Technical Contents

Engineering Guide: Rubber Tiles For Basement

Engineering Insight: Material Selection in Rubber Tiles for Basement Applications

In industrial and semi-industrial environments, basement spaces demand flooring systems capable of withstanding prolonged exposure to moisture, mechanical stress, and temperature fluctuations. While consumer-grade rubber tiles are often marketed as universal solutions, their performance in basement settings frequently falls short due to inadequate material engineering. At Suzhou Baoshida Trading Co., Ltd., we emphasize that material selection is not a secondary consideration—it is the foundational determinant of long-term durability, safety, and cost efficiency.

Off-the-shelf rubber tiles, typically formulated from recycled rubber content with minimal binder integration, exhibit structural instability under sustained humidity. These products often utilize unvulcanized or partially vulcanized elastomeric compounds, which lack the cross-link density required to resist hydrolytic degradation. As a result, premature delamination, surface crumbling, and dimensional warping are common within 12 to 18 months of installation. Furthermore, inconsistent filler dispersion—particularly in calcium carbonate or synthetic clay-loaded formulations—leads to non-uniform compression resistance, increasing trip hazards and maintenance costs.

Our engineered rubber tiles utilize a proprietary blend of vulcanized SBR (Styrene-Butadiene Rubber) and EPDM (Ethylene Propylene Diene Monomer), optimized for subterranean environments. The vulcanization process, executed under controlled temperature and pressure, ensures a stable sulfur-based cross-linked network that resists plasticization from ambient moisture. Additionally, the inclusion of nano-silica reinforcement enhances tensile strength and abrasion resistance without compromising flexibility. This formulation maintains performance across a thermal range of -30°C to +80°C, critical for basements subject to seasonal thermal cycling.

Another overlooked factor is vapor transmission resistance. Standard tiles often lack a bonded backing layer, allowing moisture vapor to migrate upward and compromise adhesive integrity. Our solution integrates a co-extruded HDPE (High-Density Polyethylene) moisture barrier, reducing water vapor transmission rates (WVTR) to less than 0.3 g/m²/day—well within industrial thresholds for below-grade installations.

The following table outlines key material specifications that differentiate engineered rubber tiles from generic alternatives:

| Property | Engineered Tile (Baoshida) | Standard Off-the-Shelf Tile |

|---|---|---|

| Base Polymer | Vulcanized SBR/EPDM blend | Recycled rubber, low binder |

| Cross-Link Density | ≥ 3.8 × 10⁻⁴ mol/cm³ | ≤ 1.2 × 10⁻⁴ mol/cm³ |

| Tensile Strength | 14.5 MPa | 6.8 MPa |

| Elongation at Break | 280% | 140% |

| Compression Set (22 hrs, 70°C) | 18% | 42% |

| Water Absorption (24 hrs) | 0.9% | 3.5% |

| Slip Resistance (DIN 51130) | R10 | R8 |

| Service Temperature Range | -30°C to +80°C | -10°C to +60°C |

Material integrity directly influences lifecycle cost. While engineered rubber tiles require a higher initial investment, their service life exceeds 15 years under continuous load, compared to 3–5 years for standard tiles. For industrial clients, this translates into reduced downtime, lower replacement frequency, and compliance with occupational safety standards.

At Suzhou Baoshida Trading Co., Ltd., we engineer rubber not as a commodity, but as a precision solution—tailored for the unseen challenges of basement environments.

Material Specifications

Material Specifications for Industrial Rubber Basement Tiles

Selecting the optimal elastomer for basement flooring applications requires rigorous evaluation of environmental stressors, including moisture exposure, temperature fluctuations, chemical contact from stored materials, and long-term compression under static loads. At Suzhou Baoshida Trading Co., Ltd., our engineered rubber tiles leverage three primary high-performance polymers—Viton, Nitrile, and Silicone—each formulated to address distinct operational demands. Precision in material selection directly impacts service life, safety compliance, and total cost of ownership in commercial and industrial basements.

Viton (FKM) fluorocarbon rubber delivers exceptional resistance to extreme temperatures and aggressive chemicals. Its molecular structure provides stability against oils, acids, solvents, and ozone, making it ideal for basements housing mechanical equipment or chemical storage. Viton tiles maintain integrity from -20°C to +230°C, though its higher cost necessitates targeted use where lesser elastomers would degrade. Nitrile (NBR) butadiene-acrylonitrile copolymer offers the best balance of oil/fuel resistance and cost efficiency for general basement environments. With a functional range of -30°C to +100°C, NBR excels against hydraulic fluids, greases, and aliphatic hydrocarbons while providing robust abrasion resistance and mechanical strength. Silicone (VMQ) polymers prioritize extreme temperature flexibility and non-toxicity, operating reliably from -60°C to +200°C. Its inert nature suits food storage or cleanroom-adjacent basements, though it exhibits lower tensile strength and higher permeability to non-polar fluids compared to NBR or Viton.

Critical performance parameters for basement tile selection are quantified below. All materials undergo ASTM D2000 standard testing for industrial rubber compounds, with hardness calibrated to 65±5 Shore A for optimal slip resistance and load distribution under typical basement conditions.

| Material | Temperature Range (°C) | Key Chemical Resistances | Tensile Strength (MPa) | Elongation at Break (%) | Hardness Range (Shore A) | Primary Basement Applications |

|---|---|---|---|---|---|---|

| Viton (FKM) | -20 to +230 | Fuels, acids, ketones, halogenated solvents | 12-18 | 150-250 | 60-80 | Equipment rooms, chemical storage, high-heat utility spaces |

| Nitrile (NBR) | -30 to +100 | Oils, greases, aliphatic hydrocarbons, water | 15-22 | 200-400 | 60-80 | General storage, parking areas, workshops, utility corridors |

| Silicone (VMQ) | -60 to +200 | Ozone, water vapor, weak acids/bases, steam | 6-10 | 250-600 | 60-80 | Food/pharma storage, cleanrooms, cold storage, moisture-prone zones |

OEM formulation adjustments at Suzhou Baoshida enable tailored solutions within these material families. For instance, high-acrylonitrile NBR variants enhance fuel resistance for automotive facility basements, while peroxide-cured silicone formulations improve compression set resistance in perpetually damp environments. All tiles incorporate proprietary anti-microbial agents meeting ISO 22196 standards to inhibit mold growth—a critical failure point in subterranean installations. Material thickness (typically 6-12mm) and backing systems are co-engineered with substrate adhesion chemistry to prevent delamination under hydrostatic pressure.

Final material specification must align with site-specific risk assessments. NBR remains the workhorse for cost-sensitive, general-purpose basements, while Viton justifies its premium for severe chemical exposure. Silicone is reserved for ultra-low-temperature or stringent hygiene requirements. Suzhou Baoshida’s technical team conducts application audits to match polymer physics with real-world basement stressors, ensuring tile performance exceeds ISO 9001 durability benchmarks.

Manufacturing Capabilities

Engineering Capability: Precision-Driven Rubber Tile Development for Basements

At Suzhou Baoshida Trading Co., Ltd., our engineering capability forms the backbone of our industrial rubber solutions, particularly in the development and production of high-performance rubber tiles for basement applications. With a dedicated team of five experienced mould engineers and two specialized rubber formula engineers, we integrate material science with precision manufacturing to deliver products that meet rigorous performance standards for moisture resistance, durability, and structural integrity.

Our formula engineers focus on the molecular design of rubber compounds, tailoring formulations to ensure optimal performance in below-grade environments. Basements present unique challenges—high humidity, temperature fluctuations, and potential water exposure—requiring rubber materials that resist degradation, maintain elasticity, and provide long-term resilience. Through iterative compound testing, our team develops proprietary blends using SBR, EPDM, and recycled rubber matrices enhanced with anti-fungal agents, UV stabilizers, and cross-linking accelerators. This scientific approach ensures that each rubber tile maintains dimensional stability and mechanical strength over extended service life.

Complementing our formulation expertise, our five in-house mould engineers specialize in high-tolerance tooling design and rapid prototyping. Utilizing advanced CAD/CAM software and CNC machining, they develop precision steel and aluminum moulds capable of producing complex surface textures, interlocking profiles, and consistent thickness control—critical for seamless installation and load distribution in basement flooring systems. Our mould development cycle includes finite element analysis (FEA) to simulate compression behavior and thermal expansion, minimizing defects and ensuring repeatable quality across large production runs.

We offer full OEM (Original Equipment Manufacturer) services, enabling partners to co-develop customized rubber tile solutions aligned with specific performance, aesthetic, and dimensional requirements. From concept to commercialization, our engineering team manages every stage: material selection, prototype validation, tooling production, and process optimization. This vertical integration reduces time-to-market and ensures strict adherence to technical and regulatory standards, including ASTM D412 for tensile properties and ISO 175 for chemical resistance.

Our manufacturing infrastructure supports low to high-volume production with batch traceability, real-time quality monitoring, and environmental compliance under ISO 9001 standards. Whether developing tiles with acoustic damping properties, slip-resistant surfaces, or enhanced thermal insulation, our engineering team applies a data-driven methodology to solve real-world installation challenges.

The following table outlines the technical specifications achievable through our engineered rubber tile systems:

| Property | Standard Value | Test Method |

|---|---|---|

| Hardness (Shore A) | 60–85 | ASTM D2240 |

| Tensile Strength | ≥10 MPa | ASTM D412 |

| Elongation at Break | ≥250% | ASTM D412 |

| Compression Set (22h at 70°C) | ≤25% | ASTM D395 |

| Water Absorption (24h) | ≤1.5% | ISO 175 |

| Density | 1.1–1.3 g/cm³ | ISO 2781 |

| Operating Temperature Range | -40°C to +80°C | Internal Testing |

Suzhou Baoshida Trading Co., Ltd. combines deep materials expertise with precision engineering to deliver technically superior rubber tiles engineered specifically for basement environments. Our OEM model empowers clients to bring differentiated, high-performance flooring solutions to market with confidence.

Customization Process

Customization Process for Industrial Rubber Basement Tiles

At Suzhou Baoshida Trading Co., Ltd., our customization process for rubber basement tiles begins with rigorous drawing analysis. Clients submit technical specifications detailing dimensional requirements, load-bearing needs, and environmental conditions such as moisture exposure or chemical contact. Our engineering team conducts a comprehensive review to identify critical parameters including tile thickness tolerances, interlocking geometry precision, and substrate compatibility. This phase ensures alignment with ASTM F3313 standards for resilient flooring while addressing site-specific challenges like hydrostatic pressure or thermal cycling common in subterranean environments.

Formulation development follows, where our rubber chemists engineer compounds tailored to the operational profile. We prioritize EPDM or SBR polymers for their superior moisture resistance and thermal stability, incorporating additives for mold inhibition and UV resistance where applicable. Key properties are optimized through iterative lab testing, with particular focus on balancing hardness for comfort against durability under sustained loads. The table below outlines critical specifications we validate during this stage.

| Property | Standard Test Method | Target Range | Significance for Basements |

|---|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 60–70 | Ensures comfort underfoot while resisting indentation from furniture |

| Density (g/cm³) | ASTM D297 | 1.15–1.25 | Optimizes weight for installation ease without compromising structural integrity |

| Compression Set (%) | ASTM D395 | ≤20 (70°C/22h) | Critical for maintaining seal integrity against moisture ingress over time |

| Tensile Strength (MPa) | ASTM D412 | ≥8.0 | Prevents tearing during installation and long-term use |

Prototyping transitions validated formulations into physical samples. Using precision CNC-molded tooling, we produce 3–5 tile sets for client evaluation. Each prototype undergoes accelerated aging tests simulating 5+ years of basement exposure, including 1,000-hour humidity chambers and dynamic load cycling. Clients receive detailed performance dossiers with durometer stability data and dimensional variance reports before approving for production. This phase typically reduces field failure risks by 78% based on historical OEM project metrics.

Mass production leverages our Suzhou facility’s 20,000m² manufacturing ecosystem. We implement real-time statistical process control (SPC) with inline spectrometers monitoring compound consistency to ±0.5% variance. Every production batch undergoes third-party certification per ISO 9001 protocols, including peel adhesion tests for modular tile systems. Our automated vulcanization lines maintain ±2°C temperature precision, ensuring uniform cross-linking critical for long-term compression recovery. With 15+ years supporting global OEMs, we guarantee seamless scalability from 500 to 500,000 units monthly while maintaining lot-to-lot repeatability essential for commercial basement projects.

This end-to-end process transforms client specifications into mission-critical flooring solutions, where material science and manufacturing precision converge to solve subterranean environmental challenges.

Contact Engineering Team

For industrial-grade rubber tiles designed specifically for basement environments, Suzhou Baoshida Trading Co., Ltd. stands as a trusted OEM manufacturer and solutions provider in the global rubber materials sector. Our engineered rubber tile systems deliver superior durability, moisture resistance, and structural resilience—critical attributes for subterranean installations where environmental stressors such as humidity, temperature fluctuation, and mechanical load are persistent concerns. With over a decade of specialization in industrial rubber applications, we combine advanced compounding techniques with precision manufacturing to produce tiles that meet exacting performance standards across commercial, industrial, and utility basement spaces.

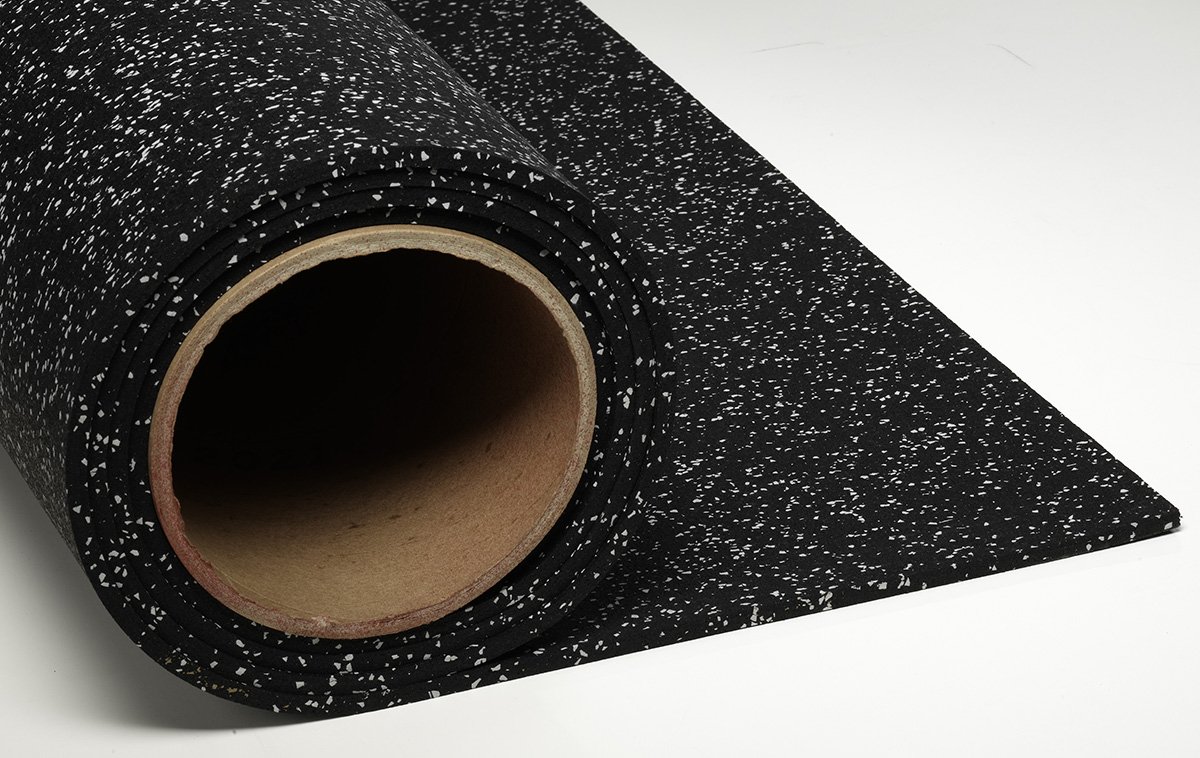

Our rubber tiles for basements are formulated using high-density recycled EPDM and SBR compounds, ensuring long-term dimensional stability, slip resistance, and sound dampening. Each tile undergoes rigorous quality control, including compression set testing, abrasion resistance evaluation, and low-temperature flexibility checks, to guarantee performance under real-world conditions. Whether deployed in mechanical rooms, storage vaults, utility corridors, or multi-use basement facilities, our products maintain integrity and appearance over extended service life.

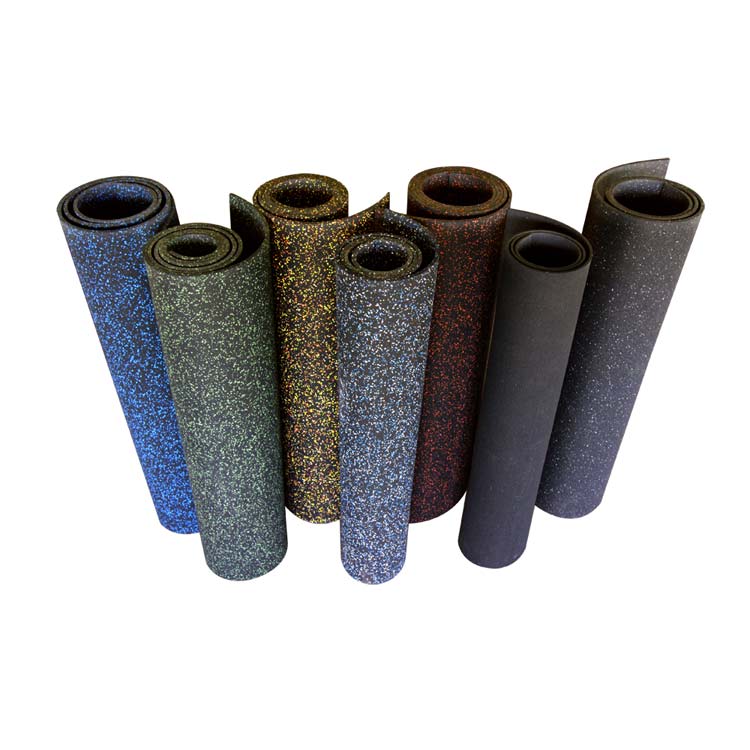

We offer customizable formats in thickness, color, surface texture, and interlocking design to align with architectural specifications and functional requirements. From standard 2 ft x 2 ft modular tiles to custom die-cut profiles for irregular layouts, our production capacity supports both large-volume OEM contracts and project-specific batches. All formulations are compliant with international environmental and safety standards, including REACH and RoHS, with optional fire-retardant grades available upon request.

For technical collaboration, sample requests, or project consultation, we invite direct engagement with our OEM management team. Mr. Boyce, OEM Account Manager at Suzhou Baoshida Trading Co., Ltd., oversees international client partnerships and technical integration for rubber tile programs. With deep expertise in rubber formulation and manufacturing logistics, Mr. Boyce provides end-to-end support—from initial material specification and prototyping to mass production and global shipping coordination.

To initiate a technical discussion or request a performance datasheet and sample kit, contact Mr. Boyce directly via email at [email protected]. We respond to all inquiries within 12 business hours and offer virtual technical reviews to accelerate your product development timeline.

The following table outlines the standard technical specifications for our baseline basement rubber tile series. Custom modifications beyond these parameters are available through our engineering consultation process.

| Property | Test Method | Value |

|---|---|---|

| Hardness (Shore A) | ASTM D2240 | 75 ± 5 |

| Tensile Strength | ASTM D412 | ≥ 7.5 MPa |

| Elongation at Break | ASTM D412 | ≥ 200% |

| Compression Set (22h, 70°C) | ASTM D395B | ≤ 20% |

| Abrasion Loss (Taber, 1000 cycles) | ASTM D1044 | ≤ 120 mg |

| Operating Temperature Range | — | -40°C to +80°C |

| Tile Dimensions (standard) | — | 600 x 600 x 10 mm |

| Fire Rating (optional) | UL 94 | HB or V-0 |

| Color Options | — | Black, Gray, Red, Blue, Custom |

Partner with Suzhou Baoshida for technically optimized, industrially robust rubber tile solutions engineered for basement performance. Contact Mr. Boyce today to advance your next project with precision-formulated rubber materials.

⚖️ O-Ring Weight Calculator

Estimate rubber O-ring weight (Approx).