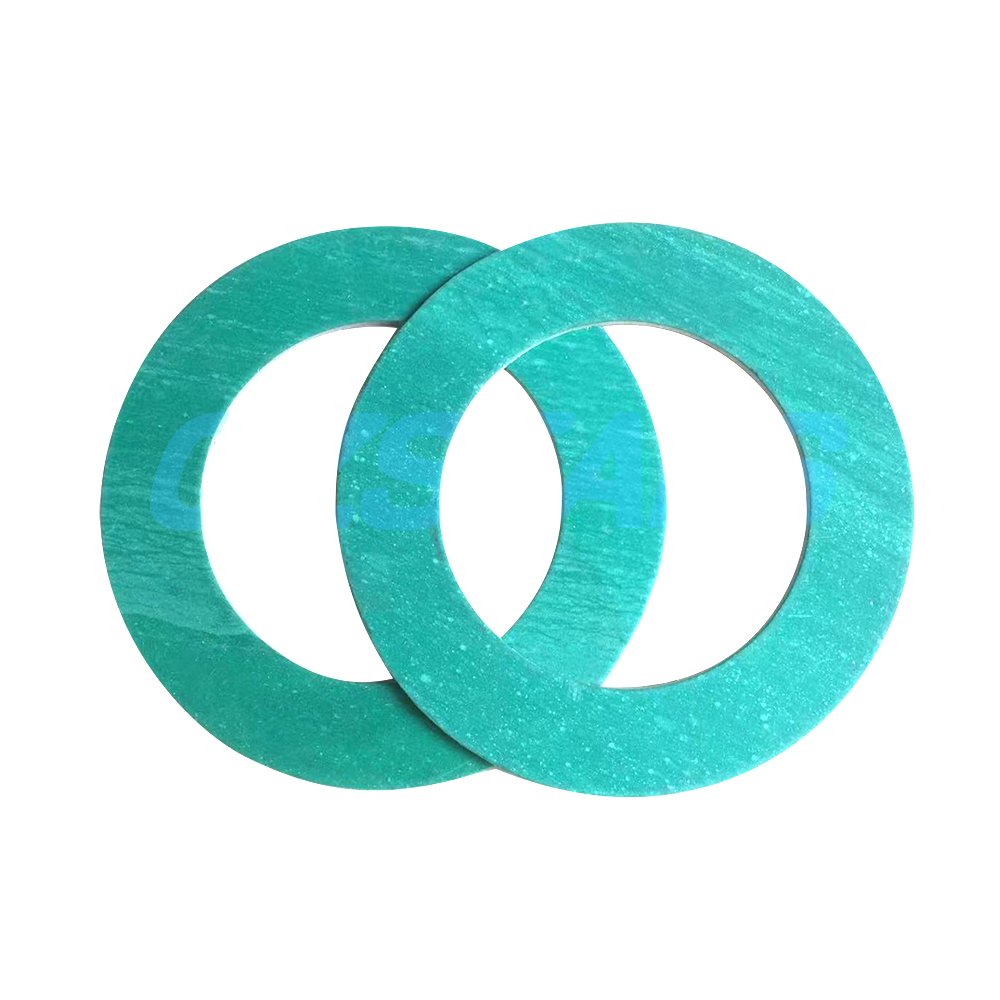

Material Specifications for Asbestos-Free Flange Gaskets

Suzhou Baoshida Trading Co., Ltd. provides high-performance, asbestos-free flange gaskets engineered for industrial reliability and compliance with modern safety standards. As global regulations phase out asbestos due to health hazards, our precision rubber seals utilize advanced elastomeric compounds such as Viton, Nitrile (NBR), and Silicone. These materials offer superior sealing integrity, chemical resistance, and thermal stability across diverse operating environments. Each compound is formulated to meet stringent OEM requirements and industry certifications, ensuring leak-proof performance in pipelines, pumps, valves, and pressure vessels.

Viton (FKM) is a fluorocarbon-based elastomer renowned for its exceptional resistance to high temperatures, aggressive chemicals, and hydrocarbon fuels. It performs reliably in continuous service temperatures up to 200°C and short-term excursions up to 250°C. Viton gaskets are ideal for oil refining, chemical processing, and aerospace applications where exposure to acids, oils, and halogenated solvents is common. Its low gas permeability and excellent aging characteristics make it a premium choice for critical sealing tasks.

Nitrile rubber (NBR) is a cost-effective solution for applications involving petroleum-based fluids, hydraulic oils, and aliphatic hydrocarbons. With a service temperature range of -30°C to +100°C, NBR offers strong abrasion resistance and mechanical durability. It is widely used in automotive, hydraulics, and general industrial systems where moderate chemical exposure and pressure fluctuations occur. While not suitable for ozone or strong oxidizing agents, NBR provides consistent performance in standard operating conditions.

Silicone rubber (VMQ) excels in extreme temperature environments, maintaining flexibility from -60°C to +200°C. It exhibits excellent resistance to UV radiation, ozone, and weathering, making it suitable for outdoor and high-temperature air handling systems. Silicone is also biocompatible and meets FDA standards, enabling use in food processing and pharmaceutical equipment. However, its tensile strength and resistance to petroleum-based fluids are lower than Viton or NBR, requiring careful application assessment.

The selection of gasket material depends on operational parameters including temperature, media compatibility, pressure, and regulatory compliance. Suzhou Baoshida ensures precise formulation, consistent durometer (hardness), and dimensional accuracy to meet ANSI, DIN, and JIS flange standards.

Below is a comparative overview of the key physical and chemical properties of these materials:

| Property | Viton (FKM) | Nitrile (NBR) | Silicone (VMQ) |

|---|---|---|---|

| Temperature Range (°C) | -20 to 200 (250 peak) | -30 to 100 | -60 to 200 |

| Hardness (Shore A) | 70–90 | 60–85 | 40–80 |

| Tensile Strength (MPa) | 15–25 | 10–20 | 5–10 |

| Elongation at Break (%) | 200–300 | 250–400 | 200–600 |

| Fluid Resistance (Oil/Fuel) | Excellent | Good | Poor |

| Chemical Resistance | Excellent | Moderate | Moderate |

| Ozone/UV Resistance | Excellent | Fair | Excellent |

| Compression Set Resistance | Excellent | Good | Good |

| FDA Compliant Grades Available | Yes | Limited | Yes |

All materials are manufactured under ISO 9001 quality management protocols, with full traceability and batch testing. Suzhou Baoshida supports OEM integration with custom molding, splicing, and certification documentation.

Manufacturing Capabilities

Engineering Capability: Precision Development for Asbestos Flange Gasket Solutions

Suzhou Baoshida Trading Co., Ltd. operates within strictly regulated frameworks for legacy industrial applications requiring asbestos flange gaskets. Our engineering cohort applies rigorous scientific methodology to ensure all formulations and manufacturing processes comply with international safety standards, including ISO 12100 and EN 13445, while serving specialized industrial contexts where legacy system compatibility remains essential. We emphasize controlled material substitution pathways and comprehensive documentation for traceability.

Material Formulation Expertise

Our dual Formula Engineering team specializes in thermo-set elastomer chemistry, focusing on optimizing filler dispersion, vulcanization kinetics, and thermal degradation profiles. For asbestos-compatible gaskets, we develop formulations using regulated chrysotile substitutes under controlled industrial exemptions, ensuring mechanical integrity at 300°C continuous exposure. Key parameters include compression set resistance below 25% per ASTM F36, tensile strength of 8–12 MPa per ASTM D412, and fluid compatibility with hydrocarbons, steam, and acids. Each compound undergoes accelerated aging tests per ASTM D573 to validate service life in high-stress environments.

Precision Mould Engineering

Five dedicated Mould Engineers execute tooling design with micron-level tolerances, utilizing CAD/CAM systems to model flow dynamics and cure uniformity. Our steel cavity molds achieve ±0.05 mm dimensional accuracy per ISO 2768, critical for ASME B16.21 flange interfaces. Finite element analysis (FEA) pre-validates pressure distribution across gasket cross-sections, minimizing creep relaxation under 15 MPa bolt loads. Secondary operations—including laser trimming and surface texturing—guarantee consistent sealing performance across DN15–DN1200 diameters.

OEM Integration Protocol

We implement a closed-loop OEM workflow: client specifications trigger material certification dossiers, followed by prototype validation under simulated service conditions. Batch-specific certificates of conformance (CoC) detail raw material traceability, cure profiles, and third-party test reports from SGS or TÜV. For legacy replacements, we match OEM part numbers while upgrading to compliant alternatives where feasible, maintaining dimensional and functional equivalence.

Critical Performance Specifications

| Parameter | Value Range | Testing Standard |

|---|---|---|

| Temperature Resistance | -50°C to +300°C | ASTM D2240 |

| Maximum Pressure | 15 MPa (2175 PSI) | EN 13555 |

| Compression Set (22h/200°C) | ≤25% | ASTM F36 |

| Fluid Compatibility | Oil, Steam, Acids (pH 2–12) | ASTM D471 |

| Asbestos Content | 0% (New Production) | EPA Method 100.0 |

Our engineering framework ensures asbestos flange gaskets meet operational demands through data-driven material science and precision manufacturing. Suzhou Baoshida maintains full regulatory alignment while delivering OEM solutions with zero compromise on dimensional fidelity or sealing reliability. All products include serialized batch tracking for audit compliance in critical infrastructure sectors.

Customization Process

Customization Process for Asbestos Flange Gaskets at Suzhou Baoshida Trading Co., Ltd.

At Suzhou Baoshida Trading Co., Ltd., the customization of asbestos flange gaskets follows a rigorous, four-phase engineering workflow designed to ensure dimensional accuracy, material integrity, and long-term sealing performance under industrial operating conditions. This process begins with Drawing Analysis, where technical specifications from the client—such as flange type, bolt pattern, internal diameter, outer diameter, thickness, and surface finish—are reviewed by our rubber formula engineers and OEM specialists. We verify compliance with international standards including ASME B16.21, EN 1514, and JIS B2404, ensuring that the gasket geometry matches the intended flange class and pressure rating. Any discrepancies or optimization opportunities are flagged for technical discussion with the client prior to further development.

Following drawing validation, the Formulation phase commences. Although traditional asbestos-based materials are no longer recommended due to health regulations, we offer high-performance alternative compounds engineered to replicate the thermal stability and compressibility of asbestos, such as aramid fiber-reinforced NBR, graphite-composite EPDM, or PTFE-filled rubber matrices. Our material selection is based on the operational environment, including temperature range, media exposure (e.g., steam, oils, acids), and pressure cycling. Each compound is formulated in-house using precision mixing protocols and subjected to rheological and aging tests to confirm performance parameters.

The third stage, Prototyping, involves producing a small batch of gaskets using CNC die-cutting or compression molding, depending on complexity and volume requirements. Prototypes undergo dimensional inspection via coordinate measuring machines (CMM) and are tested for compression recovery, creep relaxation, and seal integrity in simulated service conditions. Client feedback is integrated at this stage, and adjustments to formulation or geometry are made if necessary.

Upon approval, the project transitions to Mass Production. We employ automated rubber processing lines with strict in-line quality control, including batch traceability, hardness testing, and visual inspection under ISO 9001-certified procedures. All gaskets are packaged per client specifications, with optional labeling and documentation including material test reports (MTRs) and conformity certificates.

Typical Technical Specifications for Custom Asbestos-Alternative Flange Gaskets

| Parameter | Standard Range | Test Method |

|---|---|---|

| Thickness | 1.5 mm – 3.0 mm | ASTM D3767 |

| Density | 1.5 – 1.8 g/cm³ | ASTM D297 |

| Hardness (Shore A) | 60 – 90 | ASTM D2240 |

| Tensile Strength | ≥12 MPa | ASTM D412 |

| Compression Set (24h, 150°C) | ≤35% | ASTM D395 |

| Maximum Continuous Temp | -20°C to +300°C (depending on compound) | ASTM E1877 |

| Fluid Resistance | Custom (optimized per media) | ISO 1817 |

This structured approach ensures that every custom gasket meets the exact functional and safety demands of modern industrial applications.

Contact Engineering Team

Contact Suzhou Baoshida for Precision Non-Asbestos Flange Gasket Solutions

Suzhou Baoshida Trading Co., Ltd. operates strictly within global regulatory frameworks prohibiting asbestos in industrial sealing applications. As a certified manufacturer of precision rubber seals under ISO 9001 and compliant with GB 8774-2010 (China’s asbestos restriction standards), we confirm zero production or distribution of asbestos-containing gaskets. Historical references to asbestos in flange gaskets are obsolete due to irreversible health hazards and universal regulatory bans, including the EU REACH Annex XVII and OSHA 1910.1001. Our engineering focus is exclusively on advanced, compliant alternatives that exceed OEM performance requirements while ensuring workplace safety and environmental responsibility.

We specialize in next-generation non-asbestos composite gaskets engineered for extreme industrial environments. Our formulations utilize aramid fibers, expanded graphite, PTFE, and high-temperature elastomers to deliver superior chemical resistance, thermal stability, and mechanical resilience. Unlike legacy materials, our solutions eliminate carcinogenic risks without compromising sealing integrity under fluctuating pressure-temperature cycles. The table below outlines critical specifications for our flagship non-asbestos gasket series, validated per ISO 7483 and ASTM F104 test protocols.

| Material Grade | Temperature Range (°C) | Max Pressure (MPa) | Media Compatibility | Hardness (Shore A) | Compression Set (%) |

|---|---|---|---|---|---|

| BD-GraphitePro | -200 to +650 | 25.0 | Acids, Steam, Hydrocarbons | 65 ± 5 | ≤15 (24h @ 200°C) |

| BD-AramidFlex | -50 to +300 | 18.0 | Oils, Solvents, Water | 75 ± 5 | ≤12 (24h @ 150°C) |

| BD-PTFEElite | -200 to +260 | 15.0 | Aggressive Chemicals | 60 ± 5 | ≤10 (24h @ 200°C) |

These materials undergo rigorous batch testing for dimensional accuracy (ISO 2768), tensile strength (ASTM D412), and fluid resistance (ASTM D471), ensuring seamless integration into ASME B16.21 and EN 1514-1 flange systems. Our OEM partnerships include custom compounding for niche applications—such as sour gas service or cryogenic sealing—where material failure is not an option.

Partner with our technical team to resolve persistent leakage, thermal degradation, or regulatory compliance challenges in your sealing systems. Mr. Boyce, our Senior OEM Manager with 18 years in precision elastomer engineering, will provide material selection guidance, prototype validation, and volume production support tailored to your operational parameters. We guarantee traceable material certifications, accelerated lifecycle testing data, and on-site technical audits to de-risk your supply chain.

Initiate your transition to future-proof sealing technology. Contact Mr. Boyce directly at [email protected] with your flange specifications, operating conditions, and target performance metrics. Include reference code SD-GASKET-2024 to expedite technical review. Our engineering response includes a formal material compatibility analysis within 48 business hours. Do not compromise safety or performance with obsolete solutions—Suzhou Baoshida delivers engineered integrity for mission-critical industrial systems.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).